A core-shell platinum-based catalyst with controllable acidity and its preparation and application

A core-shell catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, climate sustainability, etc., can solve problems affecting catalytic performance and achieve controllable acidity, The effect of high hydrothermal stability and excellent oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

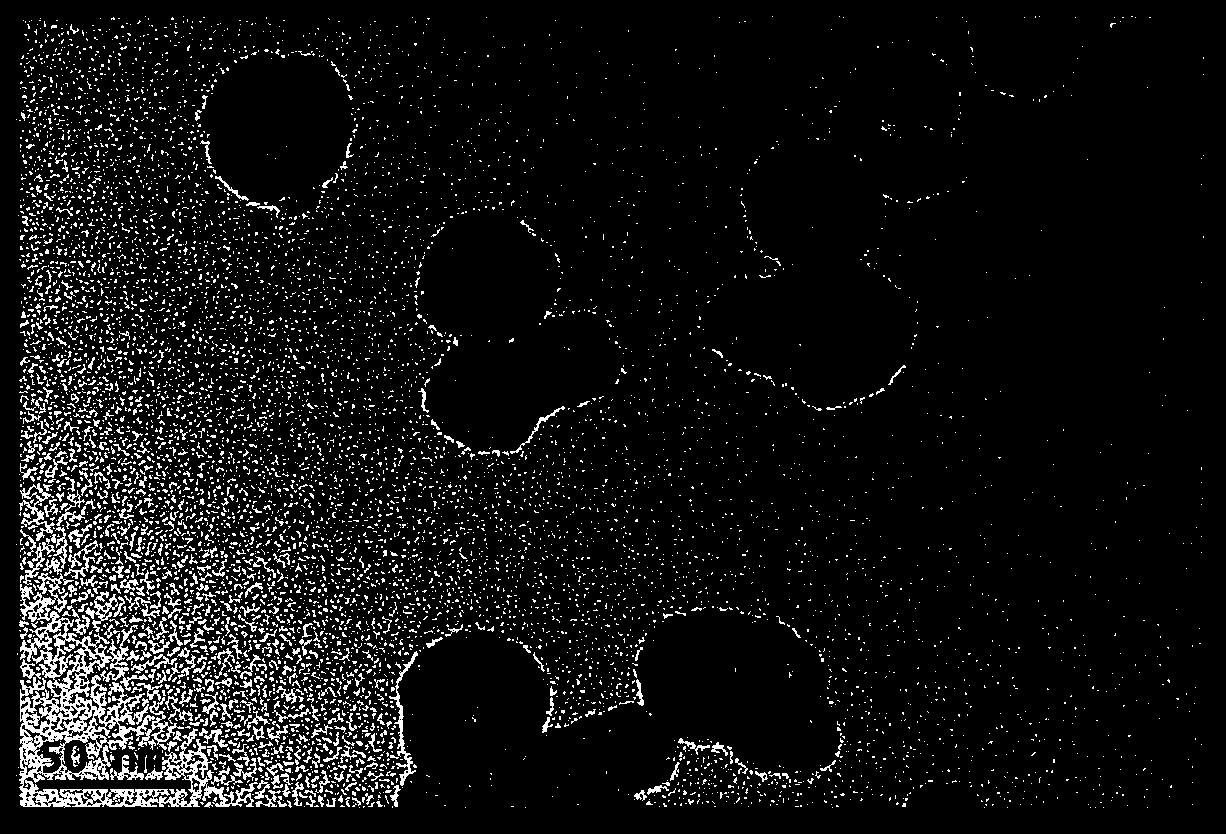

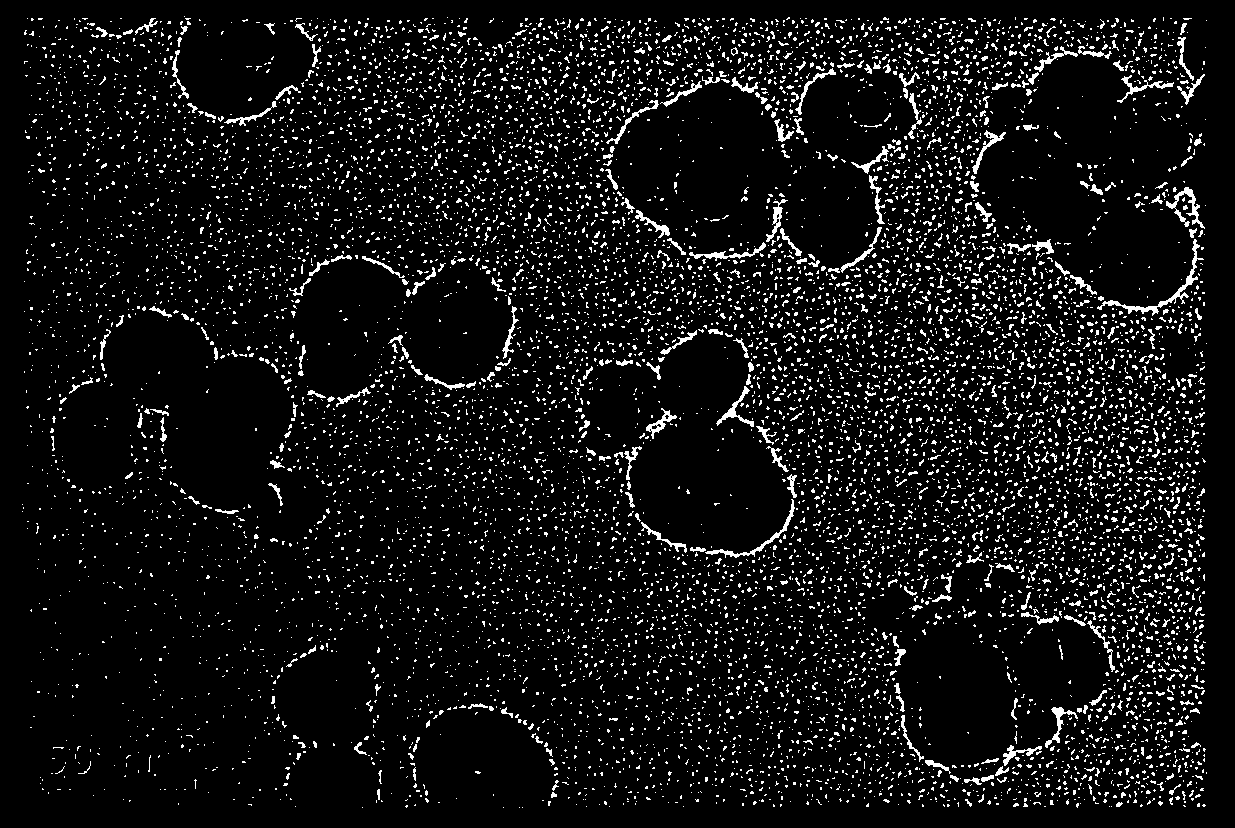

Image

Examples

Embodiment 1

[0034]1) Weigh 0.325g of platinum nitrate solution containing 18% platinum nitrate, and 0.7g of polyvinylpyrrolidone (PVP, M=58000), add 60mL of ethylene glycol together, stir vigorously to make it fully dissolve, and let it stand for 1 minute, A clear solution is obtained;

[0035] 2) The clarified liquid obtained in step 1) is heated to 180° C. under the protection of an inert atmosphere (such as nitrogen, helium), continued to stir for 20 minutes, and then cooled to room temperature under the inert atmosphere;

[0036] 3) Add about 200 mL of acetone to the solution obtained in step 2), stir for 5 minutes, and centrifuge at a centrifugal speed of 8000 r / min for 10 minutes to separate the platinum particles from the ethylene glycol. Pour off the supernatant, leaving a brown-black precipitate;

[0037] 4) Add 50 mL of absolute ethanol to the precipitate obtained in step 3), stir for 5 minutes, then add 200 mL of n-hexane, then centrifuge at a centrifugal speed of 8000 r / min f...

Embodiment 2

[0041] 1) Weigh 0.325g of platinum nitrate solution containing 18% platinum nitrate, and 0.7g of polyvinylpyrrolidone (PVP, M=58000), add 60mL of ethylene glycol together, stir vigorously to make it fully dissolve, and let it stand for 1 minute, to obtain a clear solution;

