Extreme pressure anti-corrosion addictive of benzo triazole polysulfide and method for preparing the same

A benzotriazole and benzotriazole-based technology, which is applied in the field of organic compounds and their preparation, can solve problems such as catalyst poisoning and limited lubricating oil solubility, and achieve mild synthesis process conditions, excellent extreme pressure and resistance Corrosion performance, effect of improving corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 0.1 mol of 1-chloro-n-butylbenzotriazole and 100 ml of tetrahydrofuran into a three-necked flask equipped with a thermometer, a stirring device, and a reflux condenser, and stir for 1 hour. Then weigh 0.055 mol of 35 wt% sodium trisulfide aqueous solution and slowly drop it into a three-necked flask, react at 50° C. for 5 hours, then cool to room temperature and stir for 7 hours. After the reaction, the generated salt was removed by suction filtration, the filtrate was concentrated, dissolved in ethyl acetate, washed with water three times, and then dried with anhydrous magnesium sulfate. After filtration, the filtrate was evaporated to remove the solvent under reduced pressure to obtain 16.67 g of two 1-(benzotriazolyl-1-n-butyl) polysulfides of brownish-yellow viscous oil, with a yield of 75.2% (based on 1-chloro n-butylbenzotriazole as a benchmark).

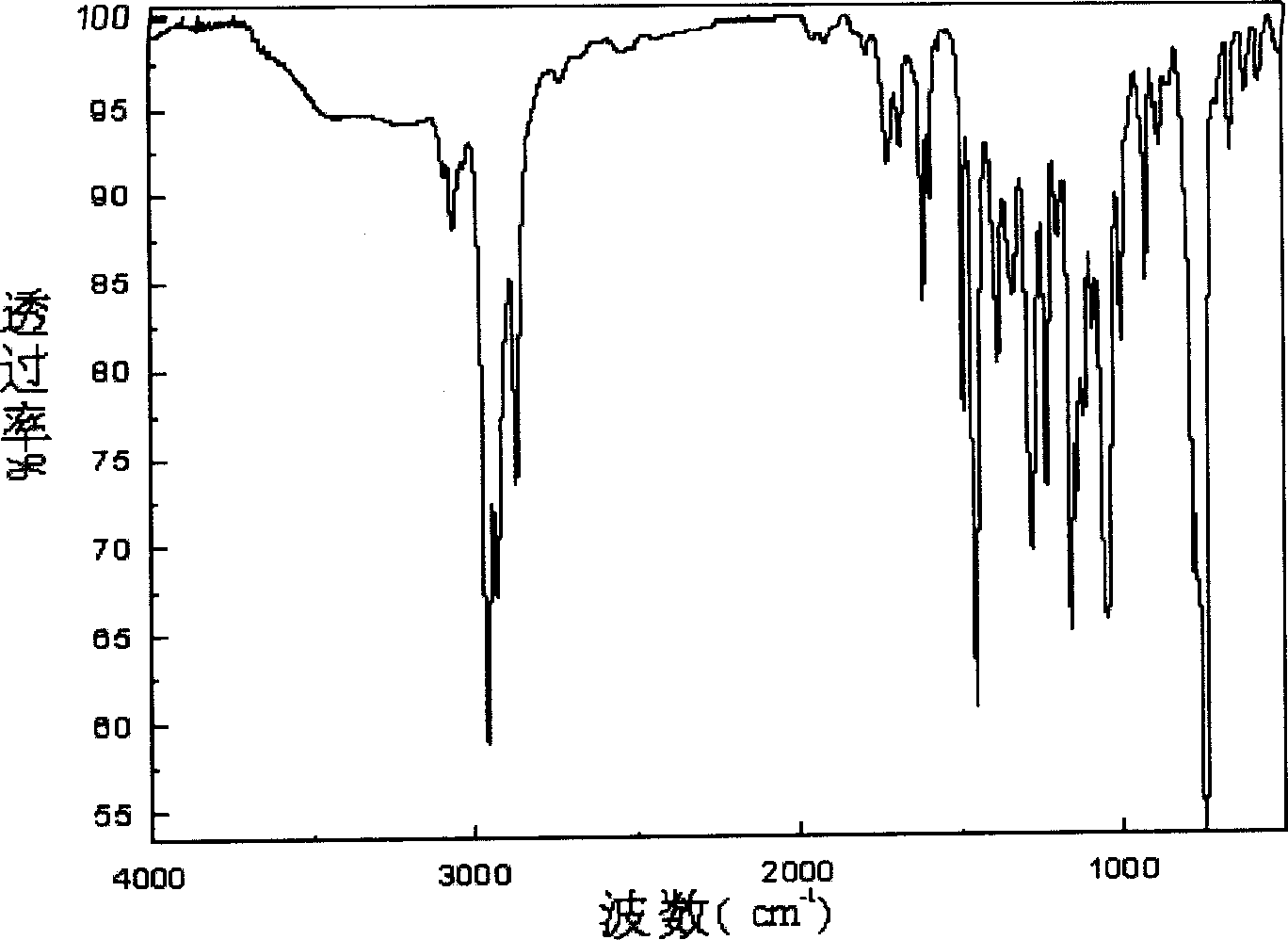

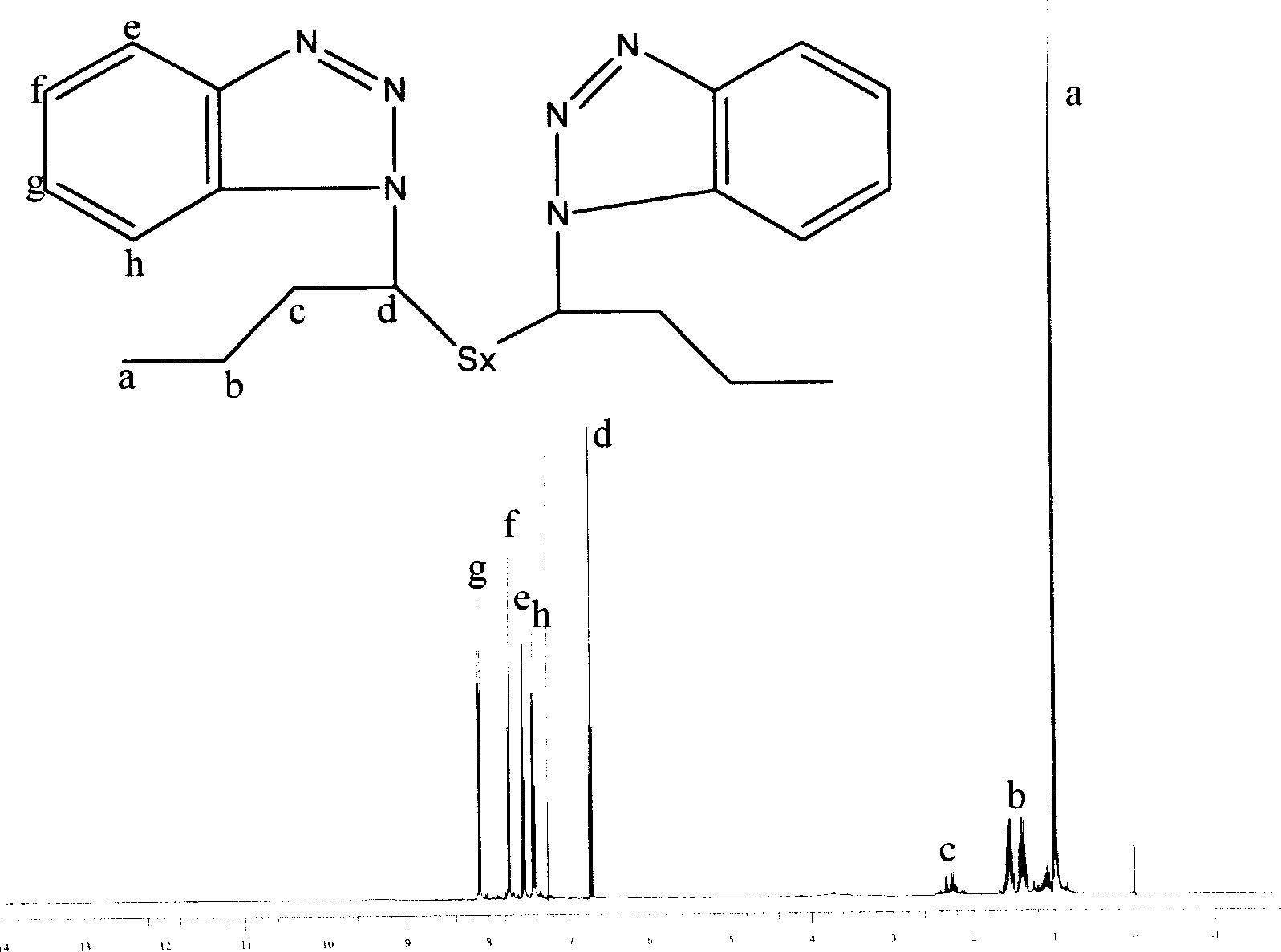

[0028] figure 1 It is the infrared (IR) spectrum of two 1-(benzotriazolyl-1-n-butyl) polysulfides, as can be ...

