Preparation method of zeolite imidazole framework structure material

A zeolite imidazole and frame structure technology is applied in the field of preparation of zeolite imidazole frame structure materials, which can solve the problems of application difficulties in integration of diagnosis and treatment, inability to effectively utilize the large specific surface area of the zeolite imidazole frame structure, etc., and achieves high-efficiency contrast effect and low toxicity. , the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

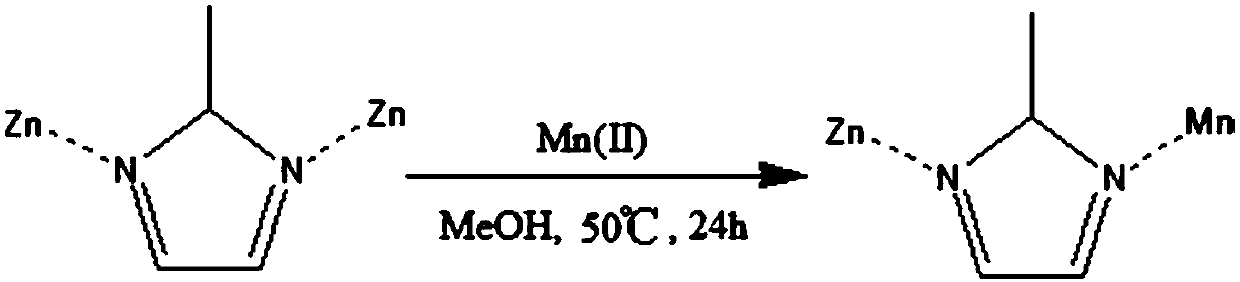

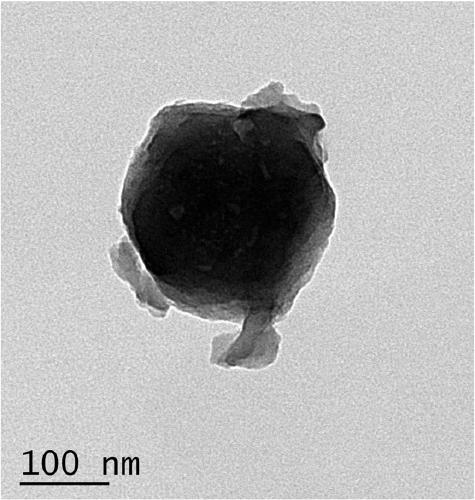

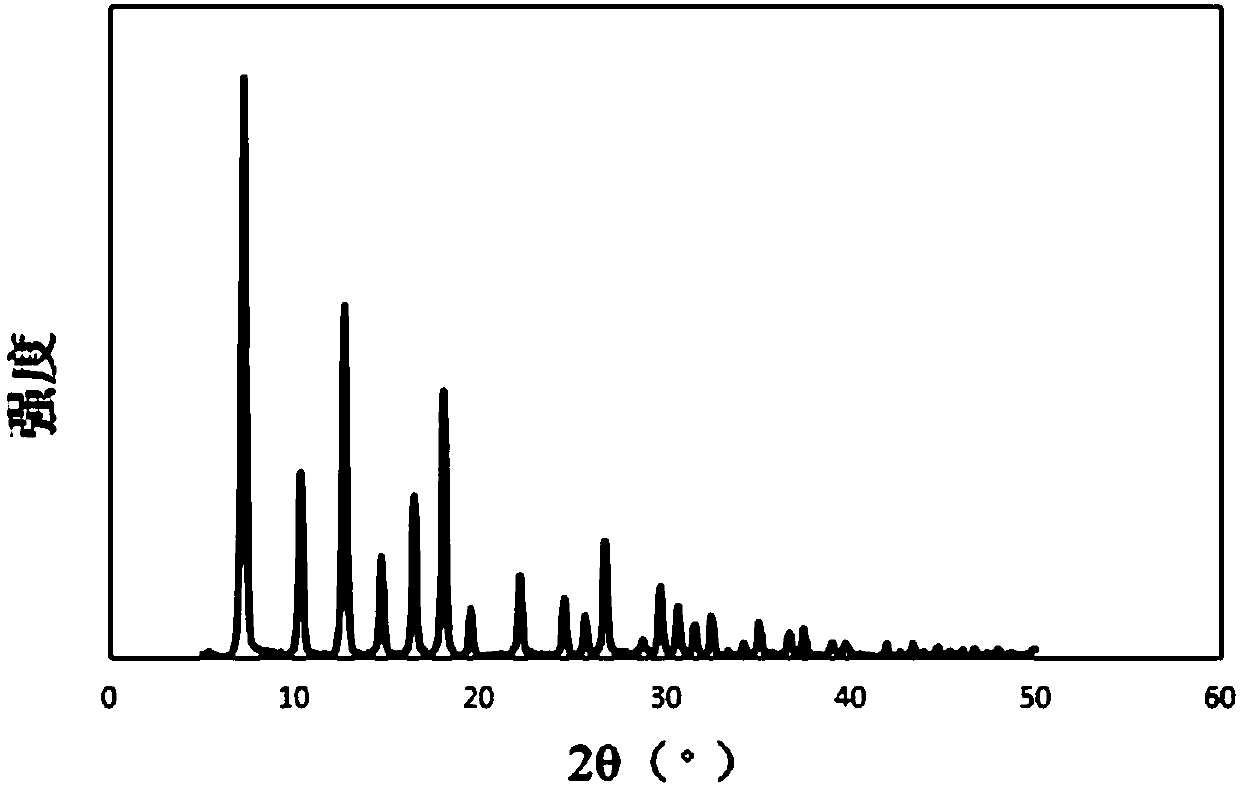

[0065] The synthesis of embodiment 1 compound C1 (Mn / Zn)-ZIF-8

[0066] Compound C1 was synthesized according to the following steps

[0067] Mix zinc nitrate hexahydrate, 2-methylimidazole, and methanol at a mass ratio of 1:2.5:100, stir at room temperature for 16 hours, centrifuge to remove the supernatant, and dry to obtain a white powder—ZIF-8. According to the molar ratio of 1:3, ZIF-8 and manganese acetate tetrahydrate were weighed in turn, mixed evenly and added to 10ml of methanol, ultrasonically dispersed evenly, added to the polytetrafluoroethylene lining, placed in a stainless steel reaction kettle, 50 °C after heating for 24 hours. Take out and centrifuge to take out the supernatant, and dry to obtain a brown powder. The molar ratio of manganese to zinc in the product was found to be 0.114:1 by using an X-ray fluorescence spectrometer (Thermo).

Embodiment 2

[0068] The synthesis of embodiment 2 compound C2(Mn / Zn)-ZIF-90

[0069] Compound C2 was synthesized according to the following steps

