Composition for reducing the oxygen potential of slag

a technology of oxygen potential and slag, which is applied in the direction of furnace details, crucible furnaces, furnaces, etc., can solve the problems of limiting the rate of steel production, affecting the production of ladle slag, and taking a relatively long time to treat the slag. achieve the effect of facilitating the production of the desired ladle slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

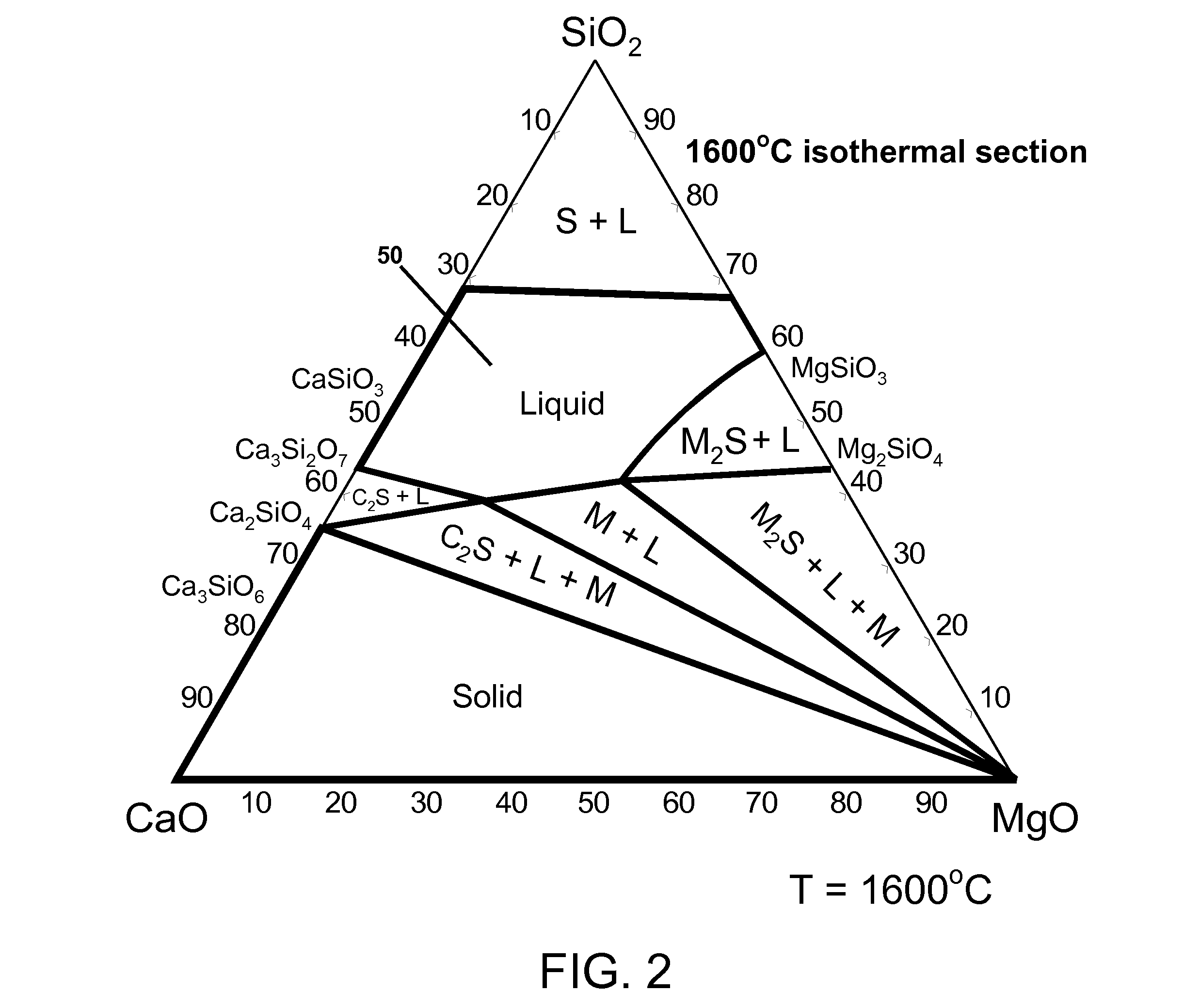

example 1

[0075]Steel was made in an electric arc furnace and tapped into a ladle. The steel making slag within the furnace had an approximate composition of 23% CaO, 30% FeO, 17% MgO, 15% SiO2, 6% MnO, and 7% Al2O3. It was estimated that 122 tons of steel and 2,500 pounds of this slag flowed from the furnace into the ladle during the tapping process. When the ladle was approximately half full, 400 pounds of slag additive reagent was added, with an approximate composition of 47% CaC2, 14% SiC, 23% CaF2, 10% CaO, 3% SiO2, and 2% Al2O3. The reagent had a particle size range of approximately 4 to 15 millimeters. In addition to the reagent, 2,300 pounds of SiMn and 500 pounds of FeSi alloys were added, and 800 pounds of CaO was also added to the ladle. All additions were complete prior to three quarters of the way through the tapping process. During and after tapping, the contents of the ladle were stirred by injecting argon gas through a porous element in the bottom of the ladle. Approximately 8...

example 2

[0076]In the following hypothetical example, steel is made in an electric arc furnace and then tapped into a ladle. During the tapping process, alloys and lime are added to create the desired steel and slag chemistry. After tapping, the ladle is moved to a refining station where it is heated and further refined. Upon analysis, the slag on the ladle may be found to contain 6% FeO and 2% MnO. These levels of the reducible oxides are too high for effective refining of the steel and it is desired to lower them to a maximum of 2% FeO and 0.5% MnO. A reducing agent comprised of a mixture of 75% commercial grade calcium carbide and 25% commercial grade silicon carbide with average particle size of ⅜ inch is used to adjust the slag. The reagent has approximately 60% CaC2 and 23.5% SiC, with a ratio of 2.55 CaC2 to SiC. It is calculated that about 450 pounds of FeO and MnO will need to be reduced to create a desirable slag chemistry. Based on stoichiometry and reagent efficiency, it is furth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com