Method, device and system for controlling furnace conditions of convertor steelmaking

A converter steelmaking and converter technology, which is applied in the manufacture of converters, etc., can solve problems such as poor control effects, and achieve the effects of overcoming poor stability, improving stability, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

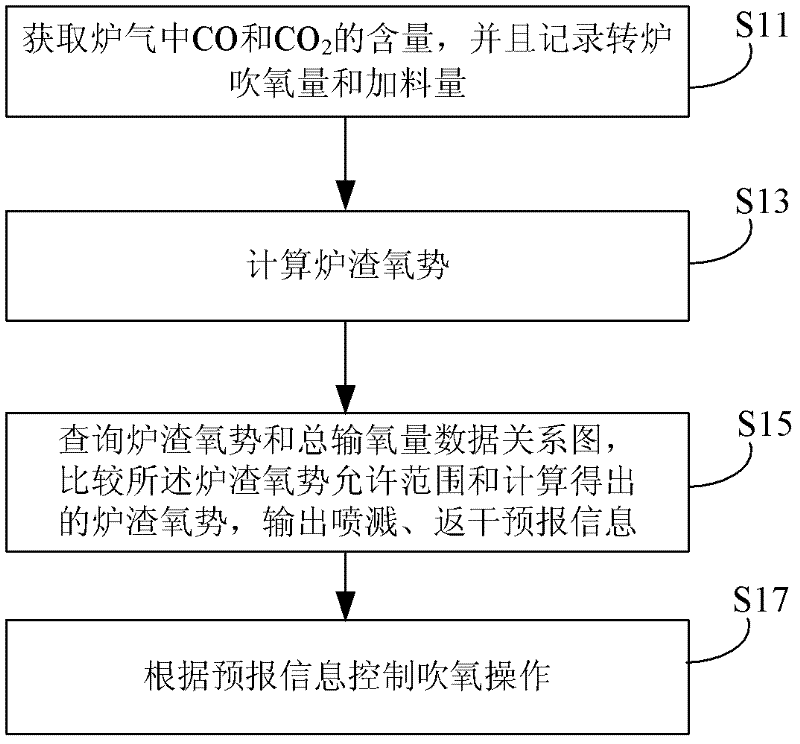

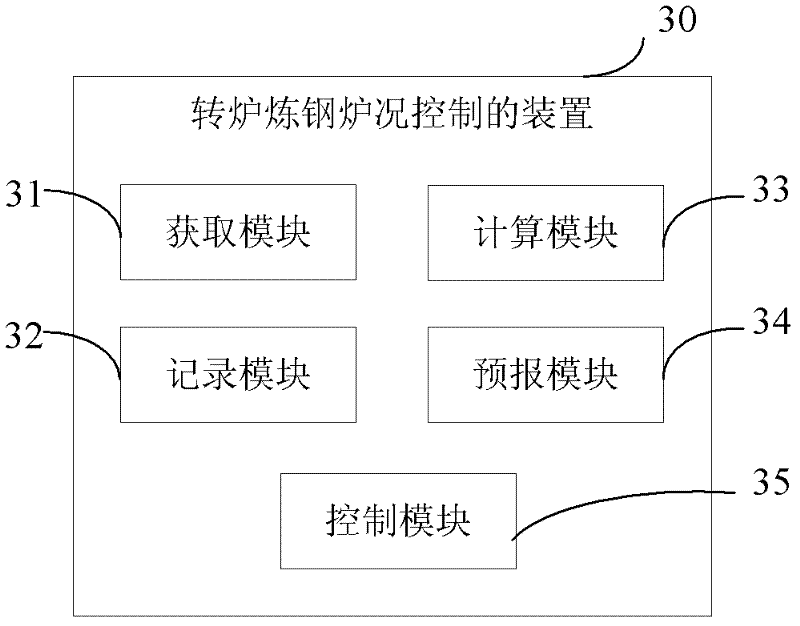

[0034] figure 1 is a schematic diagram of a converter steelmaking furnace condition control method according to an embodiment of the present invention, such as figure 1 As shown, the method mainly includes the following steps:

[0035] Step S11, obtaining CO and CO in the furnace gas composition 2 Wait for the gas content, and record the oxygen blowing amount and feeding amount of the converter;

[0036] Step S13, according to CO and CO 2 Calculate the oxygen potential of the slag based on the content of the gas, the amount of oxygen blown into the converter, and the amount of feed;

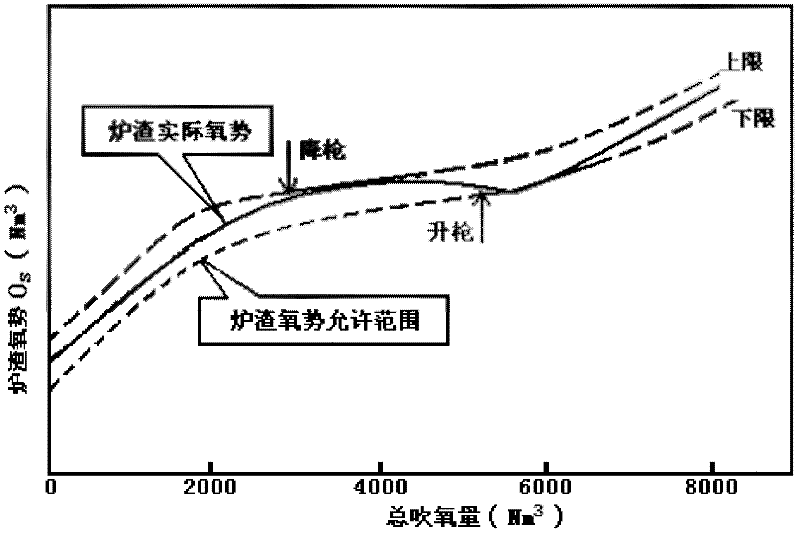

[0037]Step S15, querying the allowable range of the slag oxygen potential from the data relationship graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com