Metal fiber and porous ceramic media surface burner

A metal fiber, medium surface technology, applied in burners, gas fuel burners, combustion methods, etc., to achieve the effect of increasing the adjustment range, increasing the combustion temperature, and improving the thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

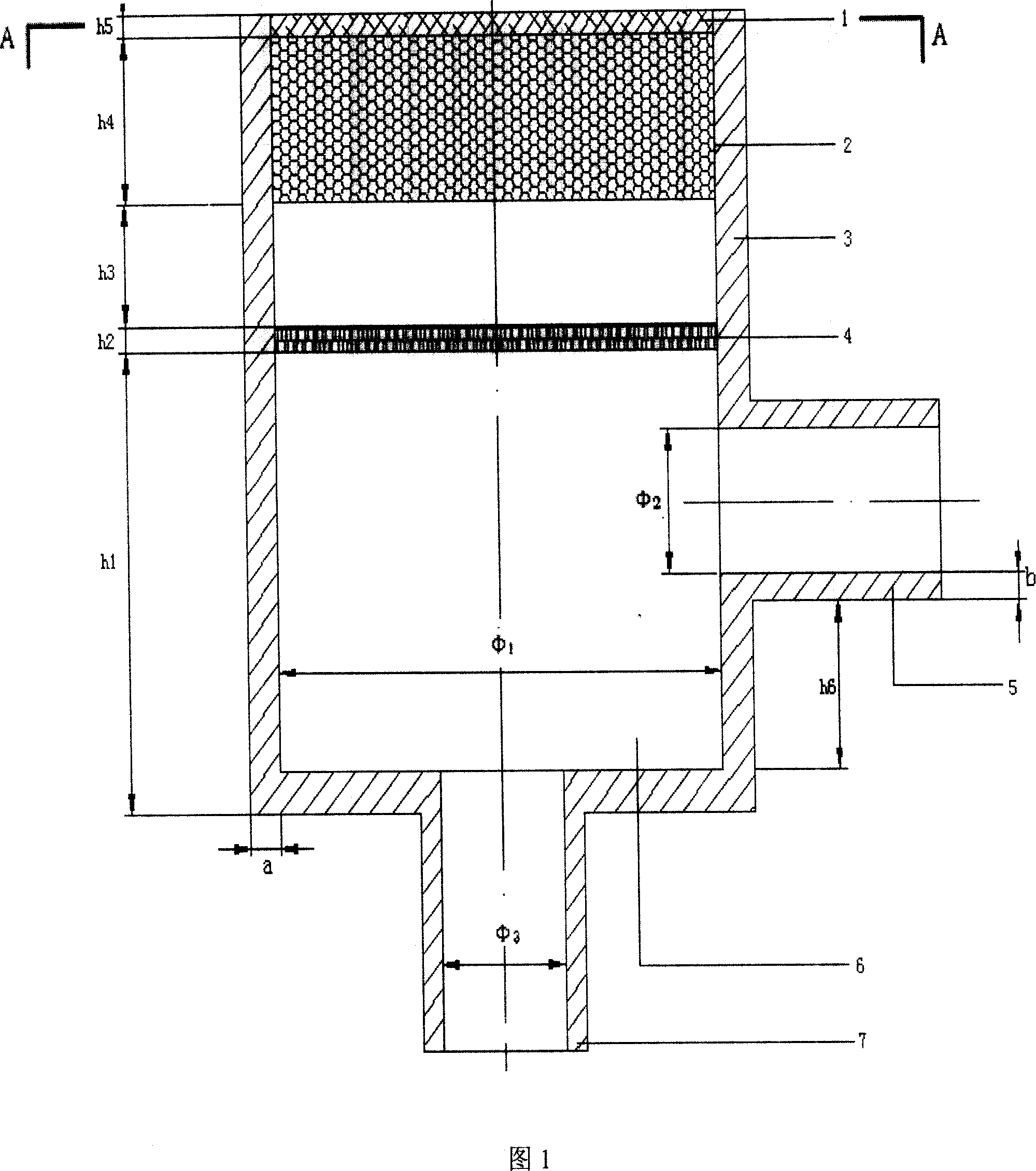

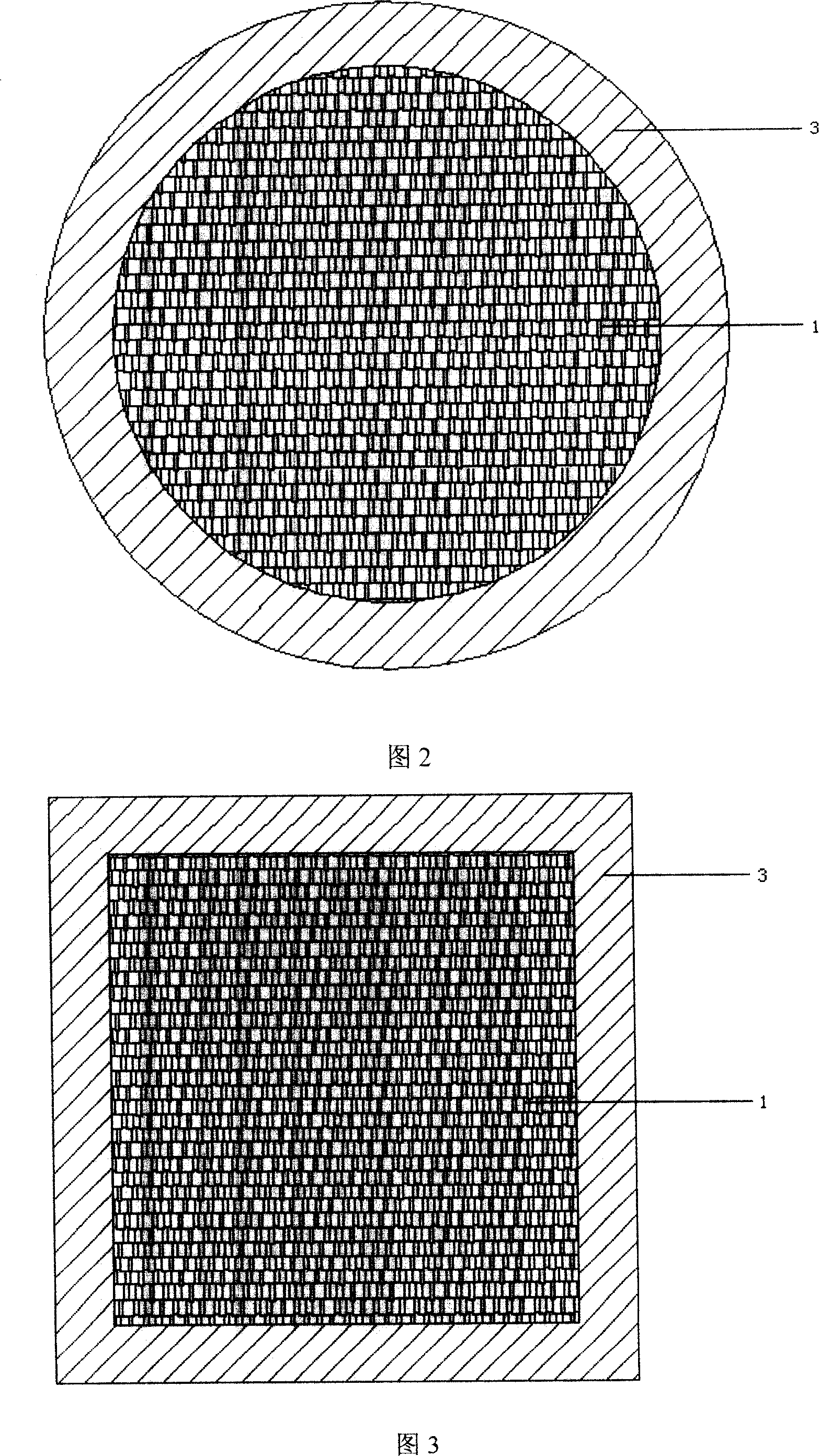

[0026] As shown in Figure 1 and Figure 2, the main body of the burner is composed of: 1 metal fiber medium in the combustion zone, 2 ceramic medium in the preheating zone, 3 burner shell, 4 dust removal metal mesh or metal brush, 5 gas pipeline, 6 premixing In the cavity formed by the burner shell 3, the metal fiber medium 1 in the combustion zone, the ceramic medium 2 in the preheating zone, and the materials for the metal fiber medium 1 in the combustion zone are arranged in sequence from top to bottom. Iron-chromium-aluminum alloy can be used, and the ceramic medium 2 in the preheating zone is made of zirconia or silicon carbide. The top of the metal fiber 1 in the combustion zone is flush with the top of the burner shell 3, and the metal fiber medium 1 in the combustion zone and the ceramic medium 2 in the preheating zone can be integrated. Inside the cavity formed by the burner casing 3, dust removal metal mesh or metal brush 4 is set under the ceramic medium 2 in the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com