Preparation method of silver particle with sheet-strip integrated structural shape

A silver particle and integrated technology, which is applied in the field of preparation of silver particle materials with special morphology, can solve the problem of not seeing silver particles, and achieve the effect of low cost of waste liquid treatment, high yield, and no raw materials and by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Dissolve 2g of silver nitrate in 20ml of deionized water to prepare a silver nitrate solution, add 0.8ml of nitric acid (65-68% mass concentration) into the silver nitrate solution under stirring, and then add 0.001g of ethylene dichloride Disodium amine tetraacetate, the mixed solution that obtains is used as oxidation solution;

[0040] (2) Dissolve 1.2g of ascorbic acid in 8ml of deionized water as the reducing solution;

[0041] (3) Under the conditions of a temperature of 20°C and a stirring speed of 400 rpm, quickly mix all the oxidizing solution obtained in step (1) with all the reducing solution obtained in step (2), and then let it stand for reaction after mixing evenly 15 minutes; then stir to collect the precipitated product, wash the precipitated product 3 to 5 times with deionized water and then wash it twice with ethanol, and dry at low temperature after suction to obtain silver particles with an integrated structure.

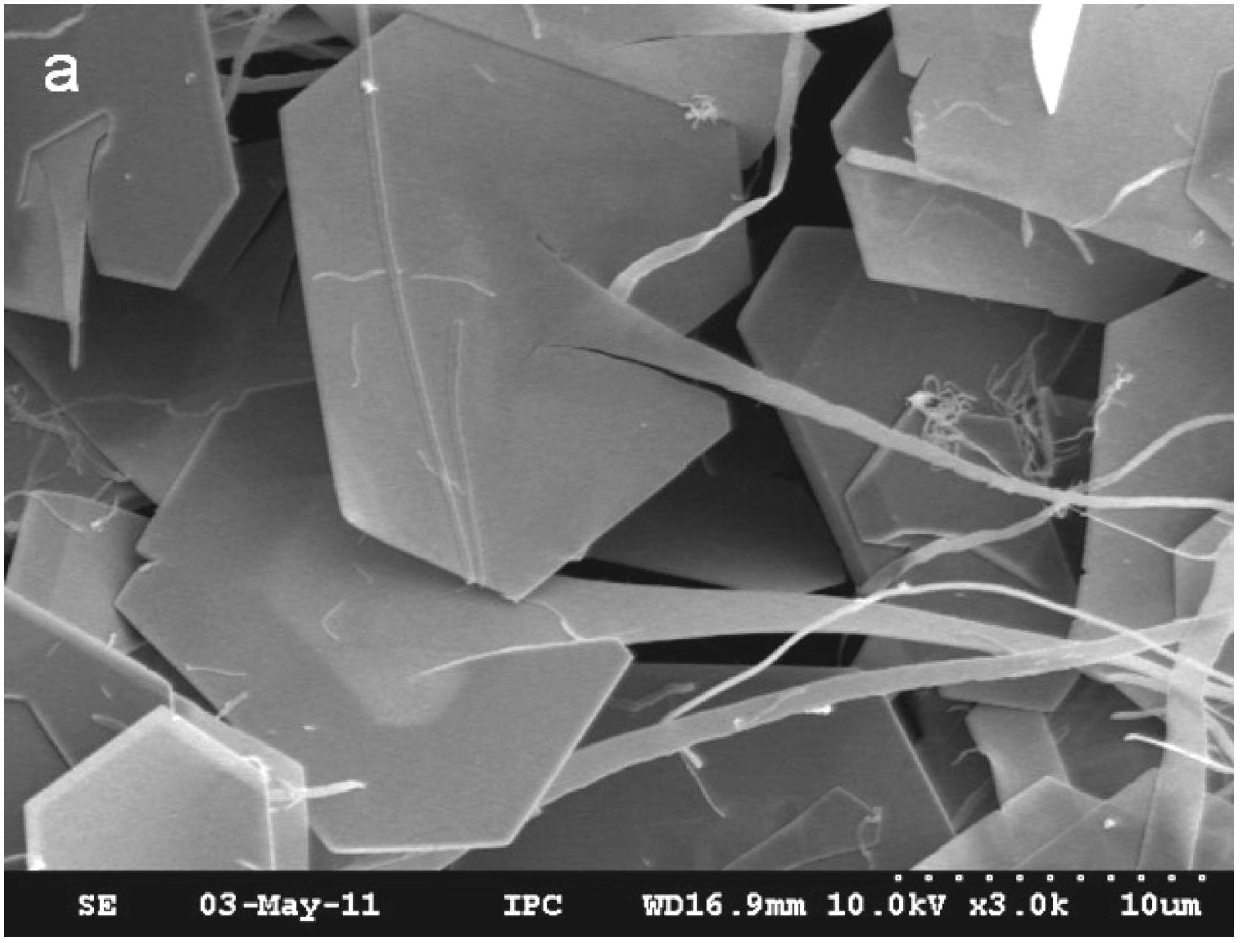

[0042] Such as Figure 1a As sho...

