Soft magnetic powder for compact powder body and compact powder body using the same

A soft magnetic and compressed powder technology, which is applied in the fields of inorganic material magnetism, inductor/transformer/magnet manufacturing, transportation and packaging, etc., can solve the problems of difficult growth characteristics of precipitates and difficulty in reducing the adverse effects of O

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] In this example, the storage properties of water atomized powders produced by adding Nb, Ta, Ti, Zr, or V to several types of pure Fe were investigated.

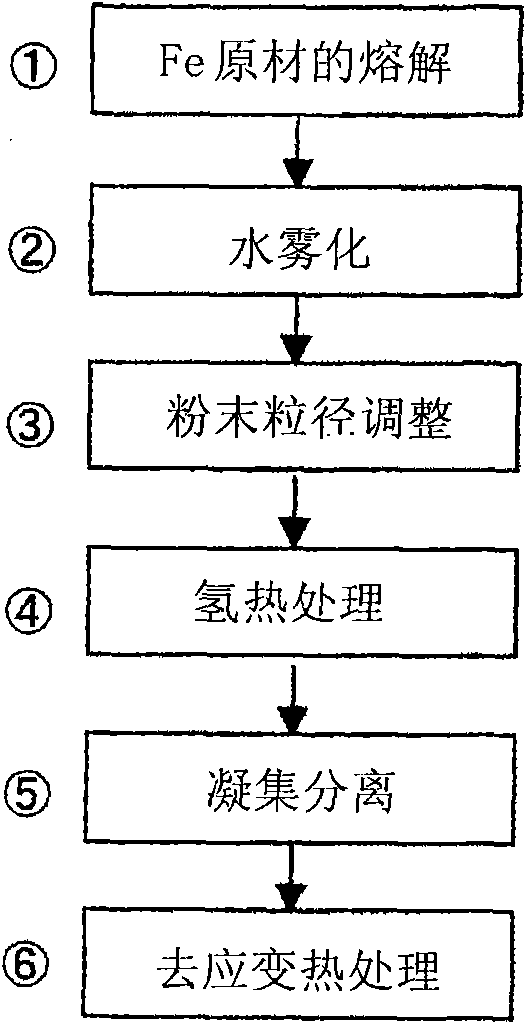

[0070] figure 1 Shows the manufacturing process of water atomized Fe powder. Pure Fe is selected so that it has a predetermined chemical composition, additive elements are prepared, these raw materials are melted, molten Fe is pulverized and rapidly solidified using high-pressure water, and Fe is pulverized (steps 1 and 2). Fe powder coated with an oxide film on the surface was sieved to have an average particle size of 100 μm, and the sieved powder was heat-treated at 950°C ± 4°C for 1 hour in an atmosphere of circulating dry hydrogen in order to reduce gas impurities (steps 3 and 4 ). Since the aggregation of some of the powders proceeds during the heat treatment, in order to disperse the individual powders, it is necessary to mechanically pulverize them while taking into account that strain is not applied as much...

