Manufacturing equipment for five-layer melt co-extruded fiber reinforced plastic sheet and its application method

A fiber reinforced plastic, melt co-extrusion technology, used in other household appliances, applications, flat products, etc., can solve the problems of sheet bending, warping, shrinkage, elongation, insufficient tensile strength, low elastic modulus, etc. Achieve the effect of excellent comprehensive mechanical properties of cross-sectional structure, reasonable product structure design, and effective material structure enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

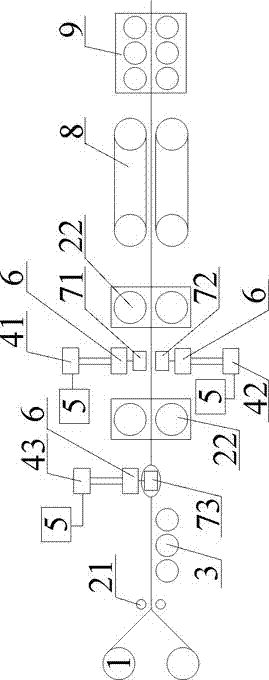

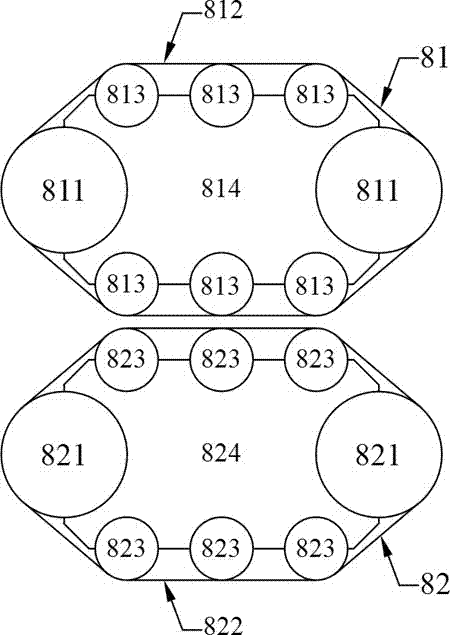

[0031] A five-layer melt co-extruded fiber-reinforced plastic sheet manufacturing equipment, including two-layer synchronous fiber unwinding support 1, fiber mat clamping machine 21 and fiber mat conveying table 3, upper layer screw extruder 41, lower layer screw extruder Extruder 42, middle layer screw extruder 43, feeder 5, melt pump 6, plate clamping machine 22, upper flat die 71, lower flat die 72, core layer extrusion flat die 73, steel strip extrusion Press 8 and flattener 9, such as Figure 1 to Figure 4 As shown, the specific structure is:

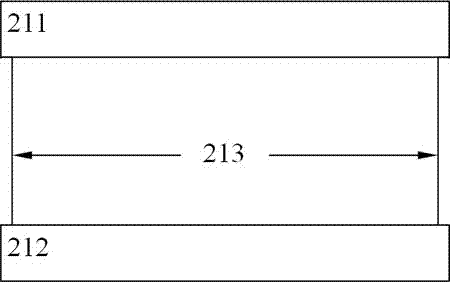

[0032] The two-layer synchronous fiber unwinding support 1 is set at the starting end of the central axis of the production line, the two-layer synchronous fiber unwinding support 1 has two outlets, and the fiber mat clamping machine 21 is located at the outlet of the two-layer synchronous fiber unwinding support 1 In front of the feeding port, the fiber mat clamping machine 21 is composed of an upper fiber pressing roller 211, a ...

Embodiment 2

[0057] A five-layer melt co-extruded fiber-reinforced plastic sheet manufacturing equipment, including two-layer synchronous fiber unwinding support 1, fiber mat clamping machine 21 and fiber mat conveying table 3, upper layer screw extruder 41, lower layer screw extruder Extruder 42, middle surface layer screw extruder 43, feeder 5, plate clamping machine 22, upper flat die 71, lower flat die 72, core layer extrusion flat die 73, steel strip extruder 8 and press flat machine 9, such as Figure 5 As shown, the specific structure is:

[0058] The two-layer synchronous fiber unwinding support 1 is set at the starting end of the central axis of the production line, the two-layer synchronous fiber unwinding support 1 has two outlets, and the fiber mat clamping machine 21 is located at the outlet of the two-layer synchronous fiber unwinding support 1 In front of the feeding port, the fiber mat clamping machine 21 is composed of an upper fiber pressing roller 211, a lower fiber pre...

Embodiment 3

[0073] A five-layer melt co-extruded fiber-reinforced plastic sheet manufacturing equipment, including two-layer synchronous fiber unwinding support 1, fiber mat clamping machine 21 and fiber mat conveying table 3, upper layer screw extruder 41, lower layer screw extruder Extruder 42, middle layer screw extruder 43, feeder 5, melt pump 6, plate clamping machine 22, upper flat die 71, lower flat die 72, core layer extrusion flat die 73, steel strip extrusion Press machine 8, flattener 9, cooling platform 11, tractor 12, edge trimming machine 13, cutting edge trimming machine 14, cutting machine waste collector 15 and conveying platform 16, such as figure 1 and Figure 6 Shown, concrete structure is: be provided with cooling platform 11, haul-off machine 12, edge trimming machine 13, cutting edge trimming machine 14 and conveying platform 16 successively before the discharge port of flattening machine 9, cutting machine scrap collector 15 It is located at the waste material suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com