Test device for burning speed/burning temperature of solid propellant and test method thereof

A solid propellant and testing device technology, applied in chemical analysis by combustion, can solve problems such as errors, complex processing of experimental data, uncalculated, etc., and achieve the effect of solving the large proportion of heat loss, accurate measurement and calculation, and reliable data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following examples are a further description of the content of the present invention as an explanation of the technical content of the present invention, but the essential content of the present invention is not limited to the following examples, those of ordinary skill in the art can and should know any Simple changes or replacements of the essential spirit of the invention shall fall within the scope of protection required by the present invention.

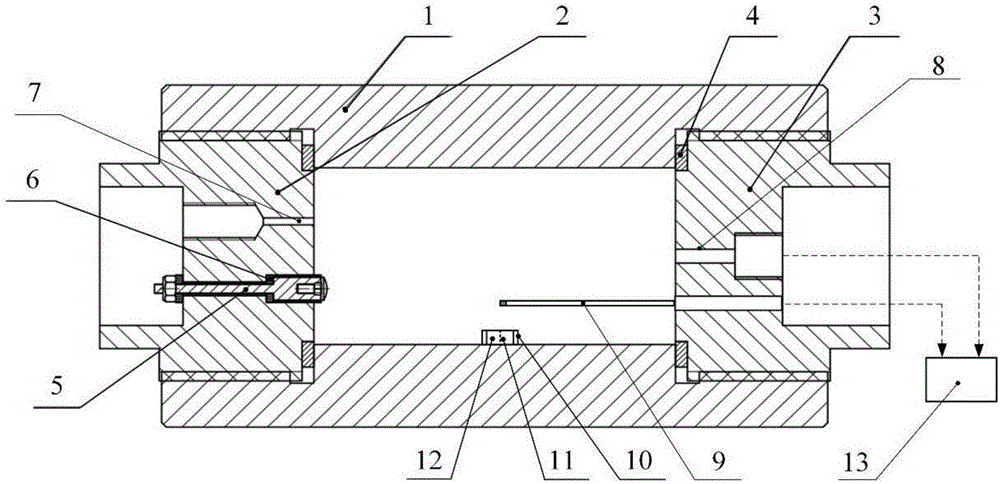

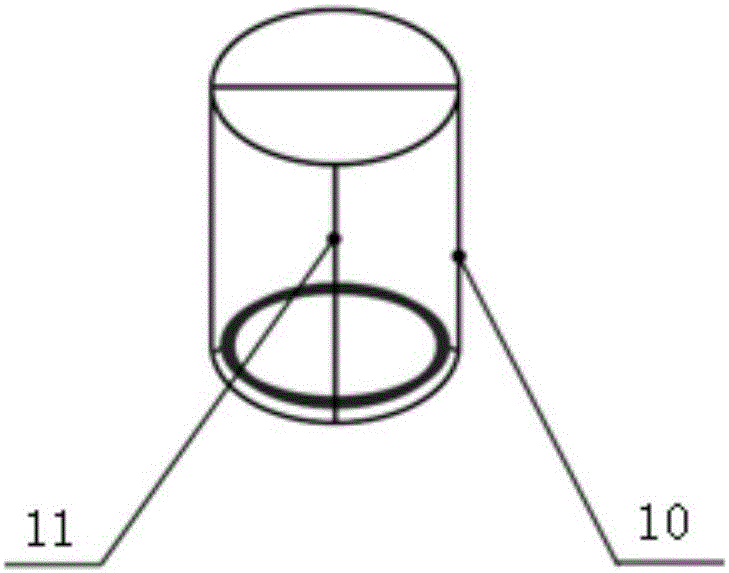

[0043] Such as figure 1 , figure 2As shown, a test device for solid propellant burning rate / burning temperature, comprising a constant volume burner body 1, a plug 2 and a plug 2 3 arranged at both ends of the constant volume burner body 1, The ignition electrode 5 and the pressure relief valve 7 on the head one 2, and the temperature sensor 9 and the pressure sensor 8 arranged on the plug two 3;

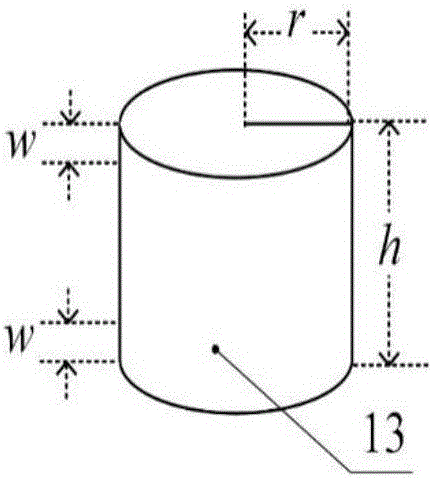

[0044] The constant-volume burner body 1 is a cylindrical chamber structure, which is manufactured by ultra-high press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com