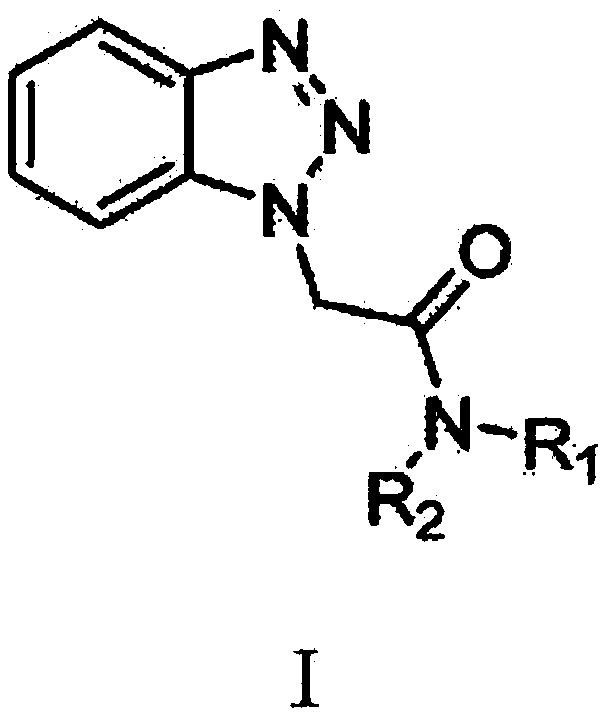

Multifunctional oil additive and preparation method and application thereof

A lubricating oil additive and additive technology, applied in additives, petroleum industry, lubricating composition, etc., can solve the problems of high raw material price of chlorinated alkyl compounds, poor anti-wear performance, and insufficient extreme pressure performance, etc., and achieve good Anti-corrosion and anti-rust performance, low cost, excellent extreme pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

