Precipitated iron catalyst for Fischer-Tropsch synthesis and preparation method thereof

A technology for catalyst, torrefaction synthesis, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc. high CO conversion rate and reactivity, high selectivity and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

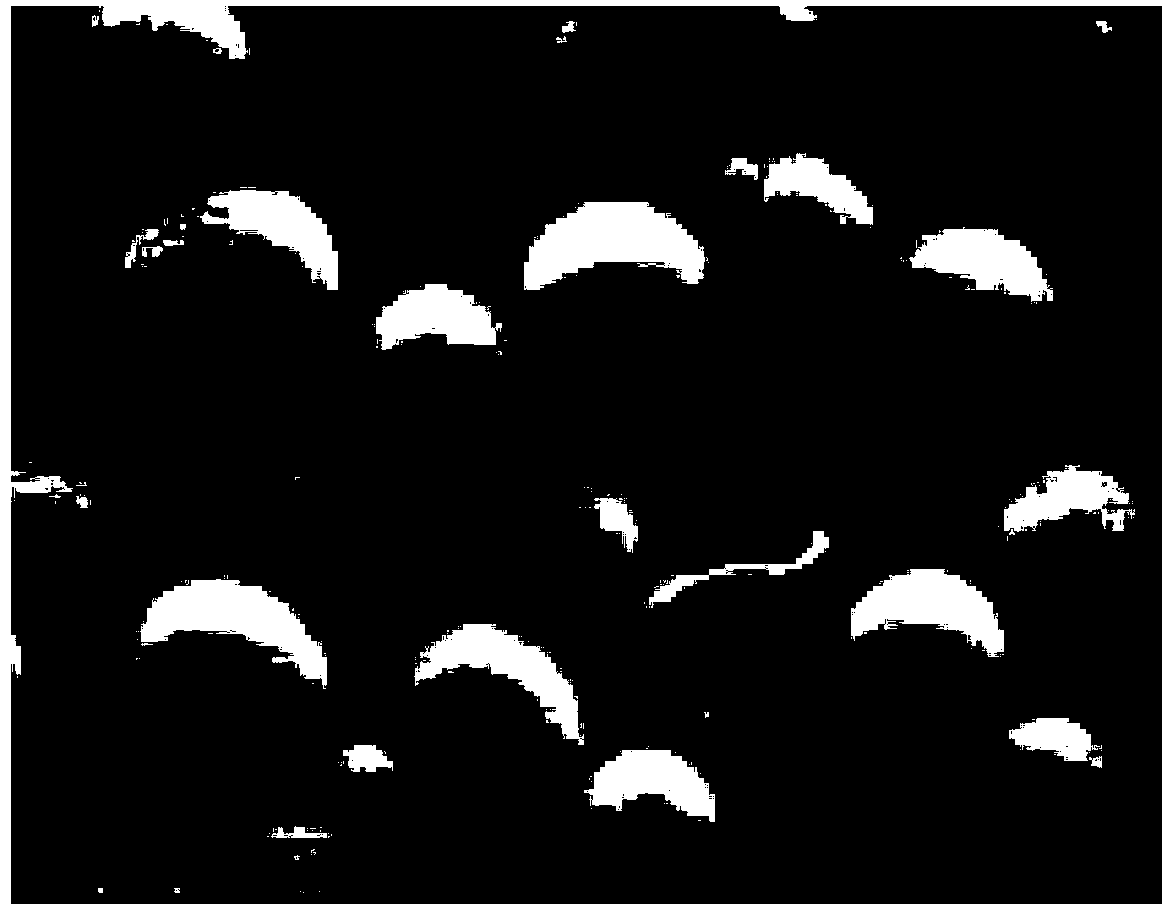

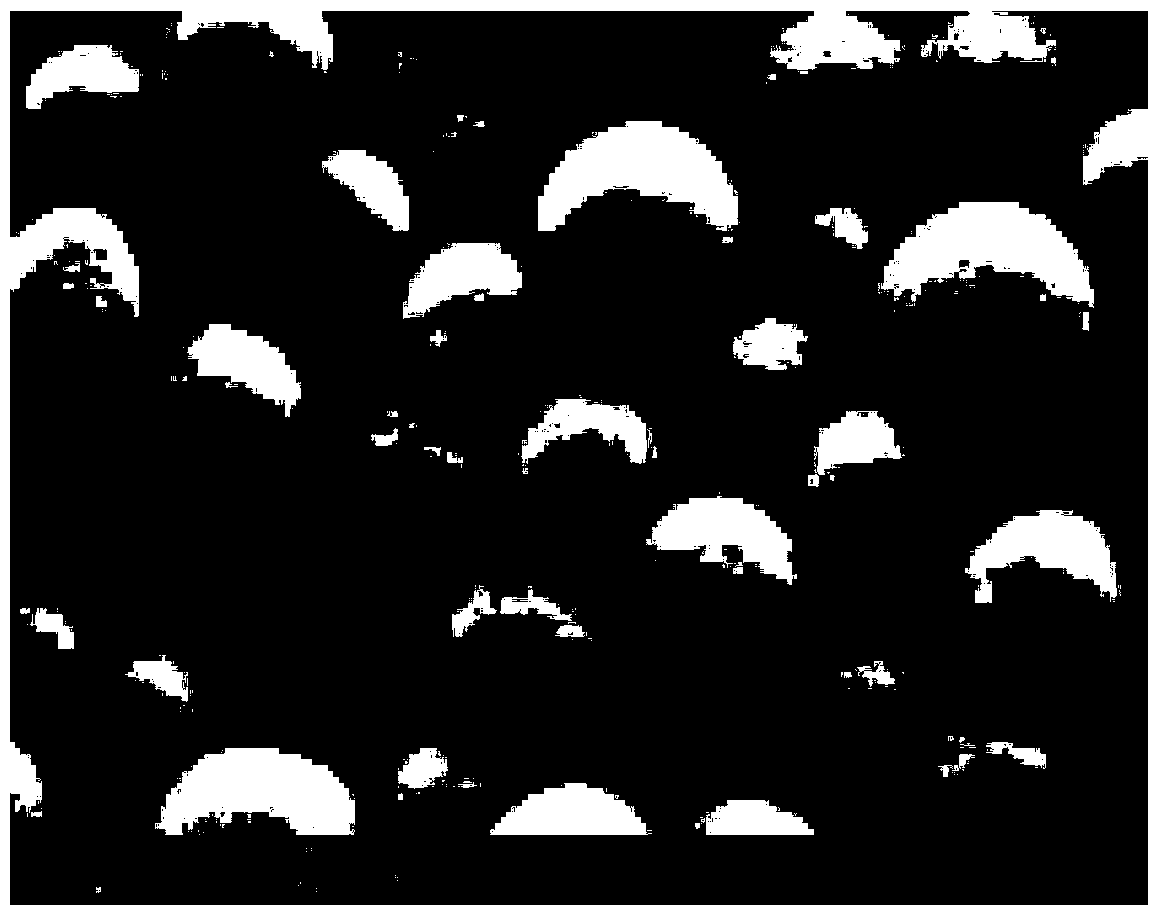

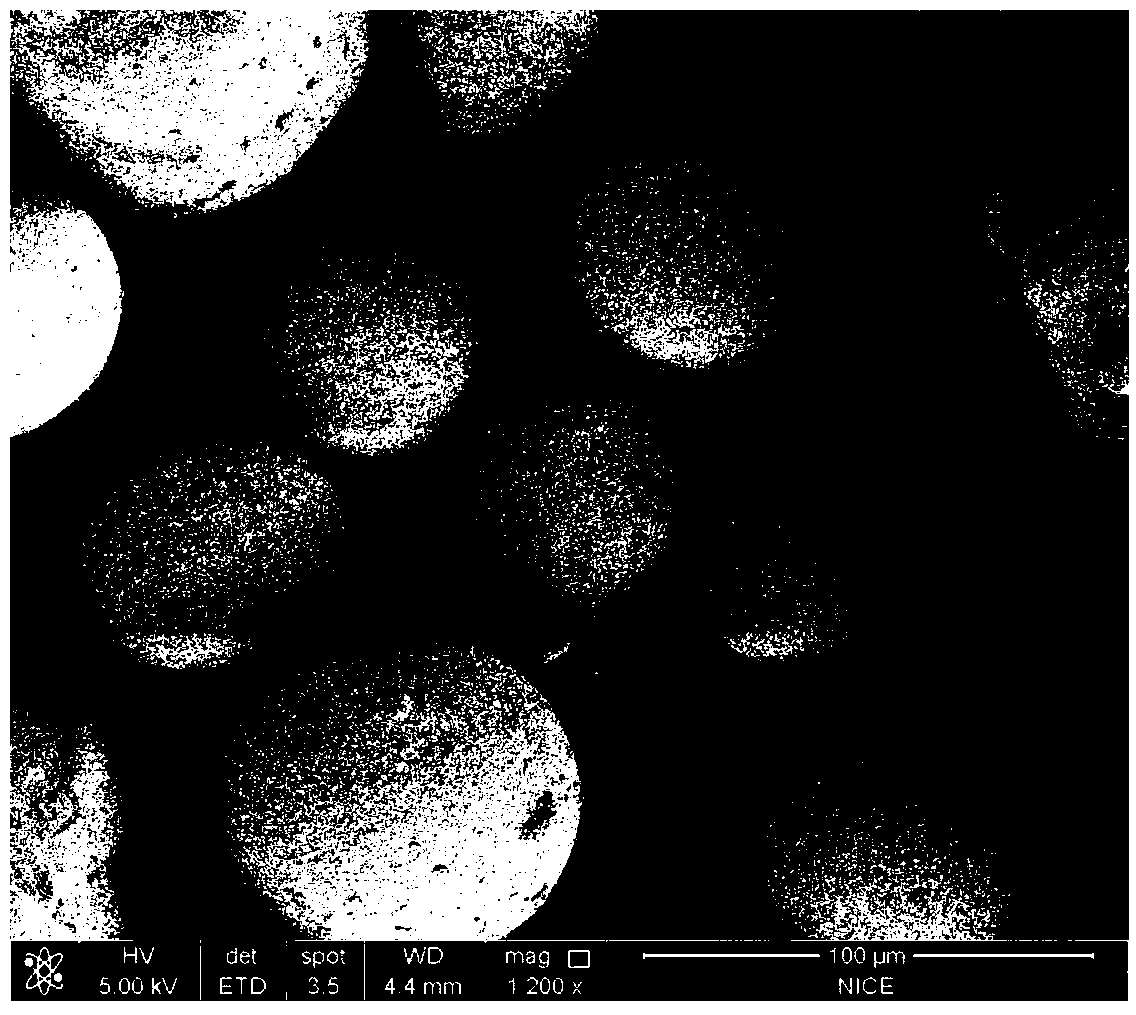

Image

Examples

Example Embodiment

[0031] In the preparation method provided by the present invention, soluble metal salts include but are not limited to metal nitrates, sulfates and oxalates, as long as they have good solubility in deionized water. Specifically, Fe raw materials are preferred Fe(NO 3 ) 3 ; Mn raw material is preferably Mn (NO 3 ) 2 ; Ti raw material is preferably potassium titanium oxalate (K 2 TiO(C 2 O 4 ) 2 ); The raw material of Cu is preferably Cu(NO 3 ) 2 Or CuCl 2 .

[0032] In the preparation method provided by the present invention, the precipitant solution in step (2) includes, but is not limited to, a deionized aqueous solution of ammonium carbonate, sodium carbonate, potassium carbonate, potassium bicarbonate, sodium