A kind of preparation method of cathode material of lithium-sulfur battery

A lithium-sulfur battery and cathode material technology, applied in the energy field, can solve the problems of limiting the large-scale application of doped carbon materials, the complexity of the preparation process, the volume change of the sulfur cathode, etc., so as to achieve high value-added utilization and improve cycle stability. and discharge specific capacity, the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

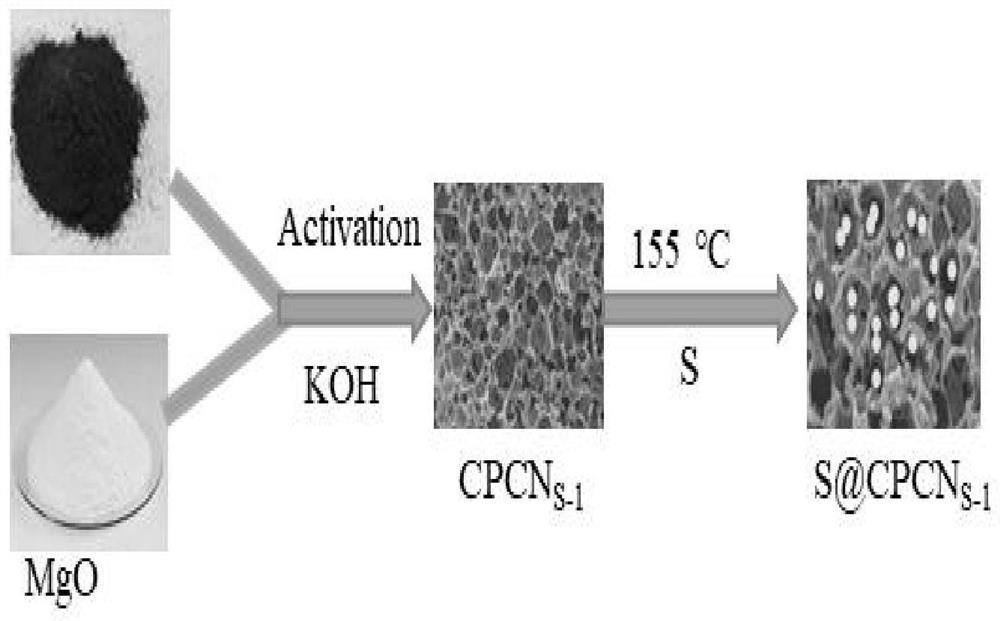

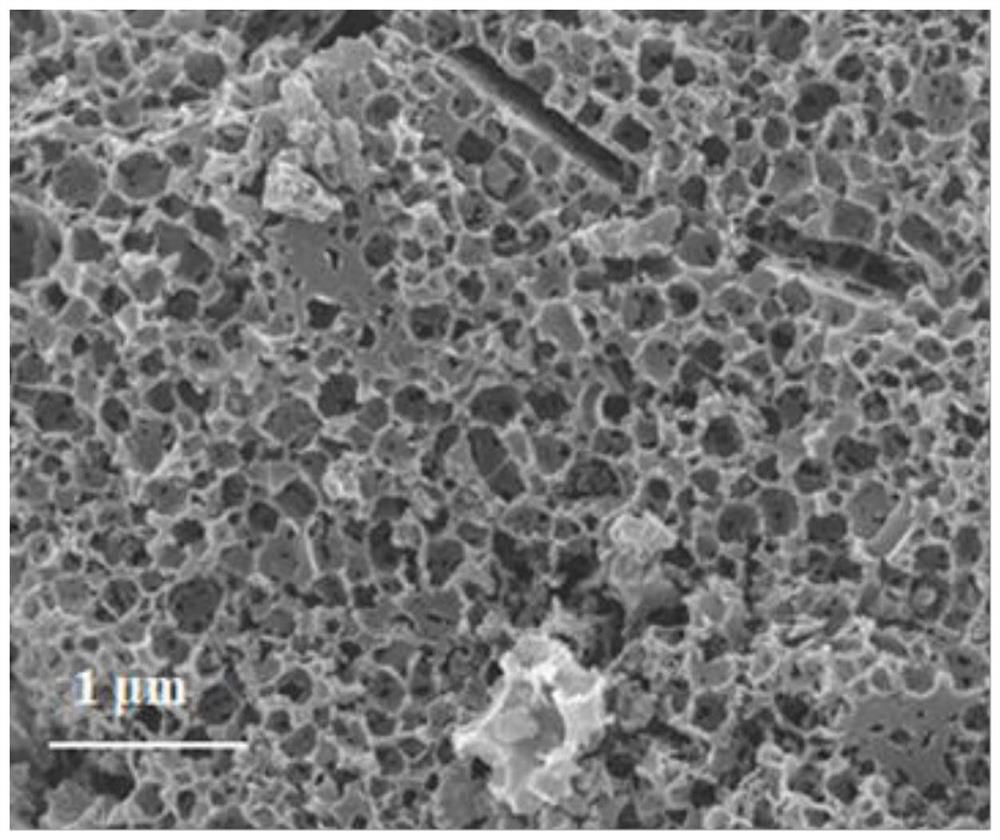

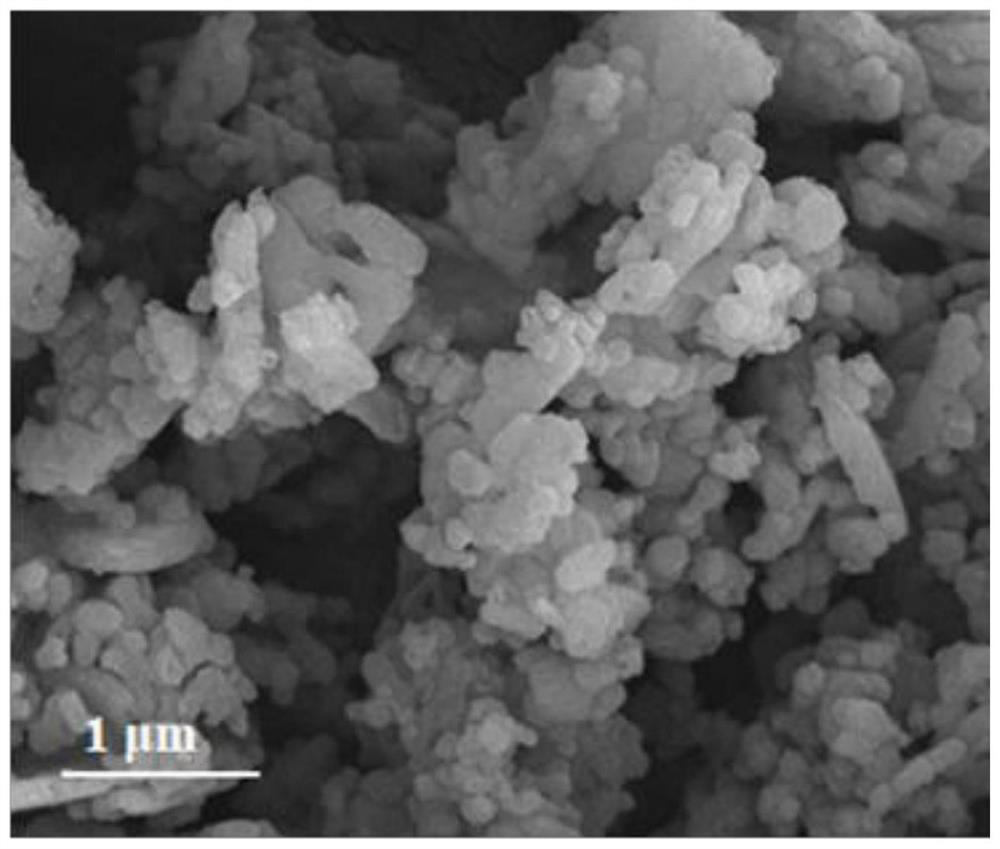

[0040] 1. Preparation of high-sulfur coal-based honeycomb porous carbon material: (1) Weigh 10.16g of magnesium chloride hexahydrate (MgCl 2 6H 2 O) and 12.85g of ammonium bicarbonate (NH 4 HCO 3 ) was dissolved in 500 ml of water to form a white emulsion under magnetic stirring. And heated to 50° C. in a water bath and stirred for 10 hours. The obtained white emulsion was suction-filtered, washed repeatedly with deionized water for more than 3 times, and dried at 60°C. The obtained white powder was pyrolyzed in a tube furnace at 500 °C, the atmosphere was air, and the heating rate was 5 °C min -1 , kept at 500°C for 3 hours, and naturally cooled to room temperature to obtain white magnesium oxide (MgO) powder. (2) Weigh 10 grams of dry high-sulfur coal into a flask, add 150 milliliters of concentrated nitric acid, heat in a water bath to 80 degrees Celsius, and stir magnetically at a constant temperature for 16 hours. After taking it out, wash it repeatedly with distill...

Embodiment 2

