Construction waste regenerated imitation stone brick and preparation method thereof

A technology of construction waste and stone bricks, which is applied in the field of construction waste recycled imitation stone bricks and its preparation, can solve the problems of complex composition, poor strength, and inability to make fully recycled aggregate imitation stone bricks, and achieve cost reduction and significant Economic and social benefits, and the effect of achieving harmlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

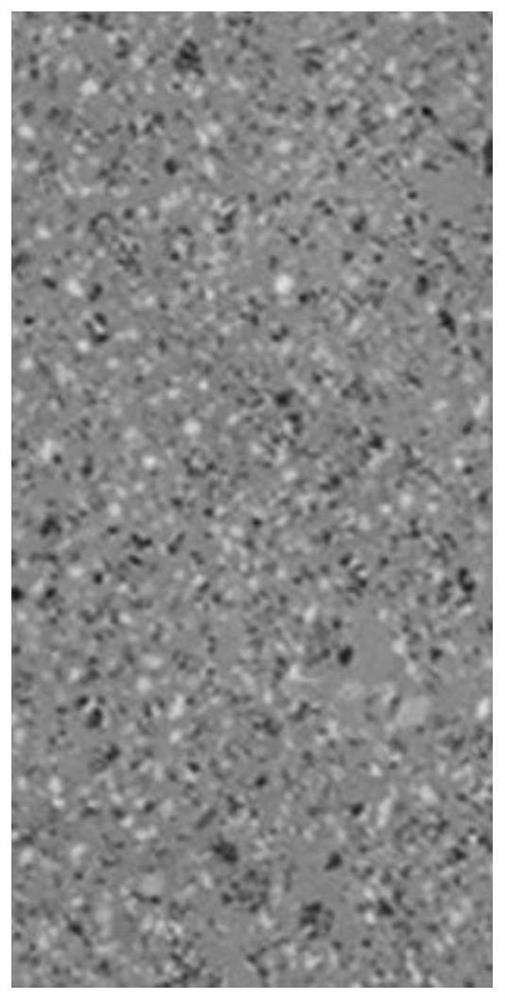

Embodiment 1

[0036] A construction waste recycled imitation stone brick, comprising a surface layer and a base layer, in the base layer: ash cement, 0-5mm recycled brick and tile aggregate and recycled concrete aggregate compound, 5-10mm of recycled brick and tile aggregate and recycled The weight ratio of the concrete-aggregate compound is 20:45:35, and the weight of the adjuvant is 0.5‰ of the weight of the gray cement; in the surface layer: gray cement or white cement, 0-5mm and 5-10mm regeneration The weight ratio of the concrete-aggregate compound is 30:70, the weight of the pigment is 1% of the weight of the grey cement or the white cement, and the weight of the auxiliary agent is 0.5‰ of the weight of the grey cement or the white cement; The cement is ordinary Portland cement; the white cement is sulfoaluminate cement; the adjuvant is VAE resin; in the composite of 0-5mm recycled brick and tile aggregate and recycled concrete aggregate, 0-5mm The mass ratio of recycled brick and til...

