Resource process for percolation liquid of city life garbage landfill

A technology for municipal solid waste and landfills, applied in incinerators, climate change adaptation, anaerobic digestion, etc., can solve the problems of high retention rate, high concentration, high cost, etc., and achieve no secondary pollution and simple process , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

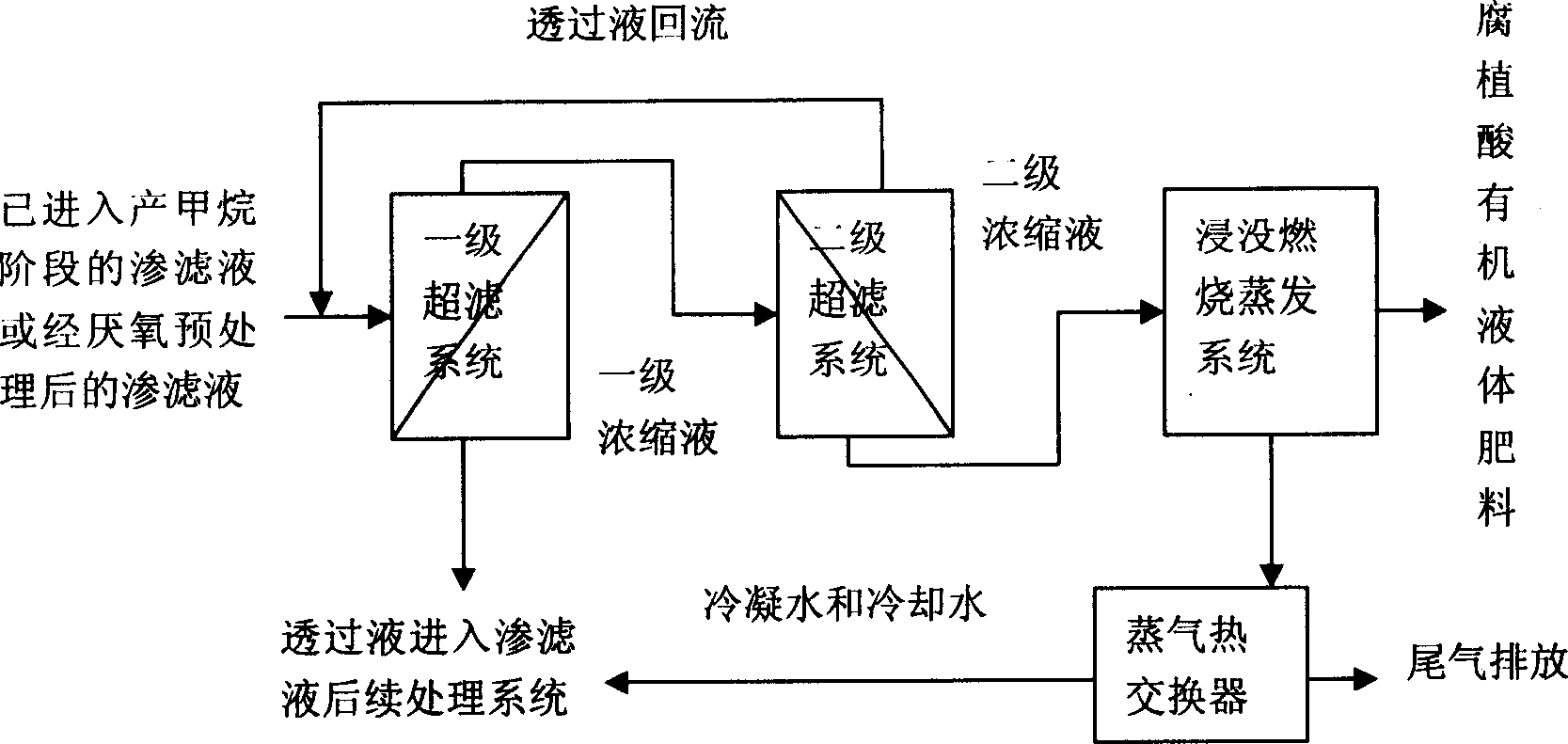

[0014] The leachate recycling process of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown, most of the organic matter contained in the leachate decomposed by the anaerobic bioreactor, or the leachate that has entered the landfill in the methanogenic stage, is relatively stable. This type of leachate is lifted by the pump into the sand filter tank to remove sludge and other particulate matter with a particle size greater than 1 to 10 μm to ensure the good operation of the subsequent ultrafiltration system. The effluent is then pumped into the first-stage ultrafiltration system, and the leachate is divided into two parts under the pressure (operating pressure difference: 0.3-0.5Mpa): one part is the first-class concentrated solution (concentration ratio: 5-10 times) intercepted by the membrane, It is rich in refractory biodegradable organic matter mainly composed of humic acid, and the concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com