Flame retardant additive, preparation method of flame retardant additive and lithium battery

A technology of flame retardant additives and flame retardants, which is applied in the field of electrochemistry and can solve the problems of low safety performance of lithium batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention also provides a preparation method of the flame retardant additive,

[0050] Method I includes the following steps:

[0051] (1) uniformly mixing the flame retardant, organic matter and water to obtain the first mixed solution, wherein the mass ratio of the flame retardant, organic matter and water is 1:1:998-1:1:98;

[0052] (2) Spray drying the first mixed solution to obtain a flame retardant additive whose shell is an organic shell, wherein the drying temperature is 100°C-150°C, and the injection rate is 5-25mL / min.

[0053] Method II includes the following steps:

[0054] (1) Tetraethyl orthosilicate (TEOS) and water are mixed uniformly to obtain a second mixed solution, and cetyltrimethylammonium bromide (CTAB) is added in the second mixed solution to prepare silicon dioxide. The prepared silica is sintered at high temperature to obtain hollow silica;

[0055] Wherein, the mass fraction of ethyl orthosilicate (TEOS) in the second mixed solution is ...

Embodiment 1

[0065] This example is used to illustrate the flame retardant additive prepared according to method I of the present invention.

[0066] (1) 1g triphenyl phosphate (TPP), 1g polyvinylpyrrolidone (PVP) and 998g water are mixed uniformly to obtain the first mixed solution;

[0067] (2) Spray-dry the first mixed solution, set the inlet temperature of the spray dryer to 150° C., and the injection rate to 10 mL / min to prepare the flame retardant additive.

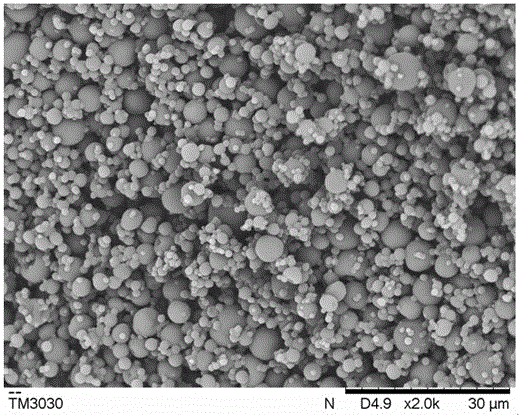

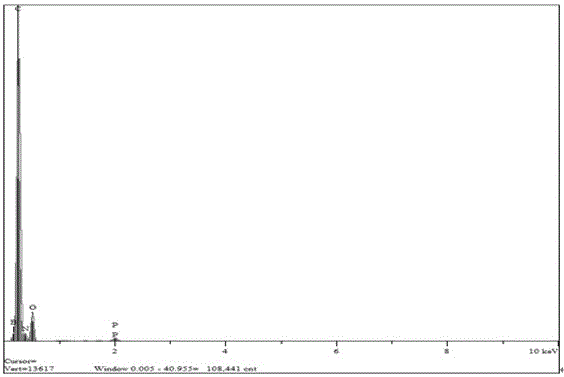

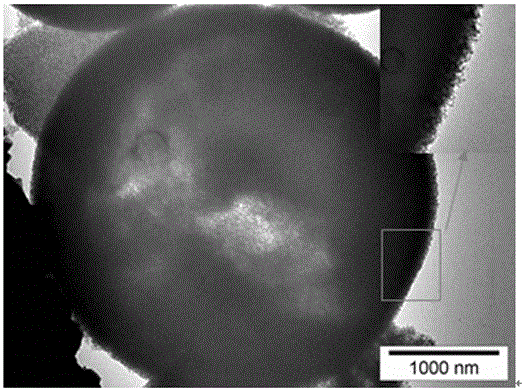

[0068] Since polyvinylpyrrolidone (PVP) is less soluble in water than triphenyl phosphate (TPP), polyvinylpyrrolidone (PVP) will preferentially precipitate and become solid, covering the outer surface of triphenyl phosphate (TPP). A flame retardant additive that forms a core-shell structure with an outer shell of polyvinylpyrrolidone (PVP) and an inner shell of triphenyl phosphate (TPP). The diameter of the core-shell structure is 0.2 μm-5 μm, and the thickness of the polyvinylpyrrolidone (PVP) shell 0.1μm-0.5μm.

[0069] fig...

Embodiment 2

[0074] This example is used to illustrate the flame retardant additive prepared according to method I of the present invention.

[0075] (1) Mix 1g triphenyl phosphate (TPP), 1g polyethylene oxide (PEO) and 500g water to obtain the first mixed solution;

[0076] (2) Spray-dry the first mixed solution, set the inlet temperature of the spray dryer to 120°C, and the injection rate to 15mL / min to prepare the flame retardant additive.

[0077] Since the solubility of polyethylene oxide (PEO) in water is lower than that of triphenyl phosphate (TPP), polyethylene oxide (PEO) will preferentially precipitate and become a solid state, covering the outer surface of triphenyl phosphate (TPP). A flame retardant additive that forms a core-shell structure with polyethylene oxide (PEO) as the outer shell and triphenyl phosphate (TPP) as the inner. The diameter of the core-shell structure is 0.5 μm-3 μm, and the thickness of the polyethylene oxide (PEO) shell is 0.1μm-1μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com