Patents

Literature

117results about How to "The preparation process conditions are mild" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

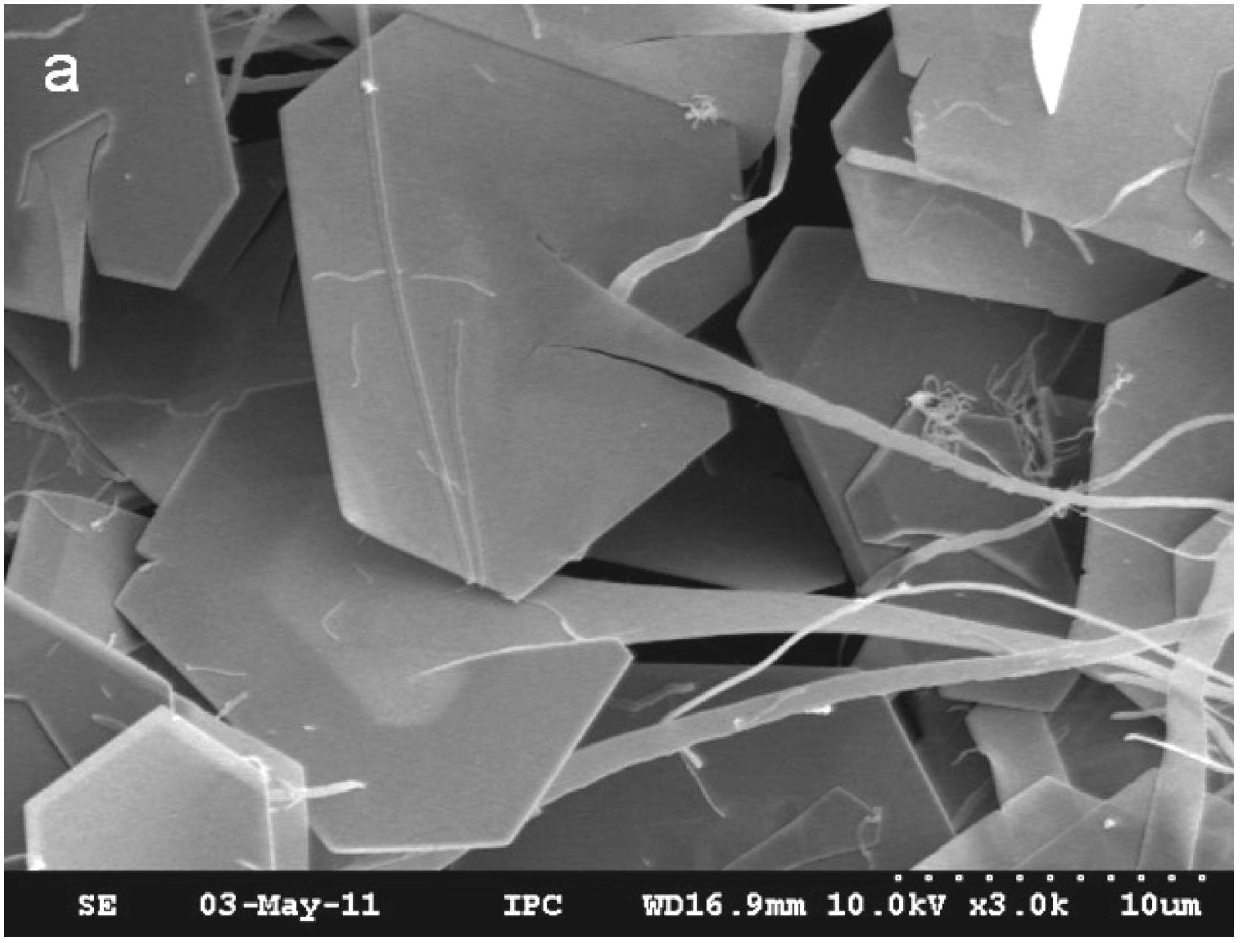

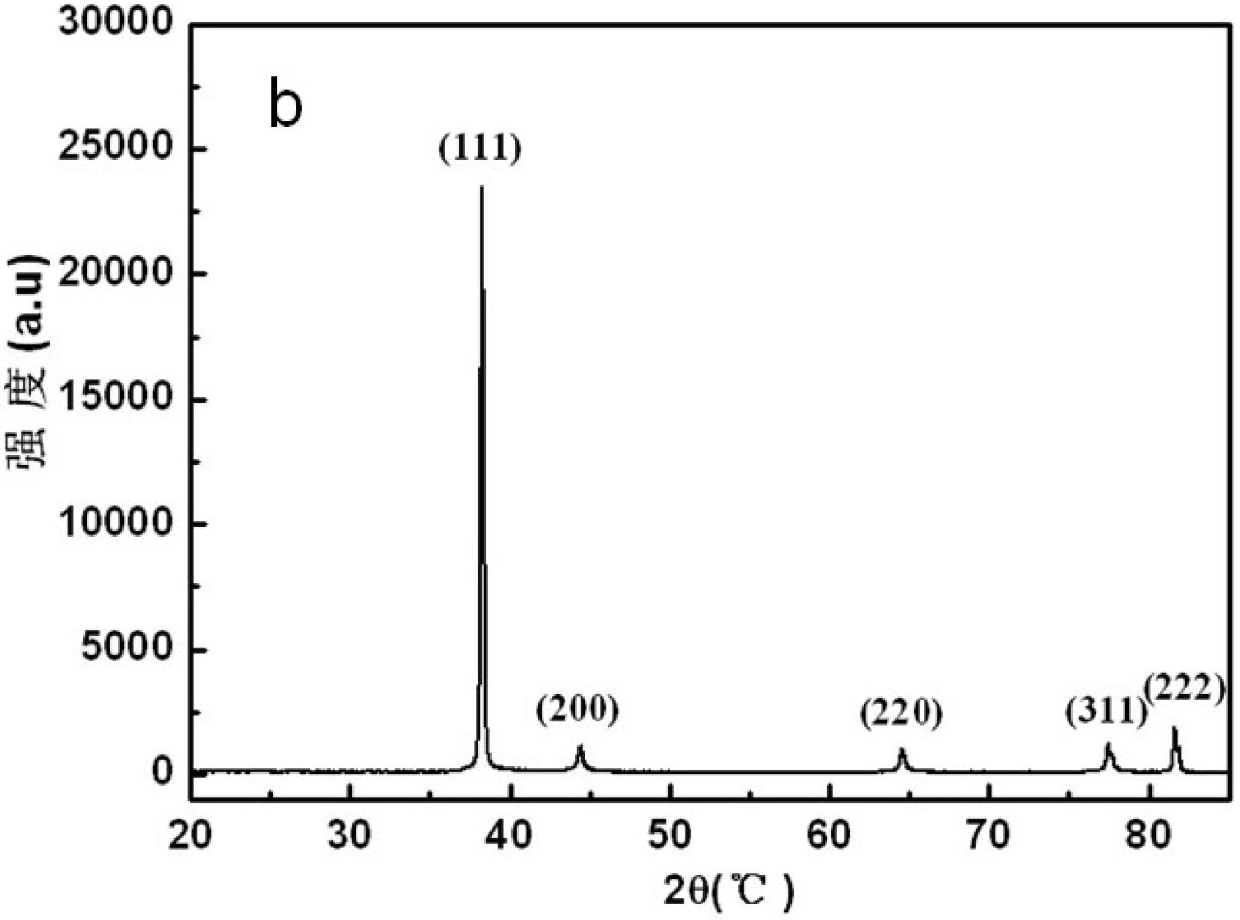

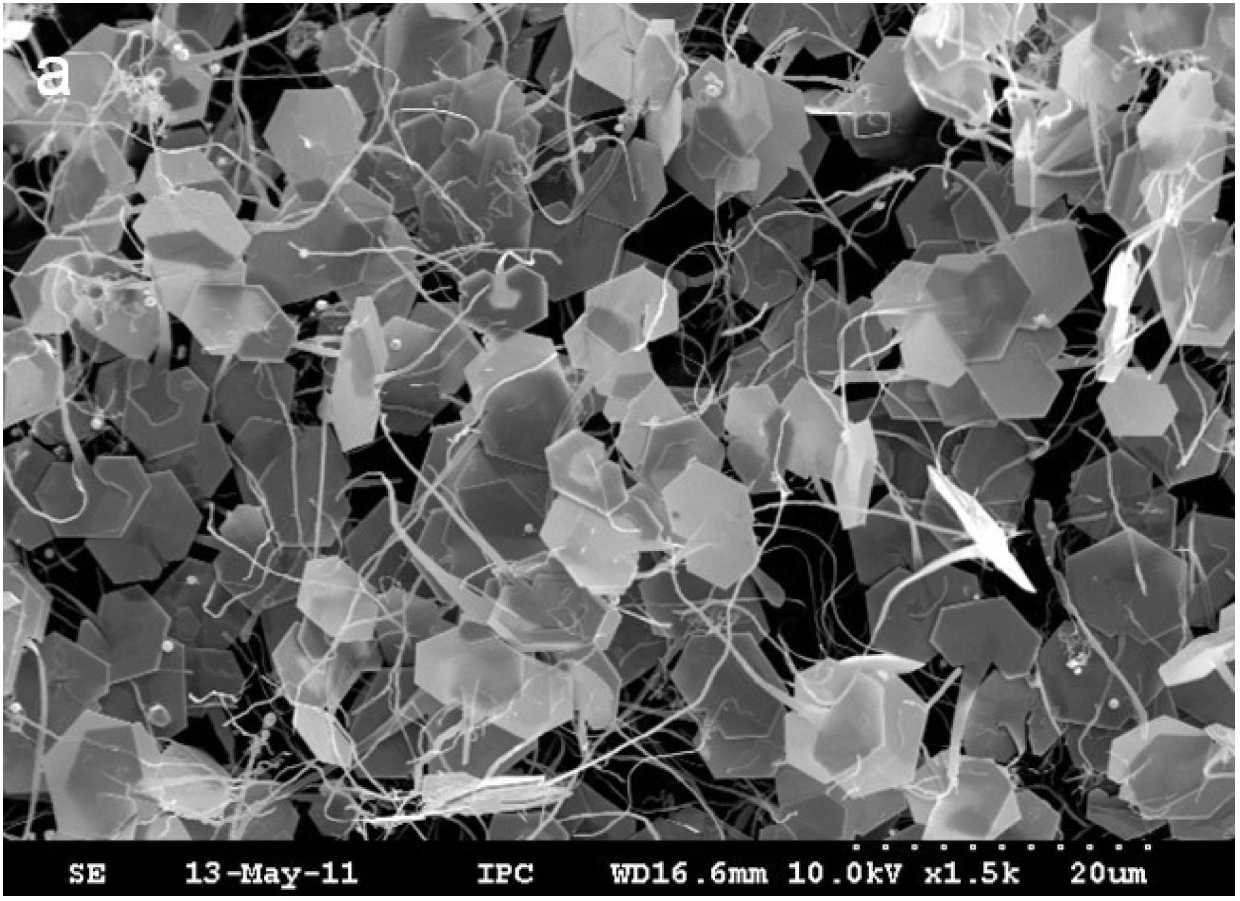

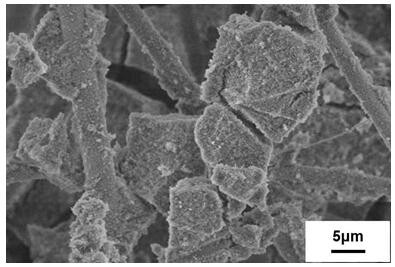

Preparation method of silver particle with sheet-strip integrated structural shape

The invention relates to a preparation method of a silver particle with a sheet-strip integrated structural shape. The preparation method of the silver particle with the sheet-strip integrated structural shape comprises the following step of preparing the silver particle with the sheet-strip integrated structural shape by a chemical liquid-phase reduction method by taking deionized water or distilled water as a solvent, a soluble silver salt as a silver source, an organic acid and / or an organic acid salt and an inorganic acid as main shape controlling agents, a small molecular alcohol and / or ketone as a modifier, and ascorbic acid and / or ascorbate as a reductant, wherein the silver particle has an integral structure consisting of silver by sheet-shaped silver and strip-shaped silver; the width of the sheet-shaped silver is between 2-20 microns and adjustable; the thickness of the sheet-shaped silver is 100-300 nanometers and adjustable; the length of the strip-shaped silver is 5-50microns and adjustable; the width of the strip-shaped silver is 200-500 nanometers and adjustable; and the thickness of the strip-shaped silver is 100-300 nanometers and adjustable. The preparation method of the silver particle with the sheet-strip integrated structural shape is mild in preparation conditions; and prepared silver particles are high in yield and high in purity.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Carbon nano tube/collagen based composite material and preparation method thereof

ActiveCN103013140AGood biocompatibilityImprove tissue repair abilityTissue repairBiocompatibility Testing

The invention discloses a carbon nano tube / collagen based composite material and a preparation method of the composite material. The composite material comprises collagen protein and carbon nano tubes, wherein the content of the collagen protein is 96.0-99.8 percent by mass percentage, and the content of the carbon nano tubes is 0.2-4.0 percent by mass percentage. According to the invention, the obtained carbon nano tube / collagen based composite material is provided with favorable biocompatibility, tissue repair property and extremely low immunogenicity; the required raw materials are easy to get; the conditions of the preparation technology are milder; and the composite material is provided with wide popularization and application value.

Owner:福建省博特生物科技有限公司 +1

Nitrogen-doped lithium sulfur battery cathode material, preparation method and application

ActiveCN110336034AThe preparation process conditions are mildSimple stepsSecondary cellsPositive electrodesChemistryInorganic salts

The invention provides a nitrogen-doped lithium sulfur battery cathode material, a preparation method and an application. Sodium chloride, melamine and starch are mixed in water; precursor gel is obtained through gelatinization reaction; the precursor gel is freeze-dried, baked at high temperature, soaked and washed; and sodium chloride is removed to obtain nitrogen-doped porous carbon powder. Inorganic salt sodium chloride is added as a pore forming agent, which enables the product to have a uniform micro nano pore structure and high specific surface area. Finally, sulfur particles are loadedby sulfur fumigation to obtain a nitrogen-doped porous carbon-loaded sulfur composite material as a lithium sulfur battery cathode material. The porous structure of the composite material provides alarge number of active sites, which helps to bind polysulfides and inhibit the shuttle effect of polysulfides. The material has good cycle stability and high specific capacity when used as a lithium sulfur battery cathode material. In addition, the preparation method of nitrogen-doped porous carbon has the advantages of mild process conditions, simple steps, cheap raw materials and easy large-scale production.

Owner:ANHUI NORMAL UNIV

Triglycidyl isocyanurate production method

ActiveCN103319469AThe temperature parameter is not highProcess safety and stabilityOrganic chemistryEpoxyDistillation

The invention relates to a triglycidyl isocyanurate production method comprising the steps of synthesizing, distillation, crystallization, centrifugation, and drying. Especially, in the distillation process, a solvent which has a boiling point lower than 110 DEG C, which can be subjected to binary azeotrope with epoxy chloropropane, and which cannot be subjected to a reaction with components of the reaction system is slowly added, wherein an addition amount is 5-10% of that of a triglycidyl isocyanurate crude product. The materials are stirred for 20min; through reduced-pressure distillation under a vacuum degree of -0.090MPa to -0.0999MPa, solvent and epoxy chloropropane are removed by azeotrope, wherein a temperature is controlled under 95 DEG C. With the method, preparation process conditions are mild, all ECH solvent can be recovered, working environment can be improved, production cost can be reduced, and the process is stable and safety. Various performance indexes of the product are excellent. With the triglycidyl isocyanurate production method, no epoxy chloropropane residue is caused.