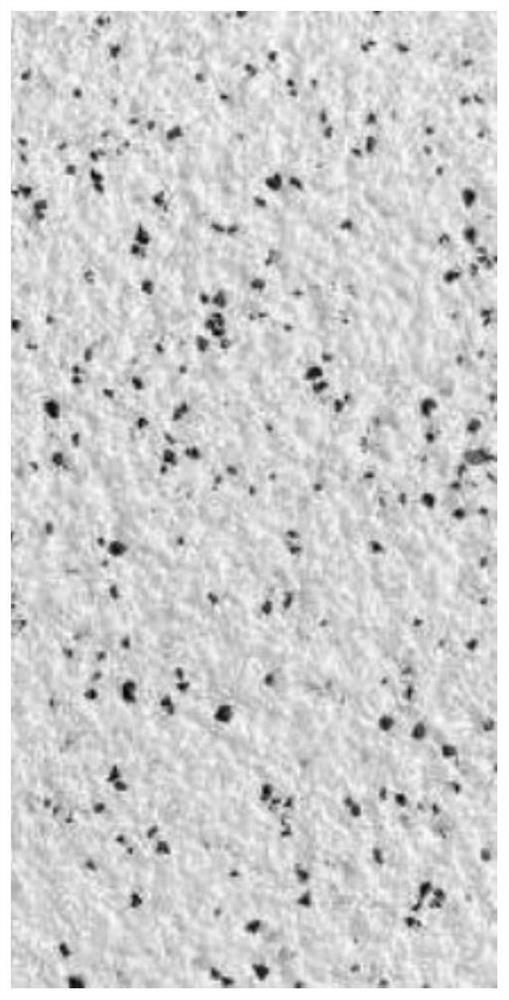

Embodiment 2

[0043] A construction waste recycled imitation stone brick, comprising a surface layer and a base layer, in the base layer: ash cement, 0-5mm recycled brick and tile aggregate and recycled concrete aggregate compound, 5-10mm of recycled brick and tile aggregate and recycled The weight ratio of the concrete-aggregate compound is 15:45:40, and the weight of the adjuvant is 0.1‰ of the weight of the gray cement; in the surface layer: gray cement or white cement, 0-5mm and 5-10mm regeneration The weight ratio of the concrete-aggregate compound is 15:85, the weight of the pigment is 2.0% of the weight of the grey cement or the white cement, and the weight of the auxiliary agent is 0.1‰ of the weight of the grey cement or the white cement; The cement is Portland cement; the white cement is white Portland cement; the adjuvant is acrylic resin; in the compound of 0-5mm recycled brick and tile aggregate and recycled concrete aggregate, 0-5mm recycled The mass ratio of brick and tile ag...

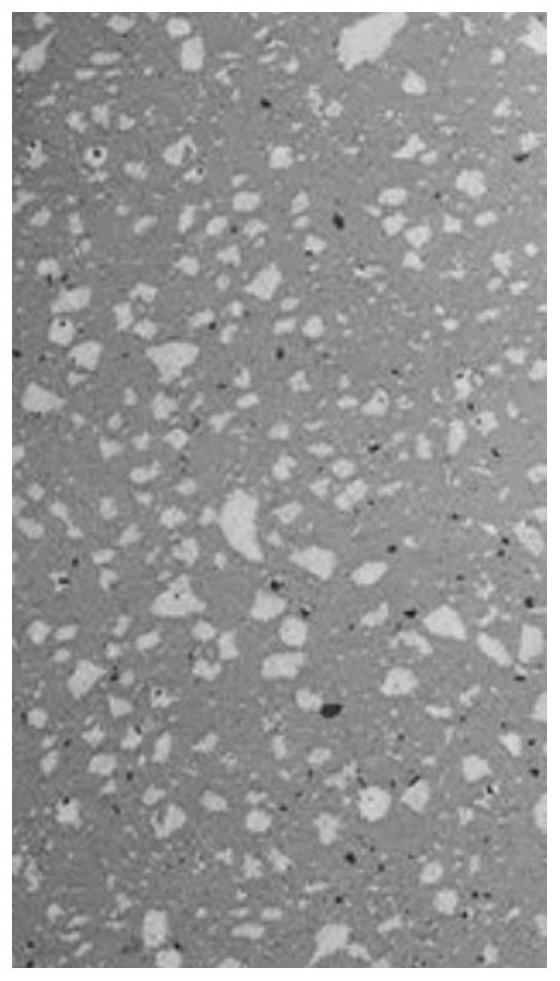

Embodiment 3

[0047] A construction waste recycled imitation stone brick, comprising a surface layer and a base layer, in the base layer: ash cement, 0-5mm recycled brick and tile aggregate and recycled concrete aggregate compound, 5-10mm of recycled brick and tile aggregate and recycled The weight ratio of the concrete-aggregate compound is 20:45:35, and the weight of the adjuvant is 0.1‰ of the weight of the gray cement; in the surface layer: gray cement or white cement, 0-5mm and 5-10mm regeneration The weight ratio of the concrete-aggregate compound is 20:80, the weight of the pigment is 2.0% of the weight of the grey cement or the white cement, and the weight of the auxiliary agent is 0.2‰ of the weight of the grey cement or the white cement; The cement is ordinary Portland cement; the white cement is sulfoaluminate cement; the adjuvant is VAE resin; in the composite of 0-5mm recycled brick and tile aggregate and recycled concrete aggregate, 0-5mm The mass ratio of recycled brick and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com