Low-sulfur and low-shear viscosity loss vehicle gear lubricating oil

A gear lubricating oil, low shear viscosity technology, used in the chemical field, can solve the problems of short service life, increased sludge and carbon deposits, high KRL shear loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

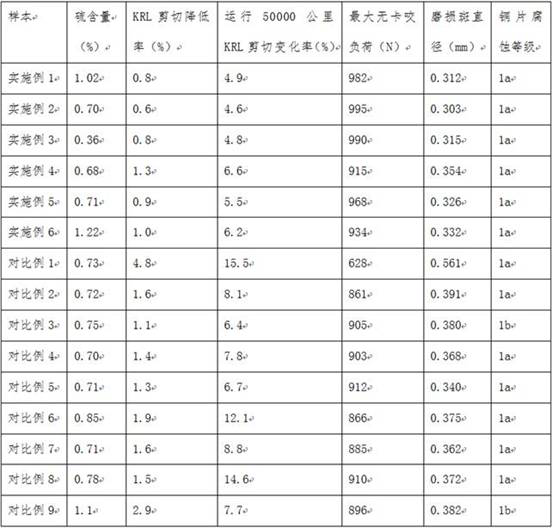

Examples

Embodiment 1

[0049]A vehicle gear lubricating oil with low sulfur and low shear viscosity loss, comprising the following components by weight percentage:

[0050] Vehicle gear oil compound 6%

[0051] 1- Propylene and ethylene polymer 20%

[0052] High viscosity polyalphaolefin 30%

[0053] Synthetic ester 15%

[0054] Nano rare earth wear reducer 1%

[0055] Organic Friction Modifier 5%

[0056] Alkylated naphthalene (AN) 5%

[0057] Pour point depressant 0.3%

[0058] Demulsifier 0.01%

[0059] Defoamer 50ppm

[0060] Metal deactivator 0.05%

[0061] Rust inhibitor 0.05%

[0062] Antioxidant 0.1%

[0063] Base oil balance

[0064] The vehicle gear oil compound is a heavy-duty vehicle gear oil compound meeting the GL-5 level.

[0065] The 1-propylene and ethylene polymer is LUCANT HC-100 from Mitsui Chemicals.

[0066] The high-viscosity polyalphaolefin is metallocene polyalphaolefin (mPAO), and its kinematic viscosity at 100°C is 40cSt.

[0067] The kinematic viscosity of t...

Embodiment 2

[0084] A vehicle gear lubricating oil with low sulfur and low shear viscosity loss, comprising the following components by weight percentage:

[0085] Vehicle gear oil compound 4%

[0086] 1- Propylene and ethylene polymer 30%

[0087] High viscosity polyalphaolefin 20%

[0088] Synthetic ester 10%

[0089] Nano rare earth wear reducer 3%

[0090] Organic Friction Modifier 3%

[0091] Alkylated naphthalene (AN) 10%

[0092] Pour-point depressant 0.5%

[0093] Demulsifier 0.03%

[0094] Defoamer 100ppm

[0095] Metal deactivator 0.08%

[0096] Rust inhibitor 0.3%

[0097] Antioxidant 0.5%

[0098] Base oil balance

[0099] The vehicle gear oil compound is a heavy-duty vehicle gear oil compound meeting the GL-5 level.

[0100] The 1-propylene and ethylene polymer is LUCANT HC-600 from Mitsui Chemicals.

[0101] The high-viscosity polyalphaolefin is metallocene polyalphaolefin (mPAO), and the kinematic viscosity at 100°C is 500cSt.

[0102] The kinematic viscosity o...

Embodiment 3

[0119] A vehicle gear lubricating oil with low sulfur and low shear viscosity loss, comprising the following components by weight percentage:

[0120] Vehicle gear oil compound 2%

[0121] 1- Propylene and ethylene polymer 40%

[0122] High viscosity polyalphaolefin 15%

[0123] Synthetic ester 5%

[0124] Nano rare earth wear reducer 5%

[0125] Organic friction modifier 1%

[0126] Alkylated naphthalene (AN) 15%

[0127] Pour point depressant 1%

[0128] Demulsifier 0.05%

[0129] Defoamer 200ppm

[0130] Metal deactivator 0.1%

[0131] Rust inhibitor 0.5%

[0132] Antioxidant 1.0%

[0133] Base oil balance

[0134] The vehicle gear oil compound is a heavy-duty vehicle gear oil compound meeting the GL-5 level.

[0135] The 1-propylene and ethylene polymer is LUCANT HC-2000 from Mitsui Chemicals.

[0136] The high-viscosity polyalphaolefin is metallocene polyalphaolefin (mPAO), and the kinematic viscosity at 100°C is 1000cSt.

[0137] The kinematic viscosity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com