Owner:HUANGSHAN HUAHUI TECH

Preparation method of anisotropic FeSiAl magnetic core and product

InactiveCN107369550AMiniaturizationAchieve high frequencyTransportation and packagingMetal-working apparatusIngotProcess conditions

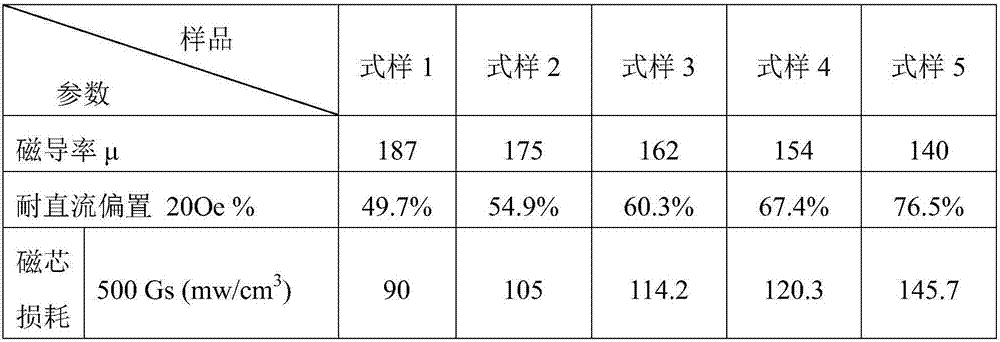

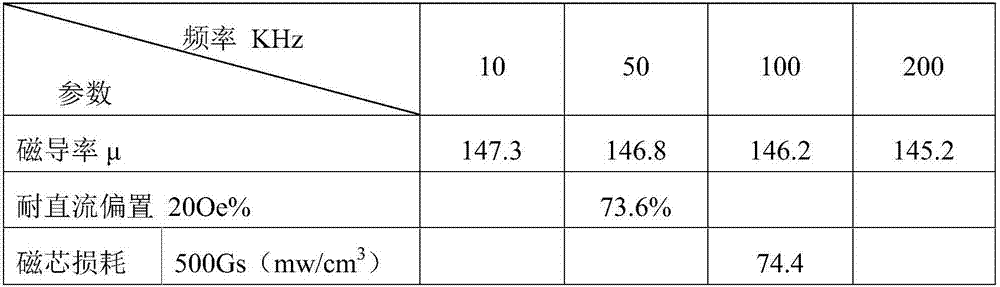

The invention discloses a preparation method of an anisotropic FeSiAl magnetic core and a product. The preparation flow comprises the steps of (1) performing smashing on a FeSiAl cast ingot by adopting a sand mill and then performing flattening treatment to obtain flake-shaped FeSiAl magnetic powder; (2) coating the surface of the flake-shaped FeSiAl magnetic powder with an SiO<2> insulating material by adopting a sol-gel process; (3) performing uniform mixing on the coated FeSiAl and a binder to prepare coating paste, and coating a substrate with the paste, and next, putting the product into a magnetic field to be subjected to orientation; (4) performing hot pressing compaction treatment on the oriented coating sheet, and performing curing at a certain temperature; and (5) performing punch forming on the cured coating sheet to obtain the anisotropic FeSiAl magnetic core. The anisotropic FeSiAl magnetic core prepared in the invention has high insulativity as well as high heat resistance; high magnetic conductivity and low loss value still can be maintained at 1MHz, and high direct current biasing resistance characteristic is still kept; and in addition, the preparation process for the anisotropic FeSiAl magnetic core is mild in conditions, convenient and quick to operate and high in efficiency, and batch production can be promoted.

Owner:CENT SOUTH UNIV

Method for preparing cation type composite flocculant for treating waste drilling fluid

ActiveCN102167431AWide variety of sourcesLow costWater/sewage treatment by flocculation/precipitationFlocculationCollagenan

The invention relates to a composite flocculant for treating waste drilling fluid generated in the petroleum drilling process, and a preparation method thereof. The preparation method comprises the following steps of: extracting gelatin with larger relative molecular mass from waste skin collagen through alkaline hydrolysis; further hydrolyzing the extracted gelatin into collagen with moderate relative molecular mass by using different hydrolytic reagents; and loading proper metal ions on the collagen by using a tanning mechanism in tanning chemistry to obtain a cation type composite flocculant, and performing flocculation on anionic waste drilling fluid. The composite flocculant prepared by the method has the advantages of low cost, simple operation, high flocculating efficiency, safety and nontoxicity for a human body and the like, and is an environment-friendly product. Meanwhile, the waste skin collagen is reutilized, waste is used to treat contamination, and secondary pollution on the environment is avoided.

Owner:江苏肇方智能装备有限公司

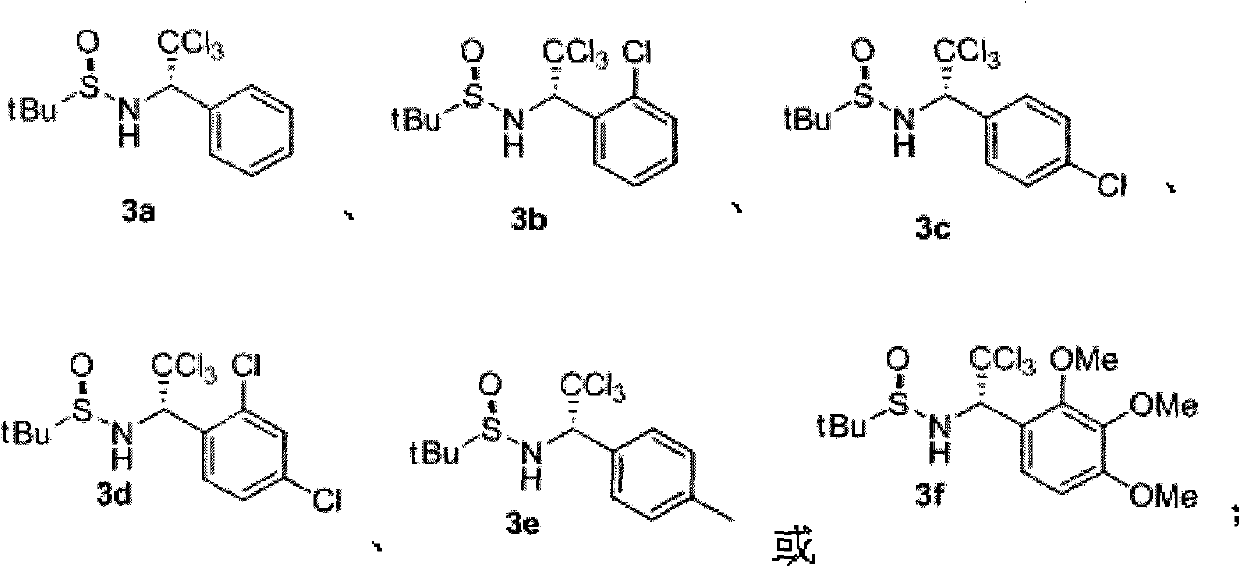

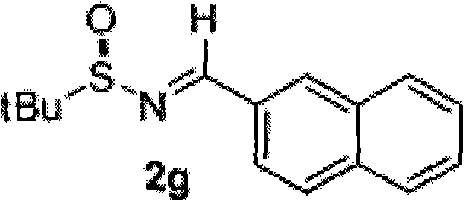

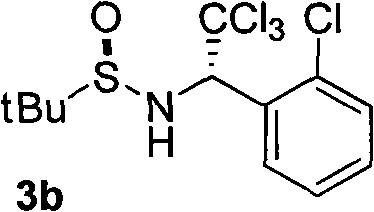

Chiral alpha-(trichloromethyl) amine compound and preparation method thereof

InactiveCN101857559AHigh optical purityThe preparation process conditions are mildAsymmetric synthesesEnantioselective synthesisAziridine

The invention discloses a chiral alpha-(trichloromethyl) amine compound and a preparation method thereof. The chiral alpha-(trichloromethyl) amine compound is a potential bioactive molecule synthesis building block and can serve as an important midbody for synthesizing chiral chloric amine compounds, such as 2,2-dichloro aziridine. The preparation method of the invention has moderate technological condition and abundant and cheap raw materials, and the prepared alpha-(trichloromethyl) amine has high optical purity and is convenient to industrially apply. The alpha-(trichloromethyl) amine prepared by the invention can be widely applied in the fields of asymmetric synthesis and medicine research and development. The structural general formula is disclosed in formula (3).

Owner:SHANGHAI UNIV OF ENG SCI

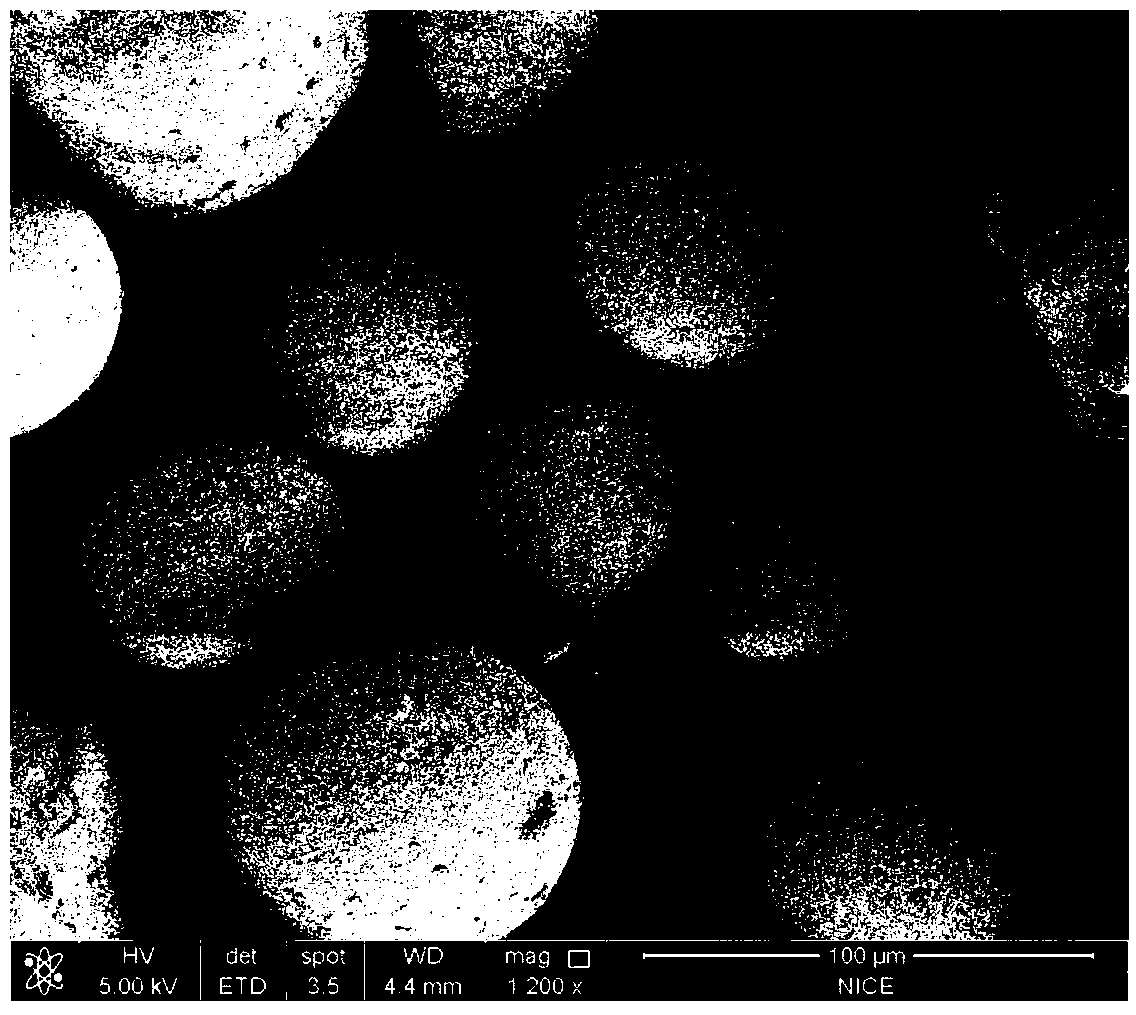

Precipitated iron catalyst for Fischer-Tropsch synthesis and preparation method thereof

ActiveCN103801324AGood sphericityHigh abrasion strengthLiquid hydrocarbon mixture productionMineral wax recovery/refiningWaxCarbon dioxide

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for preparing silicon dioxide aerogel from quartz tailings as raw material

ActiveCN106430220ARaw materials are cheap and easy to getLow equipment requirementsSilicaAlkaneSilicon dioxide

The invention provides a method for preparing silicon dioxide aerogel from quartz tailings as a raw material. The method comprises the following steps: step 1, the quartz tailings are washed, dried, ground and sieved and then ground and mixed with sodium carbonate powder, a mixture is calcined, and a calcination product is obtained; step 2, the calcination product is ground and sieved, undersized matter is added to hot water to be stirred and dissolved, the solution is filtered, a filtrate is taken, and water glass is obtained; step 3, the pH value of the water glass is regulated with hydrochloric acid, a sol-gel reaction is performed, a product is left to stand for aging, and hydrogel is obtained; step 4, free water in the hydrogel is filtered out, residual moisture is replaced with absolute ethyl alcohol, and alcogel is obtained; step 5, the alcogel is soaked with an n-hexane solution of trimethylchlorosilane, and hydrophobically modified alkane gel is obtained; step 6, drying is performed, and the silicon dioxide aerogel is obtained. The raw materials are cheap and available, the preparation process adopts mild conditions and has low equipment requirements, so that the production cost of the silicon dioxide aerogel is reduced greatly, and the prepared aerogel has good performance.

