A method of fabricating a vertical cavity surface emitting laser that prevents excessive oxidation during wet oxidation

A technology of vertical cavity surface emission and wet oxidation, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of no good solution to the degree of oxidation, fluctuation of oxidation rate, and difficulty in ensuring oxidation, so as to make up for the cost and Efficiency loss, prevent excessive oxidation, enhance large effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] A method for producing a vertical cavity surface emitting laser that prevents excessive oxidation during wet oxidation, taking the production of a 980nm vertical cavity surface emitting laser as an example, comprises the following steps:

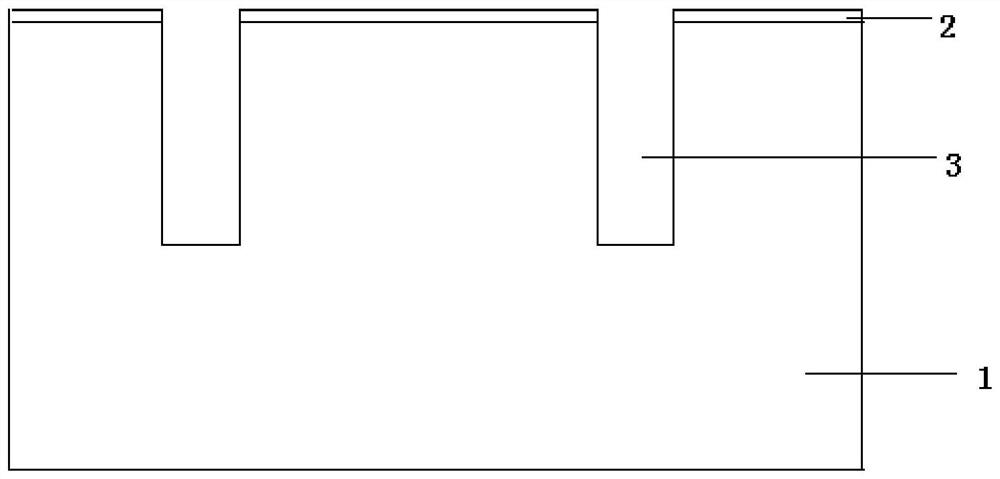

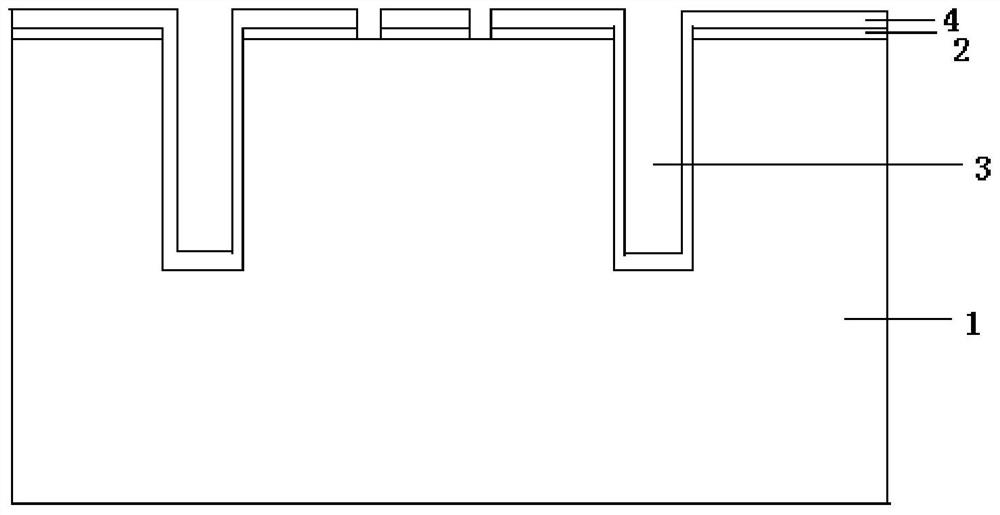

[0067] (1) if figure 1 As shown, the mesa is produced; the mesa after fabrication includes the wafer 1 with the epitaxial layer grown, the first SiO 2 The film layer 2, the channel 3, and the surface of the wafer 1 with the epitaxial layer grown with the first SiO 2 Membrane layer 2, channel 3 penetrates down through the mesa surface through the first SiO 2 film layer 2 and extends into the wafer 1 of the epitaxial layer; the first SiO 2 The thickness of film layer 2 is 3000-5000 Make countertops, including:

[0068] G. On the surface of the wafer 1 with the epitaxial layer grown, the thickness is 4000mm under the temperature condition of 200°C through thermal evaporation PECVD equipment. First SiO 2 film layer 2;

[0069] H....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com