Embodiment 2

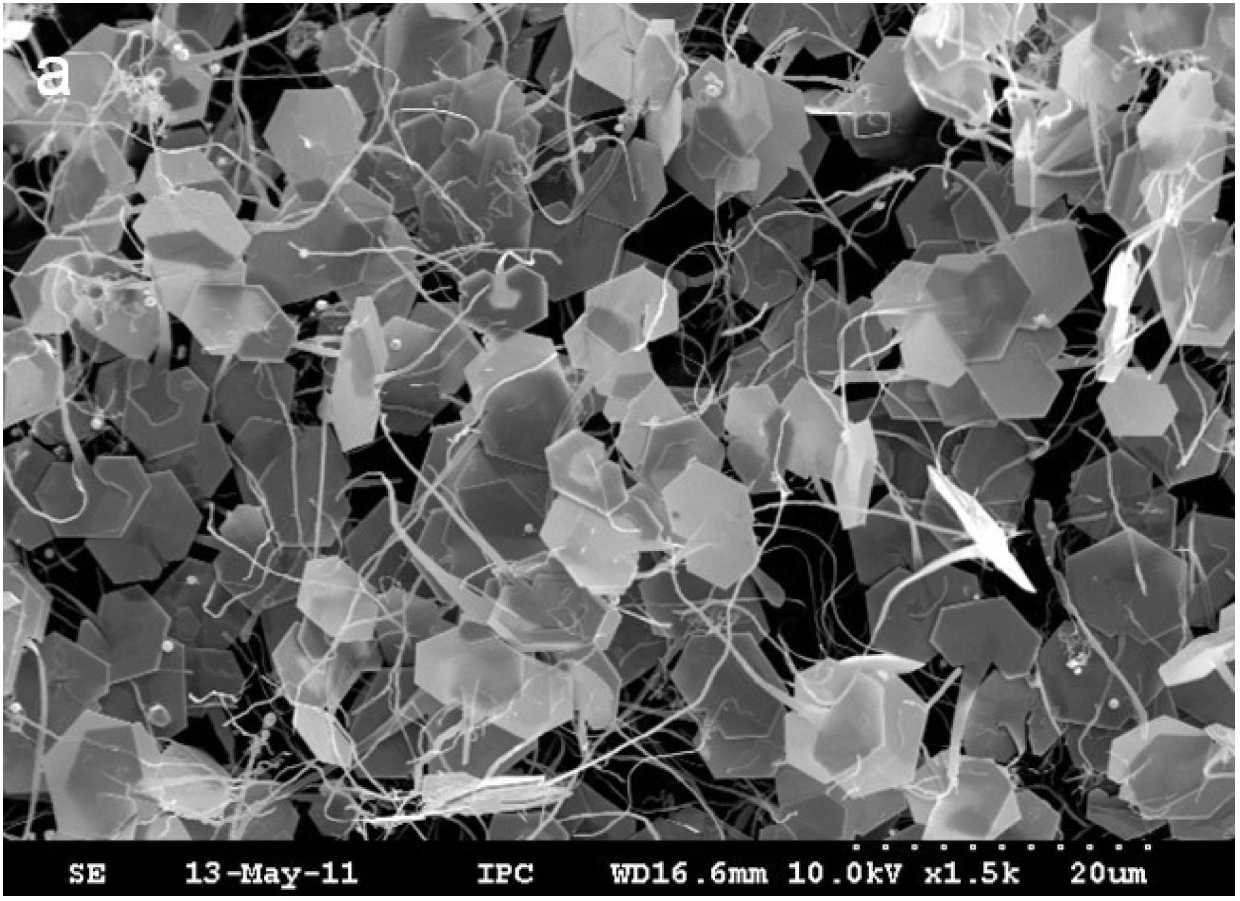

[0044] It is basically the same as Example 1, except that what used 1g silver nitrate and what used 0.6g ascorbic acid when preparing silver nitrate solution and preparing reducing solution was different. Observing with a scanning electron microscope, the silver particles with the obtained flake-band integrated structure morphology are an integral structure composed of flake silver and ribbon silver, wherein the flake width of the flake silver part is between 8 and 10 microns, and the flake silver Part of the thickness of the sheet is between 100 and 200 nanometers; the length of the band of the band-shaped silver part is between 10 and 25 microns, the width of the band is between 200 and 400 nanometers, and the thickness of the band is between 100 and 200 nanometers between.

