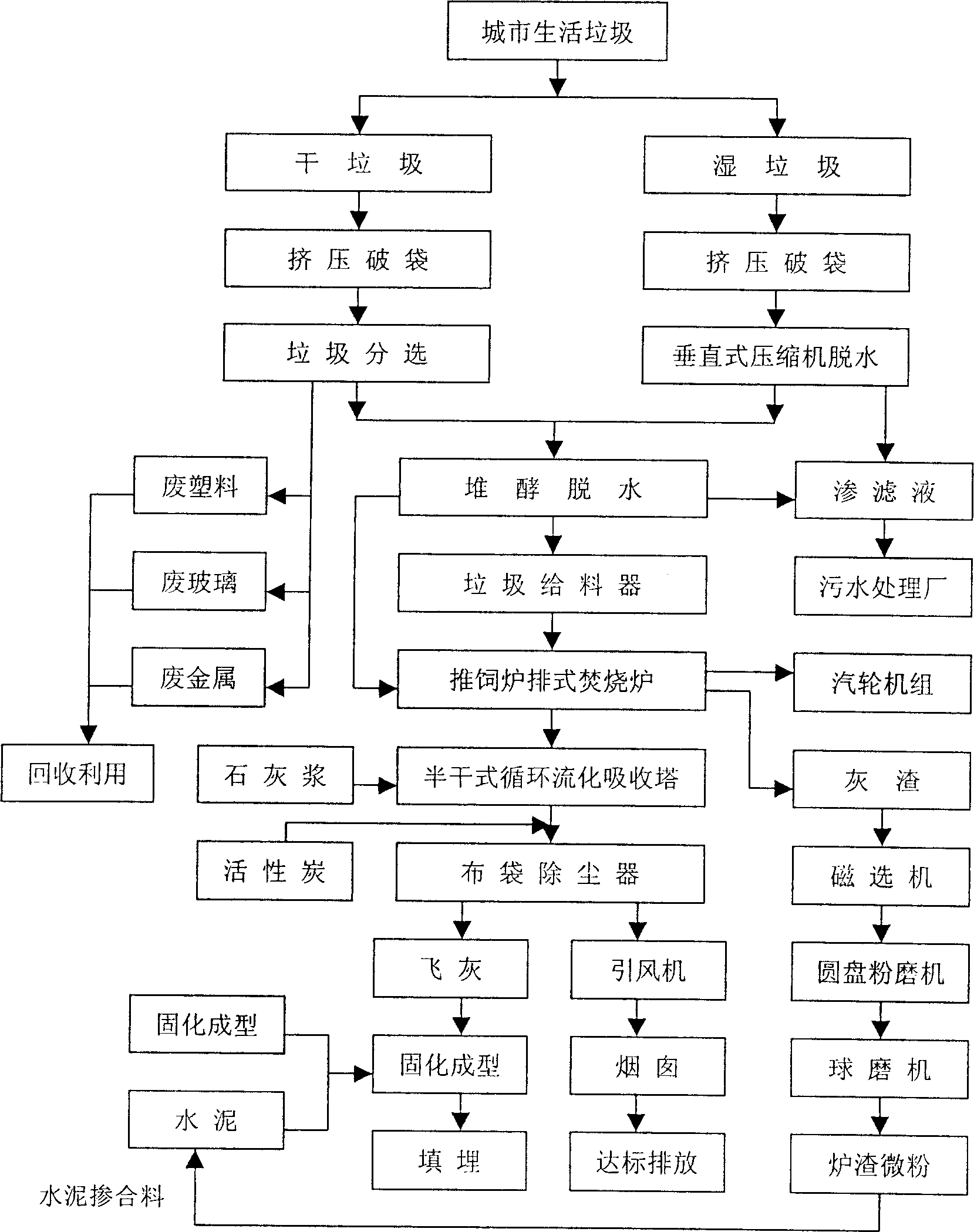

A comprehensive treatment process for urban domestic garbage

A technology for comprehensive treatment of municipal solid waste, applied in the field of waste treatment technology, can solve the problems affecting the incineration temperature, the low calorific value of the waste wet base and the increase of the incineration temperature, and the low calorific value of the waste for recycling and recycling domestic waste. Achieve the effect of shortening the dehydration time of heap fermentation, high mechanical dehydration efficiency and reducing the moisture content of garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Adopt the method of the present invention to test the treatment of municipal solid waste.

[0027] Residents divide domestic garbage at the source into two categories: bagged dry garbage and wet garbage, and use special collection vehicles to classify and collect dry garbage and wet garbage respectively. After bag breaking and compression, the volume of garbage can be increased by 1.5 times, and the effect of garbage volume reduction is remarkable. , Improve the efficiency of garbage collection and transportation. Sorting out waste plastics, waste glass, waste metal, etc. from dry waste for direct recycling. Wet waste is dehydrated by a vertical waste compression machine for 20-30 minutes, which can reduce the moisture content of waste by 12-15%. The garbage is fermented and dehydrated in the storage pit for 36 hours, and the moisture content is further reduced by 3-5%, and the low calorific value of the garbage wet basis reaches 5993kJ / kg. Use the 150t / d scale reverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com