Coke powder pretreatment process for sintering and iron ore sintering process and system

A technology for pretreatment and coke powder is applied in the field of new sintering process and system, coke powder pretreatment process, and new sintering process and system using pretreated coke powder, which can solve the problem of high investment cost, low investment cost and increased investment cost. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

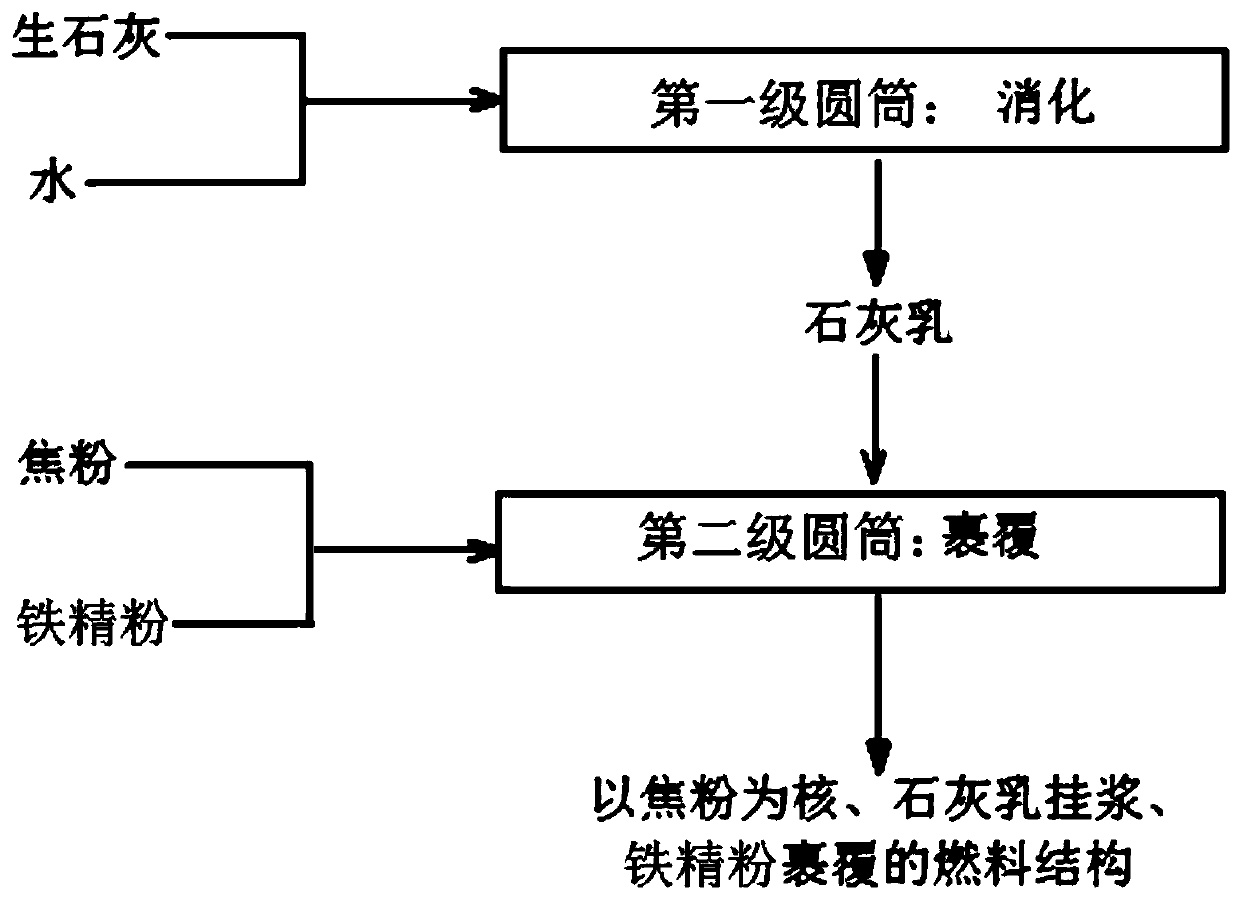

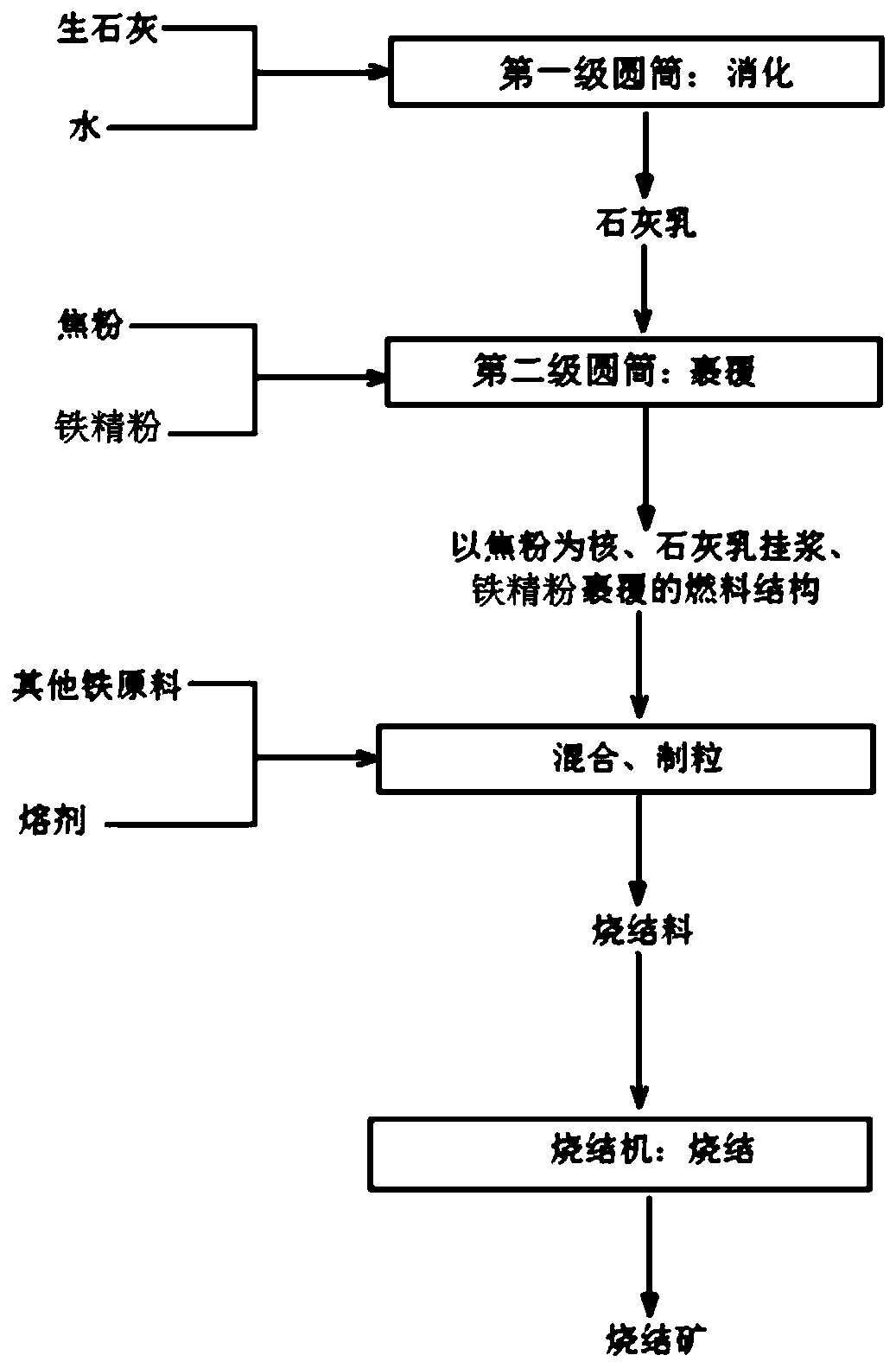

[0096] Such as figure 1 As shown, a pretreatment process for coke powder for sintering includes the following steps:

[0097] 1) Transport the quicklime to the first-stage cylinder 1, and spray water into the first-stage cylinder 1. The quicklime is digested in the first-stage cylinder 1 to obtain lime milk;

[0098] 2) The lime milk obtained in step 1) is transported to the second-stage cylinder 2, while the coke powder and iron concentrate are transported to the second-stage cylinder 2. The lime milk, coke powder, and iron concentrate pass through the second stage cylinder 2. It is mixed in the stage cylinder 2 to form a fuel structure with coke powder as the core, lime milk slurry, and iron fine powder coating.

[0099] Among them: in step 1): the weight ratio of quicklime to water is 1:1.5; in step 2): the weight ratio of lime milk and iron powder is 1:0.5, the weight sum of the mixture of iron powder and lime milk and coke The ratio of powder mass is 1:1.

[0100] In step 1): th...

