Method for improving performance of furnace slag obtained by smelting vanadic titanomagnetite in blast furnace

A vanadium-titanium magnetite and blast furnace smelting technology, which is applied in the field of improving the performance of high-titanium blast furnace slag in the blast furnace smelting of vanadium-titanium magnetite, and can solve problems such as increased viscosity of slag, poor performance of slag, and difficulties in blast furnace smelting. Achieve the effects of lowering the melting point, reducing the viscosity, and improving the performance of high-titanium slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

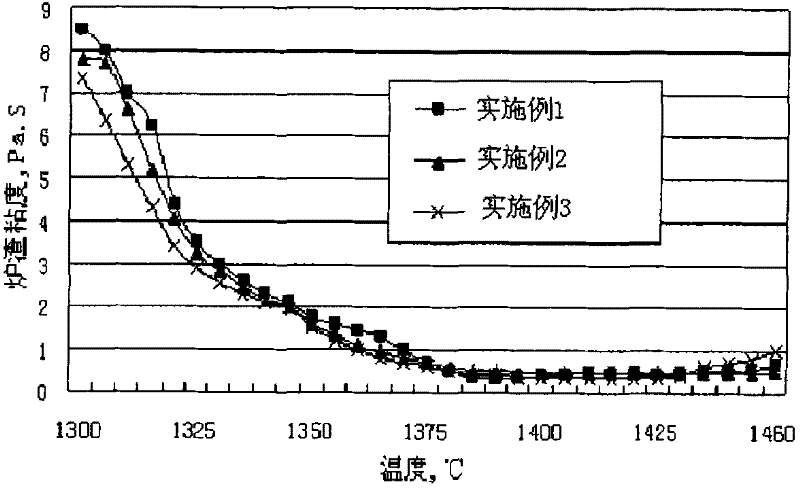

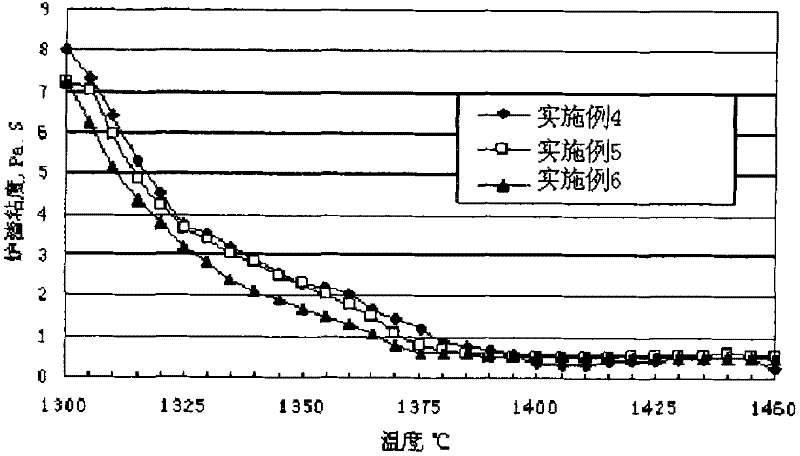

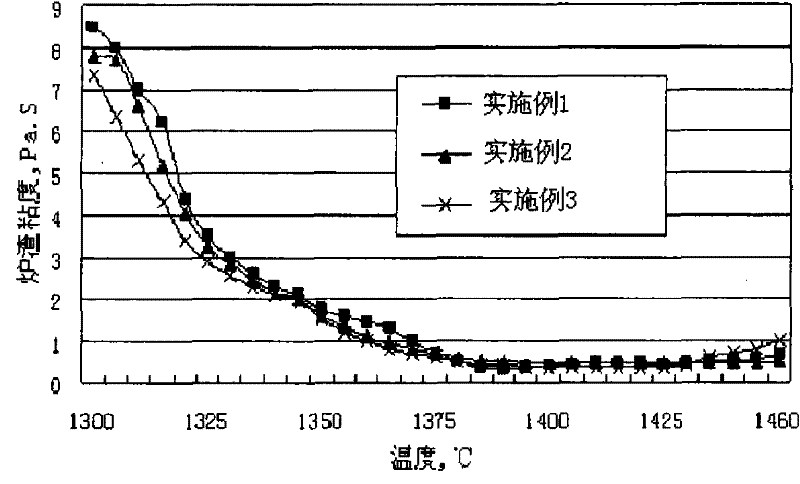

Examples

preparation example Construction

[0017] The preparation method of described vanadium-titanium sintered ore can be carried out according to the conventional preparation method in this field, for example, according to the proportion described in the present invention, vanadium-titanium iron concentrate and common iron concentrate and fuel (charcoal, coke powder) and flux ( quicklime and / or limestone) and sintered. Wherein, the dosage of vanadium-titanium iron concentrate and ordinary iron concentrate can be the conventional dosage of vanadium-titanium-iron concentrate in the preparation of sintered ore in this field. 50-55% of the total weight, and the amount of ordinary iron ore concentrate is 25-30% by weight of the total weight of raw materials used to form vanadium-titanium sintered ore. The commonly used sintering method is to carry out sintering on a belt sintering machine. For example, the mixed iron concentrate and flux are added to the trolley through the distributor, and the sintering is carried out b...

Embodiment 1

[0037] This embodiment is used to illustrate the method for blast furnace smelting of the present invention.

[0038] Preparation of vanadium-titanium sintered ore: 52 parts by weight of vanadium-titanium iron ore concentrate, 28 parts by weight of ordinary iron ore concentrate, 52 parts by weight of coke powder and 15 parts by weight of limestone are distributed on the magnetic roller distributor and added to the table Car, and then sintered at 1350°C for 30min to obtain vanadium-titanium sintered ore. The sintering machine speed of the obtained vanadium-titanium sintered ore is 1.71m / min, the vertical sintering speed is 21.60mm / min, and the drum strength (according to the ISO defined in GB13242 Drum strength refers to taking 7.5 kg of 40-10mm sinter and turning it in the ISO drum machine (SQZG--4 type; Hebi Metallurgical Machinery Equipment Co., Ltd.) for 200 revolutions. The percentage by weight is an important index to measure the strength of sintered ore, the higher it is...

Embodiment 2

[0045] This embodiment is used to illustrate the method for blast furnace smelting of the present invention.

[0046] The sintered ore was prepared according to the method of Example 1, except that the amount of each substance was: 45 parts by weight of vanadium-titanium iron concentrate, 35 parts by weight of ordinary iron concentrate, 6 parts by weight of coke powder and 14 parts by weight of limestone.

[0047] Vanadium-titanium pellets were prepared according to the method of Example 1, the difference being that the amount of vanadium-titanium iron concentrate was 90 parts by weight, and the amount of ordinary iron concentrate was 10 parts by weight. The compressive strength of the pellets is 2350N / piece.

[0048] Blast furnace smelting: vanadium-titanium magnetite and 5 parts by weight of lean manganese ore (MnO content is 3 % by weight, TFe content is 50% by weight) into the blast furnace for blast furnace smelting. TiO in the obtained slag was determined 2 The conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com