A kind of ceria nanorod and its preparation method and application

A ceria and nanorod technology is applied to the preparation of ceria nanorods and the field of nanorods, which can solve the problems of high preparation cycle preparation cost, cumbersome preparation process, difficult popularization and application, etc., and achieves simple and controllable preparation method, The preparation process is cumbersome and the preparation cycle is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the present embodiment, the preparation method adopted is as follows:

[0032] Add 1.0 g of cerium nitrate into 10 ml of tetraethylammonium hydroxide (20 wt%), hydrolyze and stir for 0.5 h to form a brown mixture, and then add the brown mixture into the hydrothermal reaction kettle. Put the reaction kettle in an oven and keep the temperature at 80°C for 12h. Then, the obtained mixed solution was washed four times with deionized water, placed in a vacuum drying oven, dried at 100° C. for 12 hours, and then calcined at 300° C. for 0.5 h to obtain ceria nanorods.

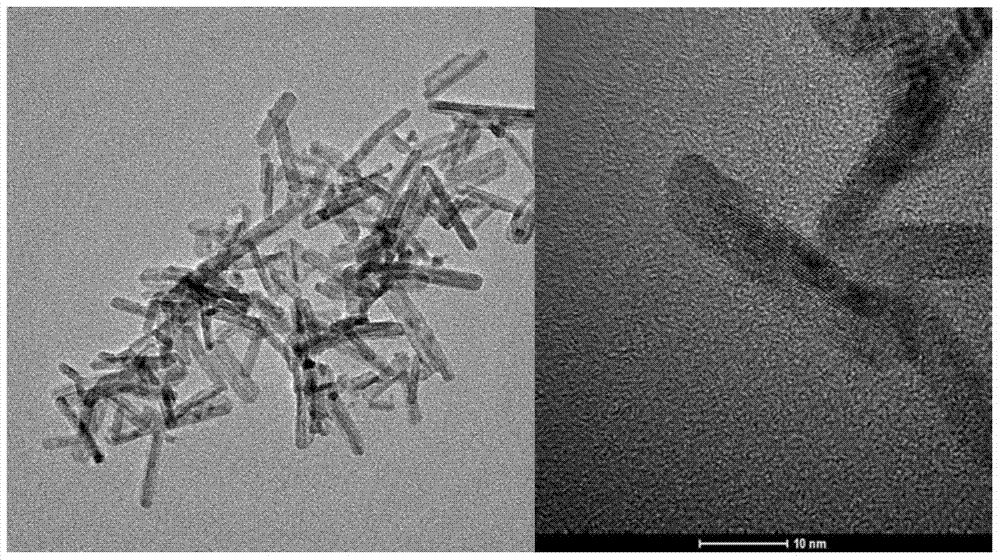

[0033] Such as figure 1 Shown is the SEM image of the cerium oxide prepared in this example, which presents a good nanorod structure.

