Method for producing low carbon olefinic hydrocarbon from methanol or dimethyl ether

A technology of low-carbon olefins and dimethyl ether, which is applied in the direction of ethylene production, bulk chemical production, chemical instruments and methods, etc., can solve the problems of low yield of low-carbon olefins, poor control of reactor temperature, etc. High density, small footprint, and reduced circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

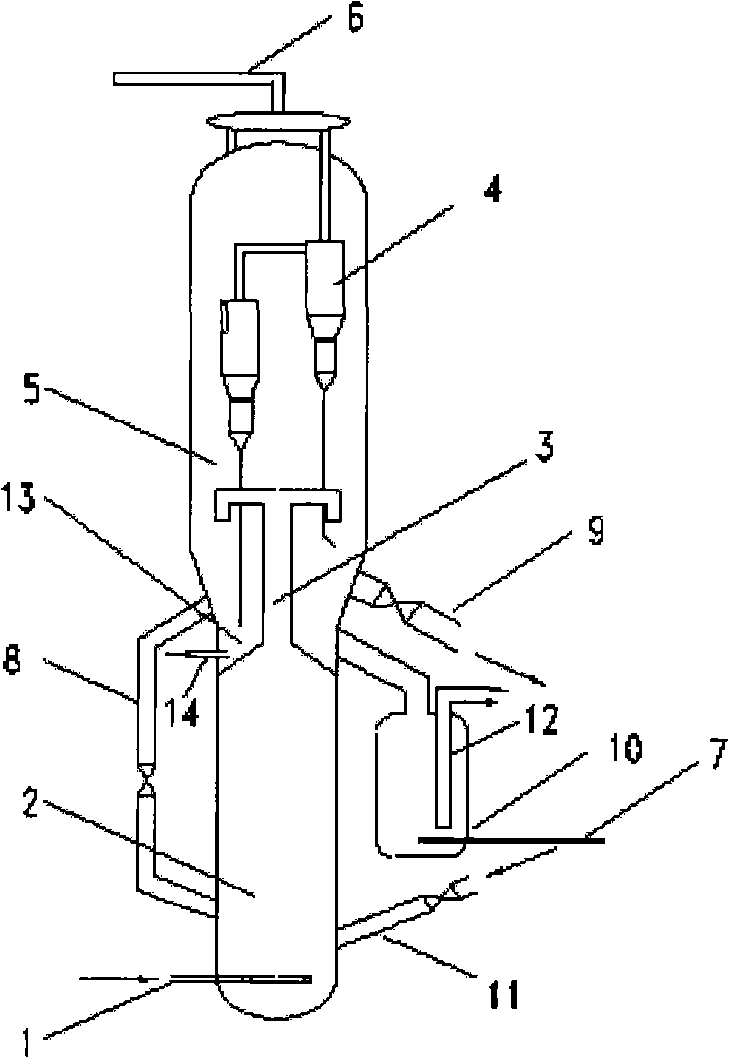

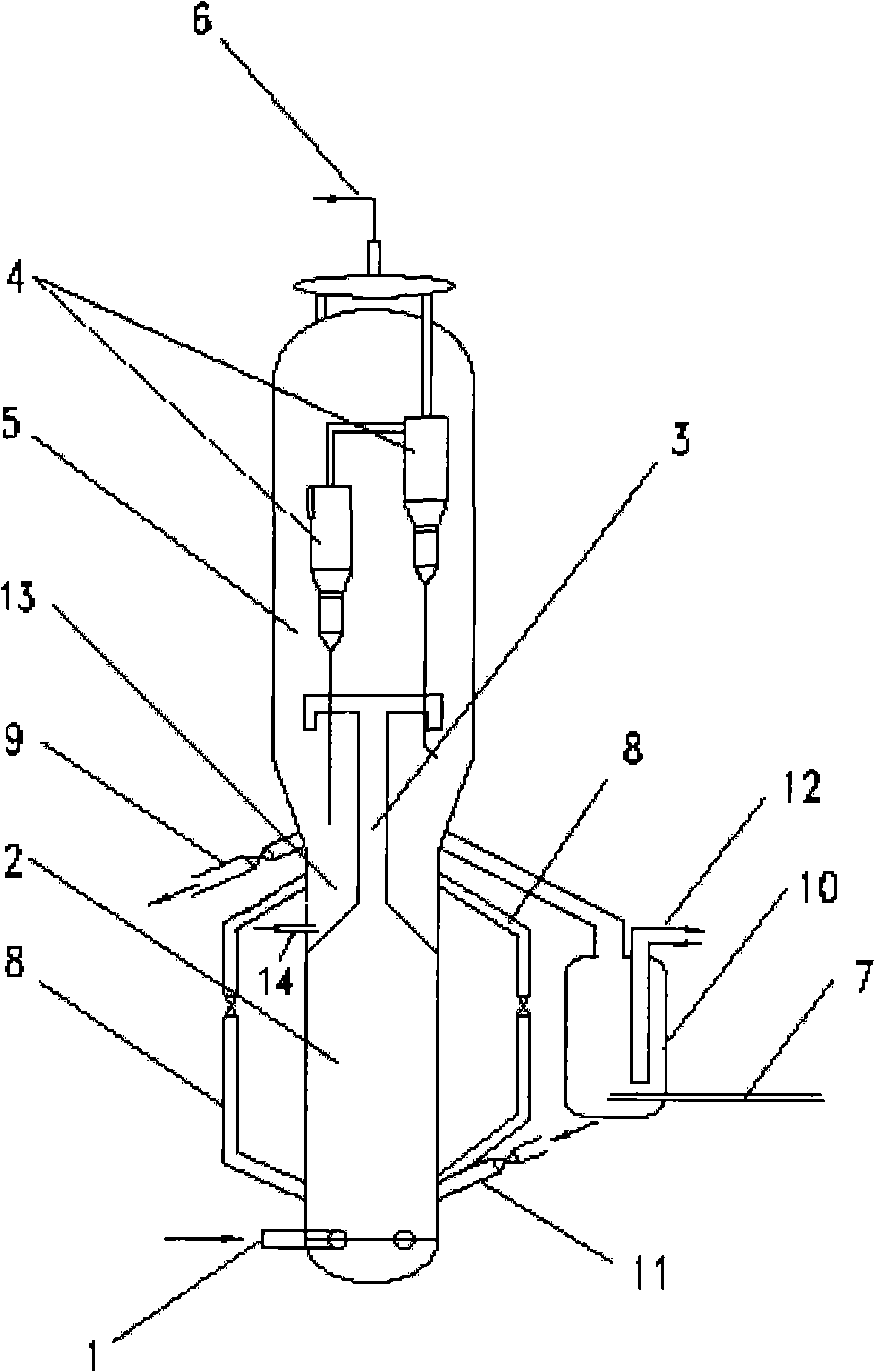

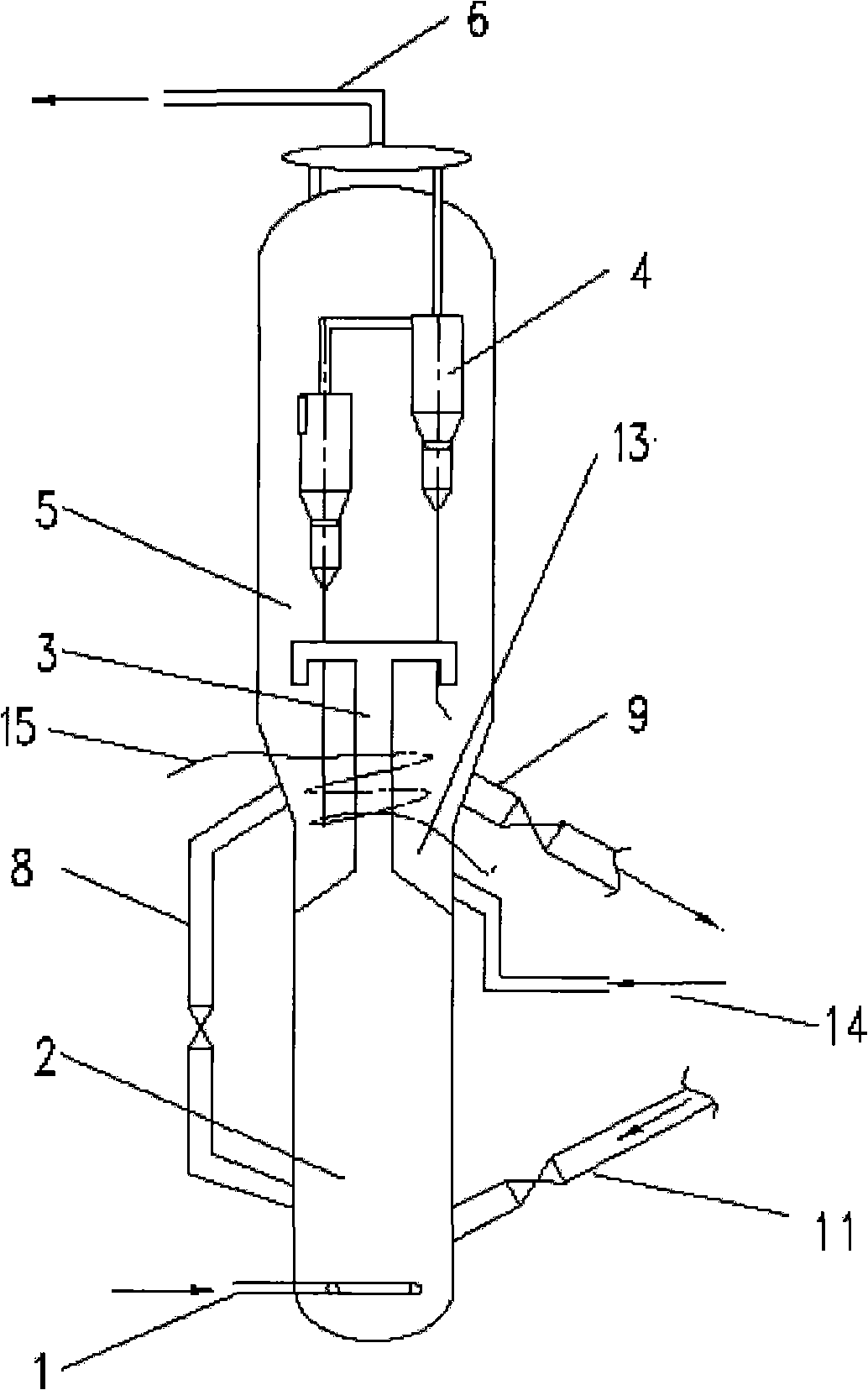

[0026] exist figure 1 In the small fast fluidized bed reaction device shown, pure methanol is used as raw material, the average temperature of the reaction zone is 500°C, the reaction pressure is 0.1MPa in terms of gauge pressure, the catalyst is SAPO-34, and the average linear velocity of the reaction zone is 1.6 m / s , the average carbon deposit in the reaction zone is 2.0% by weight, and the average density in the reaction zone is 50 kg / m3. The catalyst in the second dense phase stripping zone after stripping and heat extraction is divided into two parts, the first part returns to the bottom of the fast bed reaction