Embodiment 2

[0032] Weigh 0.1 mol of 1-chloro-n-heptylbenzotriazole and 120 milliliters of ethanol into a three-necked flask equipped with a thermometer, a stirring device and a reflux condenser, and stir for 1 hour. Then weigh 0.05 mol of 30 wt% ammonium trisulfide aqueous solution and slowly drop it into the three-necked flask, react at 70° C. for 7 hours, then cool to room temperature and stir for 5 hours. After the reaction, the generated salt was removed by suction filtration, the filtrate was concentrated, dissolved in ethyl acetate, washed with water three times, and then dried with anhydrous magnesium sulfate. After filtration, the filtrate was evaporated to remove the solvent under reduced pressure, and 19.02 g of double 1-(benzotriazolyl-1-n-heptyl) polysulfide of brown-yellow viscous oil was obtained, with a yield of 72.3% (based on 1-chloro based on n-heptylbenzotriazole).

[0033] The product that obtains in the above-mentioned example, C, H, N, S elemental analysis result is...

PUM

| Property | Measurement | Unit |

|---|---|---|

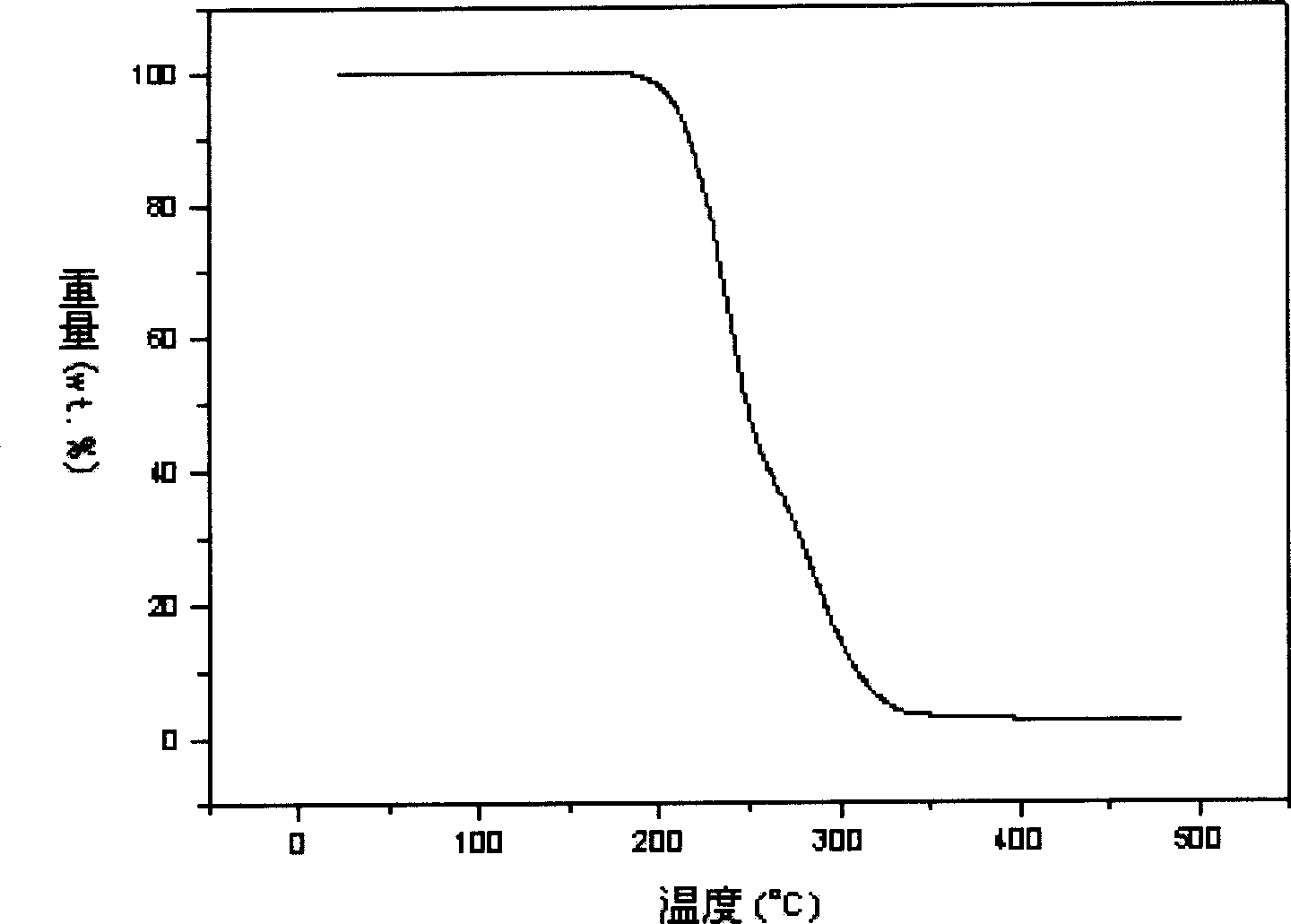

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com