Fischer-Tropsch synthesis iron-based catalyst, preparation method thereof and Fischer-Tropsch synthesis method

An iron-based catalyst and Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve the problems of low catalyst activity and selectivity, harsh preparation conditions, and cumbersome preparation processes, etc. problem, to achieve the effect of high added value of the product, mild preparation process conditions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

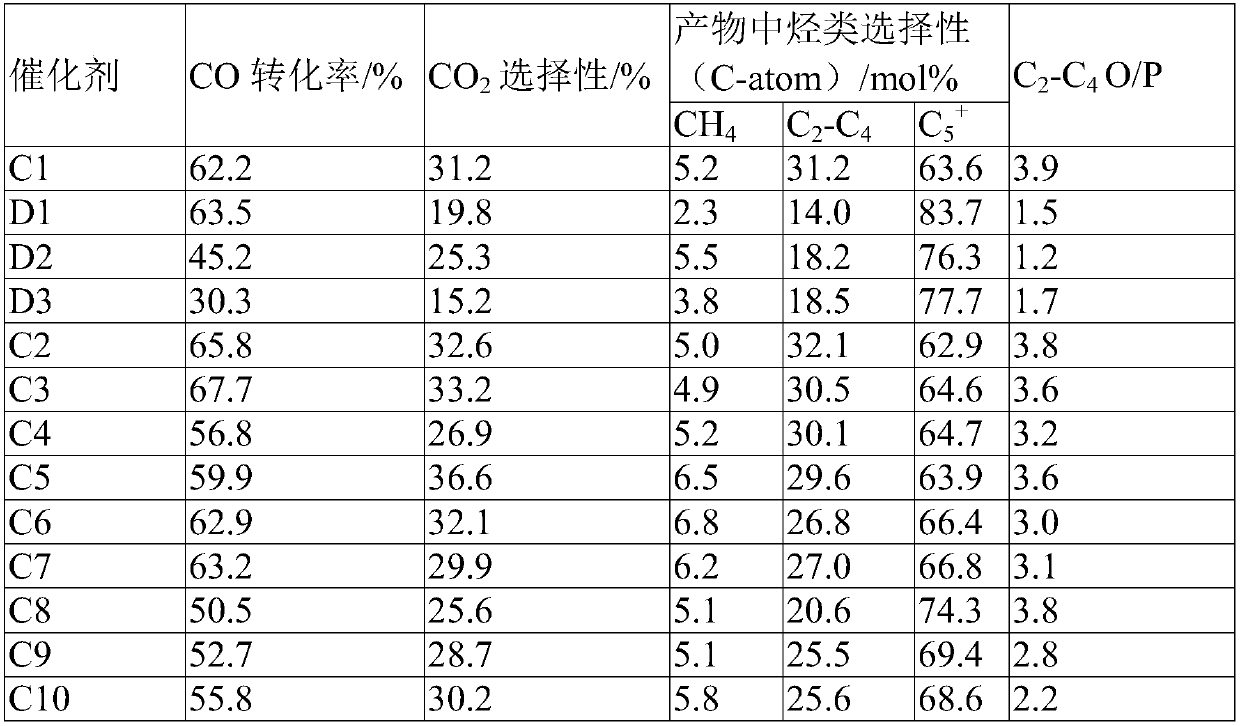

Examples

preparation example Construction

[0019] The first aspect of the present invention provides a kind of preparation method of Fischer-Tropsch synthesis iron-based catalyst, the method comprises:

[0020] (1) Etching the first mixture containing iron oxide and acid solution at 20-120° C. for at least 2 hours to obtain a dispersion slurry;

[0021] (2) Mix the dispersion slurry, M salt, copper salt, potassium salt, silicon-containing compound and optionally water to obtain a second mixture, wherein M is selected from Ti, V, Cr, Mn, Co, Ni, At least one of Zn, Al and Nd;

[0022] (3) adjusting the pH value of the second mixture to 4-9 to obtain a third mixture;

[0023] (4) The third mixture is spray-dried and calcined.

[0024] According to the present invention, the iron oxide may be at least one of ferrous oxide, ferric oxide and ferric oxide, preferably, the iron oxide is ferric oxide.

[0025] According to a preferred embodiment of the present invention, the average particle size of the ferric oxide is not ...

Embodiment approach

[0045] According to a most preferred embodiment of the present invention, the method comprises:

[0046] (1) Mix the solution of ferric oxide and nitric acid / acetic acid with an average particle diameter of 0.5-1.2 microns to obtain the first mixture, the pH of the first mixture is 0.5-2, and the first mixture is mixed at 50 Etching at -90°C for 5-48 hours to obtain a dispersion slurry;

[0047] (2) The dispersion slurry, M salt solution, copper salt solution, potassium salt solution, silicon-containing compound solution and optionally water are mixed to obtain a second mixture, M is selected from at least one of Mn, Co, Ni and Zn A sort of;

[0048] (3) adding ammonium carbonate to the second mixture to adjust the pH value to 5-8 to obtain a third mixture;

[0049] (4) The third mixture is spray-dried and calcined.

[0050] According to the method of the present invention, preferably in step (4), the spray drying conditions include: the inlet air temperature is 220-300°C, ...

Embodiment 1

[0066] (1) 100g of ferroferric oxide (average particle size is about 1 micron, specific surface area is 0.2m 2 / g) is mixed with nitric acid / acetic acid mixed acid solution (the mass ratio of nitric acid and acetic acid is 1:2, and the mass concentration of nitric acid is 18% by weight) is mixed to obtain the first mixture, adjust the pH of the first mixture to 0.6, and the first The mixture was put into an airtight container, and was incubated (etched) at 80°C for 24 hours to obtain a dispersion slurry (the specific surface area of ferric oxide in it was 22.9m 2 / g);

[0067] (2) Add 37.5g of zinc nitrate solution (12.5g of zinc nitrate), 36.7g of copper nitrate solution (11.7g of copper nitrate), 35.1g of potassium nitrate solution (10.1g of potassium nitrate) and 61g of Silica sol (silicon dioxide content is 20% by weight), mixed to obtain the second mixture;

[0068] (3) Adding a concentration of 30% by weight of ammonium carbonate solution to the second mixture, adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com