Flash smelting method and device for zinc sulfide concentrates and materials containing lead and zinc

A flash smelting and materials technology, applied in the field of non-ferrous metal smelting, can solve the problems of long process flow, high production cost, poor comprehensive recovery, etc., and achieve the effects of solving long-term pollution, improving production efficiency, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

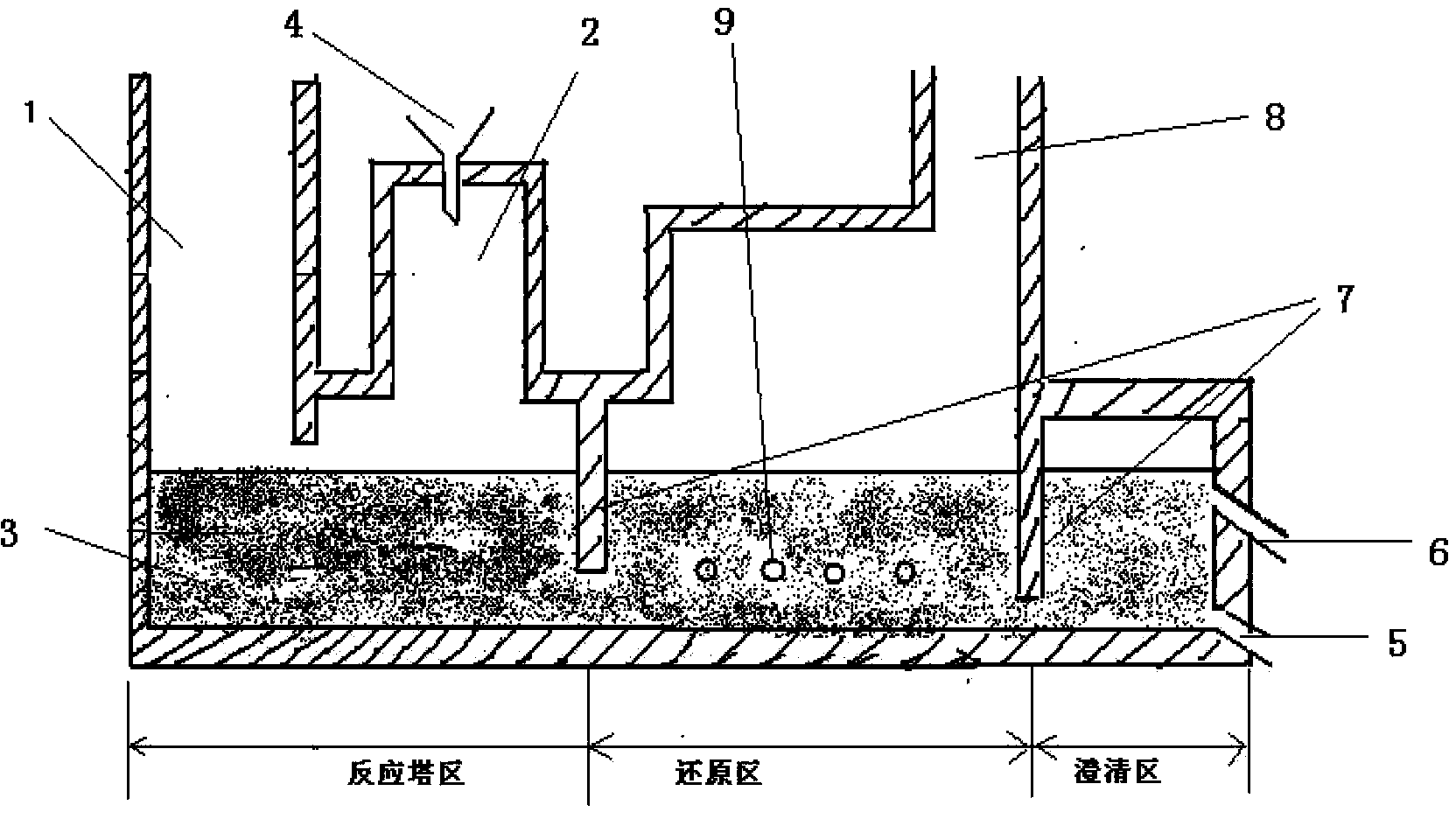

[0057] See attached figure 1 , a flash smelting equipment for zinc sulfide concentrate and lead-zinc-containing materials in the present invention, comprising a smelting furnace body, the bottom of the smelting furnace body is a rectangular space 3 made of refractory materials, and the area of the bottom is 20-120m 2 , the rectangular space 3 is provided with two partition walls 7, and the rectangular space 3 is divided into three areas connected to each other at the bottom, which are respectively the reaction tower area, the reduction area, and the clarification area; in the reaction tower area, along the bottom of the furnace body In the vertical direction, a vertical flue 1 and a reaction tower 2 are arranged successively; in the reduction zone, a zinc steam flue 8 is arranged vertically along the bottom surface of the furnace body, and on the walls on both sides of the furnace body, extension To the nozzle 9 of the inner cavity of the furnace; in the clarification zone, ...

Embodiment 2

[0065] A flash smelting smelting method for zinc sulfide concentrate and lead-zinc-containing materials, comprising the following steps:

[0066] Step 1: Ingredients

[0067] The average particle size of the preparation is ≤0.045mm, calculated by mass percentage, and the composition includes Zn26.73%, lead 18.44%, Fe14.23%, S19.15%, SiO 2 8.42%, CaO2.67%, H 2 O ≤ 0.3%, the mass percent sum of each component is 100% lead-zinc powdery material;

[0068] The second step: oxidative desulfurization

[0069] The lead-zinc-containing material and oxygen obtained in the first step are sprayed from the top of the reaction tower through the feeding spray gun, and the lead-zinc-containing material completes the oxidation desulfurization reaction in the air of the reaction tower, and the generated high-concentration desulfurization flue gas passes through the vertical flue to the waste heat boiler After cooling down and collecting dust, it is sent to the acid production process; the re...

Embodiment 3

[0084] A flash smelting smelting method for zinc sulfide concentrate and lead-zinc-containing materials, comprising the following steps:

[0085] Step 1: Ingredients

[0086] The average particle size of the preparation is ≤0.045mm, calculated by mass percentage, and the composition includes Zn30.16%, lead 12.16%, Fe14.42%, S20.08%, SiO 2 6.92%, CaO1.84%, H 2 O ≤ 0.3%, the mass percent sum of each component is 100% lead-zinc powdery material;

[0087] The second step: oxidative desulfurization

[0088] The lead-zinc-containing material and oxygen obtained in the first step are sprayed from the top of the reaction tower through the feeding spray gun, and the lead-zinc-containing material completes the oxidation desulfurization reaction in the air of the reaction tower, and the generated high-concentration desulfurization flue gas passes through the vertical flue to the waste heat boiler After cooling down and collecting dust, it is sent to the acid production process; the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com