Embodiment 2

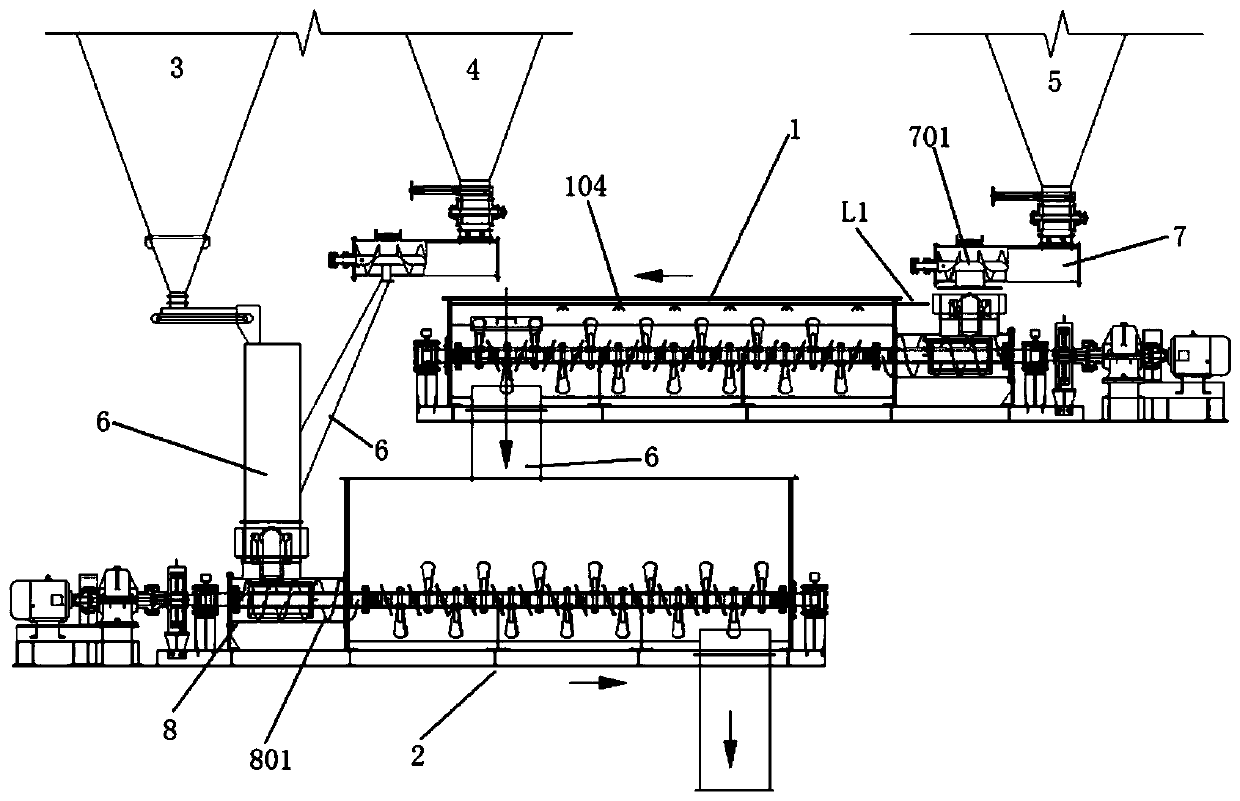

[0102] Example 1 is repeated, except that the first rotating shaft 101 is provided in the first-stage cylinder 1. Blades are provided on the first rotating shaft 101. The first rotating shaft 101 rotates in a clockwise direction. The quicklime and water are stirred and mixed by the blade on the first rotating shaft 101. The quicklime and water are digested and mixed in the first-stage cylinder 1 while being transported to the direction of the discharge port of the first-stage cylinder 1.

[0103] In step 2), the second-stage cylinder 2 is set directly below the first-stage cylinder 1. The conveying direction of the first-stage cylinder 1 is opposite to the conveying direction of the second-stage cylinder 2. The lime milk obtained through the digestion of the first stage cylinder 1 enters the second stage cylinder 2. A second rotating shaft 201 is provided in the second-stage cylinder 2. Blades are provided on the second rotating shaft 201. The second rotating shaft 201 rota...

Embodiment 3

[0105] Repeat Embodiment 2 except that the second rotating shaft 201 is eccentrically arranged. The cylinder 202 of the second-stage cylinder 2 has a rotating structure. The rotation direction of the second-stage cylinder 2 is opposite to the direction of the second rotation shaft 201. The milk of lime, coke powder, and fine iron powder are subjected to the shearing force of the barrel 202 of the second-stage cylinder and the second rotating shaft 201 in the opposite direction in the second-stage cylinder 2, forming convection, mixing, and mixing the iron fine powder And lime milk wrapped on the surface of coke powder. The ratio of the rotation speed of the second rotating shaft 201 to the rotation speed of the cylinder 202 is 9:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com