Chemical agent for removing antimony in printing and dyeing wastewater and removal method of antimony

A technology for printing and dyeing wastewater and pharmaceuticals, applied in chemical instruments and methods, textile industry wastewater treatment, water/sewage treatment, etc., to achieve the effects of uniform particle dispersion, short reaction time, and easy application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The printing and dyeing wastewater comes from the comprehensive wastewater of a printing and dyeing factory, and the concentration of T-Sb is 1080 μg L -1 , the concentration of CODCr is 1091mg·L -1 , the pH of the water is around 10.1. First, the printing and dyeing wastewater is pretreated, and the impurity components in the printing and dyeing wastewater are filtered out by sedimentation to prevent interference with subsequent experimental results.

[0030] MnO x / SiO 2 / FeSO 4 The preparation of the mixed system matching agent material: the raw material is selected from the iron and manganese tailings of a manganese mining enterprise in Hunan, and the effective component in the tailings is MnO x , after grinding, the particles with uniform particle size are screened out as the components of the medicine, and the MnO x / SiO 2 / FeSO 4 The mass ratio is 1:1:8.

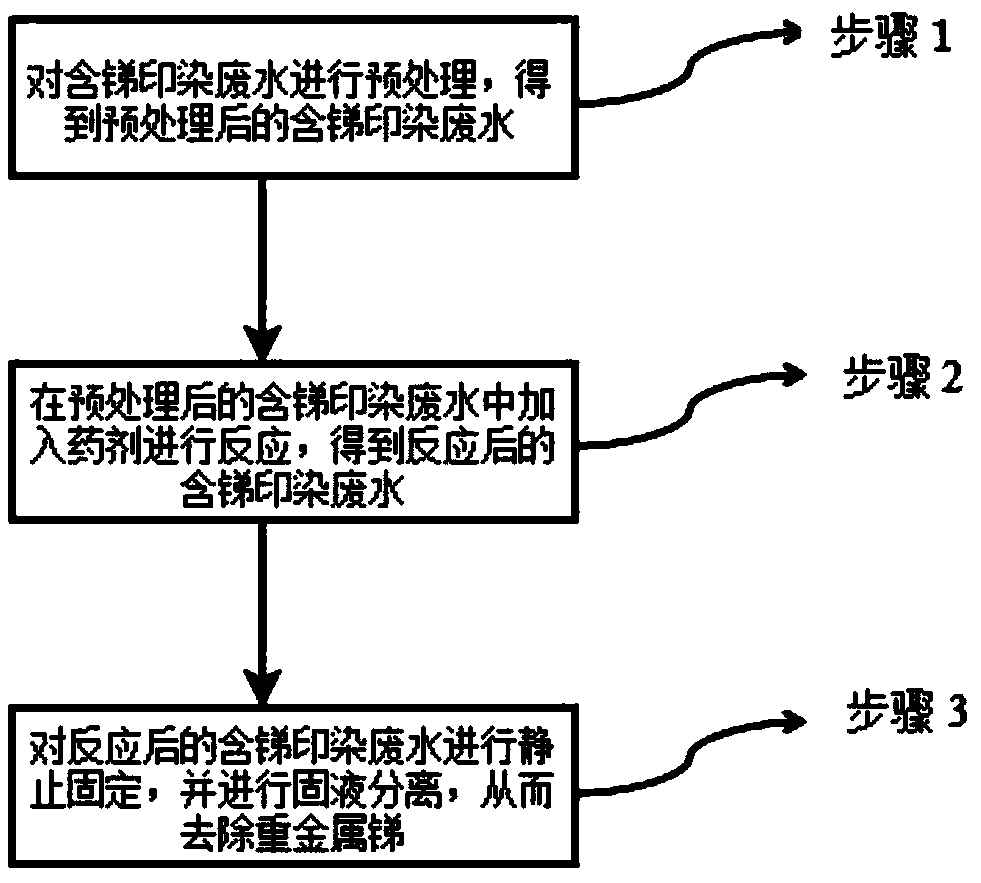

[0031] Such as figure 1As shown, in step 1, the printing and dyeing wastewater is firstly flowed in...

Embodiment 2

[0036] The printing and dyeing wastewater comes from the comprehensive wastewater of a printing and dyeing factory, and the concentration of T-Sb is 1080 μg L -1 , the concentration of CODCr is 1091mg·L -1 , the pH of the water is around 10.1. First, the printing and dyeing wastewater is pretreated, and the impurity components in the printing and dyeing wastewater are filtered out by sedimentation to prevent interference with subsequent experimental results.

[0037] MnO x / SiO 2 / FeSO 4 The preparation of the mixed system matching agent material: the raw material is selected from the iron and manganese tailings of a manganese mining enterprise in Hunan, and the effective component in the tailings is MnO x , after grinding, the particles with uniform particle size are screened out as the components of the medicine, and the MnO x / SiO 2 / FeSO 4 The mass ratio is 1:1:8.

[0038] Such as figure 1 As shown, in step 1, the printing and dyeing wastewater is firstly flowed i...

Embodiment 3

[0043] The printing and dyeing wastewater comes from the comprehensive wastewater of a printing and dyeing factory, and the concentration of T-Sb is 1080 μg L -1 , the concentration of CODCr is 1091mg·L -1 , the pH of the water is around 10.1. First, the printing and dyeing wastewater is pretreated, and the impurity components in the printing and dyeing wastewater are filtered out by sedimentation to prevent interference with subsequent experimental results.

[0044] MnO x / SiO 2 / FeSO 4 The preparation of the mixed system matching agent material: the raw material is selected from the iron and manganese tailings of a manganese mining enterprise in Hunan, and the effective component in the tailings is MnO x , after grinding, the particles with uniform particle size are screened out as the components of the medicine, and the MnO x / SiO 2 / FeSO 4 The mass ratio is 1:1:8.

[0045] Such as figure 1 As shown, in step 1, the printing and dyeing wastewater is first flowed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com