Owner:SHANGLUO UNIV

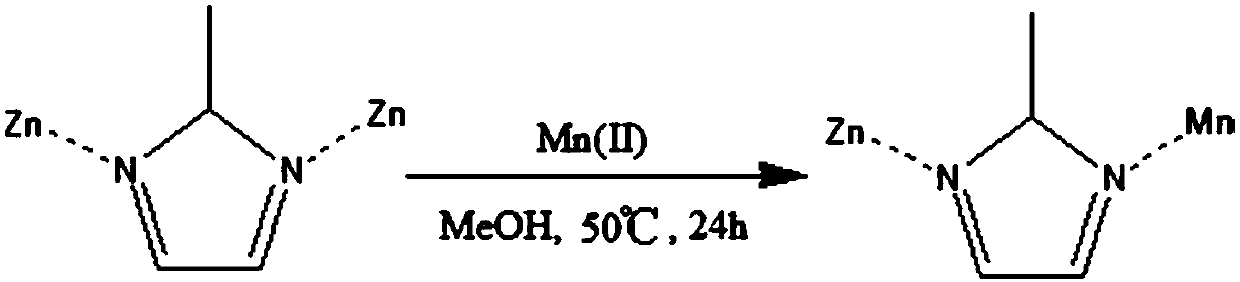

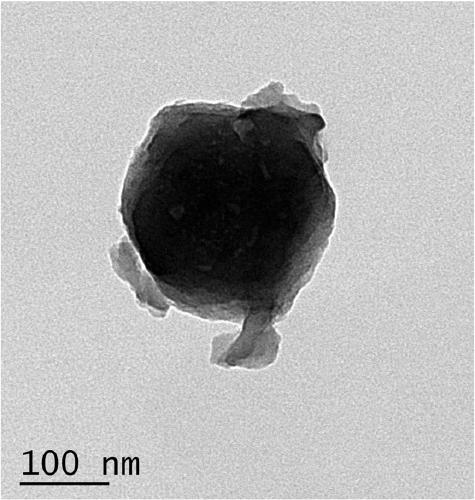

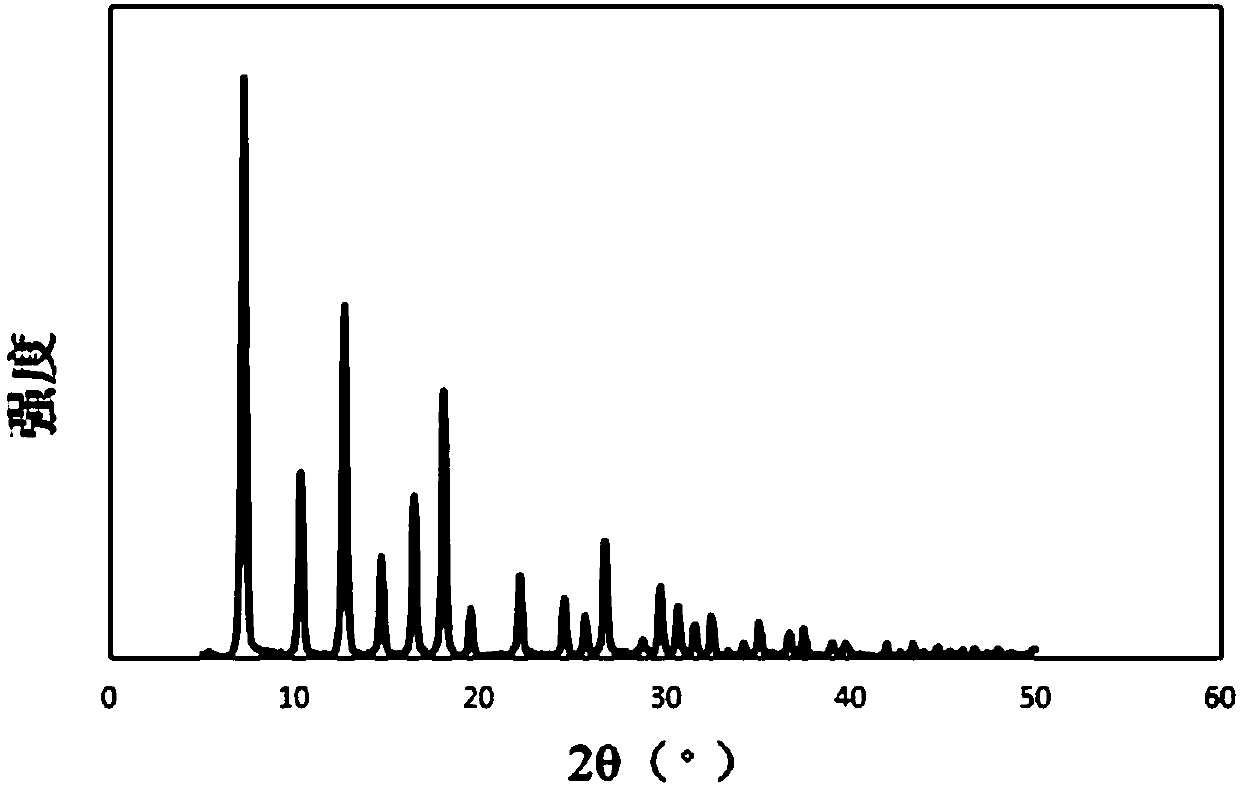

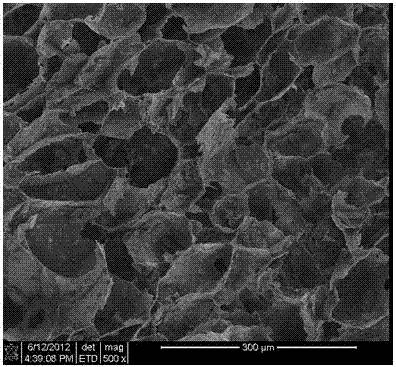

Preparation method of zeolite imidazole framework structure material

The invention discloses a preparation method of a zeolite imidazole framework structure material. According to the method, a zeolite imidazole framework structure is subjected to ion exchange to become a composite of two metal ions, wherein post-exchanged particles have a nuclear magnetic resonance effect. The method is mild in reaction condition, easy to operate and low in raw material cost and comprises simple steps. The zeolite imidazole framework structure contrast medium prepared with the method has good water solubility, improved application safety, small toxicity to normal cells and efficient contrast effects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Nano-hydroxyapatite/chitosan/chondroitin sulfuric acid composite stent

The invention discloses a nano-hydroxyapatite / chitosan / chondroitin sulfuric acid composite stent with high biological response and a preparation method of the nano-hydroxyapatite / chitosan / chondroitin sulfuric acid composite stent. The preparation method comprises the steps of: using chitosan / chondroitin sulfuric acid as an organic matrix and using a calcium-phosphor salt solution as an inorganic phase precursor; fully uniformly mixing a chitosan / chondroitin sulfuric acid acetic acid solution with a soluble calcium-phosphor salt solution, crosslinking with a crosslinking agent, carrying out injection molding and forming, carrying out in-situ biomimetic mineralization crystallization in alkaline liquor, freezing and drying to obtain the nano-hydroxyapatite / chitosan / chondroitin sulfuric acid composite stent with high biological response. The preparation method can be used for simulating a composition and a structure of natural bone on the aspect of material preparation, is mild in preparation condition, and is simple to operate; and the prepared material can be randomly shaped and re-machined according to the use demand.

Owner:FUZHOU UNIV

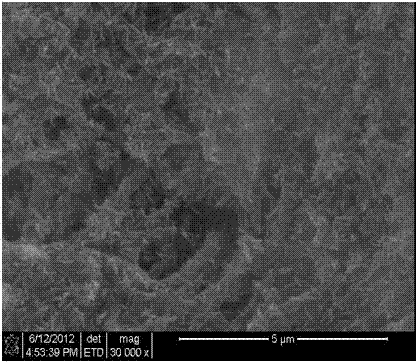

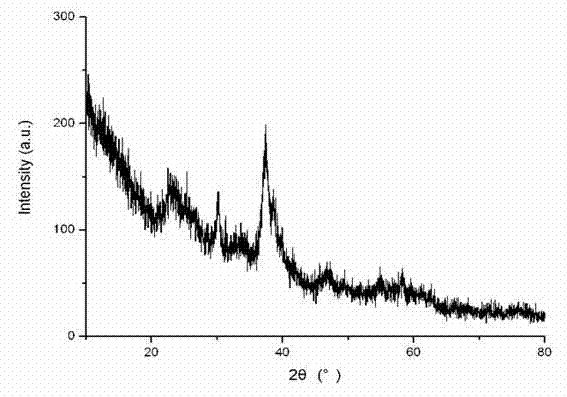

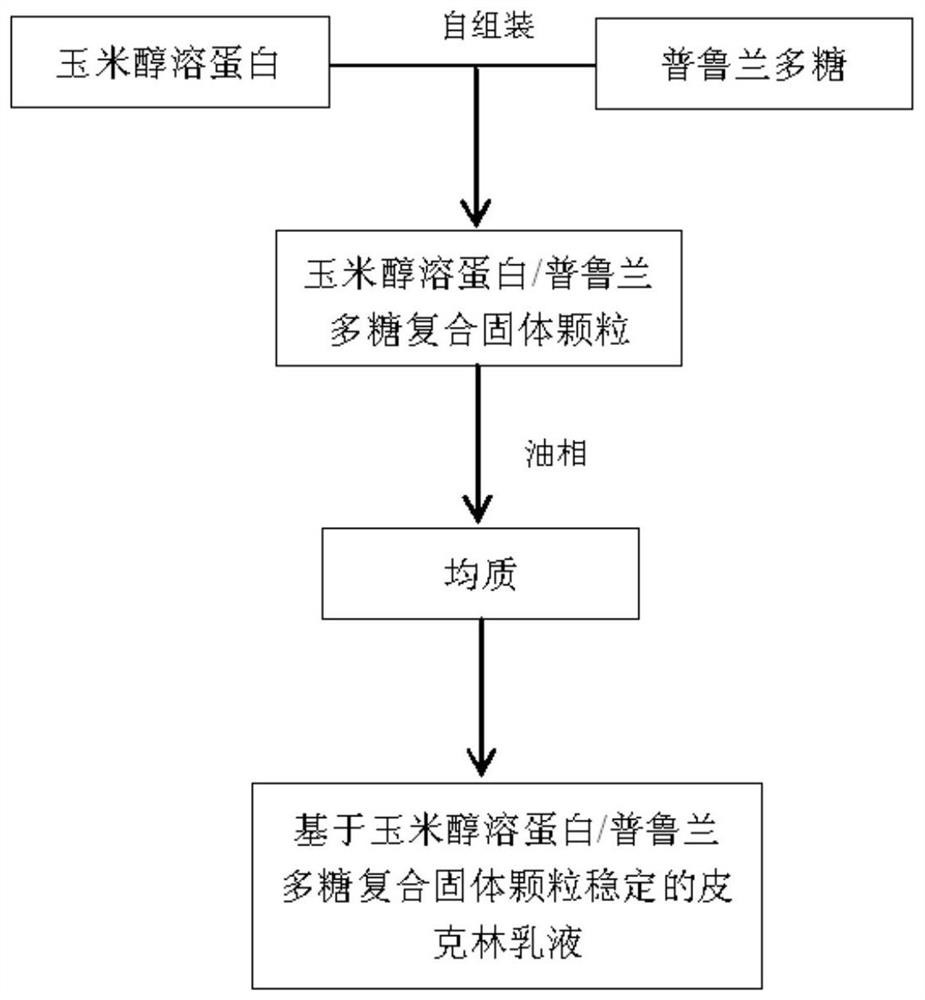

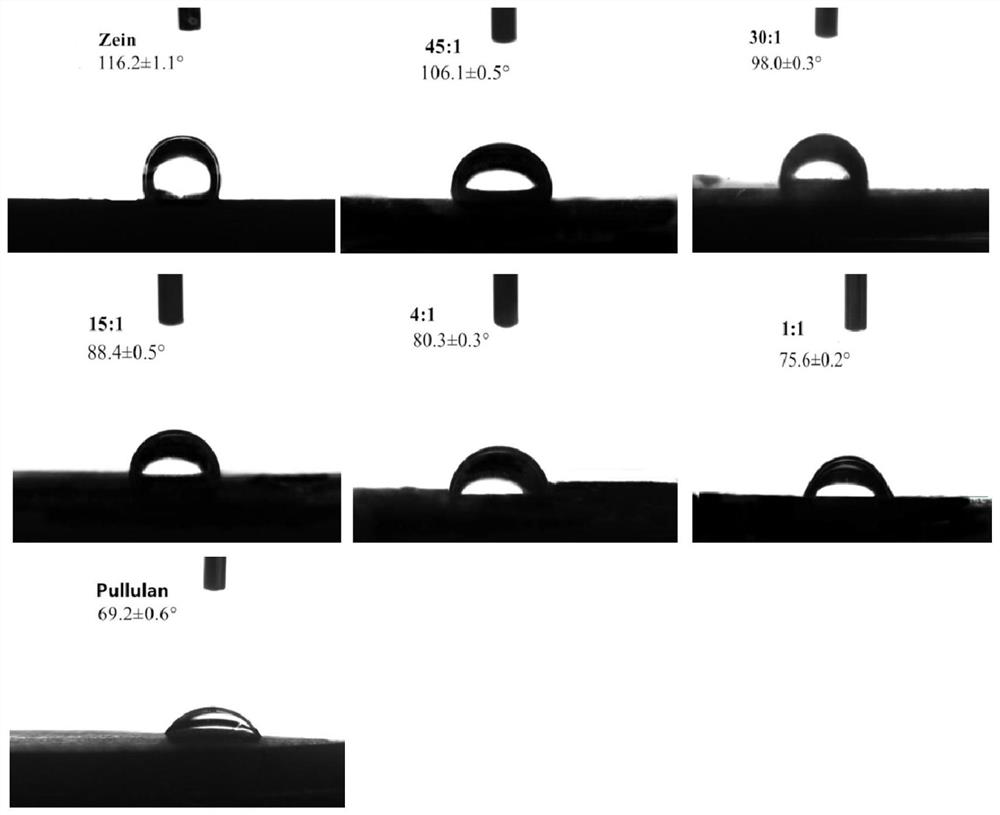

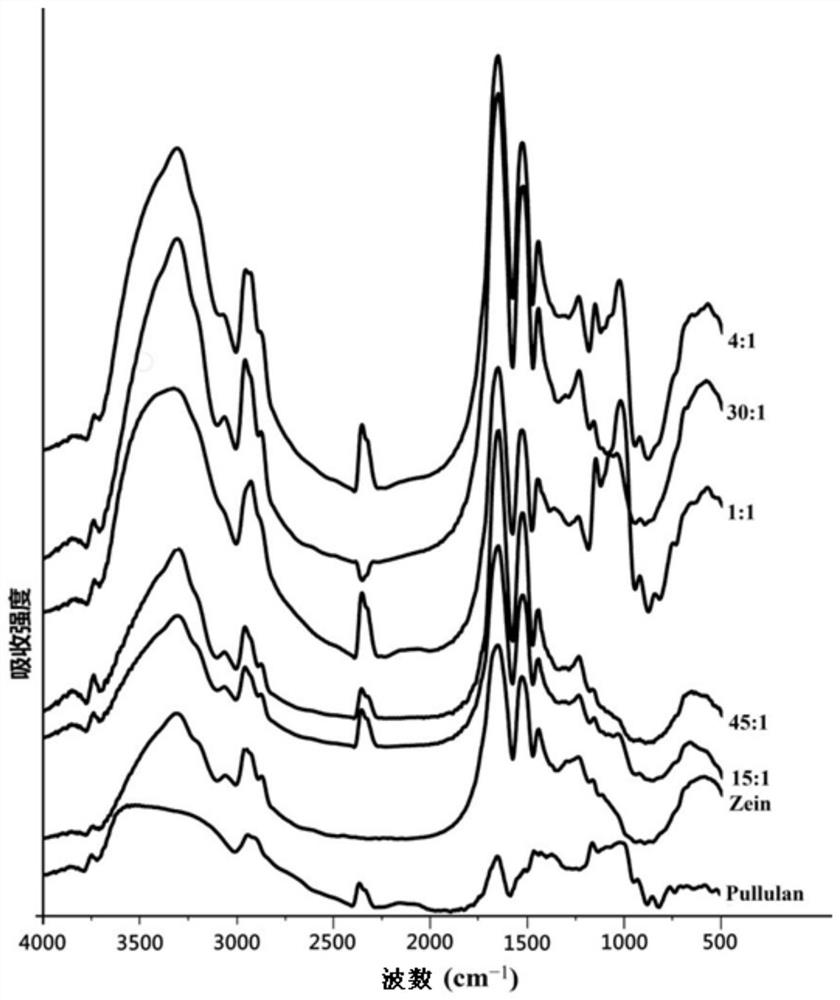

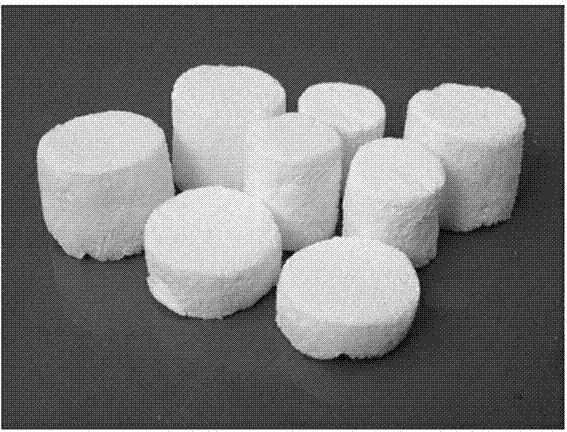

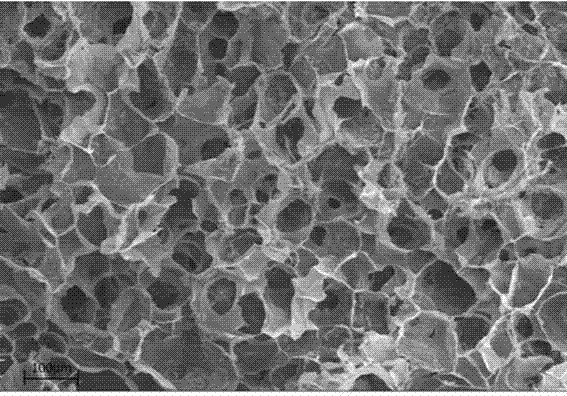

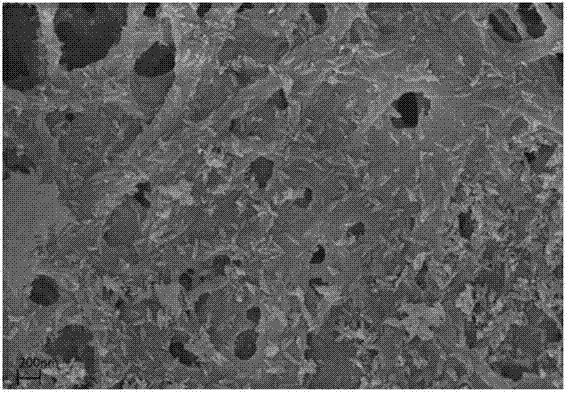

Preparation method and application of stable Pickering emulsion based on zein/pullulan composite solid particles

ActiveCN112544991AIncrease moistureHigh nutritional valueOrganic active ingredientsNervous disorderPullulanPickering emulsion

The invention discloses a preparation method and application of a stable Pickering emulsion based on zein / pullulan composite solid particles. The preparation method comprises the following steps: firstly, preparing zein solid particles, then preparing zein / pullulan composite solid particles, and homogenizing the zein / pullulan composite solid particles with an oil phase to construct the stable Pickering emulsion based on the zein / pullulan composite solid particles. The Pickering emulsion can be used for loading various citrus polymethoxylated flavonoid compounds. According to the preparation method disclosed by the invention, zein can achieve neutral wettability, the dosage of pullulan is small, the nutritional value is high, the pullulan is biodegradable, the preparation process is simple,the stability is high, the method is green and safe, and the obtained Pickering emulsion can be used for fresh keeping and drug loading.

