Methane oxidation catalyst

A methane oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, etc., can solve the problems of methane escape and achieve excellent methane oxidation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-4

[0100] Dissolve dinitrosodiammine platinum in nitric acid to prepare a Pt solution with a pH of 1 or less, and then heat the solution to 60°C, then add tin oxide powder of a specified concentration (D50 = 44 μm, BET =14m 2 / g), making Pt loaded on SnO 2 After granulation, heat the solution to evaporate to dryness, and then use a large hot air dryer to dry it, bake it at 550°C for 3 hours in the atmosphere, and crush it with a mortar to obtain Pt-loaded tin oxide powder (sample).

[0101] At this time, the Pt content of the Pt solution is adjusted so that the Pt (platinum) relative to the SnO 2 The content is 2wt% (embodiment 1-1), 4wt% (embodiment 1-2), 8wt% (embodiment 1-3), 12wt% (embodiment 1-4).

Embodiment 2-1~2-4

[0103] Dissolve dinitrosodiammine platinum in nitric acid to prepare a Pt solution with a pH of 1 or less, and then heat the solution to 60°C, then add tin oxide powder of a specified concentration (D50 = 1.2 μm, BET=39m 2 / g), making Pt loaded on SnO 2 After granulation, heat the solution to evaporate to dryness, and then use a large hot air dryer to dry it, bake it at 550°C for 3 hours in the atmosphere, and crush it with a mortar to obtain Pt-loaded tin oxide powder (sample).

[0104] At this time, the Pt content of the Pt solution is adjusted so that the Pt (platinum) relative to the SnO 2 The content is 2wt% (embodiment 2-1), 4wt% (embodiment 2-2), 8wt% (embodiment 2-3), 12wt% (embodiment 2-4).