[0044] 1. Preparation of multi-layer honeycomb porous carbon material: (1) take 10.16g of magnesium chloride hexahydrate (MgCl 2 6H 2 O) and 12.85g of ammonium bicarbonate (NH 4 HCO 3 ) was dissolved in 500 ml of water to form a white emulsion under magnetic stirring. And heated to 50° C. in a water bath and stirred for 10 hours. The obtained white emulsion was suction-filtered, washed repeatedly with deionized water for more than 3 times, and dried at 60°C. The obtained white powder is pyrolyzed in a tube furnace, and the heating program is started to 500°C, the atmosphere is air, and the heating rate is 5°C min -1 , kept at 500°C for 3 hours, and naturally cooled to room temperature to obtain white magnesium oxide (MgO) powder. (2) Coal (unoxidized) sample 2g, magnesia template 6g and activator KOH 4g (ratio 1:3:2), ground and mixed thoroughly and placed in a corundum boat. Flow meter flow is set to 30 ~ 60ml min -1 (N 2 atmosphere), set at 5°C min -1 The heating pr...

Embodiment 3

[0048] 1. Preparation of high-sulfur coal-based honeycomb porous carbon material: (1) weigh 10.16g of magnesium chloride hexahydrate (MgCl 2 6H 2 O) and 12.85g of ammonium bicarbonate (NH 4 HCO 3 ) was dissolved in 500 ml of water to form a white emulsion under magnetic stirring. And heated to 50° C. in a water bath and stirred for 10 hours. The obtained white emulsion was suction-filtered, washed repeatedly with deionized water for more than 3 times, and dried at 60°C. The obtained white powder is pyrolyzed in a tube furnace, and the heating program is started to 500°C, the atmosphere is air, and the heating rate is 5°C min -1 , kept at 500°C for 3 hours, and naturally cooled to room temperature to obtain white magnesium oxide (MgO) powder. (2) Weigh 10 grams of dry high-sulfur coal into a flask, add 150 milliliters of concentrated nitric acid, heat to 80 degrees Celsius in a water bath in a fume hood, and stir magnetically at a constant temperature for 16 hours. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com