[0070] Mix zinc nitrate hexahydrate, 2-formaldehyde imidazole, and methanol at a mass ratio of 1:2.5:100, stir at room temperature for 24 hours, centrifuge to remove the supernatant, and dry to obtain a white powder—ZIF-90. Weigh ZIF-90 and manganese acetate tetrahydrate sequentially according to the molar ratio of 1:6, mix them and add them to 10ml of methanol, ultrasonically disperse them evenly, add them to the polytetrafluoroethylene lining, place them in a stainless steel reaction kettle, 55 °C after heating for 24 hours. Take out and centrifuge to take out the supernatant, disperse the crude product in methanol solution, replace the alcohol solution every 24 hours, centrifuge after 72 hours, and dry in a vacuum oven to obtain a gray-black powder. The molar ratio of manganese to zinc in the product was found to be 0.127:1 by using an X-r...

Embodiment 3

[0071] The synthesis of embodiment 3 compound C3(Mn / Zn)-ZIF-91

[0072] Compound C3 was synthesized according to the following steps

[0073] Mix zinc nitrate hexahydrate, 2-formaldehyde imidazole, and methanol at a mass ratio of 1:2.5:100, stir at room temperature for 16 hours, centrifuge to remove the supernatant, and dry to obtain a white powder—ZIF-90. According to the molar ratio of 1:10, ZIF-90 and sodium borohydride were weighed once, dissolved in 20ml of methanol, reacted at 60°C for 24 hours, centrifuged to take out the supernatant and dried to obtain white powder-ZIF-91. Weigh ZIF-91 and manganese acetate tetrahydrate sequentially according to the molar ratio of 1:5, mix them and add them to 10ml methanol, ultrasonically disperse them evenly, add them to the polytetrafluoroethylene lining, place them in a stainless steel reaction kettle, 55 °C after heating for 24 hours. Take out and centrifuge to take out the supernatant, disperse the crude product in methanol sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com