Embodiment 2

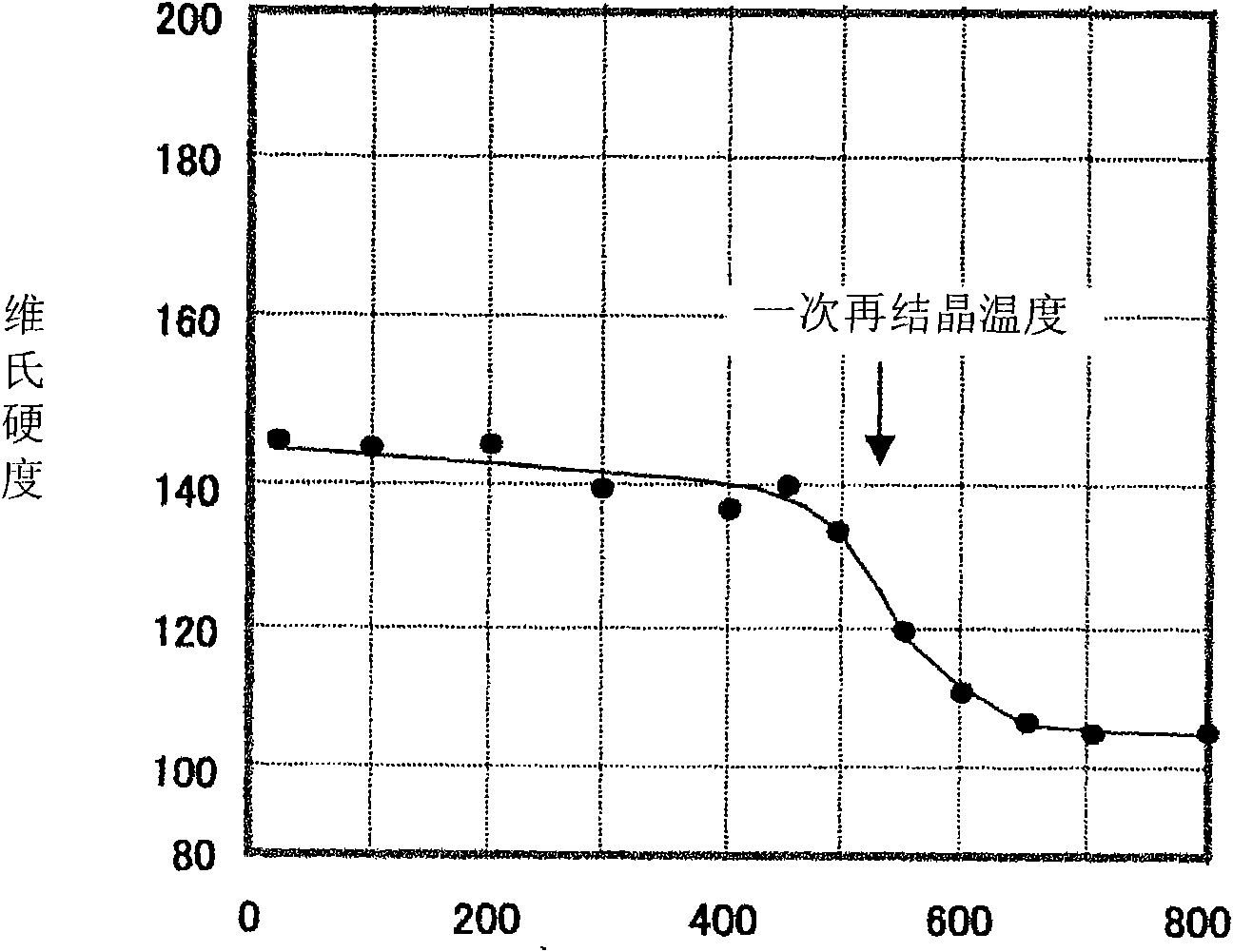

[0092] The magnetic properties of the dust core as the water atomized powder of the present invention were confirmed. The hydrogen heat-treated powder with a particle diameter of 30 μm to 200 μm centered at 100 μm is immersed in a phosphate aqueous solution to form iron phosphate glass on the surface. Next, a lubricant was added to the insulating-coated Fe powder and press-molded at a pressure of 980 MPa to produce a dust magnet. The shape of the molded body was a ring shape with an outer shape of 25 mm, an inner diameter of 15 mm, and a thickness of 5 mm. The heat-resistant temperature of iron phosphate glass is 550°C at most, so the molded body was heat-treated at 530°C for 60 minutes in a nitrogen atmosphere.

[0093] Magnetic properties were evaluated by coercive force. Table 2 shows the results of the coercive force of the insulating-coated powder compacts. The coercivity values of comparative materials No. 1, 2, and 3 that do not contain Nb, Ta, Ti, Zr, or V exceed ...