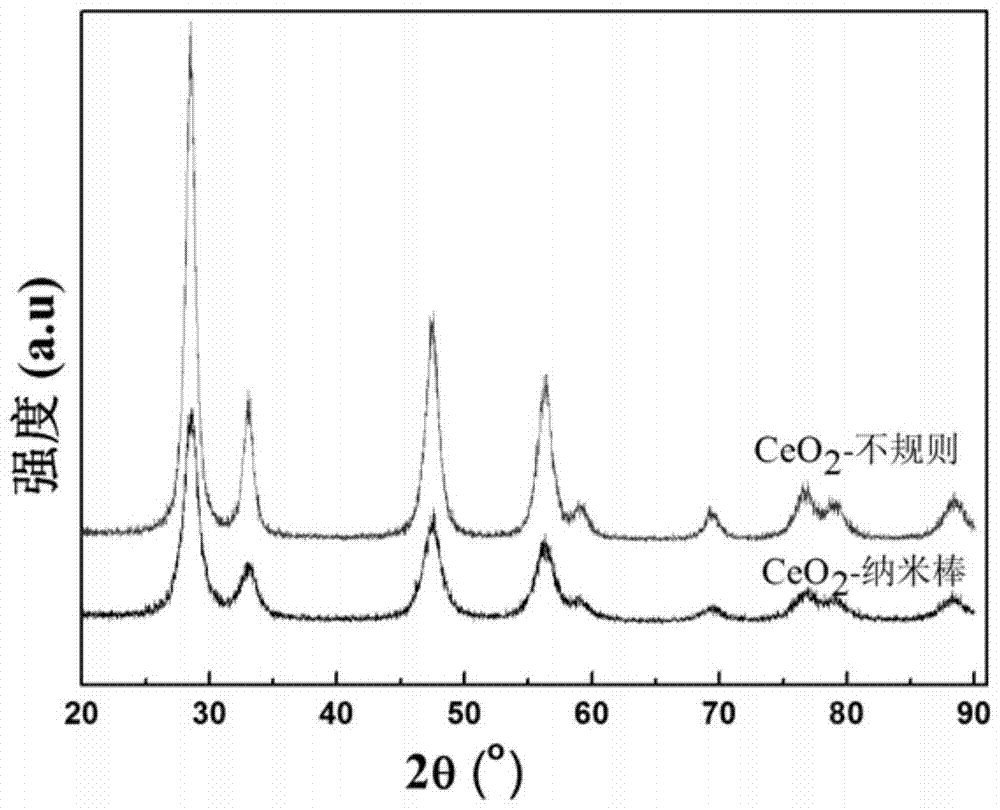

[0034] Such as figure 2 Shown are the XRD patterns of ceria nanorods and irregular ceria prepared in this example. It can be seen from the figure that both of them present cubic fluorite structure CeO 2 (PDF-ICDD34-0394).

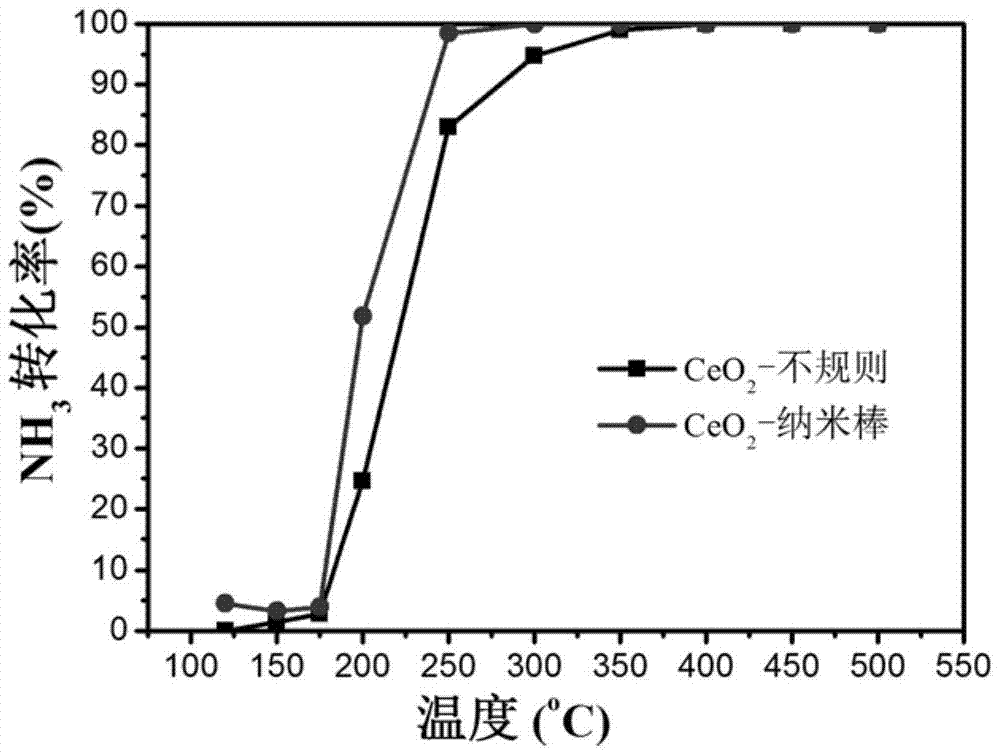

[0035] Such as image 3 As shown, the use of ...

Embodiment 2

[0037] In the present embodiment, the preparation method adopted is as follows:

[0038] Add 1.5 g of cerium nitrate into 12 ml of tetraethylammonium hydroxide (25 wt%), hydrolyze and stir for 0.5 h to form a brown mixture, and then add the brown mixture into the hydrothermal reaction kettle. Put the reaction kettle in an oven and keep the temperature at 75°C for 12h. Then, the obtained mixed solution was washed four times with deionized water, placed in a vacuum drying oven, dried at 100°C for 14 hours, and then calcined at 320°C for 0.6h to obtain ceria nanorods.

Embodiment 3

[0040] In the present embodiment, the preparation method adopted is as follows:

[0041] Add 0.8 g of cerium nitrate into 10 ml of tetraethylammonium hydroxide (18 wt%), hydrolyze and stir for 0.5 h to form a brown mixture, and then add the brown mixture into the hydrothermal reaction kettle. Put the reaction kettle in an oven and keep the temperature at 85°C for 12h. Then, the obtained mixed solution was washed four times with deionized water, placed in a vacuum drying oven, dried at 100° C. for 10 hours, and then calcined at 280° C. for 0.5 h to obtain ceria nanorods.

[0042] The present invention compares the ceria nanorods prepared in the above three examples, and finds that although the ceria nanorods can also be obtained in the second and third examples, the structure is not as good as that obtained in the first example. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com