Supported silver catalyst for reducing soot particle burning temperature and preparation method

A technology of combustion temperature and supported silver, which is applied in the field of supported silver catalysts and preparations, and can solve problems such as high price, pollution, and metering fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

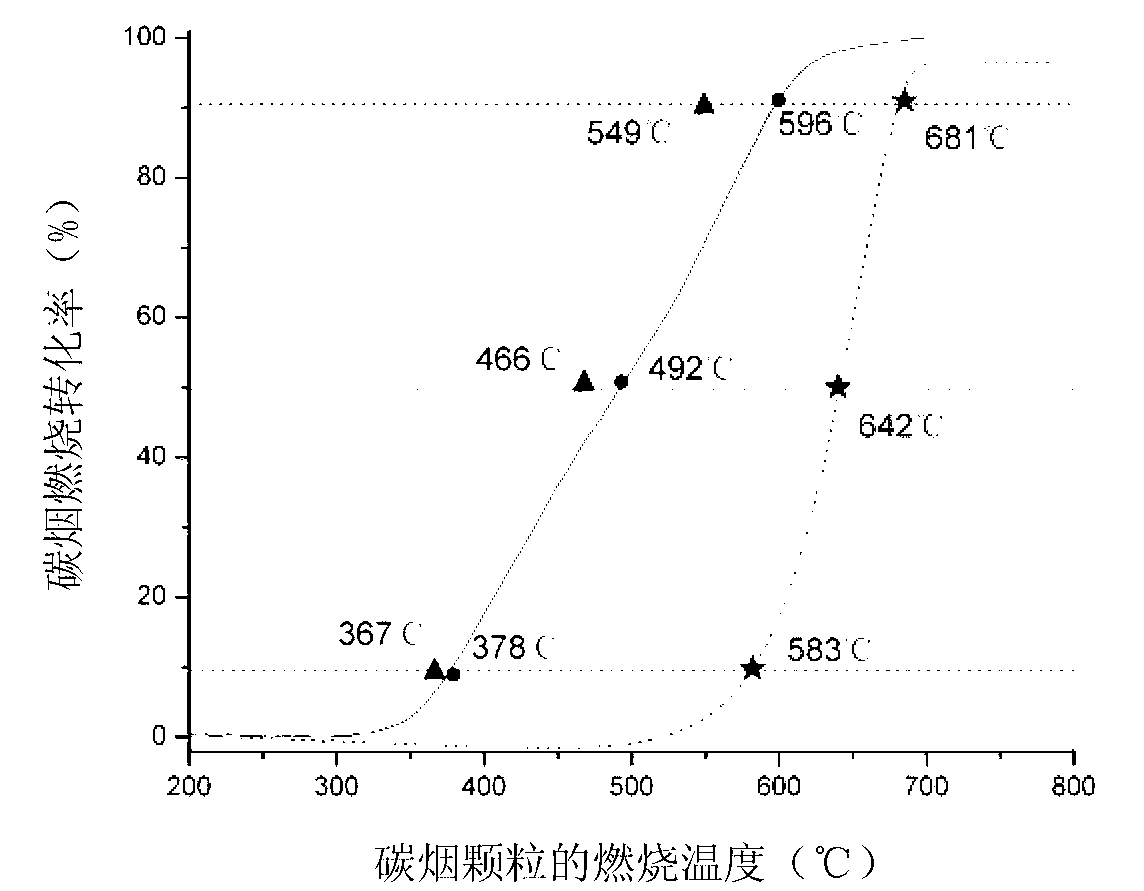

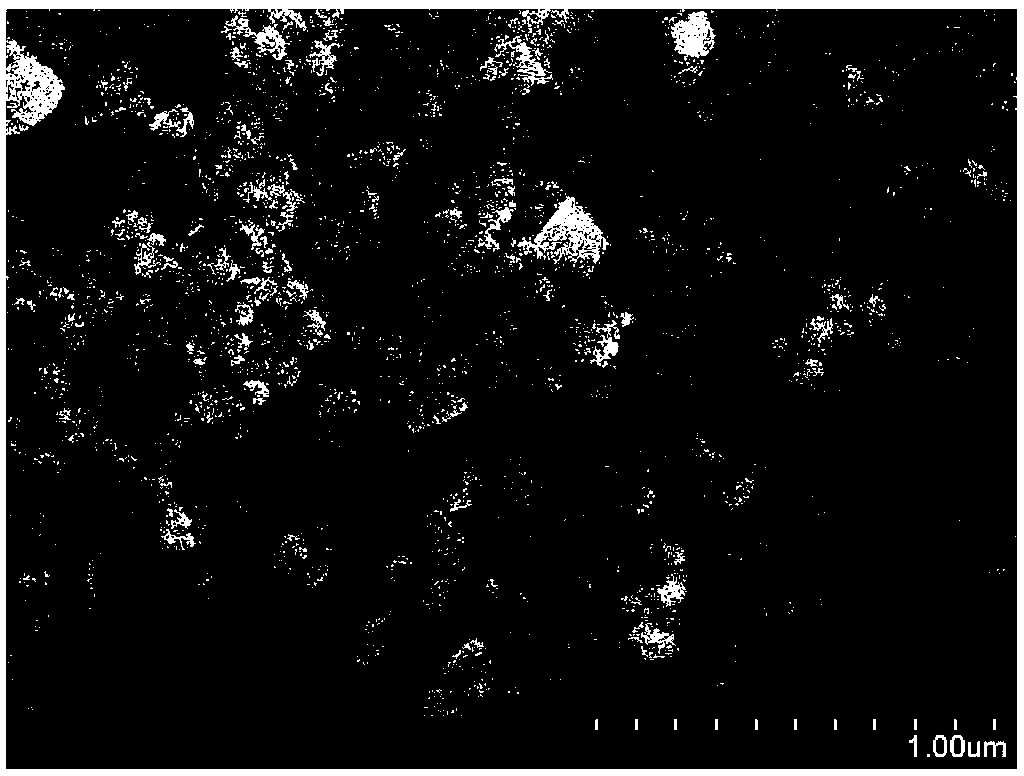

[0026] Weigh 100ml of 0.1M cerium nitrate solution, add 0.21g of surfactant polyvinyl alcohol (5%wt), stir evenly, add 0.1M ammonium carbonate aqueous solution to the solution, stir for 0.5h, put it into water Heat at 120° C. for 12 hours in a hot kettle, cool to room temperature, and centrifuge and wash to obtain a ceria precursor. The precursor was dried at 110°C overnight and then calcined at 500°C for 5 hours to obtain the carrier ceria. SEM results (see figure 2 ) shows that the CeO 2 The particles are spherical particles with uniform size, and the average particle diameter is about 100nm.

[0027] Weigh 0.25g of silver nitrate, dissolve it to form a solution, then add isovaleric acid (the molar ratio of isovaleric acid to silver nitrate is 3), and stir evenly. Add 1 gram of ceria to the solution, heat and stir the resulting solution at 100°C until it is evaporated to dryness, dry the obtained solid at 110°C for one night, and then calcinate at 500°C for 7 hours to ob...

