Straight-pull eight-inch silicon single crystal thermal field and production method of eight-inch silicon single crystal

A production process, silicon single crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of low yield and crystal pulling speed, unreasonable structure of graphite crucible, and insufficient compactness of the thermal field as a whole , to achieve the effect of improving yield and crystal pulling speed, good heat insulation effect, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

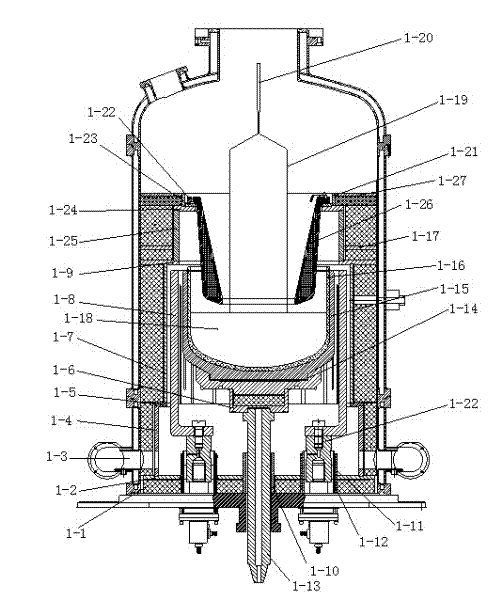

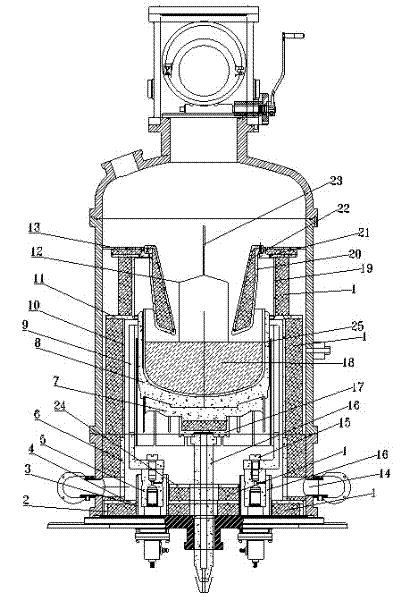

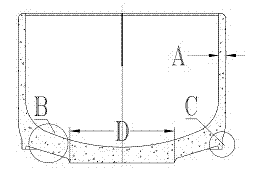

[0043] A Czochralski eight-inch silicon single crystal thermal field, such as figure 2 , image 3 , Figure 4 As shown, the thermal field includes graphite felt 1, furnace bottom support ring 2, electrode sheath 3, lower protective plate pressing sheet 4, graphite electrode 5, lower insulation cylinder 6, crucible support 7, graphite crucible 8, heater 9, main Insulation cylinder 10, upper support ring 11, upper insulation cover 13, electrode bolt 15, graphite central shaft 16, central shaft extension shaft 17, upper insulation cylinder 19, outer guide cylinder 20, guide cylinder support ring 21, inner guide Cylinder 22, guard disc pressing sheet 24 and quartz crucible 25, main insulation cylinder 10 is arranged on heater 9 periphery, and heater 9 is arranged on graphite electrode 5; The central axis extension shaft 17, the central axis extension shaft 17 supports the crucible support 7, and the protective disk pressing piece 24 is arranged on the lower protective disk pres...

Embodiment 2

[0069] The thermal field for Czochralski eight-inch silicon single crystal is the same as that of Embodiment 1.

[0070] The production process of the eight-inch silicon single crystal is the same as the process steps of Example 1, but the parameters in the SOP file are set differently, and the obtained effects are also different.

[0071] Its process steps are as follows:

[0072] Step 1: ventilation pressure 0.25Mpa, argon flow rate 45slpm, furnace pressure 12Torr;

[0073] Step 3: Crystal rotation: 12 rpm, pot rotation: 6 rpm; adjust the position of the crucible to the position of the seeding pot, and the position of the seeding pot is 32mm from the bottom edge of the guide tube to the liquid surface.

[0074] Step 4: The "Neck Diameter Set Point" is 4.8mm, and the "Target Thin Neck Length" is 130mm.

[0075] Step 5: The equipment automatically sets the shoulders according to the parameter settings in the SOP file. The specific shoulder setting table is shown in Table 5. ...

Embodiment 3

[0088] A thermal field for Czochralski eight-inch silicon single crystal: the same as in Embodiment 1.

[0089] A production process method for an eight-inch silicon single crystal: the process steps are the same as in Embodiment 1, but the parameter settings in the SOP file are slightly different.

[0090] Step 1: ventilation pressure 0.3Mpa, argon gas flow rate 50slpm, furnace pressure 15Torr;

[0091] Step 3: Crystal rotation: 12 rpm, crucible rotation: 8 rpm; adjust the position of the crucible to the position of the seeding crucible, and the position of the seeding crucible is 35mm from the bottom edge of the guide tube to the liquid surface.

[0092] Step 4: The "neck diameter set point" is 4.7mm, and the "target narrow neck length" is 150mm.

[0093] Step 5: The equipment automatically sets the shoulders according to the parameter settings in the SOP file. The specific shoulder setting table is shown in Table 9. When the shoulder is placed less than the required diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com