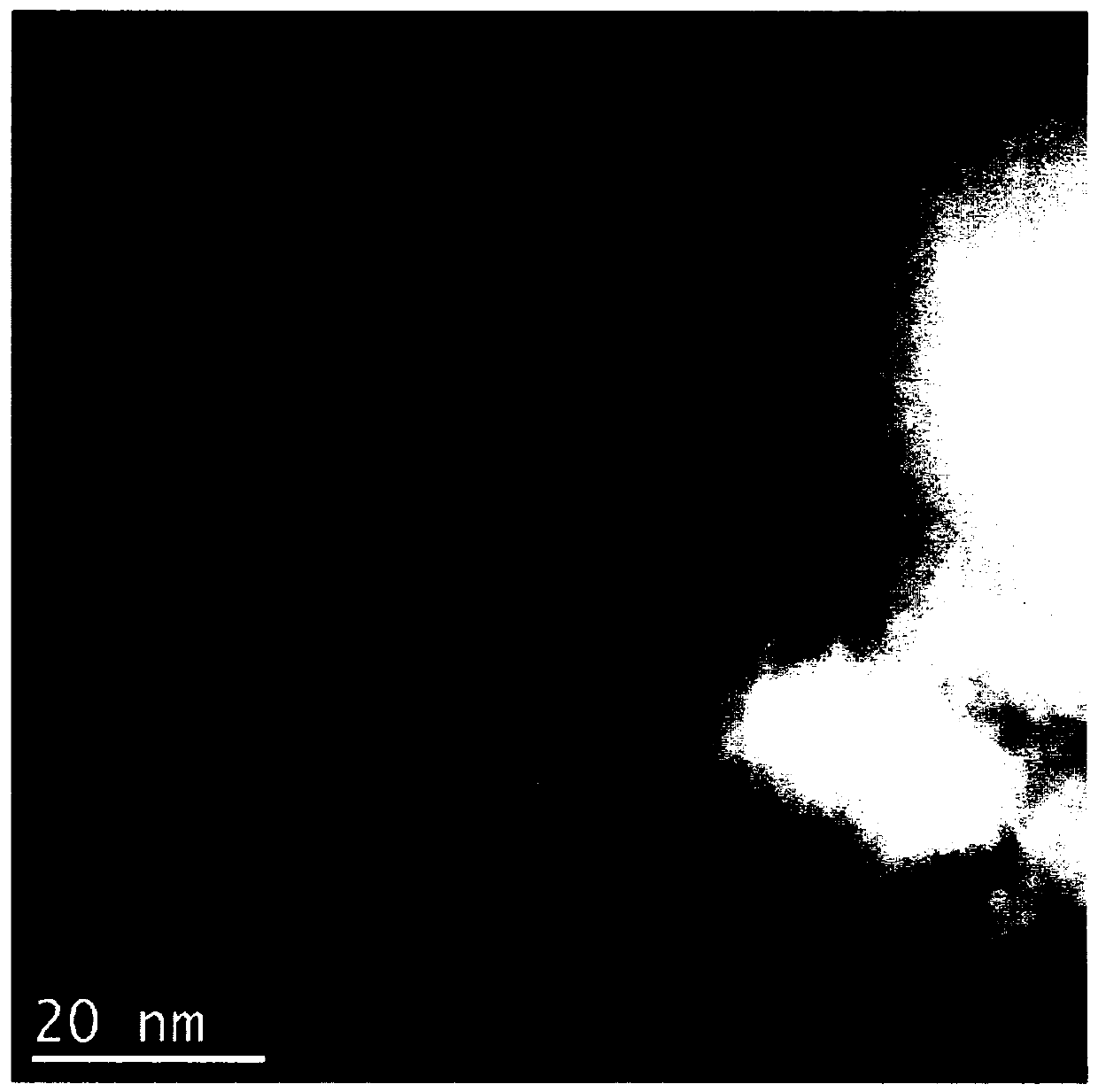

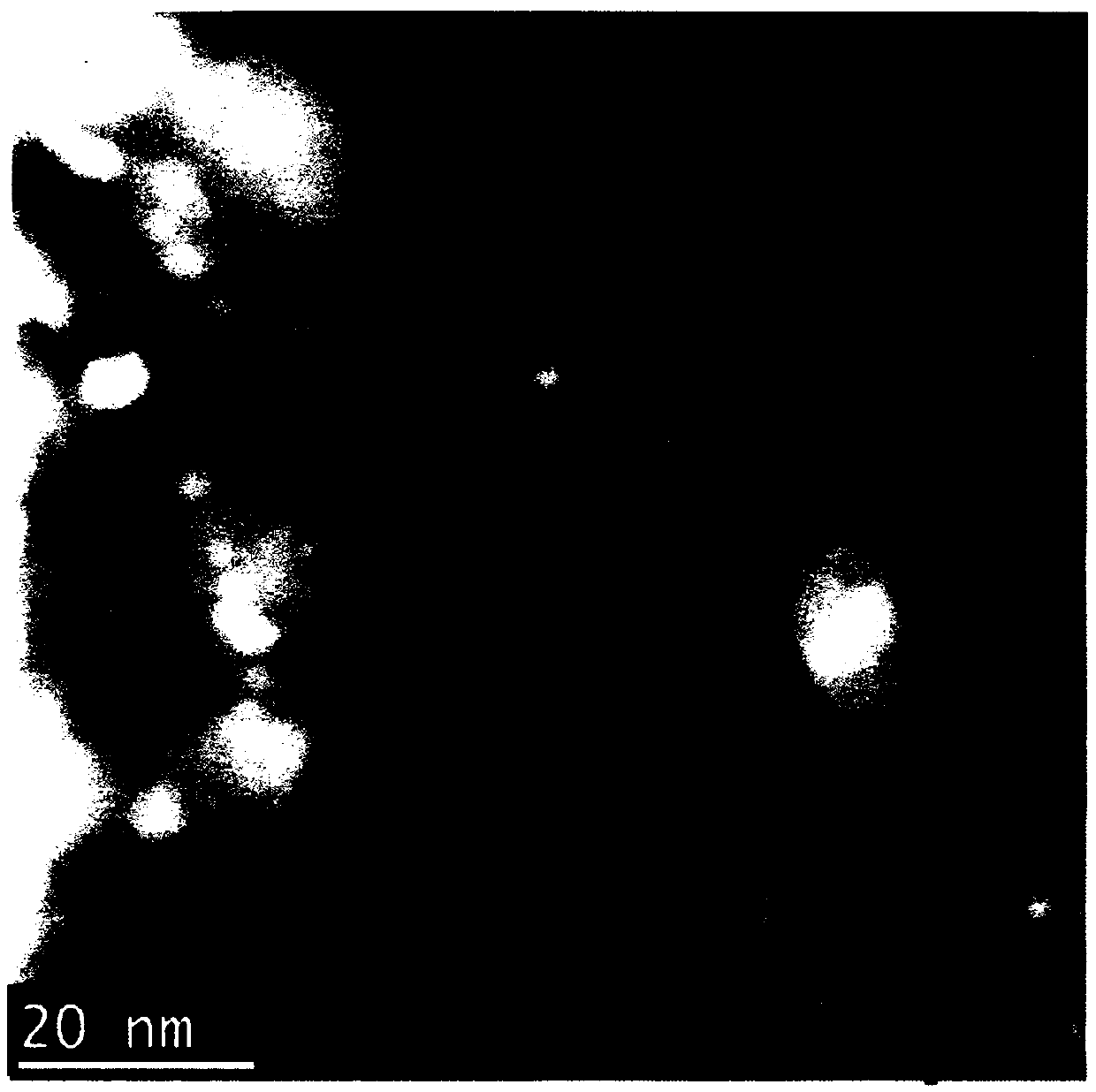

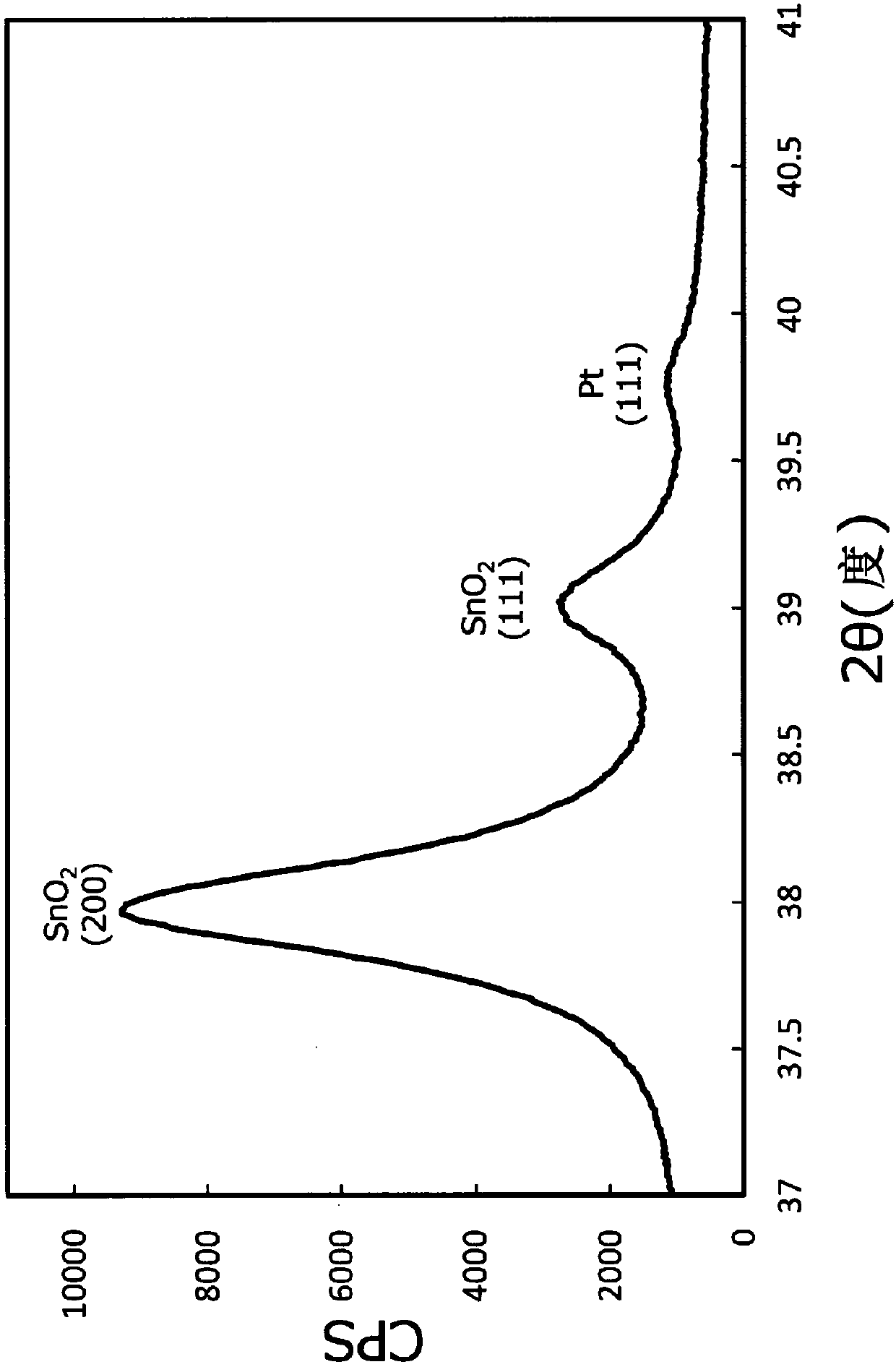

[0105] (Crystalline diameter of Pt-loaded tin oxide)

[0106] The crystallite diameter (base material) of the tin oxide of the Pt-loaded tin oxide powder obtained in the example / comparative example was measured by the Rietveld method as follows.

[0107] Analysis was perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com