Owner:HUNAN AGRI PRODS PROCESSING INST

Oil-soluble/water-soluble organic-inorganic three-phase porous micro-nanometer composite bone repair material

ActiveCN104707179AImprove adhesionPromote growthProsthesisCell-Extracellular MatrixSeparation technology

The invention discloses an oil-soluble / water-soluble organic-inorganic three-phase porous micro-nanometer composite bone repair material and a preparation method thereof. From the bionic angle, for better simulating the components, structure and function of natural bone tissues, chitosan and collagen are selected as water-soluble organic matrixes; an oil-soluble high-molecular material polylactic acid is added for improving the performance; a water-soluble phase can be combined with an oil-soluble phase by crosslinking; an in-situ crystallization process of inorganic calcium and phosphorus mineral in the natural bone tissues under the regulation and control of organic matrix biological large molecules is simulated by a hybridization method; a nanometer hydroxyapatite crystal is synthesized on the matrix; an artificial bone defect repair scaffold similar to natural bone extracellular matrix is molded and prepared by utilizing a freeze-drying phase separation technology. The preparation method of the oil-soluble / water-soluble organic-inorganic three-phase porous micro-nanometer composite bone repair material disclosed by the invention is simple in procedures and mild in condition; the prepared composite scaffold is similar to natural bone matrix in constitution and structure, has a typical micro-nanometer structure (micrometer-grade hole diameter size and nanometer crystal), is excellent in performance and high in figurability and can be processed into required shapes.

Owner:FUZHOU UNIV

Catalyst for catalyzing and oxidizing carbon monoxide at low temperature and preparation method thereof

InactiveCN101879454AHigh catalytic oxidation activityExtended service lifeDispersed particle separationCatalyst activation/preparationActive carbonActivated carbon

The invention discloses a catalyst for catalyzing and oxidizing carbon monoxide at low temperature and a preparation method thereof. The catalyst comprises an active component Pd, additive Fe and a carrier, wherein the carrier is active carbon modified from chitosan; and the active component Pd and the additive Fe are loaded on the carrier. In the catalyst, the mass of the active component Pd is 0.5 to 3 percent of that of the carrier, and the mass of the additive Fe is 3 to 24 percent of that of the carrier. The preparation method of the catalyst comprises the following steps: adopting a step impregnation method, acidizing the active carbon, treating the acidized active carbon with chitosan solution, then sequentially soaking and absorbing the additive Fe and the active component Pd, filtering, washing and drying to obtain the catalyst. The catalyst is characterized by low precious metal content, high activity at low temperature, good moisture resistance property and the like.

Owner:CHINA AGRI UNIV

Efficient electric promoting absorptive fluorine removal adsorbent and preparation method thereof

InactiveCN102335590AImprove adsorption capacityLarge adsorption capacityOther chemical processesWater contaminantsHydration reactionSorbent

The invention relates to the field of fluorine removal, in particular to an efficient electric promoting absorptive fluorine removal adsorbent and a preparation method thereof. The composite efficient electric promoting absorptive fluorine removal adsorbent provided by the invention comprises an active metal oxide, a conductive material and a dispersant. The fluorine removal adsorbent provided bythe invention is a composite absorption system containing a hydrous metal oxide and carbon material, promotes to absorb fluorine by using the non-characteristic adsorption and characteristic adsorption of double electrode layers in the reaction process and an exchange reaction between a fluorine removal material and a fluorinion, and has large absorption capability and a wide application range.

Owner:BEIJING FORESTRY UNIVERSITY

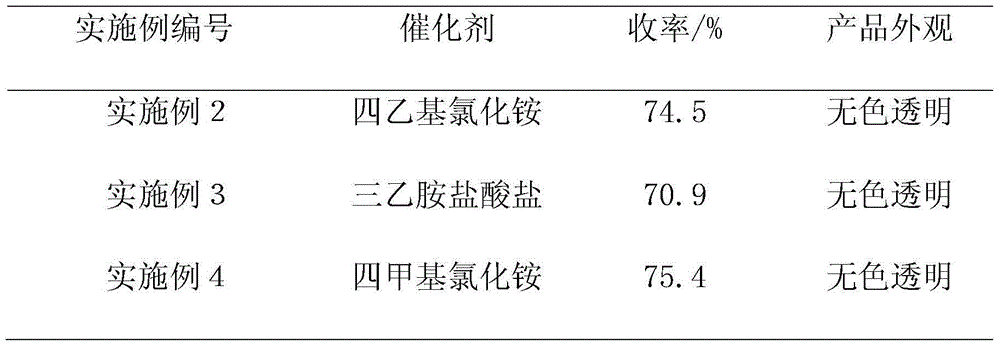

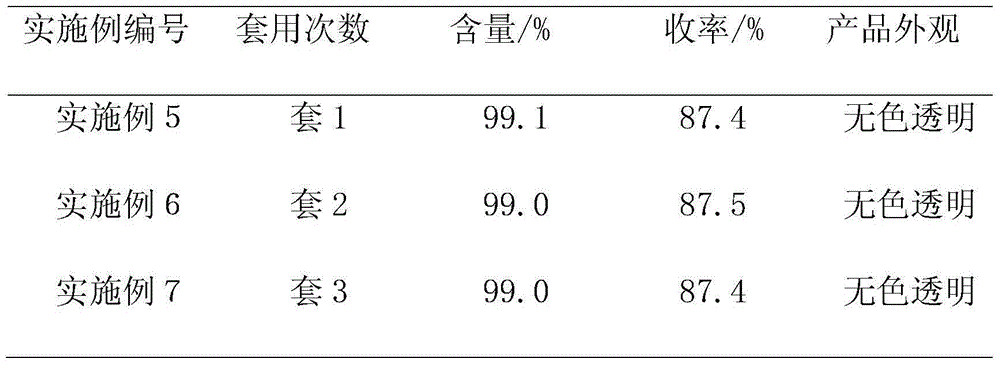

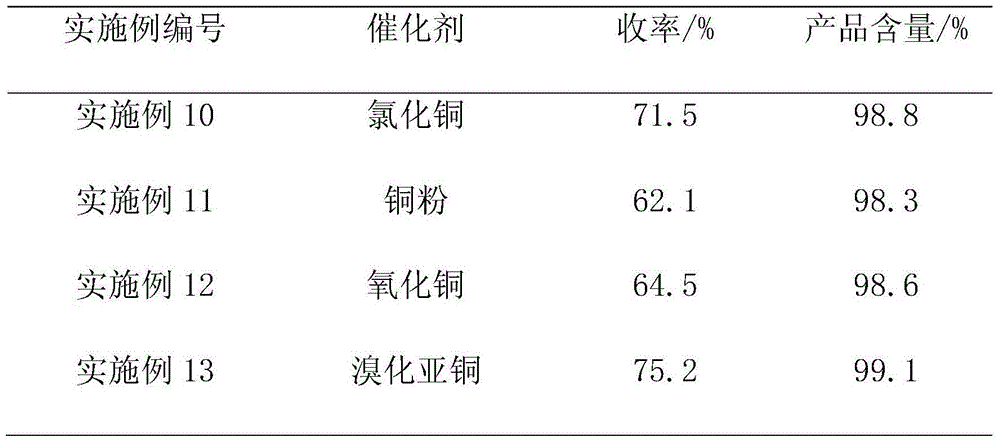

Synthetic method of pesticide intermediate 2-chloro-4-formyl valeronitrile

ActiveCN104860844ASimple and fast operationReduce pollutionCarboxylic acid nitrile preparationOrganic compound preparationAcrylonitrileChloride

The invention belongs to the technical field of organic chemical industry, and relates to a synthetic method of a precursor of an imidacloprid pesticide intermediate 2-chloro-4-formyl valeronitrile. According to the synthetic method, propionaldehyde and chlorine gas are taken as initial raw materials, 2-chloride propyl aldehyde is prepared via substitution, and catalytic addition with acrylonitrile is carried out so as to obtain 2-chloro-4-formyl valeronitrile via synthesis, and total yield is stabilized to be higher than 70%. According to the synthetic method, chlorine substitution and addition two-step reaction is adopted, 2-chloro-4-formyl valeronitrile is prepared, the synthetic method is simple in technological process, low in production cost, and low in equipment investment, and is suitable for industrialized production, and raw material recovery is convenient to realize.

Owner:JIANGSU YANGNONG CHEM GROUP +2

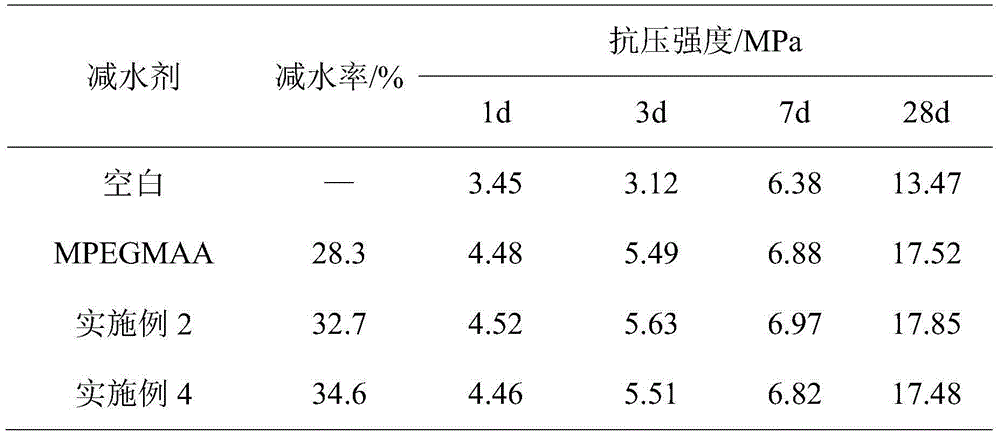

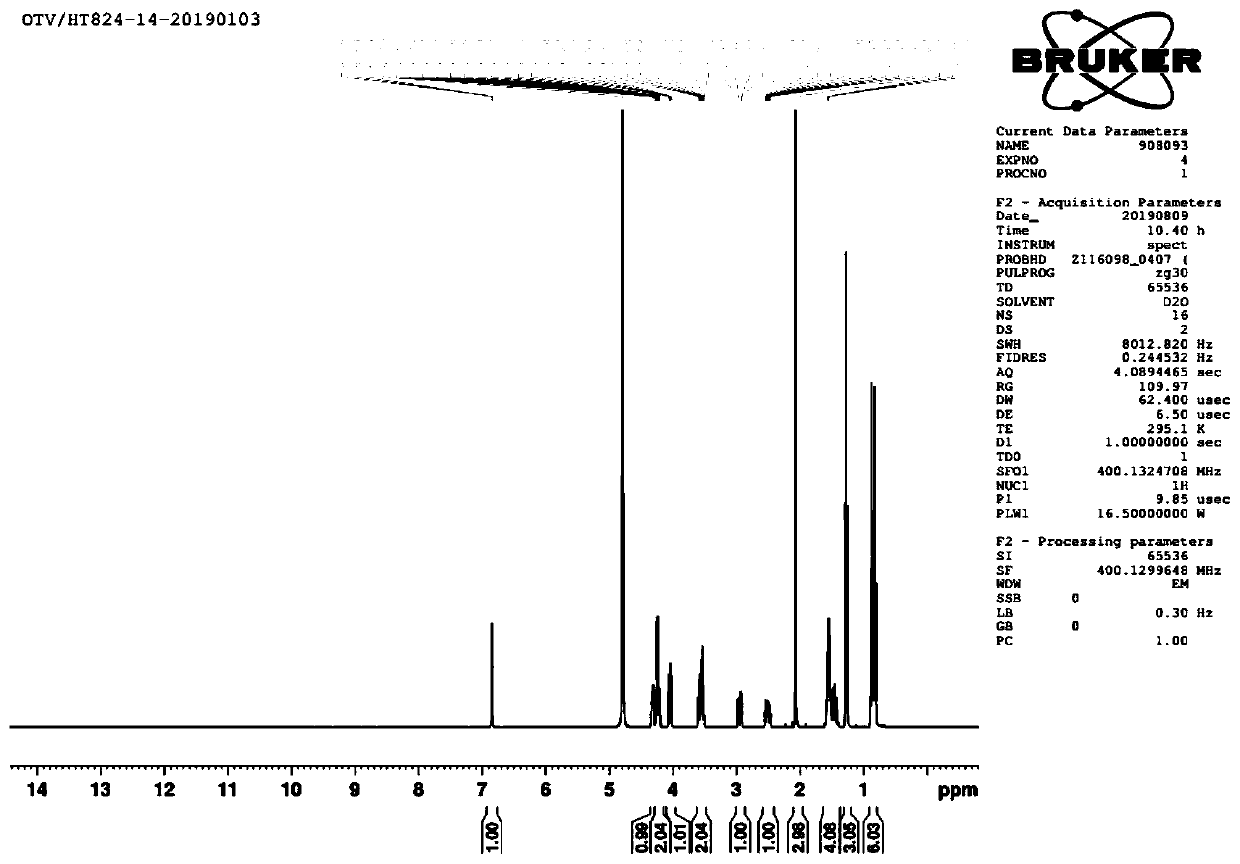

A preparing method of a ternary copolymerized water reducer

A preparing method of a ternary copolymerized water reducer is disclosed. The method includes adding a proper amount of water, modified polyether and a molecular weight regulator into a reactor, stirring, dissolving to obtain a modified polyether solution, heating to 70-85 DEG C, adding dropwise a monomer mixture of acrylic acid and acrylamide and an aqueous initiator solution at the same time, after addition of the monomer mixture and the aqueous initiator solution is finished, continuously reacting at maintained temperature for 2-4 h, cooling after the reaction is finished, adding an alkali for neutralizing, and adjusting pH of the solution to 7-8 to obtain the modified polyether-polyacrylic acid-polyacrylamide ternary copolymerized water reducer. The method reduces raw material costs, is mild in preparation process conditions, low in cost and capable of meeting environment protection requirements. The water reducer can improve early-stage strength and final-strength of concrete perforated brick setting structures. Properties of the water reducer are superior to those of polycarboxylate water reducers of the same series in the market. The water reducer has a high cost performance ratio and high market competiveness.

