Intelligent integrated optimization method based on mode matching and balance computation

A pattern matching and optimization method technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as difficult to guarantee model accuracy, and achieve the effect of optimal control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

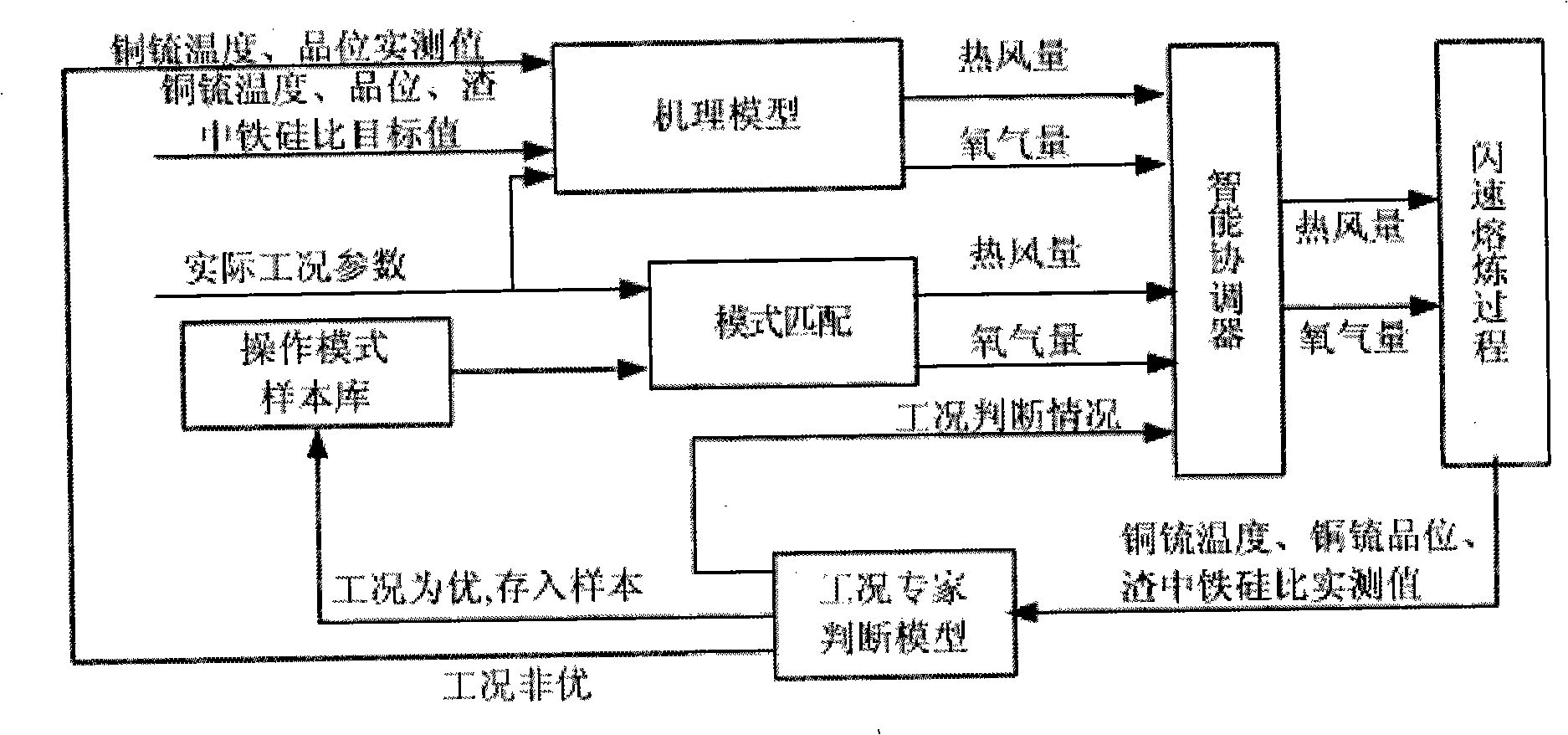

[0013] Firstly, the overall block diagram of the integrated optimization method for process parameters in the flash smelting process is given, as shown in figure 1 shown. According to the general block diagram given, the integrated optimization method is as follows: the integrated optimization method includes balance calculation, optimization sample library, matching algorithm, intelligent coordination and other units. First of all, balance calculation is carried out, that is, according to the current situation of the materials entering the furnace, the required air volume and oxygen volume are calculated by applying the principles of material balance and heat balance. Then compare the current incoming materials with the excellent samples in the optimized sample library, find out 20 excellent samples that best match the current incoming mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com