CZ Czochralski method mono-crystal furnace graphite thermal field structure

A technology of single crystal furnace and Czochralski method, which is applied in the directions of single crystal growth, self-melting liquid pulling method, crystal growth, etc. It can solve the problems such as unsatisfactory effect of heat shield device, increase heat insulation effect, and improve equipment production capacity , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

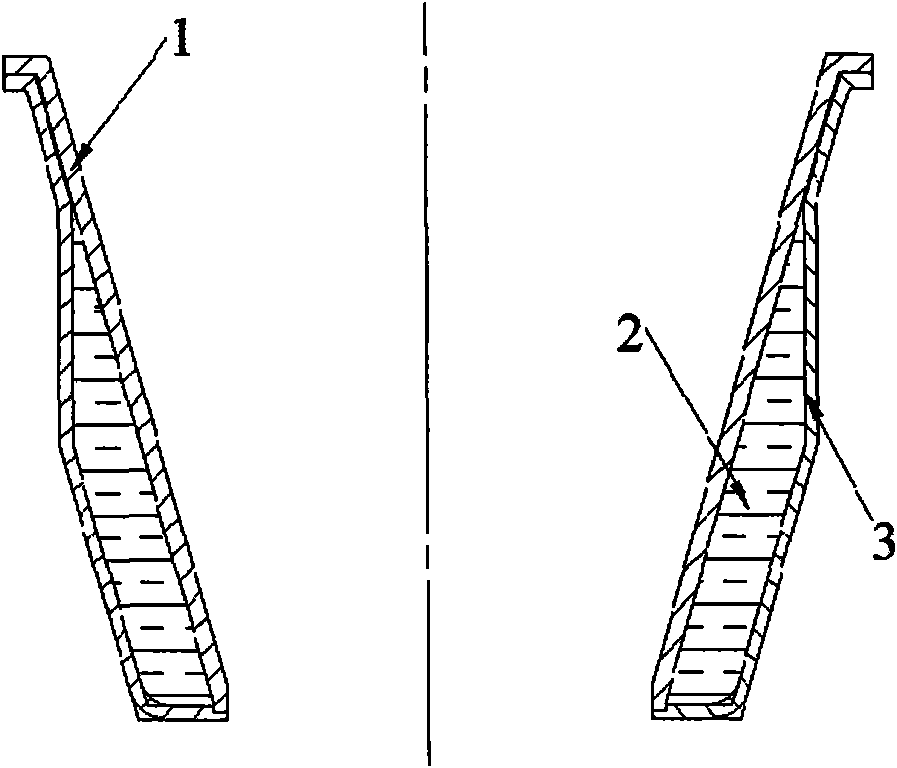

[0026] In the gap between the heat shield outer layer 3 and the heat shield inner layer 1 according to the present invention, a filled carbon felt 2 is provided.

[0027] To block heat conduction, the main influencing factors are the thermal conductivity coefficient of the thermal insulation material and the thickness of the thermal insulation layer.

[0028] The heat shield of the present invention increases the gap between the inner and outer layers of the heat shield, and can be filled with 2 to 3 layers of graphite carbon felt to increase the heat insulation performance. As we all know, because the density of carbon felt is lower than that of graphite, its thermal conductivity is greatly reduced, and it is widely used. One of the thermal insulation materials, this method improves the thermal insulation performance by 10% compared with the traditional one;

[0029] In addition, due to the increase of the gap between the inner and outer heat shields, the thermal insulation p...

Embodiment 2

[0031] The heat shield outer layer 3 of the present invention adopts the structure of slope reflection.

[0032] The outer layer 3 of the heat shield of the present invention adopts slope reflection, and the outer layer is made of high-density graphite material, which increases the emissivity of heat radiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com