Method for improving performance of high titanium slag

A technology with high titanium slag and performance, applied in the field of titanium slag control in the smelting process, can solve problems such as difficult application and corrosion of blast furnace equipment, and achieve the effects of increased metal yield, stable furnace conditions, and improved technical and economic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

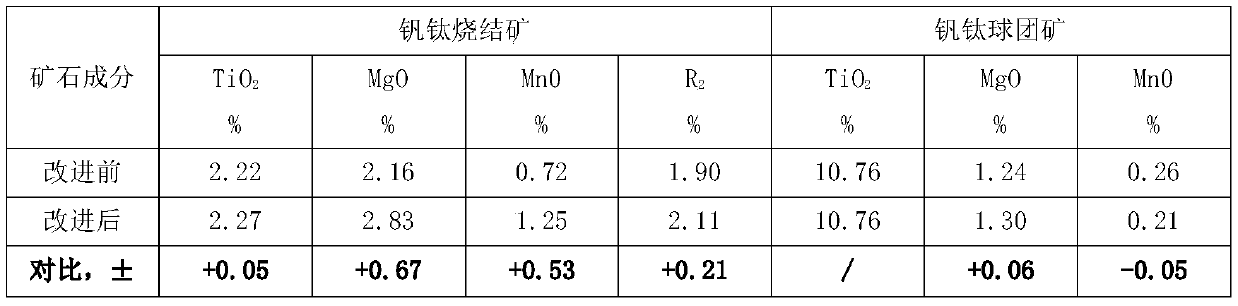

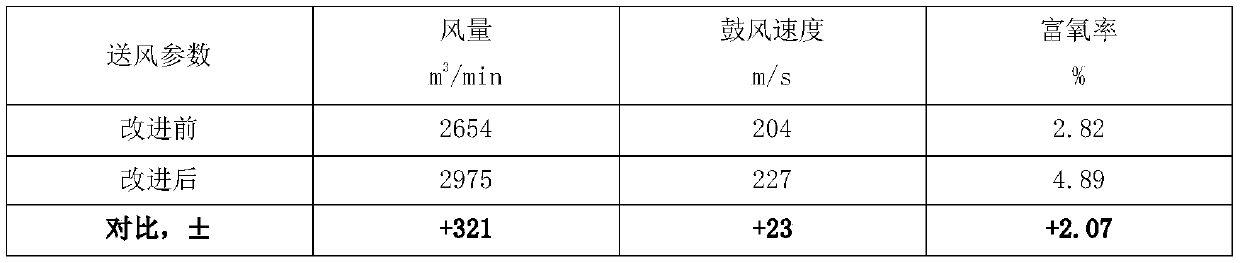

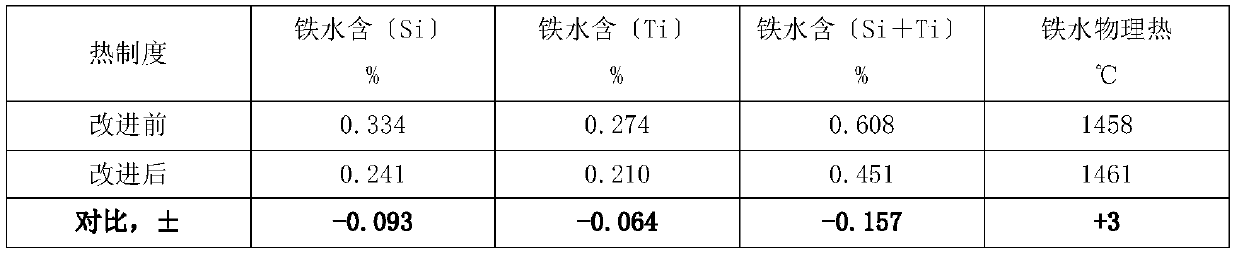

[0028] Using the production data of 1080m3 blast furnace high titanium slag smelting slag in a steel plant for two months before and after the performance improvement, the implementation effect is compared and explained. Under the condition that the integrated furnace grade is basically the same, after the performance of high titanium slag is improved: ①The viscosity of the slag decreases , the metal yield is increased; ②The gas permeability of the blast furnace material column is improved, the number of sliding materials is greatly reduced, and the furnace condition is improved; ③The effective volume utilization coefficient is increased, and the ton iron ore consumption, coke ratio, and fuel ratio are reduced.

[0029] The implementation effect of a method for improving the performance of high-titanium slag is shown in the table

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com