Embodiment 2

[0030] The preparation method of carrier ceria is the same as that in Example 1. Weigh 0.03g of silver nitrate, dissolve it to form a solution, then add propionic acid (the molar ratio of propionic acid to silver nitrate is 1), and stir well. Add 1 gram of ceria to the solution, heat and stir the resulting solution at 100°C until it evaporates to dryness, dry the resulting solid at 110°C overnight and then roast it at 500°C for 5 hours to obtain 1%Ag / CeO 2 catalyst.

[0031] Test the combustion situation of soot particle by the same method of implementation example 1, under this catalyst, T 10 , T 50 and T 90 The temperatures were 426°C, 551°C and 661°C, respectively.

Embodiment 3

[0033] The preparation method of carrier ceria is the same as that in Example 1. Weigh 0.125g of silver nitrate, dissolve it to form a solution, then add n-butyric acid (the molar ratio of n-butyric acid to silver nitrate is 2), and stir evenly. Add 1 gram of ceria to the solution, heat and stir the resulting solution at 100°C until it evaporates to dryness, dry the resulting solid at 110°C overnight and then roast at 500°C for 6 hours to obtain 4%Ag / CeO 2 catalyst.

[0034] Test the combustion situation of soot particle by the same method of implementation example 1, under this catalyst, T 10 , T 50 and T 90 The temperatures were 363°C, 509°C and 592°C, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com