[0042] 2) The clarified liquid obtained in step 1) is heated to 180° C. under the protection of an inert atmosphere (such as nitrogen, helium), continued to stir for 20 minutes, and then cooled to room temperature under the inert atmosphere;

[0043] 3) Add about 200 mL of acetone to the solution obtained in step 2), stir for 5 minutes, and centrifuge at a centrifugal speed of 8000 r / min for 10 minutes to separate the platinum particles from the ethylene glycol. Pour off the supernatant, leaving a brown-black precipitate;

[0044] 4) Add 50 mL of absolute ethanol to the precipitate obtained in step 3), stir for 5 minutes, then add 200 mL of n-hexane, then centrifuge at a centrifugal speed of 8000 r / min fo...

Embodiment 3

[0048] 1) Weigh 0.325g of platinum nitrate solution containing 18% platinum nitrate, and 1.4g of polyvinylpyrrolidone (PVP, M=58000), add 60mL of ethylene glycol together, stir vigorously to make it fully dissolve, and let it stand for 1 minute, A clear solution is obtained;

[0049] 2) The clarified liquid obtained in step 1) is heated to 180° C. under the protection of an inert atmosphere (such as nitrogen, helium), continued to stir for 20 minutes, and then cooled to room temperature under the inert atmosphere;

[0050] 3) Add about 200 mL of acetone to the solution obtained in step 2), stir for 5 minutes, and centrifuge at a centrifugal speed of 8000 r / min for 10 minutes to separate the platinum particles from the ethylene glycol. Pour off the supernatant, leaving a brown-black precipitate;

[0051] 4) Add 50 mL of absolute ethanol to the precipitate obtained in step 3), stir for 5 minutes, then add 200 mL of n-hexane, then centrifuge at a centrifugal speed of 8000 r / min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com