Solid-liquid phase metal cast rolling compounding method and device

A technology of composite equipment and metal composite strips, applied in metal processing equipment, metal rolling, metal rolling, etc., can solve the problems of low composite strength, single product, few layers, etc., and achieve the goal of increasing output and expanding product range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

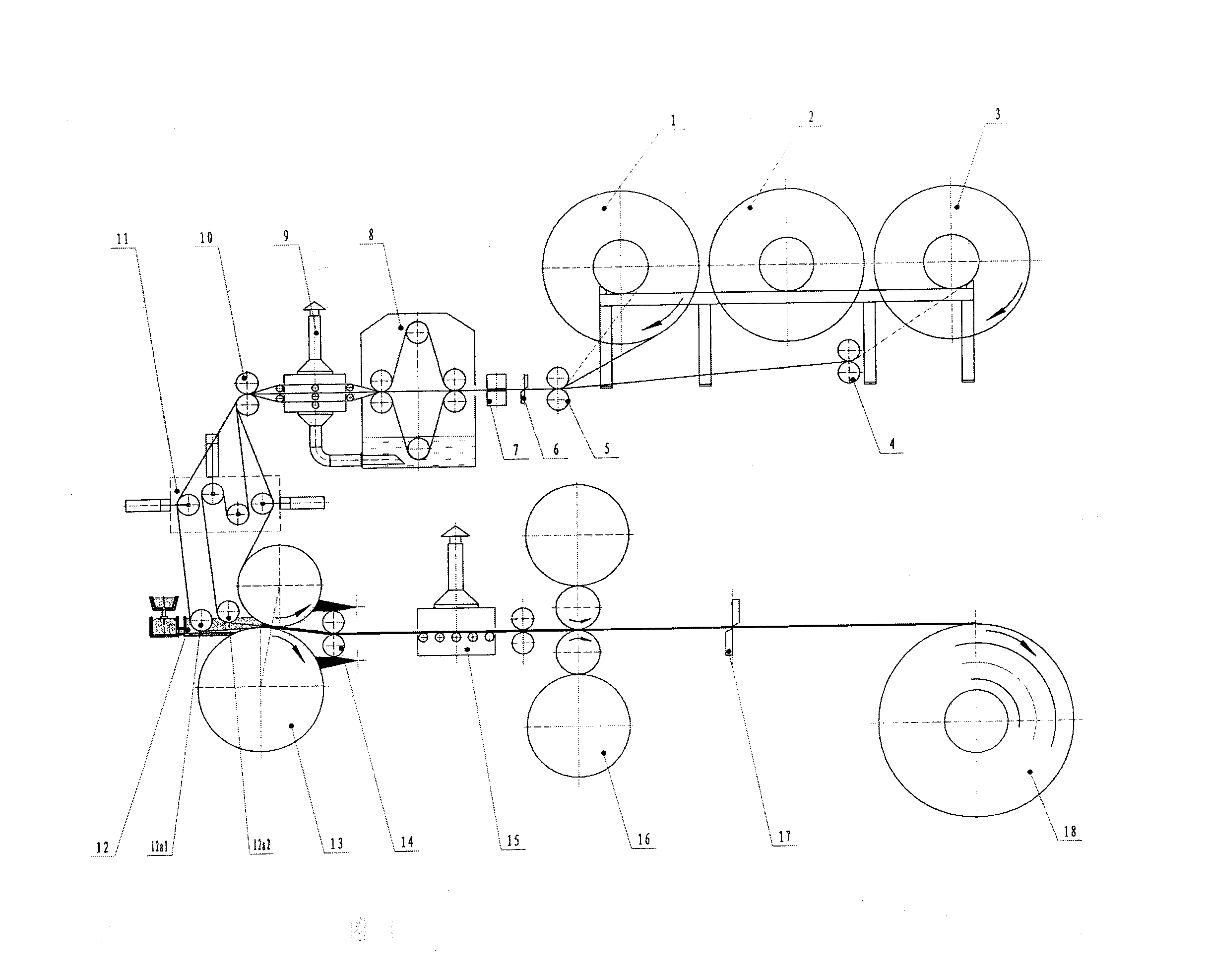

[0022] The solid metal is a single-layer coil of No. 20 carbon steel, with a thickness of 0.75-1.6mm and a width of 800-1200mm. The liquid metal (composite layer) is 3003 aluminum alloy, and the thickness of the composite product is 1.25-4.0mm.

[0023] Place the steel coil with the internal stress eliminated and the oxide film and stains removed on the surface on the unwinding rack of the uncoiler unit above the casting and rolling mill, and start the coil, start the No. Pass through: No. 2 haul-off machine - head cutting shear (cut off the head) - joint machine - cleaning machine - import haul-off machine - lower guide roller - exit haul-off machine (with water temperature of 50℃~60℃, water pressure of 0.2~0.8Mpa Weak alkaline aqueous solution cleaning steel strip) - dryer (150 ℃ ~ 400 ℃ dry hot air drying steel strip) - No. 3 tractor - strip length and tension adjustment device - No. 2 guide roller (12a2) of the feeding nozzle , and finally penetrate into the static rolling...

Embodiment 2

[0028] The solid metal is a T2 copper double-layer coil, with a thickness of 0.1-0.8mm and a width of 800-1200mm. The liquid metal (composite layer) is 1××× aluminum alloy, and the thickness of the composite product is 0.4-6.5mm.

[0029] Place the double-layer copper coil with the internal stress eliminated and the oxide film and stains removed on the surface on the unwinding rack of the uncoiler unit above the casting and rolling mill, and roll it up, start the No. The speed passes through in turn: No. 2 haul-off machine - head cutting shear (cut off the lead) - joint machine - cleaning machine - import haul-off machine (separate copper strip) - upper and lower guide rollers - exit haul-off machine (use 50 ℃ ~ 60 ℃ Water temperature, 0.2 ~ 0.8Mpa water pressure weak alkaline aqueous solution to clean the copper strip) - dryer (separate the copper strip) - the upper and lower guide rollers at the entrance - the upper and lower guide rollers in the middle - the upper and lower ...

Embodiment 3

[0034] Solid metal is 304 stainless steel / T2 copper / 304 stainless steel three-layer coil, 304 stainless steel thickness 0.1-0.6mm, width 800-1200mm, T2 copper thickness 0.2-0.6mm, width 800-1200mm, liquid metal (composite layer) is 1 ××× is an aluminum alloy, and the thickness of the compounded product is 0.6-5.5mm.

[0035] Place the three-layer stainless steel / copper / stainless steel coil material with internal stress eliminated and oxide film and stains removed on the surface on the unwinding rack of the uncoiler unit above the casting and rolling machine, roll up, start the No. 1 uncoiler, and make the three-layer coil Go through in turn at a speed of 1-8m / min: No. 2 tractor - head cutting shear (cut off the lead) - joint machine - cleaning machine - imported tractor (separate the upper and lower stainless steel belts, and pass through the upper and lower belts respectively Guide roller; the copper strip passes directly through the cleaning machine)-exit tractor (clean the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com