Owner:SHAANXI JINHAOYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Honeycomb-shaped TiO2 porous microsphere using microporous starch as template and preparation method thereof

ActiveCN107983415AHigh catalytic efficiencyLarge specific surface areaOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsEmulsionCentrifugation

The invention discloses a honeycomb-shaped TiO2 porous microsphere using microporous starch as a template and a preparation method thereof. According to the method, starch is hydrolyzed by bio-enzymeto obtain the microporous starch; dispersing agents and bonding agents are added into nanometer TiO2 to obtain nanometer TiO2 emulsion; the microporous starch and the nanometer TiO2 emulsion are mixed; centrifugation is performed; precipitates are dried and ground to obtain the honeycomb-shaped TiO2 porous microsphere. The TiO2 is directly loaded onto the microporous starch; the adsorption performance of the microporous starch is used for preparing the microporous microsphere; the prepared TiO2 porous microsphere has high specific surface area, high specific pore volume and good adsorption performance; the unique advantage of improving the light capturing efficiency and photocatalytic performance is realized; the template removal treatment is not needed; the honeycomb-shaped TiO2 porous microsphere can be directly used as a photocatalyst; the catalysis efficiency is high; the preparation process conditions are mild; the production period is short; the raw materials are cheap and can beeasily obtained; the environment-friendly effects are achieved; wide application prospects are realized in an aspect of organic pollution degradation through photocatalysis.

Owner:SOUTH CHINA AGRI UNIV

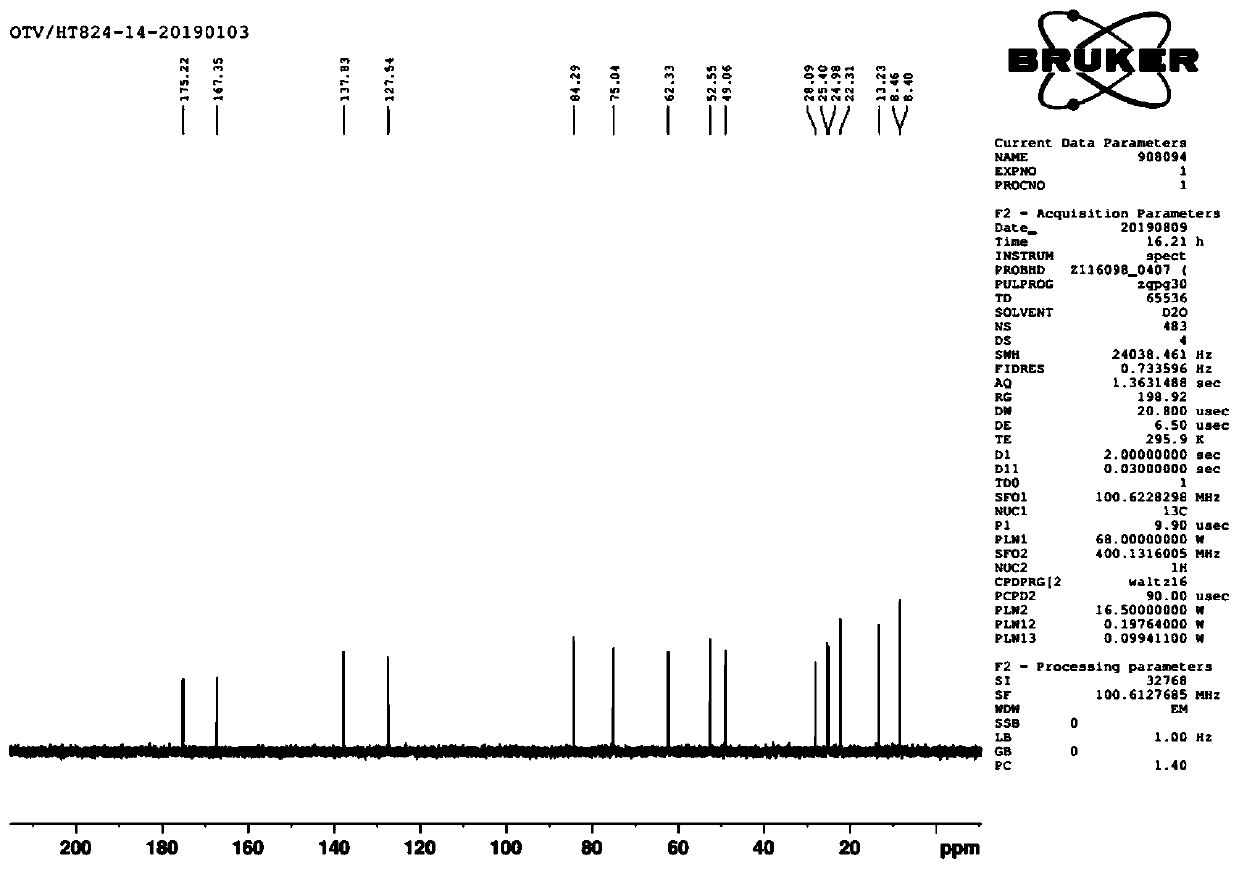

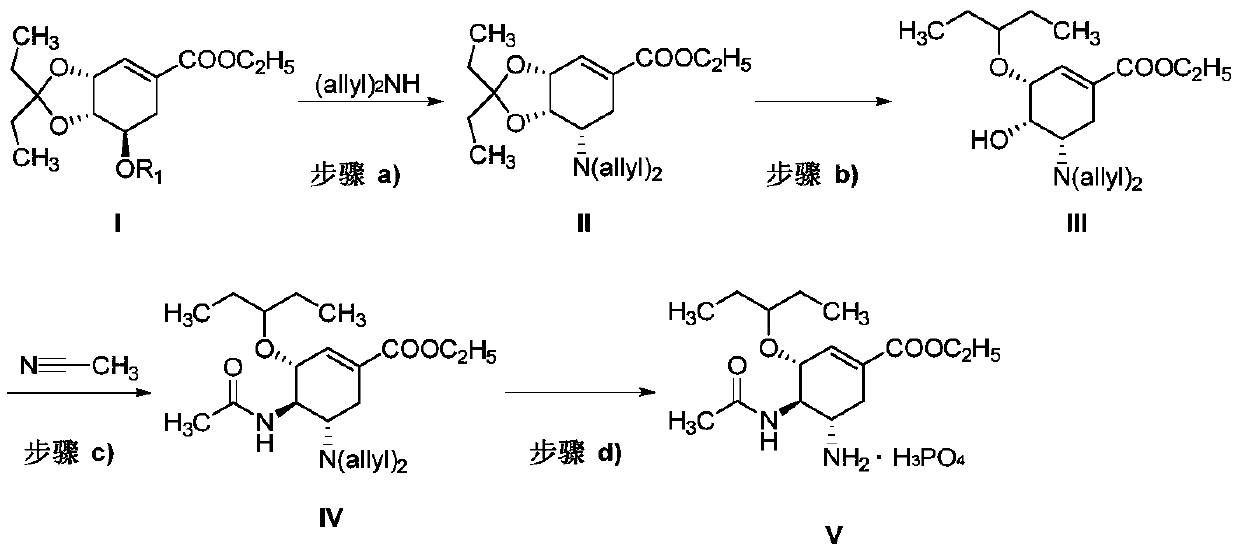

Preparation method of oseltamivir phosphate

ActiveCN110563600AFewer steps in the preparation processMild process conditionsOrganic compound preparationCarboxylic acid amides preparationOseltamivir PhosphateCarboxylate

The invention provides a novel preparation method of ethyl (3R,4R,5S)-4-acetylamino-5-amino-3-(1-ethylpropoxy)-1-cyclohexene-1-carboxylate phosphate, and belongs to the technical field of chemical drug synthesis. An acetamido group is introduced into the construction process of oseltamivir phosphate molecules by using a Ritter reaction. The preparation way of the initial raw material in the invention is close to the shikimic acid end of a natural product, so the novel preparation method has the advantages of mild conditions, simplicity in operation, high total yield, and suitableness for commercial production of oseltamivir phosphate bulk drugs. The method successfully avoids an original research route to overcome protection period limitation of an original research and preparation methodpatent, and can accelerate the solving of the problem of medication accessibility of the medicine in China.

Owner:BEIJING XINLINGXIAN MEDICAL TECH DEV CO LTD

High-conductivity and heat-resistant aluminum alloy and preparation method thereof

ActiveCN110218918AReduce inclusionsReduce porosity defectsConductive materialMetal/alloy conductorsHeat resistanceHigh pressure

The invention relates to a high-conductivity and heat-resistant aluminum alloy and a preparation method thereof, and belongs to the technical field of aluminum-based alloys. The aluminum alloy is prepared from, by mass, 1.5-3.2% of Mg, 0.7-2.8% of Si, 0.2-0.5% of Ni, 0.06-0.25% of Co, 0.1-0.2% of Zr, 0.1-0.4% of Y, and the balance Al and inevitable impurities with the total content of less than orequal to 0.03%. The conductivity and the heat resistance of the high-conductivity and heat-resistant aluminum alloy can be remarkably improved, so that the aluminum alloy better meets the requirements of high-voltage transmission.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

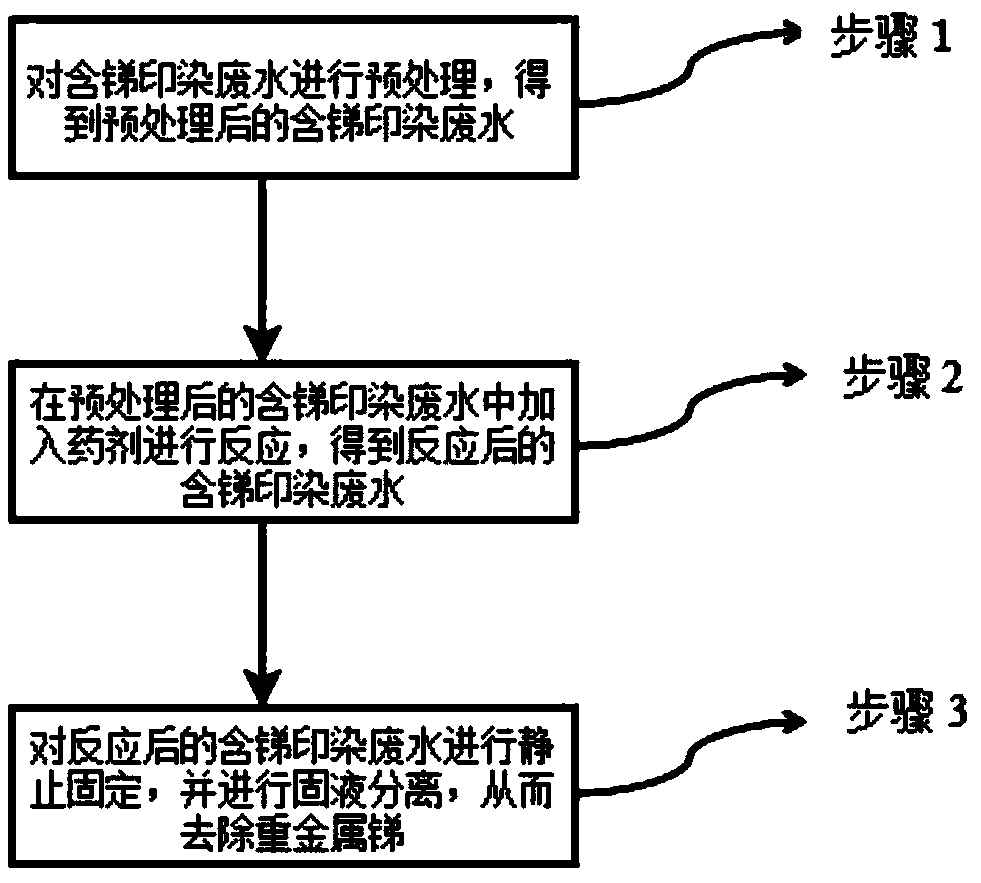

Chemical agent for removing antimony in printing and dyeing wastewater and removal method of antimony

ActiveCN109110896AThe preparation process conditions are mildThe preparation process conditions are simpleWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationSulfatePhysical chemistry

The invention discloses a chemical agent for removing antimony in printing and dyeing wastewater and a removal method of the antimony. The chemical agent comprises a mixture composed of manganese tailing powder and FeSO4, wherein the mixture is solid powder; a main component of the manganese tailing powder is MnOx / SiO2, the grain diameter is 0.075 to 0.100mm and the mass ratio of MnOx / SiO2 / FeSO4 ranges from (1 to 1 to 1) to (1 to 1 to 8); FeSO4 is FeSO4.7H2O, FeSO4.3H2O or anhydrous ferrous sulfate; the removal method comprises the following steps: step 1, putting antimony-containing printingand dyeing wastewater into a pre-treatment tank and carrying out impurity removal pre-treatment, so as to obtain pre-treated antimony-containing printing and dyeing wastewater; step 2, putting the pre-treated antimony-containing printing and dyeing wastewater into a reaction contact tank and adding a certain amount of the chemical agent and contacting and stirring; after reacting for 30 to 60min,thus obtaining reacted antimony-containing printing and dyeing wastewater; step 3, putting the reacted antimony-containing printing and dyeing wastewater into a coagulation precipitation tank, and standing and precipitating; then carrying out solid-liquid separation to remove heavy metal antimony in the printing and dyeing wastewater.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

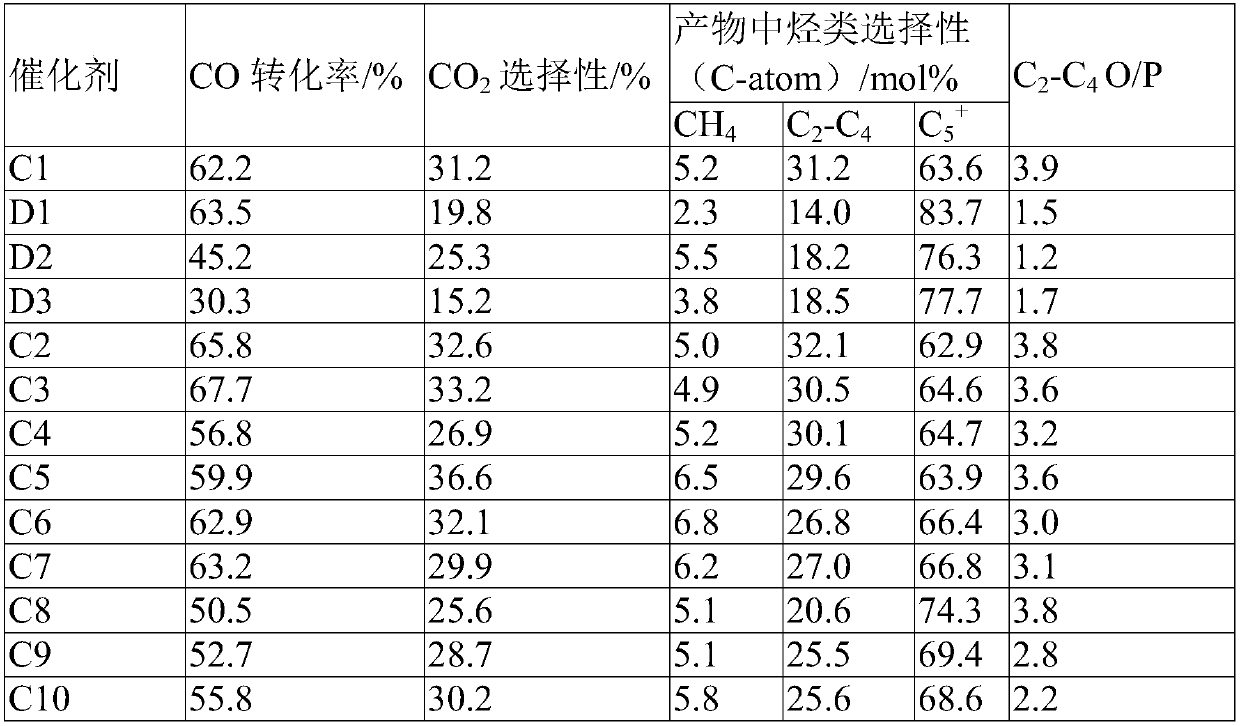

Fischer-Tropsch synthesis iron-based catalyst, preparation method thereof and Fischer-Tropsch synthesis method

