Method for producing high-grade niobium concentrate from niobium rough concentrate

A technology of rough concentrate and niobium concentrate, which is applied in the field of niobium resource utilization, can solve the problems of low grade, difficulty in high-efficiency enrichment of niobium ore phases, and failure to meet the production standards of high-grade ferroniobium, so as to achieve simple process steps and realize comprehensive Useful and operable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for producing high-grade niobium concentrate from niobium rough concentrate, comprising the steps of:

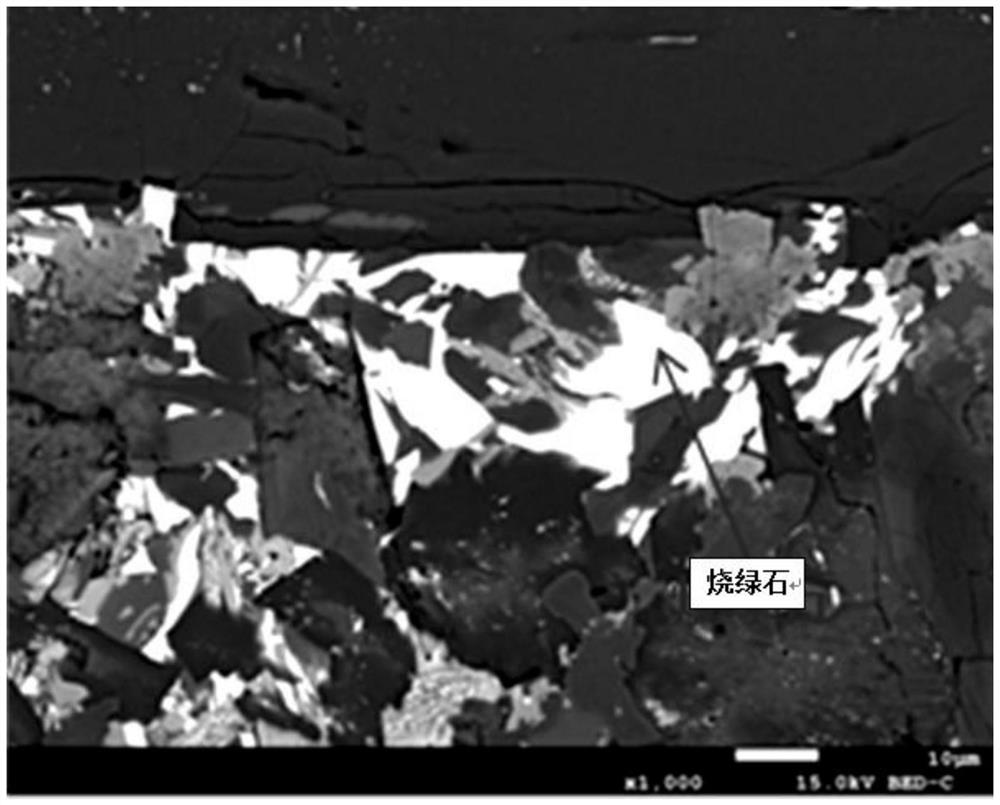

[0035] (1) Coarse niobium concentrate (Nb 2 o 5 Content is 3.52%, TiO 2 content 4.29%, rare earth oxide REO content 1.50%, total Fe content 14.03%, CaO content 14.03%, SiO 2 Content 12.75%, MgO content 10.05%, Al 2 o 3 Content 1.87%, niobium mainly exists in niobite, niobium-iron rutile, calcite form), slagging agent (this embodiment selects limestone for use), reducing agent (this embodiment selects coke for use, and its C content 84%) presses 100:30:5 mass ratio for mixing ingredients;

[0036] (2) Put the ingredients obtained in step (1) into the electric furnace for smelting, and smelt to produce iron-containing alloys, slag and flue gas; control the smelting temperature to 1500 ° C, and smelting time for 30 minutes; by controlling the ingredients in the step (1), and Monitor the recovery rate of Fe in the ferrous alloy produced by smelting to adjus...

Embodiment 2

[0042] A method for producing high-grade niobium concentrate from niobium rough concentrate, comprising the steps of:

[0043] (1) Coarse niobium concentrate (Nb 2 o 5 Content is 2.37%, TiO 2 content 4.13%, rare earth oxide REO content 3.32%, total Fe content 16.75%, CaO content 18.94%, SiO 2 content 11.23%, MgO content 11.50%, Al 2 o 3 Content 2.34%, niobium mainly exists in the form of niobite, niobium-iron rutile, calcite, niobium calcium ore), slagging agent (this embodiment selects limestone for use), reducing agent (this embodiment selects coke for use, and its carbon content 87%) carry out mixing batching by the mass ratio of 100:20:15;

[0044] (2) Put the ingredients obtained in step (1) into the converter for smelting, supply air, pure oxygen or oxygen-enriched air during smelting, and smelt to produce iron-containing alloys, slag and flue gas; control the smelting temperature to 1400°C, and the smelting time to 60 minutes; By controlling the batching compositi...

Embodiment 3

[0050] A method for producing high-grade niobium concentrate from niobium rough concentrate, comprising the steps of:

[0051] (1) Coarse niobium concentrate (Nb 2 o 5 The content is 6.31%, TiO 2 content 3.61%, rare earth oxide REO content 2.5%, total Fe content 24.03%, CaO content 4.03%, SiO 2 Content 21.87%, MgO content 1.05%, Al 2 o 3 Content 0.26%, niobium mainly exists in niobite, ferroniobium rutile, calcite form), slagging agent (this embodiment selects limestone), reducing agent (this embodiment selects coal and petroleum coke, and its average carbon content is 89 %) mix the ingredients according to the mass ratio of 100:5:20; then add binders (such as sodium humate, water glass, etc.) to the ingredients to carry out pelletizing and granulation treatment;

[0052] (2) Put the ingredients obtained in step (1) into the shaft furnace for smelting, supply air, pure oxygen or oxygen-enriched air during smelting, and smelt to produce iron-containing alloys, slag and flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com