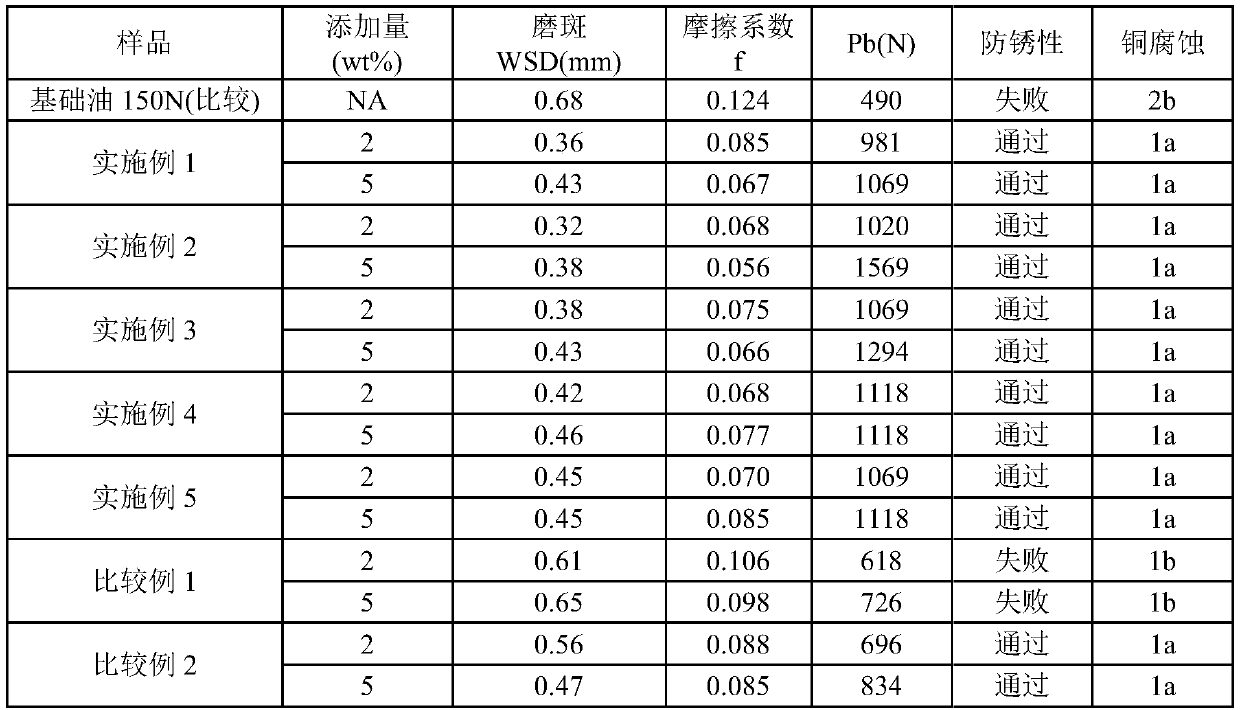

Examples

Embodiment 1

[0042] The multifunctional oil additive provided by the present embodiment is prepared by the following method:

[0043] 1) Preparation of dialkyldithiocarbamate

[0044] Put 3.92 parts of dibutylamine and an equimolar amount of sodium hydroxide into a reactor equipped with 24 parts of tetrahydrofuran solvent and stir evenly. Control the temperature not higher than 15°C, stir rapidly, then slowly add carbon disulfide in an equimolar amount to dibutylamine, raise the temperature to room temperature after the addition, and react for 2 hours to obtain dialkyldithiocarbamate.

[0045] 2) Preparation of additives

[0046] In parts by weight, 6.89 parts of dialkyldithiocarbamate, 20.66 parts of 2-mercaptobenzothiazole and 0.14 parts of benzotriazole were added to the reactor, and then added 12 parts of ethanol solvent, 5 parts of sodium hydroxide, heated to about 70°C and stirred evenly; then added 58.54 parts of No. 42 chlorinated paraffin, kept the temperature at about 70°C, and...

Embodiment 2

[0048] The multifunctional oil additive provided by the present embodiment is prepared by the following method:

[0049] In parts by weight, 10.69 parts of dialkyldithiocarbamate, 17.82 parts of 2-mercaptobenzothiazole, 0.21 part of 2,5-dimercaptothiadiazole, 50 parts of tetrahydrofuran solvent and 4.5 parts of sodium hydroxide , heated to 70°C and stirred evenly; then slowly added 57.02 parts of No. 42 chlorinated paraffin, kept the temperature at about 70°C, and reacted for 6 hours; then added 14.26 parts of dioctylamine and 3.5 parts of sodium hydroxide, kept the temperature at 70°C After about 8 hours of reaction, after the reaction, cool to room temperature, filter, evaporate the solvent under reduced pressure, and obtain the product additive.

[0050] The preparation method of the dialkyldithiocarbamate used in this example is the same as the step 1) of Example 1.

Embodiment 3

[0052] The multifunctional oil additive provided by the present embodiment is prepared by the following method:

[0053] 1) Preparation of dialkyldithiocarbamate

[0054] Put 7.33 parts of dibutylamine and an equimolar amount of sodium hydroxide (20% concentration) into a reactor equipped with 15 parts of tetrahydrofuran solvent and stir evenly. Control the temperature not higher than 15°C, stir rapidly, slowly add carbon disulfide in an equimolar amount to dibutylamine, raise the temperature to room temperature after the addition, react for 2 hours, and distill off the solvent to obtain dialkyldithiocarbamate.

[0055] 2) Preparation of additives

[0056] In parts by weight, 12.89 parts of dialkyldithiocarbamate, 16.11 parts of 2-mercaptobenzothiazole, 0.13 part of methylbenzotriazole and 20 parts of aqueous sodium hydroxide (concentration is 20%) , heated to 70°C and stirred evenly; then added 54.77 parts of No. 52 chlorinated paraffin, kept the temperature at about 70°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com