Optimization method for production full process of novel dry-process cement clinker

A dry-process cement and optimization method technology, applied in clinker production, cement production, etc., can solve problems such as unstable quality of clinker f-CaO, complicated relationship, difficulty in further reducing production energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

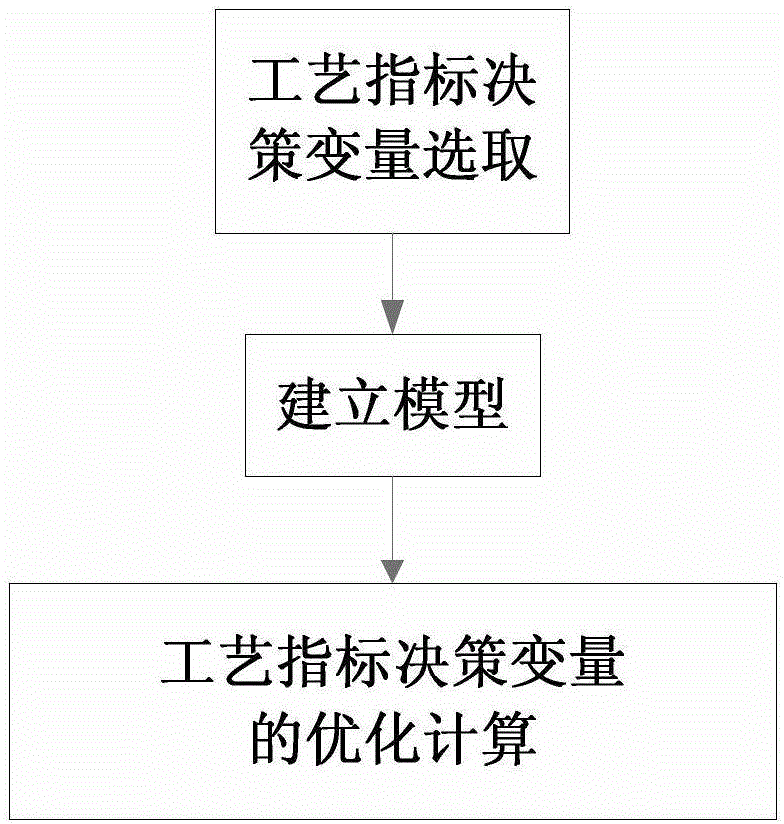

[0063] 1. Selection of process index decision variables:

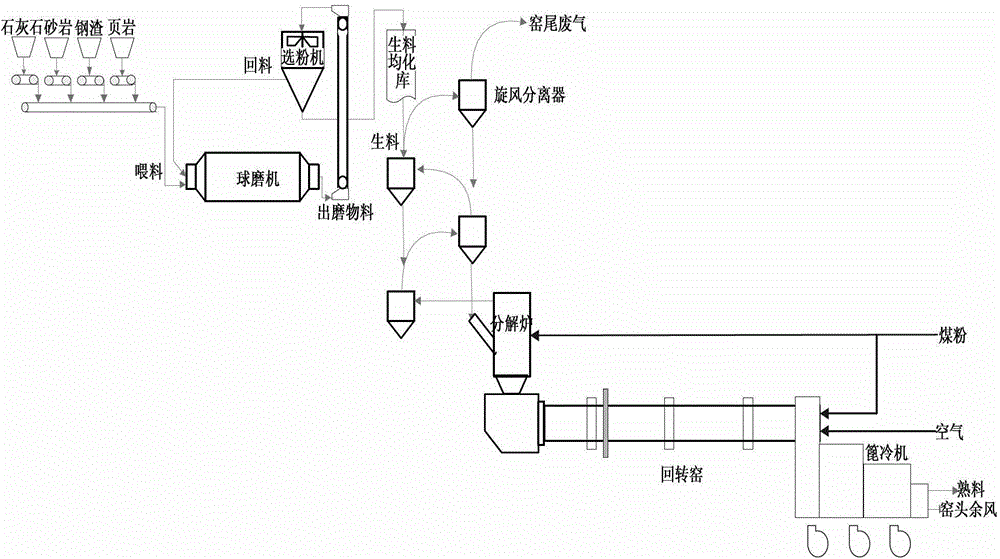

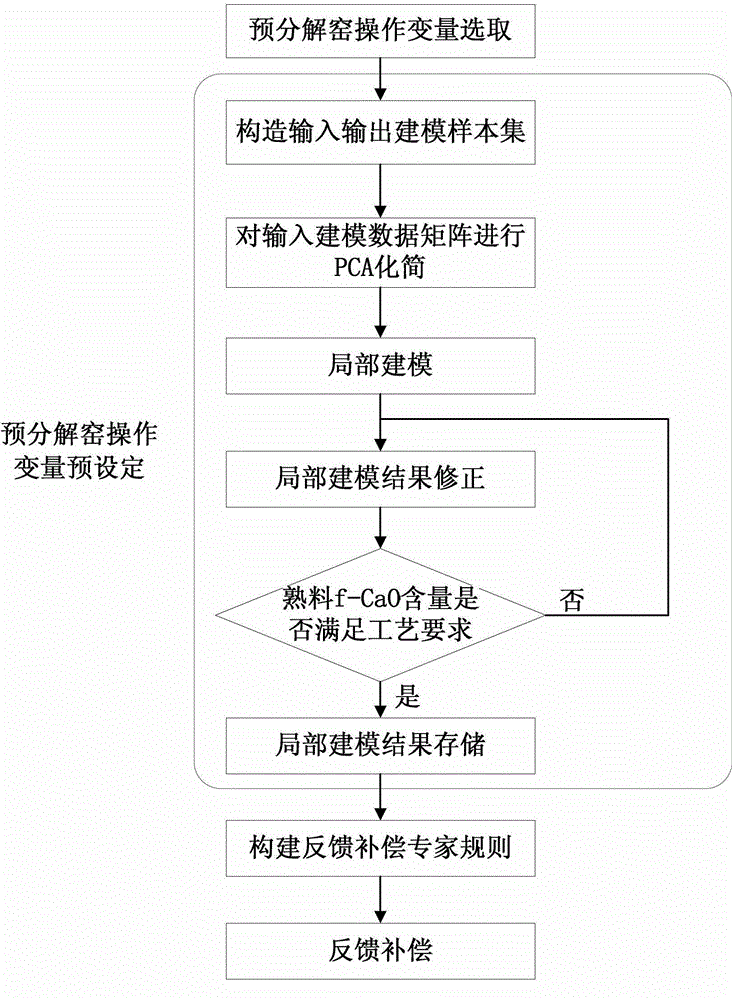

[0064] By analyzing the process and operation of the new dry process cement clinker production process, it is found that in normal production, the variables that have a greater impact on the power consumption of the raw meal mill system are the feeding amount and the raw meal fineness of the raw meal mill. The variable that has a greater influence on the power consumption of the precalcining kiln system is the feeding amount of the precalcining kiln, and the variables that have a greater impact on the coal consumption of the precalcining kiln system are the feeding amount of the precalcining kiln, the third rate value of the raw meal, the fineness of the raw meal, the coal consumption of the precalcining kiln system The pulverized calorific value, pulverized coal ash, clinker third rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com