Embodiment 3

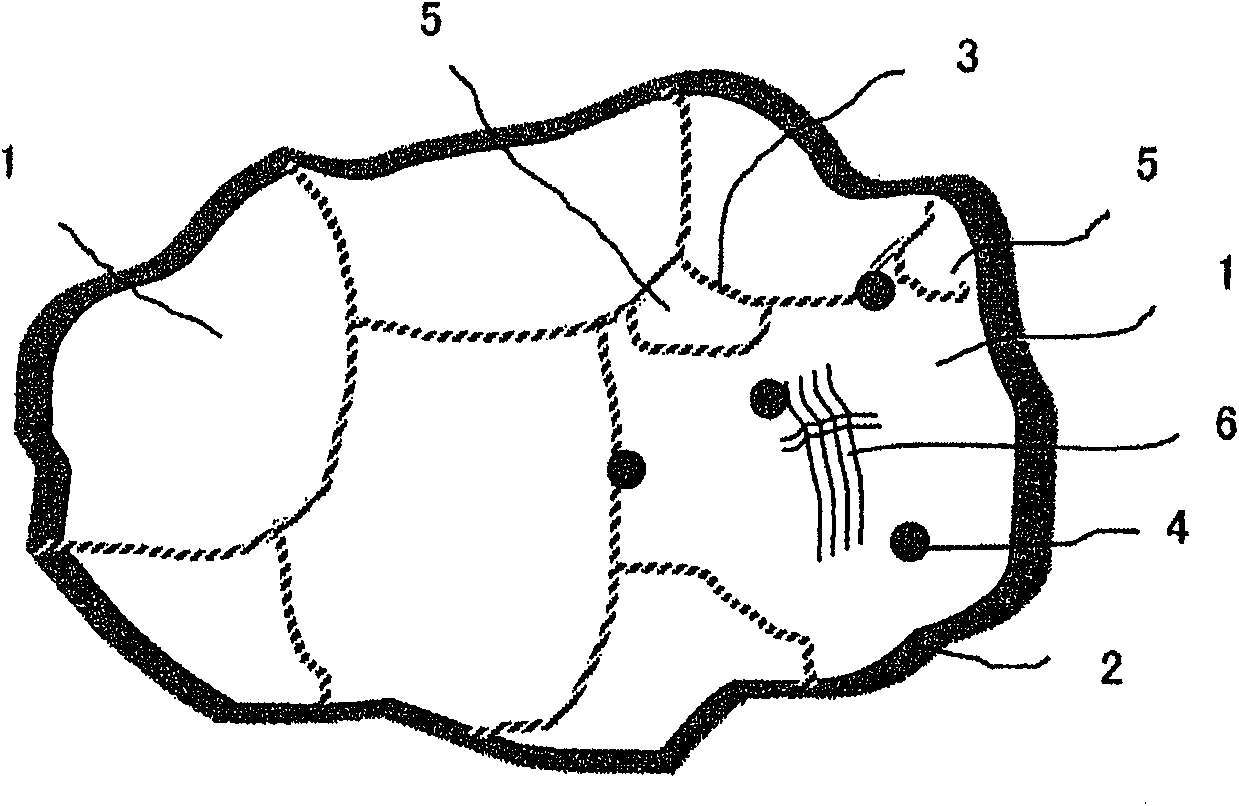

[0097] In the same manner as in Example 2, development materials No. 5, No. 12, No. 15, and No. 21 were surface-insulated and lubricated, and a three-dimensional dust core was molded as a magnetic core for a motor. Figure 5 This is an overview of the dust core, with an outer diameter of 90 mm and a height of 10 mm. The forming pressure is 980MPa. The flange portion 7 and the claw portion 8 of several development materials were cut out, and the density thereof was measured by the Archimedes method. The densities of the claw portions of No.5, No.12, No.15, and No.21 were 7.55, 7.54, 7.56, and 7.56, respectively. The flange portion including the outer periphery and the flat portion is lower than the claw portion by 0.01 to 0.03.

[0098] Although the two-dimensional and three-dimensional shapes are different from those of Example 2, high molding density was confirmed also by three-dimensional metal mold molding. Therefore, it is considered that the same thermal and magnetic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com