Preparation method of anisotropic FeSiAl magnetic core and product

An anisotropic and magnetic core technology, applied in the field of magnetic material preparation, can solve the problems of poor resistance to DC bias, low operating frequency of magnetic core, high magnetic core, etc., and achieve stable performance, which is conducive to mass production and high The effect of magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of anisotropic FeSiAl magnetic core, comprising the following steps:

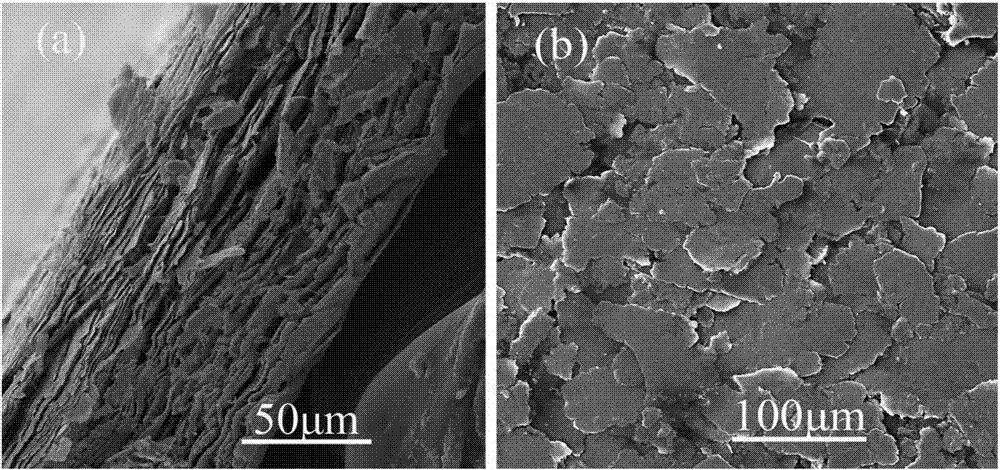

[0026] 1. Put the crushed FeSiAl ingot powder containing Si 10wt%, Al 5wt% and the balance Fe into a vertical sand mill for flattening, control the speed of the sand mill to 900r / min, and grind for 10h to obtain Flaky FeSiAl magnetic powder with a particle size of 20-120 μm and a thickness of 0.2-1.2 μm;

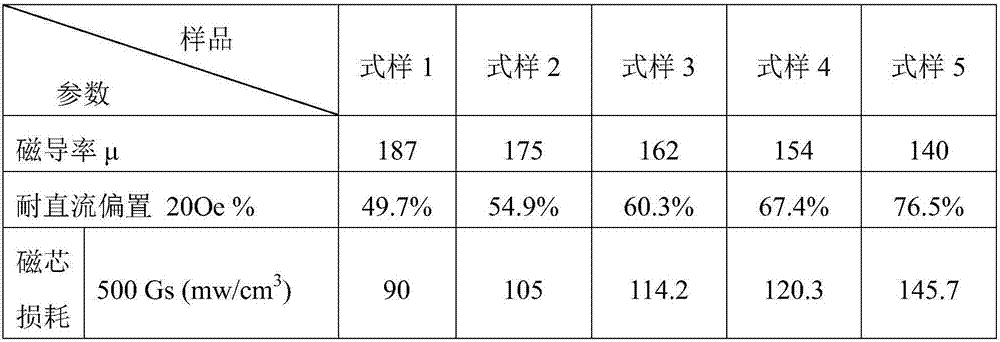

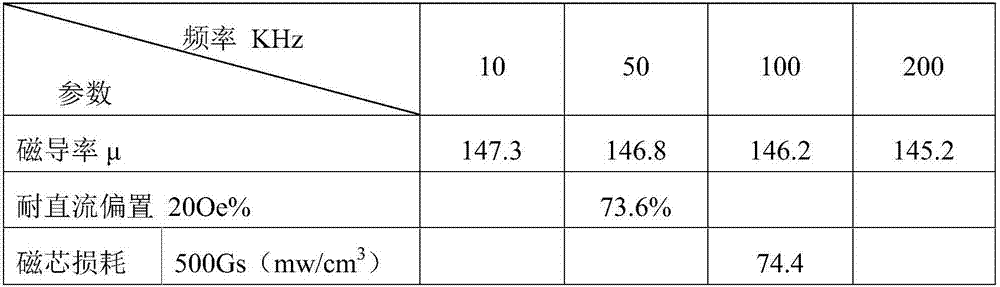

[0027] 2. Classify the obtained flaky FeSiAl magnetic powder to obtain the following five kinds of classified powders with different particle sizes: sample powder 1 (particle size above 100 μm), sample powder 2 (particle size 80-100 μm), and sample powder 3 (particle size 60~80μm), sample powder 4 (particle size 40~60μm), sample powder 5 (particle size below 40μm);

[0028] 3. Using the hydrolysis method of tetraethyl orthosilicate, the 5 kinds of flaky FeSiAl magnetic powders with different particle sizes were coated with SiO on the surface by sol-gel process. 2 deal with; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| magnetic permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com