ActiveCN110614099AHigh reactivityHigh selectivityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSynthesis methodsPotassium

The invention relates to the field of Fischer-Tropsch synthesis iron-based catalysts, and discloses a Fischer-Tropsch synthesis iron-based catalyst, a preparation method thereof, and a Fischer-Tropschsynthesis method. The preparation method comprises: (1) etching a first mixture of an iron-containing oxide and an acid solution at 20-120 DEG C for at least 2 h to obtain a dispersed slurry; (2) mixing the dispersion slurry, an M salt, a copper salt, a potassium salt, a silicon-containing compound and optionally water to obtain a second mixture; (3) adjusting the pH value of the second mixture to 4-9 to obtain a third mixture; and (4) carrying out spray drying treatment and roasting treatment on the third mixture. The preparation method provided by the invention has the advantages that the preparation process flow is simple; no catalyst needs to be washed, and water consumption is low; compared with a melting method, the preparation process is mild in condition and low in energy consumption; and the prepared catalyst has high reaction activity, high and low carbon olefin selectivity and high added value of the product.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

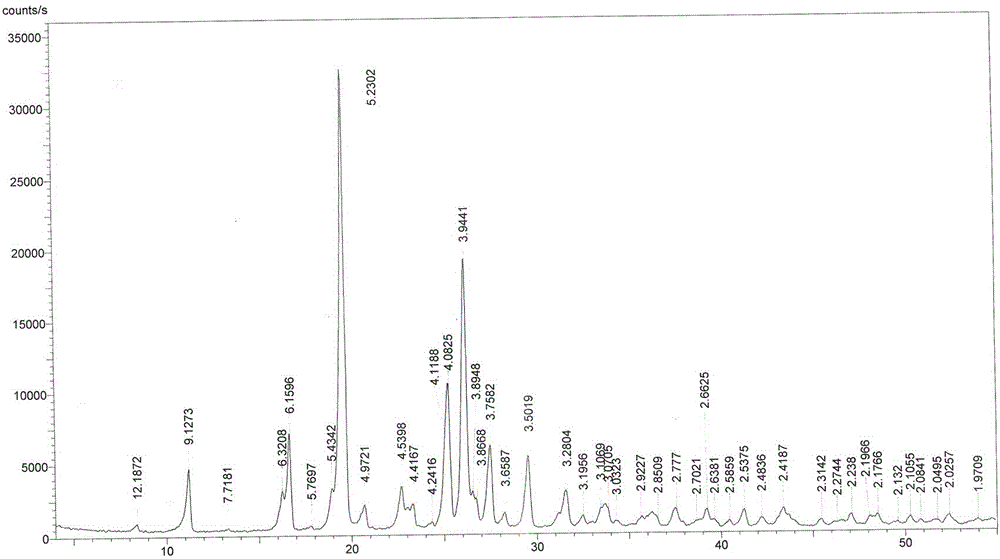

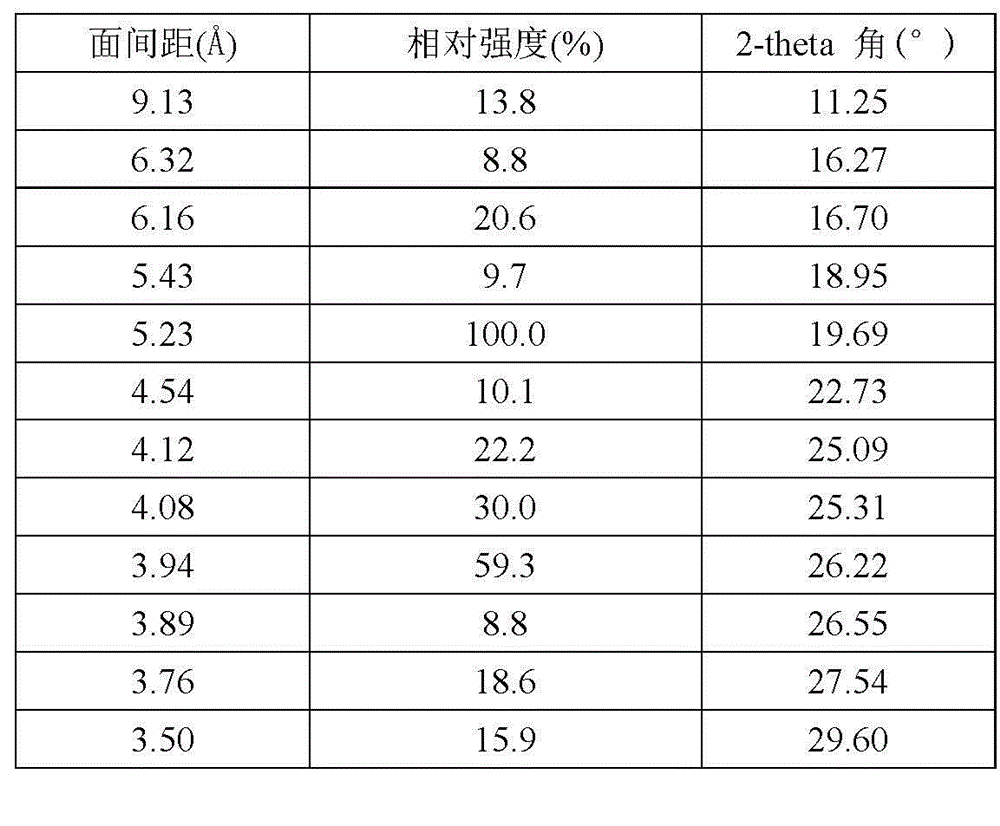

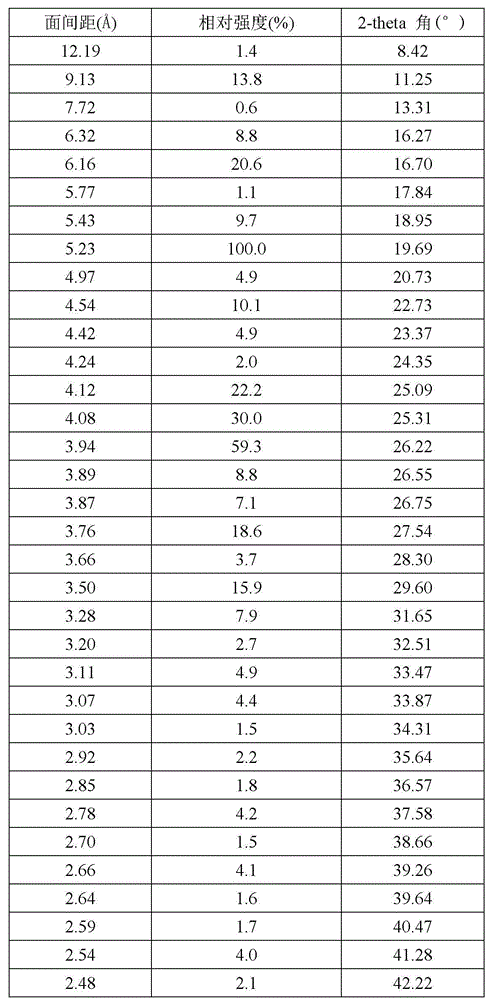

Linezolid crystal form VI and preparation method thereof

The invention relates to a linezolid crystal form VI and a preparation method thereof. In the X-ray powder diffraction spectrum, the crystal form VI powder has absorption peaks at the diffraction angle 2-theta=11.25, 16.27, 16.70, 18.95, 19.69, 22.73, 25.09, 25.31, 26.22, 26.55, 27.54 and 29.60, wherein the error range of the angle 2-theta is + / -0.1. The linezolid crystal form VI provided by the invention has favorable dissolution rate and ideal dissolution effect, and can ensure the medicinal effect; and by using water as the solvent, the preparation method of the crystal form has the advantages of mild technical conditions, no organic solvent to be recycled or discharged, environmental protection and energy saving.

Owner:CHENGDU XINJIE HIGH TECH DEV CO LTD

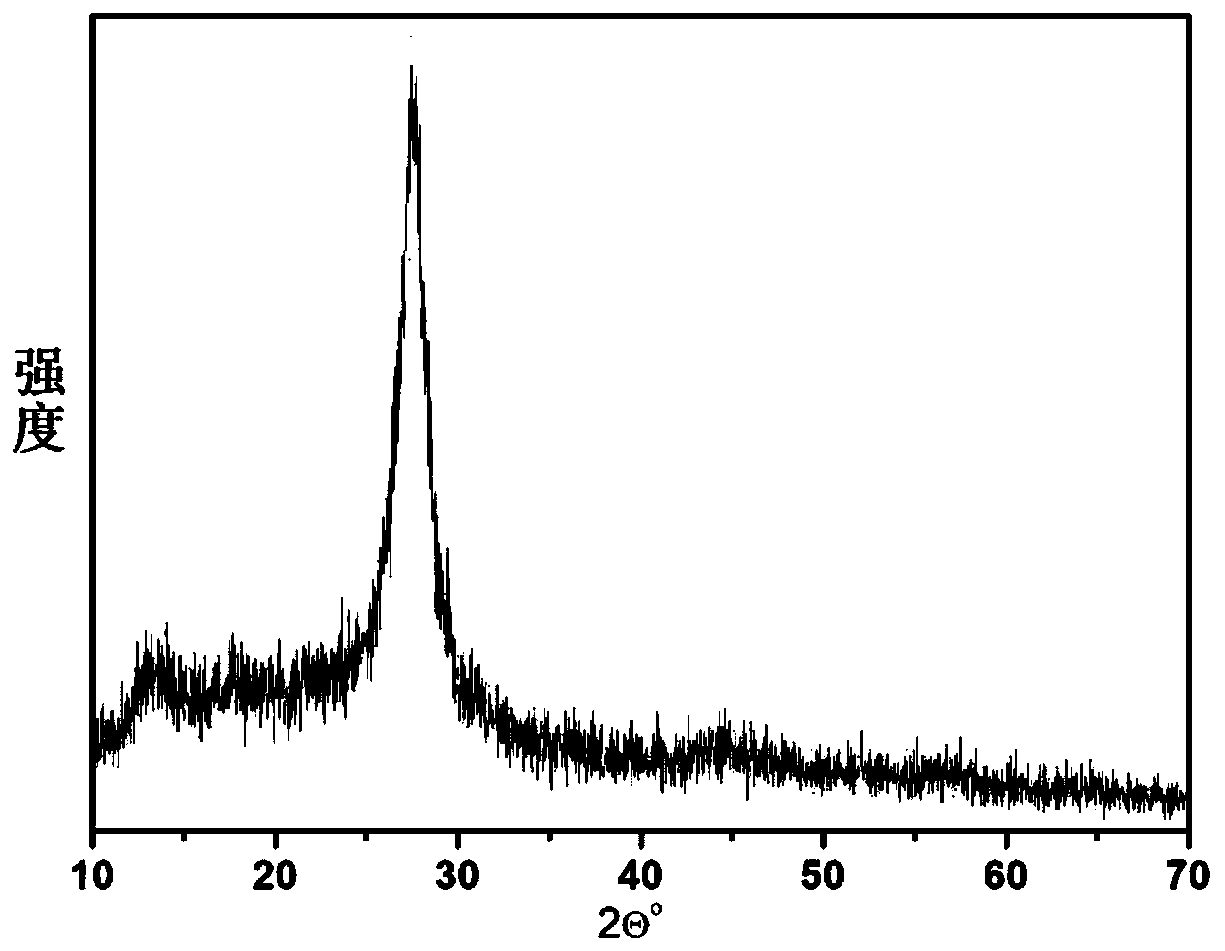

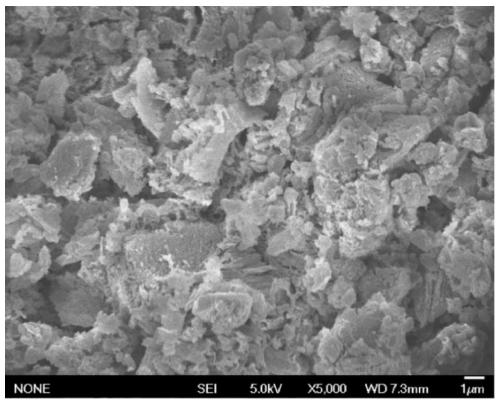

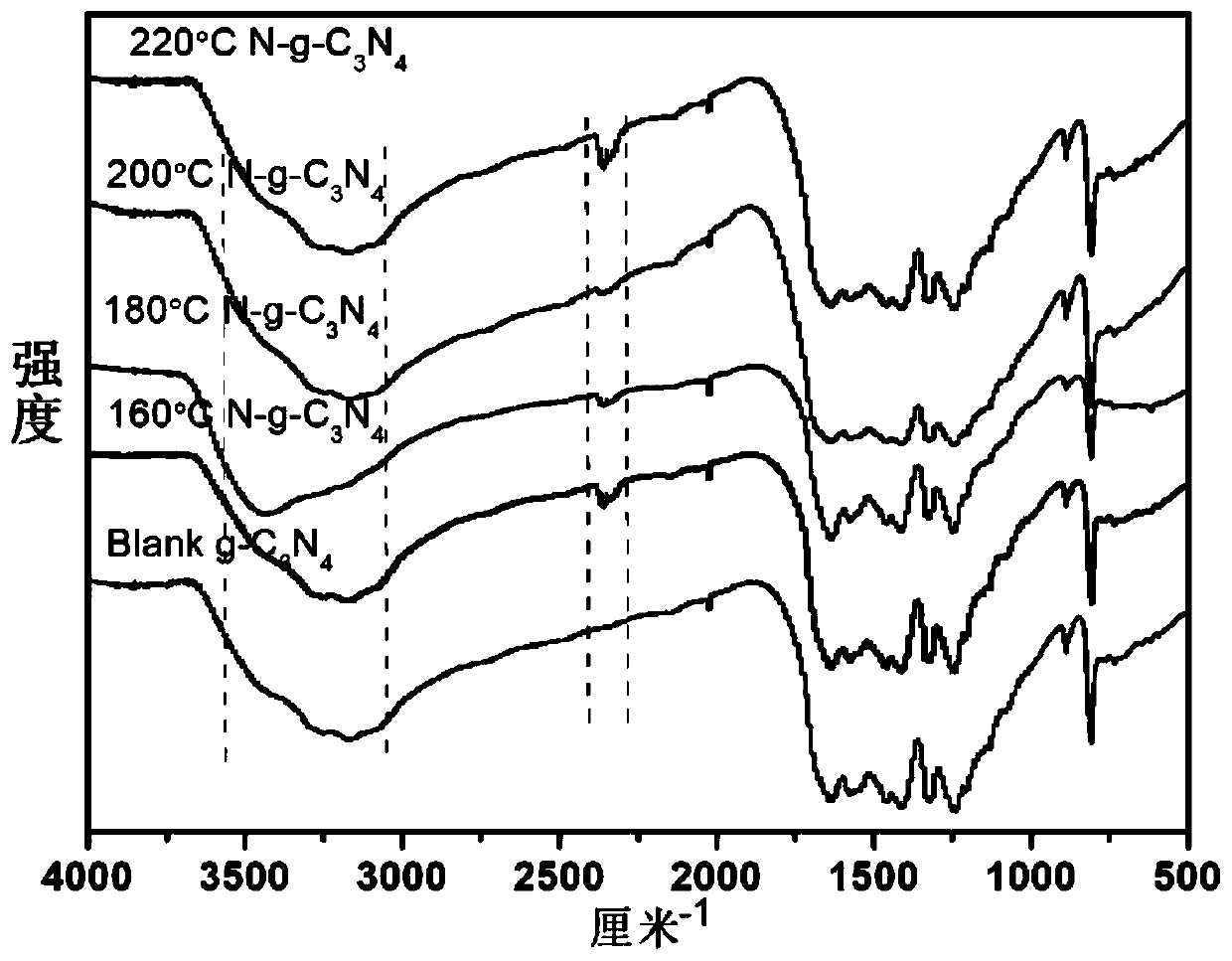

Nitrogen-doped graphite-like carbon nitride visible-light-induced photocatalyst as well as preparation method and application thereof

ActiveCN111151282AAchieve the purpose of dopingRegulating N atom doping amountPhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyePhotocatalytic degradation

The invention discloses a nitrogen-doped graphite-like carbon nitride visible-light-induced photocatalyst as well as a preparation method and application thereof. According to the method, a thermal stripping-solvothermal combination preparation method is adopted, and the synthesized N-g-C3N4 has excellent photocatalytic performance. According to the method, melamine is used as a raw material, common organic solvents such as N,N-dimethylacetamide are used for synthesizing the N-g-C3N4 photocatalyst through a solvothermal reaction, the method has the advantages that the operation is simple, theraw materials are easy to obtain, no additive is added, the cost is low, the application condition is mild, and the method is environmentally friendly, and a reference scheme is provided for nitrogenatom doping. The N-g-C3N4 photocatalyst disclosed by the invention is excellent in performance and good in stability, has great application potential in the aspect of photocatalytic degradation of organic pollutants, and has photocatalytic degradation efficiency of 95% or above on organic dyes such as rhodamine B under visible light.