hydroxide, potassium hydroxide, and ammonia , Preferably ammonium carbonate or sodium carbonate, and the concentration of the precipitation agent solution is 0.3-2 mol / L, preferably 0.5-1.5 mol / L.

[0033] During the precipitation reaction, the specific precipitation method...

Example Embodiment

[0043] Example 1

[0044] Weigh 40.4kg of iron nitrate nonahydrate, manganese nitrate (Mn(NO 3 ) 2 ·4H 2 O) 3.43kg, copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) 0.8kg, potassium titanium oxalate dihydrate (K 2 TiO(C 2 O 4 ) 2 ·2H 2 O) 2.43kg, add deionized water to dissolve, prepare Fe concentration 2.0mol / L metal salt solution, preheat to 70℃. Take 19 kg of sodium carbonate, add deionized water to dissolve it, configure it into a sodium carbonate precipitant solution with a concentration of 1.0 mol / L, and preheat to 70°C.

[0045] The metal salt solution and the precipitant solution were poured into a reaction beaker containing 300 mL of 70°C deionized water, and the precipitation reaction was carried out while keeping the temperature at 70°C and stirring. When the pH is controlled at 6.0±0.3, the stirring is ended, and the precipitation reaction time is 5 minutes to obtain the precipitation slurry. The precipitation slurry was aged at 80°C for 0.5h, filtered and washed twice to obtain a...

Example Embodiment

[0049] Example 2

[0050] Weigh 40.4kg of iron nitrate nonahydrate, manganese nitrate (Mn(NO 3 ) 2 ·4H 2 O) 0.8kg, copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) 1.1kg, potassium titanium oxalate dihydrate (K 2 TiO(C 2 O 4 ) 2 ·2H 2 O) 1.0kg, add deionized water to dissolve, prepare Fe concentration of 2.2mol / L metal salt solution, preheat to 60℃. Weigh 35 kg of solid ammonium carbonate, add deionized water to dissolve, prepare an ammonium carbonate precipitant solution with a concentration of 0.7 mol / L, and preheat to 35°C.

[0051] Pour the metal salt solution and the precipitant solution into a reaction beaker containing 25kg of deionized water at 40°C, keep the temperature at 40°C and perform the precipitation reaction while stirring, to obtain a precipitation slurry. The precipitation reaction time is 70 minutes. Adjust the pH of the precipitation slurry to 8.5±0.3, age at 60°C for 3.5h, filter and wash three times to obtain a co-precipitation filter cake.

[0052] Add water to the co-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com