Preparation method of maintenance agent for lubricating and protecting wire rope

A technology for steel wire rope and rust inhibitor, which is used in lubricating compositions, petroleum industry, etc., can solve the problems of high pour point, poor low temperature performance of semi-fluid grease, and high aromatic components, and achieves good extreme pressure, good high and low temperature performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

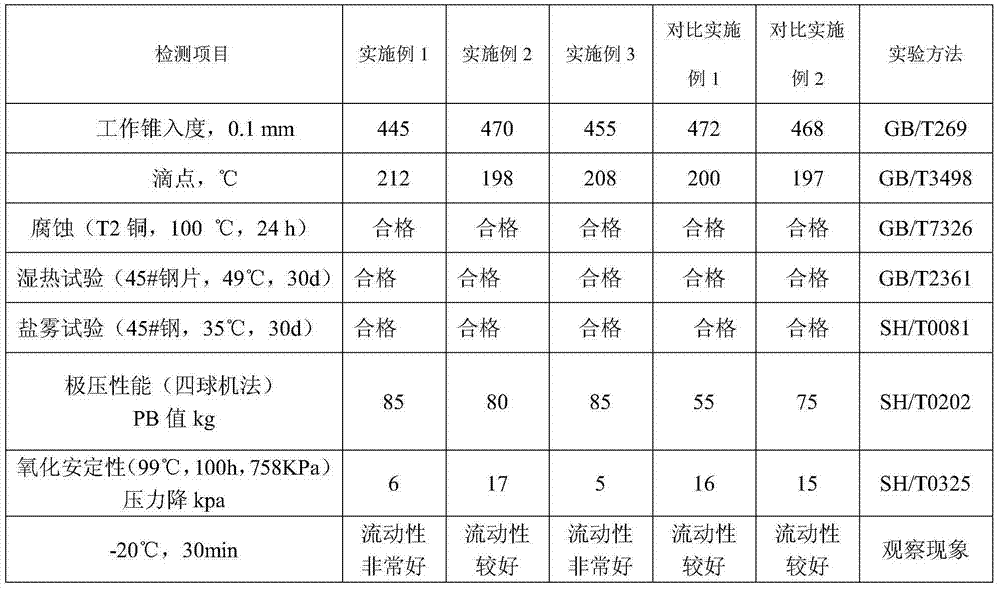

Examples

Embodiment 1

[0030] A preparation method of a wire rope maintenance agent, comprising the following steps:

[0031] Preparation of base fat:

[0032] 1) Mix 400g of base oil 600SN, 50g of lauryl hydroxystearic acid, and 15g of sebacic acid, and keep stirring at 100°C until the raw materials are completely dissolved;

[0033] 2) Dissolve 13.5g of lithium hydroxide in water, take out 1 / 3 of the lye and add it to the above material, control the reaction temperature at 100°C for 10 minutes, then add the rest of the lye to the above material, maintain the reaction temperature, and stir 60min.

[0034] 3) Raise the temperature of the above materials to 150°C, add 3.8g of diphenylamine antioxidant, then continue to raise the temperature to 210°C for high-temperature refining, and keep it for 10 minutes.

[0035] 4) When the temperature of the material is lowered to below 80°C, it is ground and homogenized by a three-roll machine to obtain the base grease.

[0036] Preparation of wire rope main...

Embodiment 2

[0042] A preparation method of a wire rope maintenance agent, comprising the following steps:

[0043] 1) Heat 480g of base oil (150BS mineral oil) and 35g of the base grease prepared in Example 1 to 80°C and mix well;

[0044] 2) Add 3.1g of diphenylamine, 5.2g of barium petroleum sulfonate, 1g of colloidal graphite, 1g of nano-molybdenum disulfide and 15.6g of polyisobutylene thickener to the mixture obtained in step 1) in sequence, stir evenly, and maintain the temperature at 90 ℃;

[0045] 3) When the material obtained in step 2) drops below 80°C, it is homogenized by a three-roll mill.

[0046] List its performance in Table 1.

Embodiment 3

[0048] A preparation method of a wire rope maintenance agent, comprising the following steps:

[0049] 1) Heat 480g of base oil (a mixture of 300g of PAO-40 and 180g of PAO-10) and 35g of the base grease prepared in Example 1 to 80°C and mix well;

[0050] 2) Add 3.1g of diphenylamine, 5.2g of barium petroleum sulfonate, 1g of colloidal graphite, 1g of nano-molybdenum disulfide and 15.6g of ethylene-propylene copolymer thickener to the mixture obtained in step 1) in sequence, stir evenly, and maintain the temperature at 90°C;

[0051] 3) When the material obtained in step 2) drops below 80°C, it is homogenized by a three-roll mill.

[0052] List its performance in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com