Owner:SOUTH CHINA UNIV OF TECH

Gridding photovoltaic backboard and preparation method thereof

ActiveCN110828595AThe preparation process conditions are mildRapid prototypingFinal product manufacturePhotovoltaic energy generationWeather resistanceEngineering

The invention discloses a gridding photovoltaic backboard and a preparation method thereof. The preparation method comprises the following steps: coating a white grid structure on the inner layer of adouble-sided coating type transparent base material by utilizing a polyvinylidene fluoride membrane casting solution containing titanium dioxide; subjecting the treated base material to precipitationand solidification through a phase inversion method; and carrying out post-treatment on the solidified base material. The gridding photovoltaic backboard has good weather resistance, a white grid area has high reflectivity, a non-white grid area has high transmittance, the generation power of a photovoltaic module is effectively improved, and the production process is high in forming speed, mildin process, economical and environmentally friendly.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

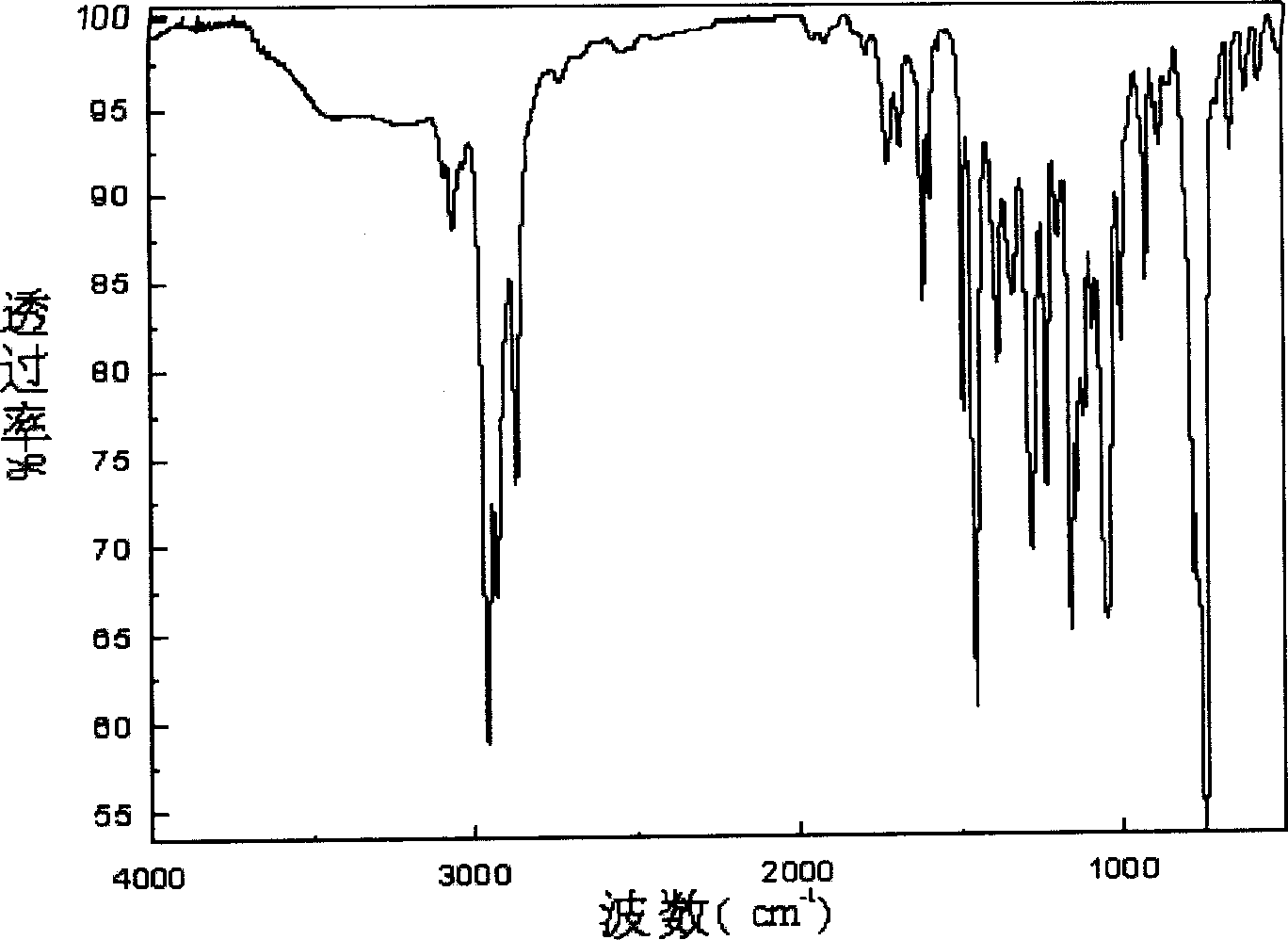

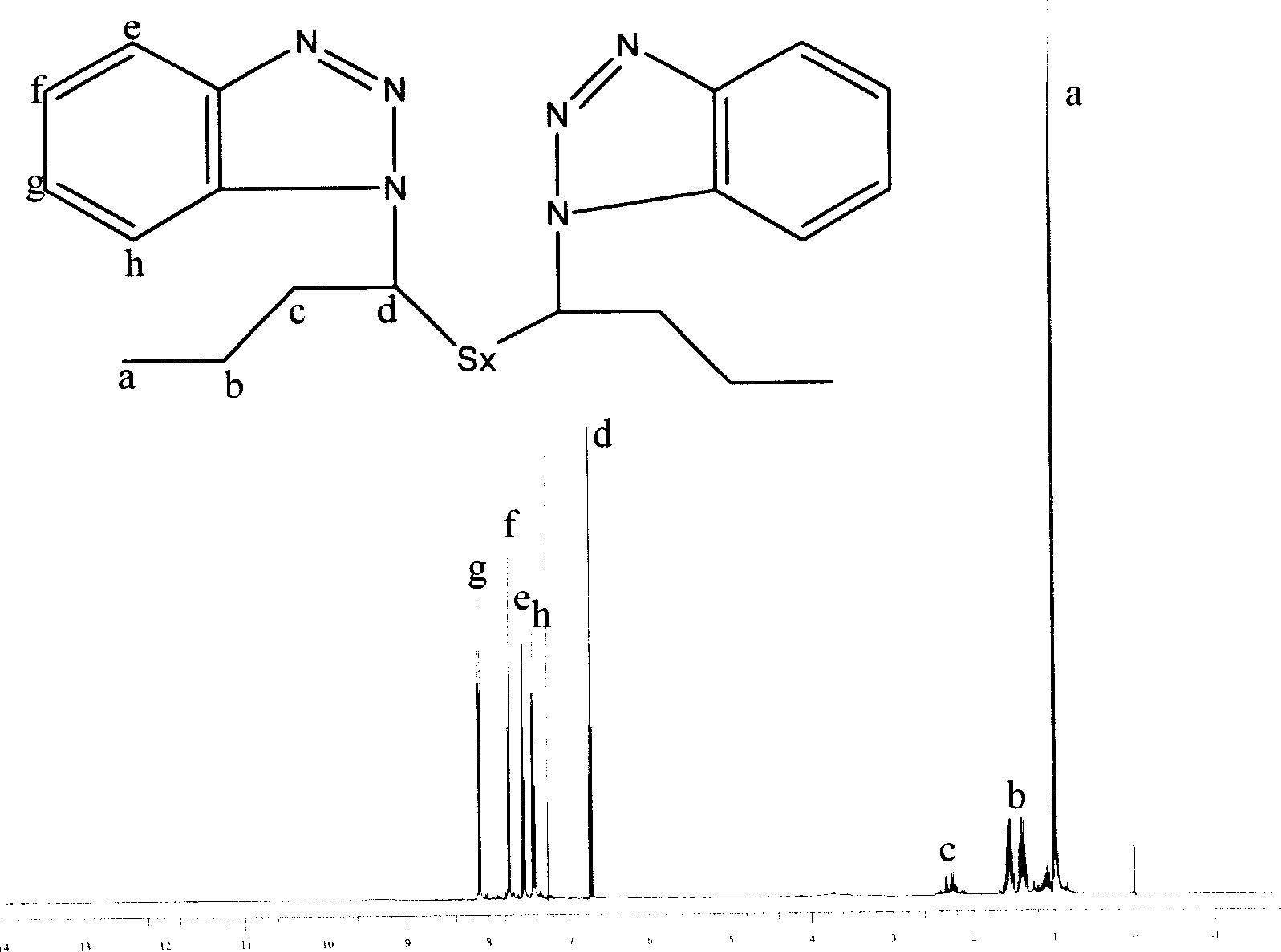

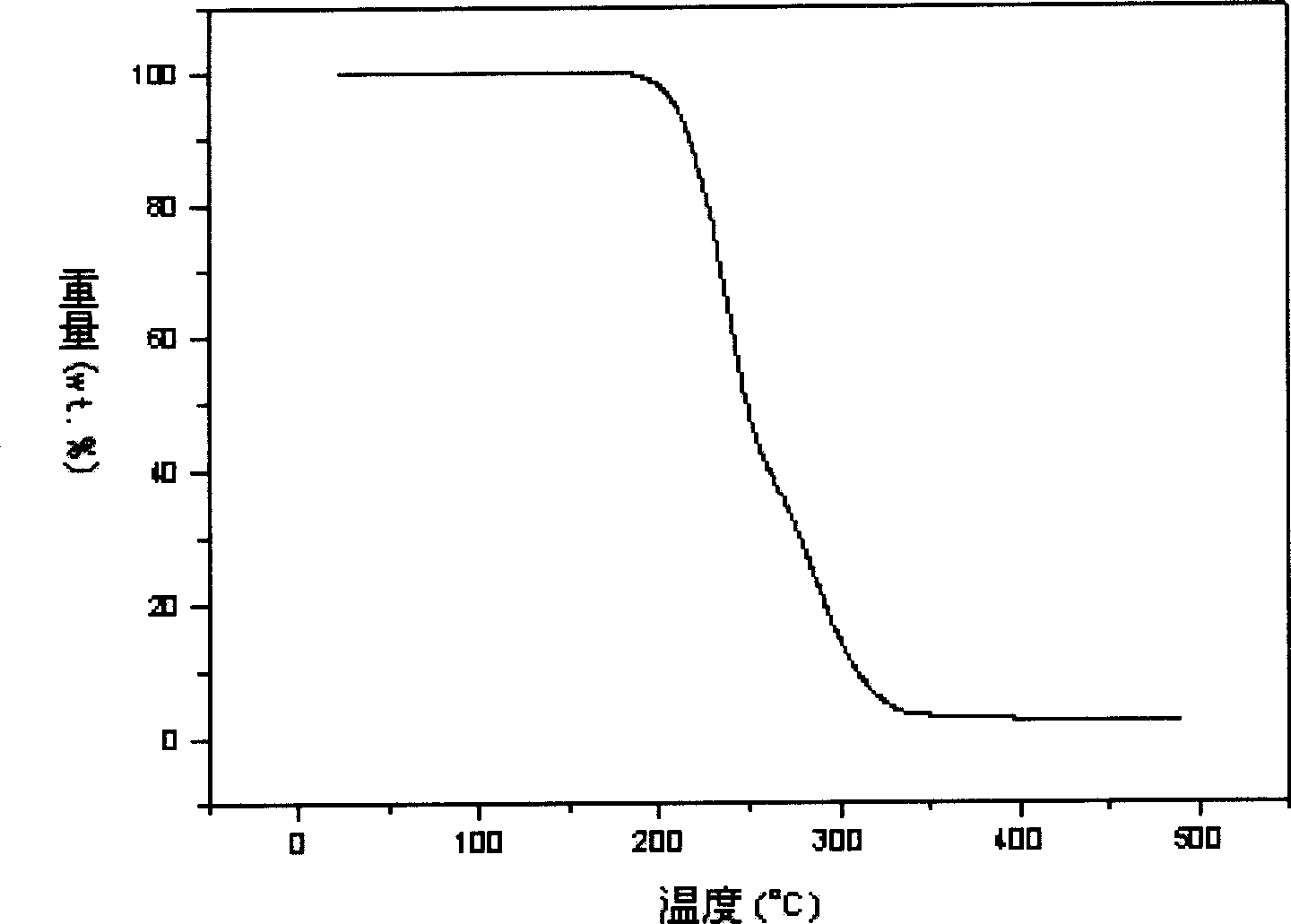

Extreme pressure anti-corrosion addictive of benzo triazole polysulfide and method for preparing the same

The invention discloses an extreme-pressure anticorrosive additive and preparing method of benzo ribavirin polysulfide, whose chemical name is which is characterized by the following: adapting 1-chloride benzo ribavirin and alkali metal polysulfide to do chemical reaction at mild technological condition; obtaining benzo ribavirin polysulfide as lubricating grease extreme pressure, anticorrosive additive or with other composite lubricating grease.

