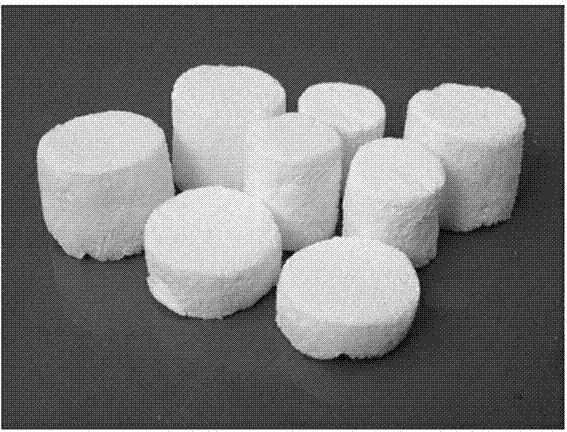

Oil-soluble/water-soluble organic-inorganic three-phase porous micro-nanometer composite bone repair material

A three-phase porous, micro-nano composite technology, used in medical science, prosthesis and other directions, can solve the problems of insufficient compressive strength and bending strength, poor mechanical properties, etc., to enhance physical and chemical properties, improve matrix properties, and improve materials. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

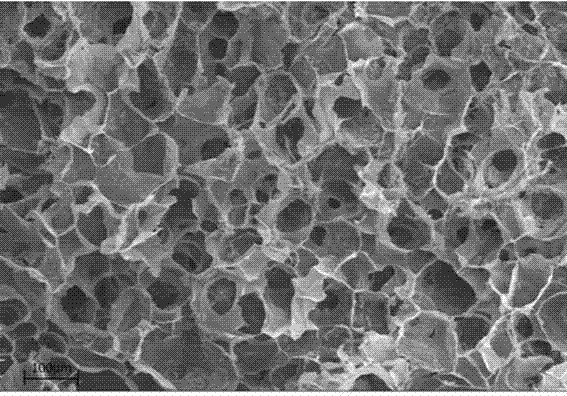

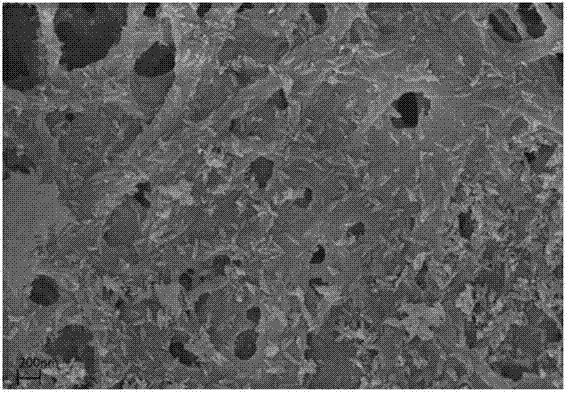

Image

Examples

Embodiment 1

[0038] The chitosan / fish skin collagen / polylactic acid composite scaffold is made of the following components by mass percentage:

[0039] Chitosan 2.0%

[0040] Fish Skin Collagen 0.2%

[0041] Polylactic acid 0.1%

[0042] Hydroxyapatite 1.2%

[0043] The balance is deionized water.

[0044] 1) Dissolve a certain amount of chitosan and collagen in 1% (v / v) acetic acid solution according to the above ratio, and dissolve a certain amount of polylactic acid in 1,4-dioxane, and mix well;

[0045] 2) Prepare 2mol / L calcium nitrate solution and 1.2mol / L dipotassium hydrogen phosphate solution, add a certain volume of soluble Calcium salt and soluble phosphate solution, the two are added at intervals of 20 minutes;

[0046] 3) Slowly add the polylactic acid solution to the chitosan / collagen acetic acid solution and stir for 1 hour to make it fully mixed;

[0047] 4) Then add a certain amount of cross-linking agent for cross-linking, and cross-link at room temperature for 5 ho...

Embodiment 2

[0051] The chitosan / fish skin collagen / polylactic acid composite scaffold is made of the following components by mass percentage:

[0052] Chitosan 2.0%

[0053] Fish Skin Collagen 0.2%

[0054] Polylactic acid 0.2%

[0055] Hydroxyapatite 1.2%

[0056] The balance is deionized water.

[0057] 1) Dissolve a certain amount of chitosan and collagen in 1% (v / v) acetic acid solution according to the above ratio, and dissolve a certain amount of polylactic acid in 1,4-dioxane, and mix well;

[0058] 2) Prepare 2mol / L calcium nitrate solution and 1.2mol / L dipotassium hydrogen phosphate solution, add a certain volume of soluble Calcium salt and soluble phosphate solution, the two are added at intervals of 20 minutes;

[0059] 3) Slowly add the polylactic acid solution to the chitosan / collagen acetic acid solution and stir for 1 hour to make it fully mixed;

[0060] 4) Then add a certain amount of cross-linking agent for cross-linking, and cross-link at room temperature for 5 ho...

Embodiment 3

[0064] The chitosan / fish skin collagen / polylactic acid composite scaffold is made of the following components by mass percentage:

[0065] Chitosan 2.0%

[0066] Fish Skin Collagen 0.2%

[0067] Polylactic acid 0.3%

[0068] Hydroxyapatite 1.2%

[0069] The balance is deionized water.

[0070] 1) Dissolve a certain amount of chitosan and collagen in 1% (v / v) acetic acid solution according to the above ratio, and dissolve a certain amount of polylactic acid in 1,4-dioxane, and mix well;

[0071] 2) Prepare 2mol / L calcium nitrate solution and 1.2mol / L dipotassium hydrogen phosphate solution, add a certain volume of soluble Calcium salt and soluble phosphate solution, the two are added at intervals of 20 minutes;

[0072] 3) Slowly add the polylactic acid solution to the chitosan / collagen acetic acid solution and stir for 1 hour to make it fully mixed;

[0073] 4) Then add a certain amount of cross-linking agent for cross-linking, and cross-link at room temperature for 5 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com