A method for improving low-temperature dispersibility of biomass fuel soot particles

A technology of biomass fuel oil and soot particles, which is applied in the direction of fuel, petroleum industry, fuel additives, etc., can solve problems such as oil thickening, and achieve the effect of improving low temperature dispersion and solving the problem of oil thickening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

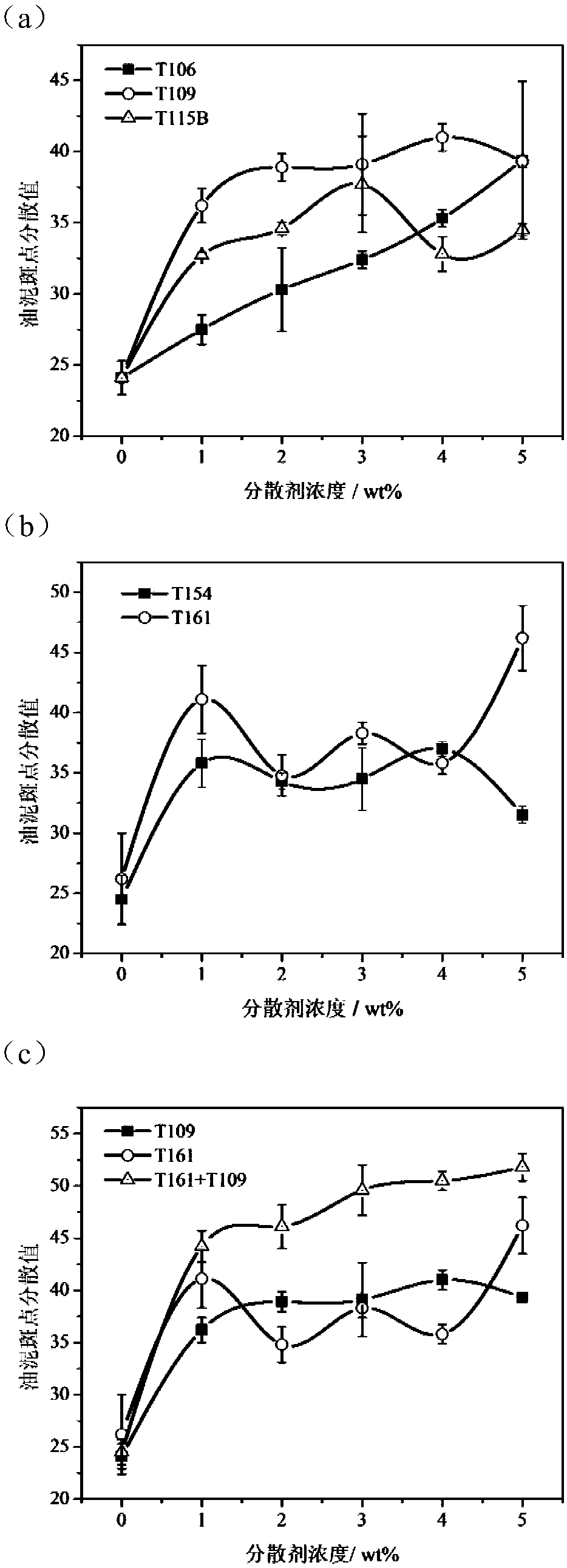

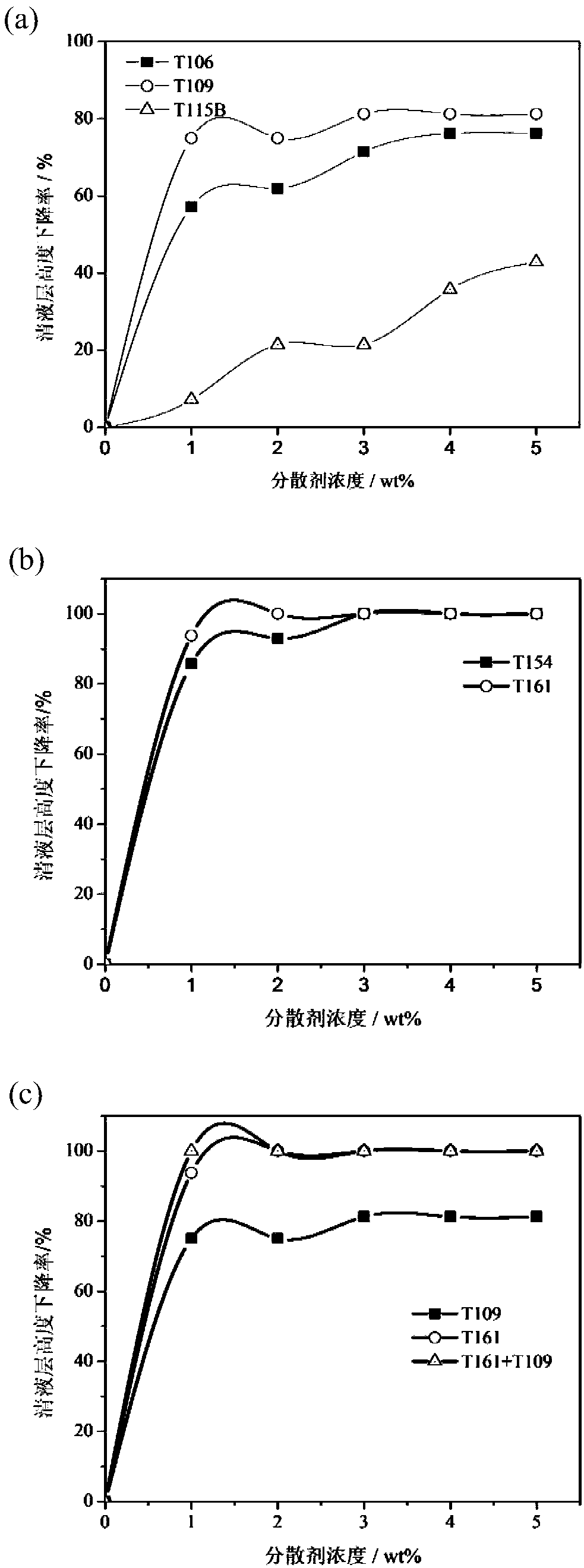

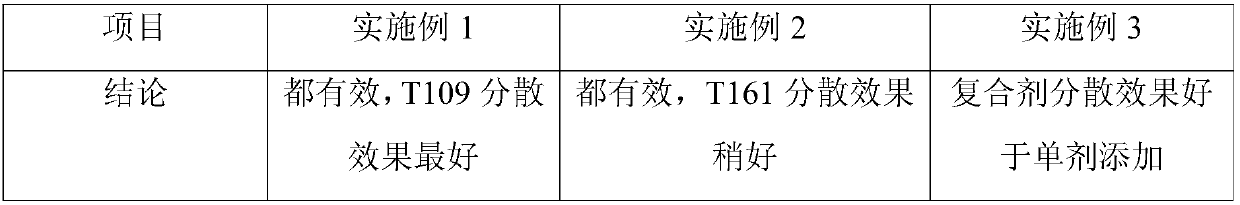

Embodiment 1

[0019] Preparation containing biomass fuel soot particle concentration 2.0wt%, calcium salt cleansing and dispersing agent T106, T109, T115B mass concentration are respectively 0, 1%, 2%, 3%, 4%, 5% liquid paraffin (lubricating oil base Oil simulant) oil sample, after fully mechanically stirred, ultrasonically dispersed at 45kHz, 300W for 10min, and then magnetically stirred at 20°C for 24h to make the system dispersion and adsorption reach equilibrium, and the soot was evenly dispersed, ready for use.

Embodiment 2

[0021] Preparation containing biomass fuel soot particle concentration 2.0wt%, amine ashless dispersant T154, T161 mass concentration are 0,1%, 2%, 3%, 4%, 5% liquid paraffin (lubricating oil base oil simulant ) oil sample, after fully mechanically stirring, ultrasonically disperse at 45kHz, 300W for 10min, then magnetically stir at 20°C for 24h to make the dispersion and adsorption of the system reach equilibrium, and the soot is evenly dispersed, ready for use.

Embodiment 3

[0023] Prepare biomass-containing fuel soot particle concentration of 2.0wt%, and composite detergent and dispersant T161+T109 (T161 and T109 in a mass ratio of 1:1) with a total mass concentration of 0, 1%, 2%, 3%, and 4% , 5% liquid paraffin (lubricating oil base oil simulant) oil sample, after fully mechanical stirring, ultrasonically disperse at 45kHz, 300W for 10min, and then magnetically stir at 20°C for 24h to make the system dispersion and adsorption reach equilibrium, and the soot is evenly dispersed ,stand-by.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com