Owner:东莞太平洋博高润滑油有限公司

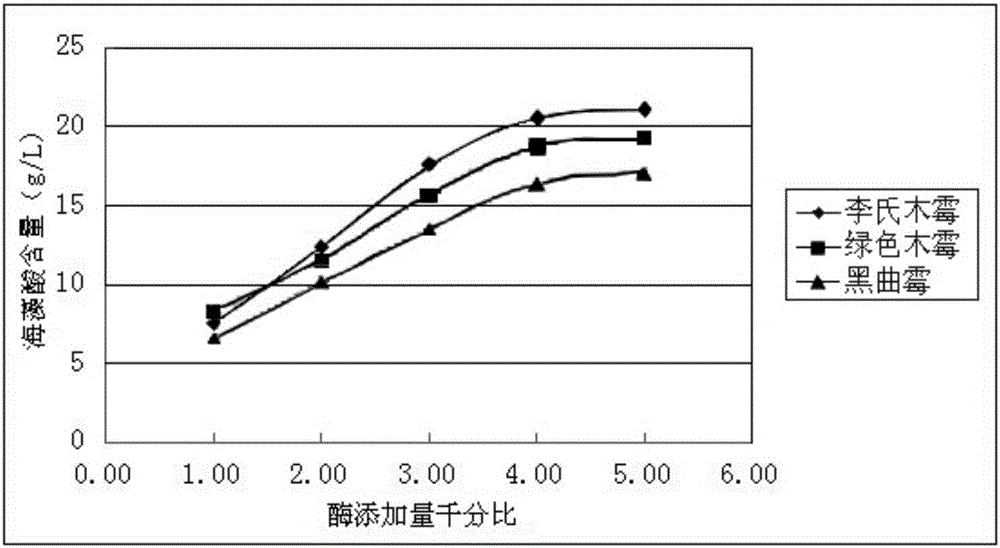

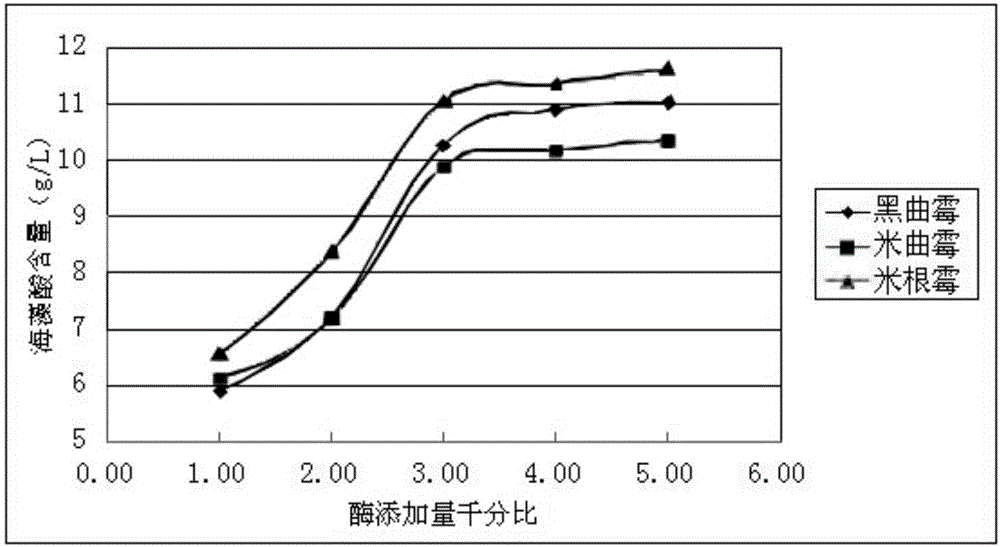

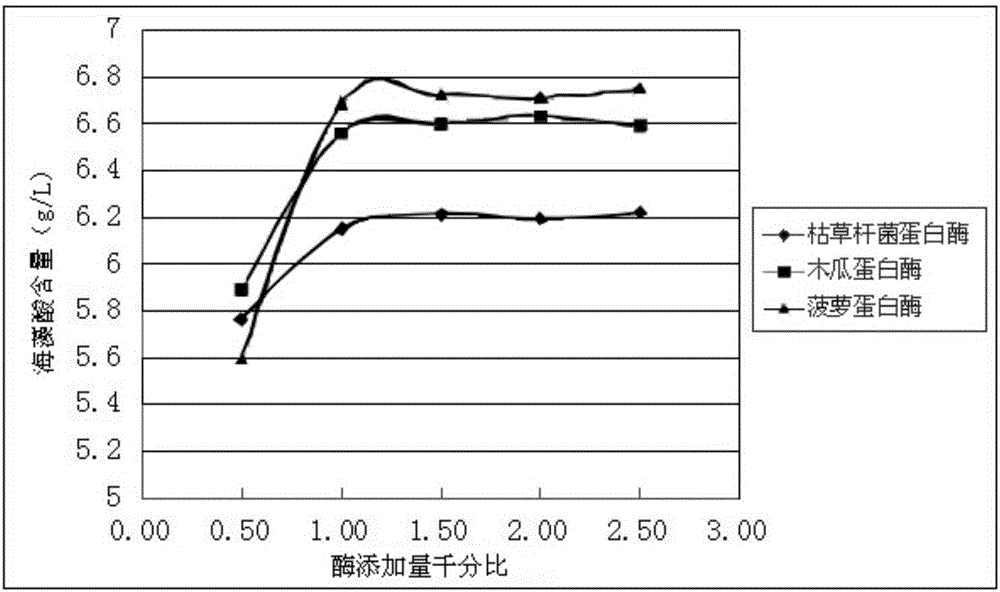

Seaweed biological feed and preparation method thereof

InactiveCN106615663AIncrease profitPromote digestion and absorptionFood processingAnimal feeding stuffPectinaseMicrobial enzymes

The invention relates to a preparation method of seaweed biological feed additive or seaweed biological feed. The preparation method is characterized in that compound microbial enzyme is added into seaweed slurry prepared from seaweed or seaweed residue for carrying out enzymolysis, so that the seaweed biological feed additive is obtained, wherein the compound microbial enzyme is prepared from multiples in cellulase, pectinase, protease and amylase. The preparation method provided by the invention is simple in process, easy to operate and low in cost; furthermore, the feed prepared by the method is rich in nutrition and easy to absorb.

Owner:WEIHAI SHIDAI MARINE BIOTECH

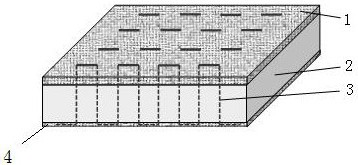

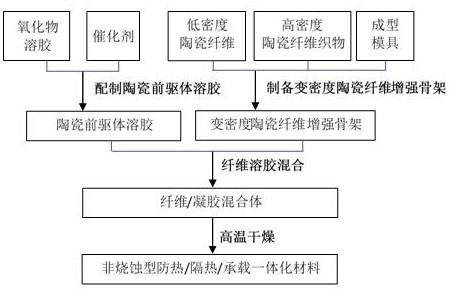

Non-ablative heat protection/heat insulation/bearing integrated material and preparation method thereof

ActiveCN113246563ALow thermal conductivityHigh strengthLamination ancillary operationsMuffle furnacesPolymer sciencePolymer chemistry

The invention relates to the technical field of heat-proof / heat-insulation / bearing materials, and provides a non-ablative heat-proof / heat-insulation / bearing integrated material and a preparation method thereof, the non-ablative heat-proof / heat-insulation / bearing integrated material comprises a variable-density ceramic fiber reinforced skeleton and nano-porous ceramic filled in the variable-density ceramic fiber reinforced skeleton; and the variable-density ceramic fiber reinforced framework sequentially comprises an upper surface layer (1), a middle layer (2) and a lower surface layer (4), and all the layers form an integral structure through needling and sewing of ceramic fiber lines (3). The mass percent of the nano porous ceramic in the non-ablative heat protection / heat insulation / bearing integrated material is 35-65%; the volume density of the upper surface layer and the lower surface layer of the variable-density ceramic fiber reinforced framework is 0.50-1.0 g / cm < 3 >, and the thickness is 0.5-4 mm; and the volume density of the middle layer of the variable-density ceramic fiber reinforced framework is 0.10-0.30 g / cm < 3 >, and the thickness of the middle layer is 5-60 mm.

Owner:NAT UNIV OF DEFENSE TECH

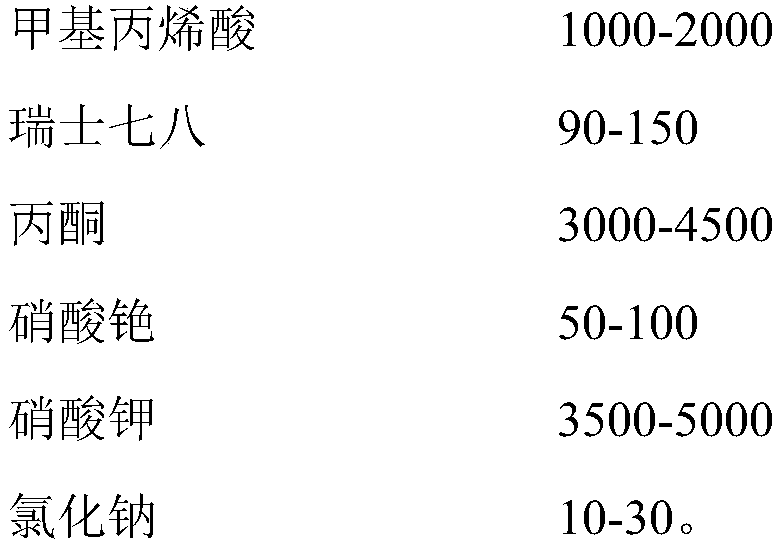

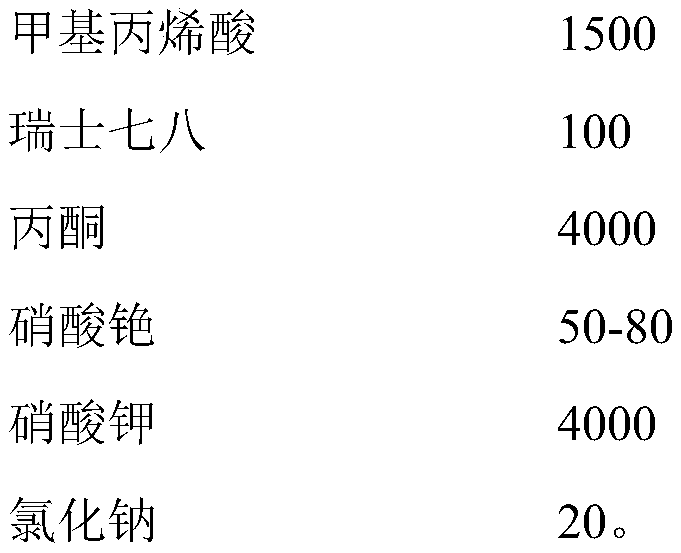

Fireproof composition for preparing fireproof glass and preparation method thereof

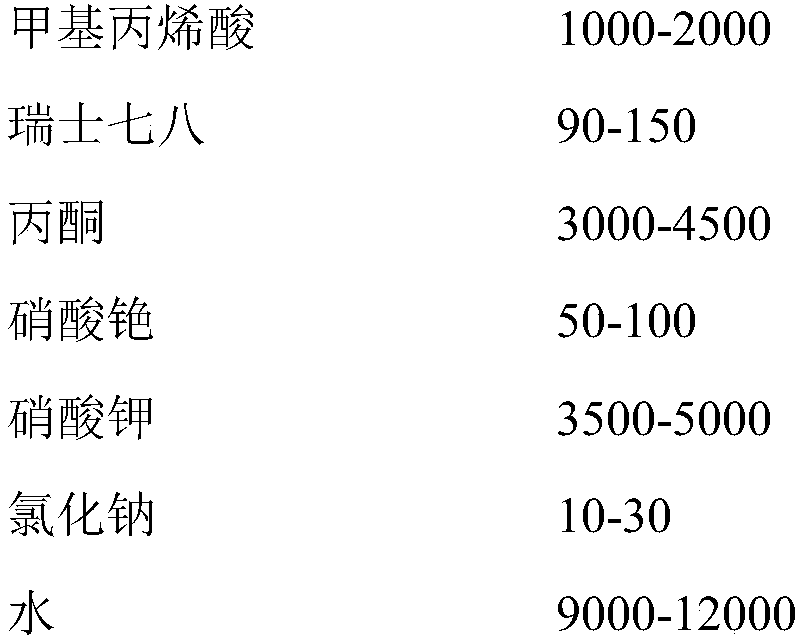

The invention discloses fireproof composition for preparing fireproof glass and a preparation method thereof. The fireproof composition disclosed by the invention is prepared from the raw materials ofmethylacrylic acid, a photoinitiator 1173, acetone, cesium nitrate, potassium nitrate and sodium chloride. A preparation method of a fireproof solution disclosed by the invention is simple, and the fireproof glass prepared from the fireproof solution disclosed by the invention has the advantages of good high temperature resistance, high fire resistance, strong impact resistance and an excellent mechanical property.

Owner:新福兴玻璃工业集团有限公司

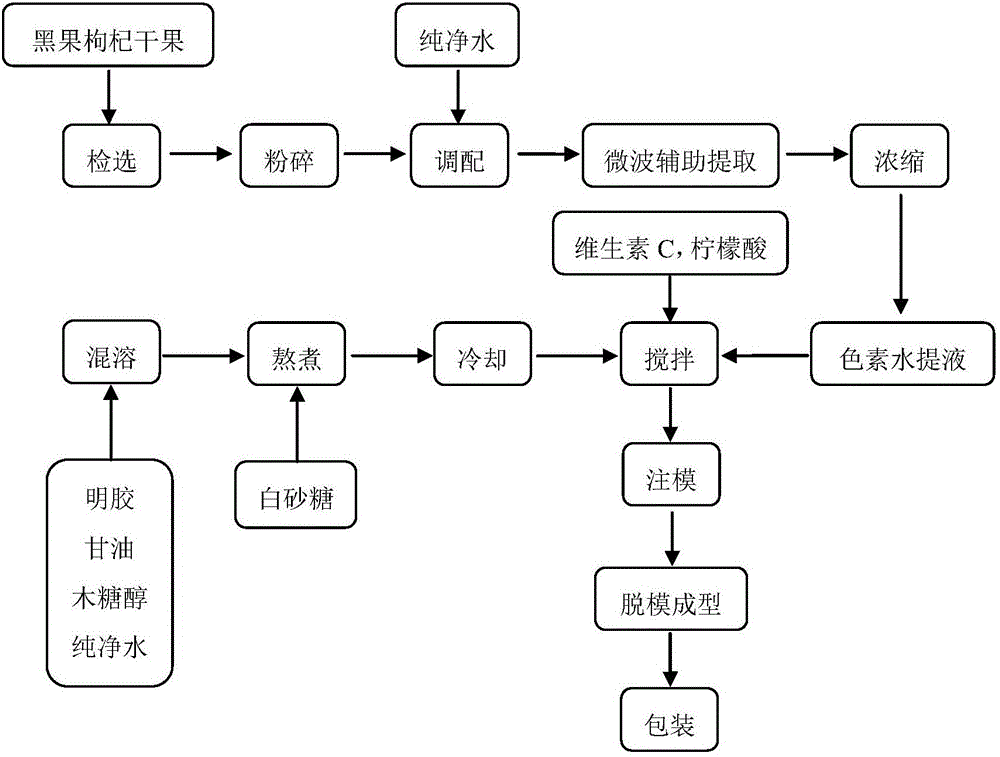

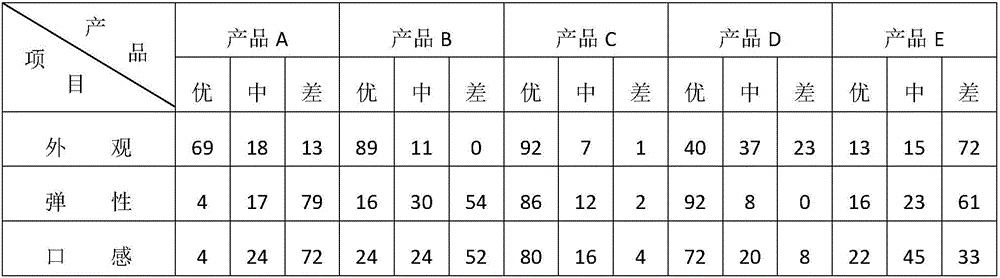

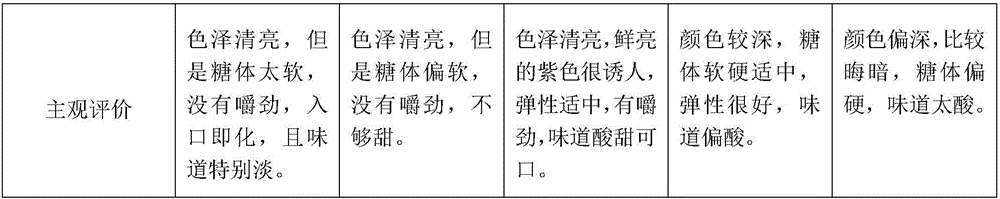

Lycium ruthenicum pigment soft sweets and preparation method thereof

InactiveCN106387272APreserve integrityNutritional balanceConfectionerySweetmeatsGelatinPolysaccharide

The present invention provides lycium ruthenicum pigment soft sweets. The lycium ruthenicum pigment soft sweets are prepared by the following raw materials in parts by weight: 10-20 parts of a lycium ruthenicum pigment water extract, 40-50 parts of gelatin, 8-15 parts of glycerin, 40-60 parts of a sweetener, 2-10 parts of an acidulant and 100 parts of water. The lycium ruthenicum pigment water extract used in the lycium ruthenicum pigment soft sweets is rich in anthocyanins, amino acids, polysaccharides and other various nutrients, so that the soft sweets are high in nutritional value and unique in taste, and have good market prospects.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com