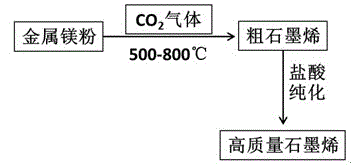

Method using carbon dioxide as raw material to prepare high-quality graphene

A technology of carbon dioxide and graphene, applied in the direction of graphene, nano-carbon, etc., can solve the problems of dry ice storage and use restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] (1) Put metal magnesium powder into a tube-type high-temperature furnace, and heat it up to the combustion temperature of magnesium powder at 600°C under the protection of carbon dioxide with a purity of 99.99% and a flow rate of 75ml / min. When the combustion temperature of magnesium powder reaches 600°C, Increase the flow rate of carbon dioxide to 150 ml / min to meet the combustion demand of magnesium powder, react at high temperature for 30 minutes until the magnesium powder is completely burned, and then under the protection of carbon dioxide, adjust the flow rate of carbon dioxide to 75ml / min and cool down to At room temperature, the black powder collected inside the furnace and at the outlet of the exhaust gas is the coarse graphene powder.

[0012] (2) Pour the coarse graphene powder obtained in step (1) into a hydrochloric acid solution with a concentration of 2mol / L, stir magnetically for 60 minutes to remove unreacted metal magnesium and other soluble impurities,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com