Embodiment 3

[0046] (1) Dissolve 1g of silver nitrate in 15ml of deionized water to prepare a silver nitrate solution, add 0.4ml of nitric acid (65-68% mass concentration) into the silver nitrate solution under stirring, and then add 0.001g of ethylene glycol Disodium amine tetraacetate, and add 4ml absolute ethanol, the mixed solution that obtains is used as oxidation solution;

[0047] (2) Dissolve 0.6g of ascorbic acid in 6ml of deionized water as the reducing solution;

[0048] (3) Under the conditions of a temperature of 20°C and a stirring speed of 200 rpm, quickly mix all the oxidizing solution obtained in step (1) with all the reducing solution obtained in step (2), and then let it stand for reaction after mixing evenly 20 minutes; then the precipitated product was collected by filtration, washed with deionized water and ethanol for 3 to 5 times, and dried naturally to obtain silver particles with an integrated structure.

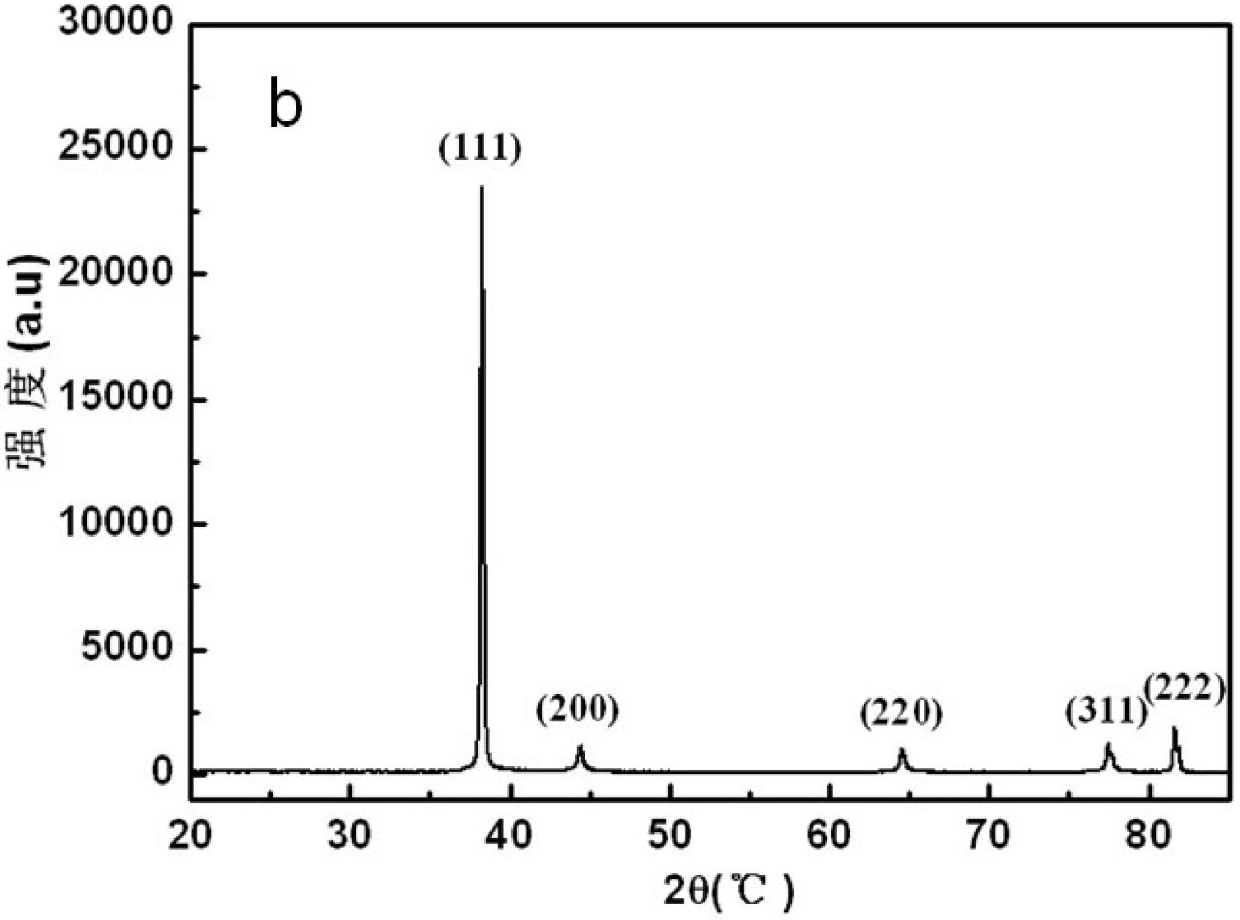

[0049] The crystal structure type of the silver particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com