Method for analyzing regenerative heating furnace flow field and internal temperature and thermal stress of workpiece

An analysis method and heating furnace technology, applied in the field of heat treatment, can solve the problems of not considering the thermal process of the heating furnace, not studying the numerical simulation dynamic analysis and calculation of the regenerative heating furnace, etc., to achieve the effect of simple modeling process and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

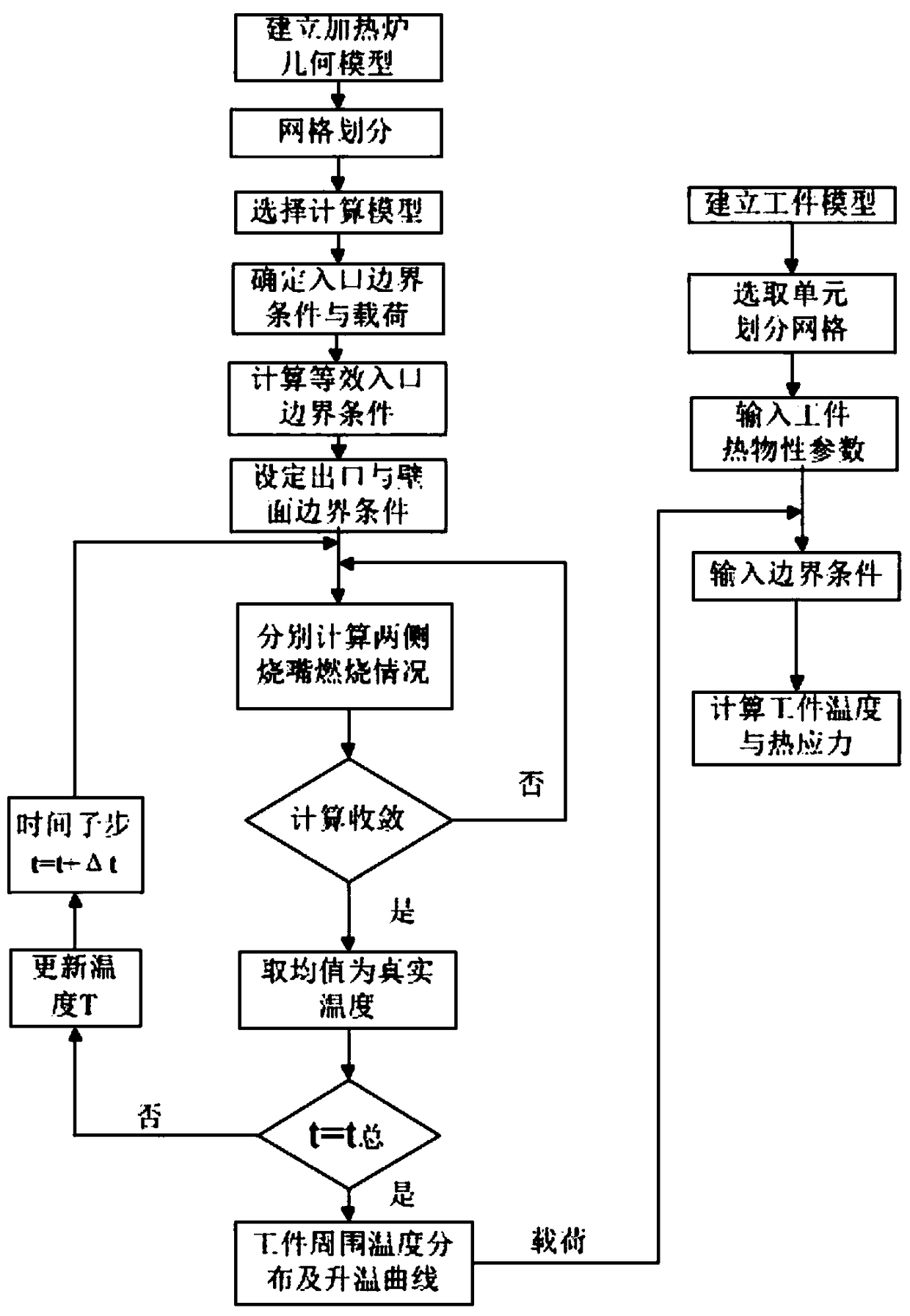

[0030] figure 1 Shown invention process figure, specific embodiment is as follows:

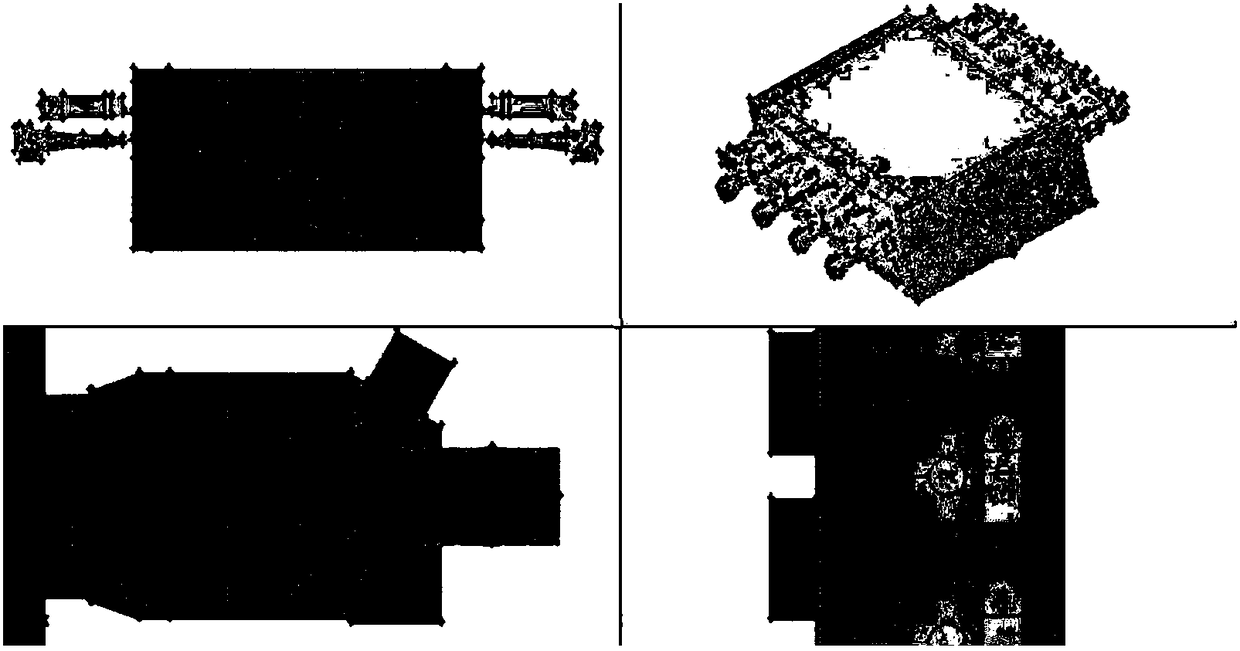

[0031] Step a) Use the 3D software SolidWorks to establish a geometric model including the main body of the heating furnace, air burners, gas burners, workpieces, and workpiece supports according to the measured dimensions on site. figure 2 shown;

[0032] Step b) Dividing the grid, adopting a combination of structured grid division and unstructured grid division, and performing grid refinement on key parts such as the surroundings of the workpiece and the burner in the furnace, and the structural grid using Gambit The Map method is used for division, and the unstructured grid is divided by TGfid method, and the number of model grids finally obtained is 4,648,860;

[0033] Step c) Select the numerical simulation calculation model, in which the k-ε model is selected for the turbulence calculation model, the Species-Transport combustion model is used for the combustion calculation model, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com