zone through the catalyst external circulation pipe in the circulation zone, and the second part passes through the circulation zone The catalyst to be generated in the inclined pipe enters the regenerator, and after being regenerated by burning charcoal, it returns to the fast bed reaction area through the catalyst regeneration inclined pipe in the circulation a...

Embodiment 2

[0028] exist figure 1 In the small fast fluidized bed reaction device shown, pure methanol is used as raw material, the average temperature of the reaction zone is 500°C, the reaction pressure is 0.3MPa in terms of gauge pressure, the catalyst is SAPO-34, and the average superficial velocity of the reaction zone is 0.8m / second, the average carbon deposit in the reaction zone is 1.5% by weight, and the average density in the reaction zone is 120 kg / m3. The catalyst in the second dense phase stripping zone after stripping and heat extraction is divided into two parts, the first part returns to the bottom of the fast bed reaction zone through the catalyst external circulation pipe in the circulation zone, and the second part passes through the circulation zone The catalyst to be generated in the inclined pipe enters the regenerator, and after being regenerated by burning charcoal, it returns to the fast bed reaction area through the catalyst regeneration inclined pipe in the ci...

Embodiment 3

[0030] exist figure 1 In the small fast fluidized bed reaction device shown, pure methanol is used as raw material, the average temperature in the reaction zone is 400°C, the reaction pressure is 0.01MPa in gauge pressure, the catalyst is SAPO-34, and the average superficial velocity in the reaction zone is 0.8m / second, the average carbon deposit in the reaction zone is 1.5% by weight, and the average density in the reaction zone is 120 kg / m3. The catalyst in the second dense phase stripping zone after stripping and heat extraction is divided into two parts, the first part returns to the bottom of the fast bed reaction zone through the catalyst external circulation pipe in the circulation zone, and the second part passes through the circulation zone The catalyst to be generated in the inclined pipe enters the regenerator, and after being regenerated by burning charcoal, it returns to the fast bed reaction area through the catalyst regeneration inclined pipe in the circulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com