Method for producing high-strength thin strip steel in short process

A high-strength, thin-strip technology, applied in the direction of workpiece surface treatment equipment, metal processing equipment, metal rolling, etc., can solve the problems of difficult production of high-strength steel with yield strength, uneven microstructure of strip steel, and formation of strip surface Water spots and other problems, to achieve the effect of homogenizing the internal microstructure, improving cooling uniformity, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

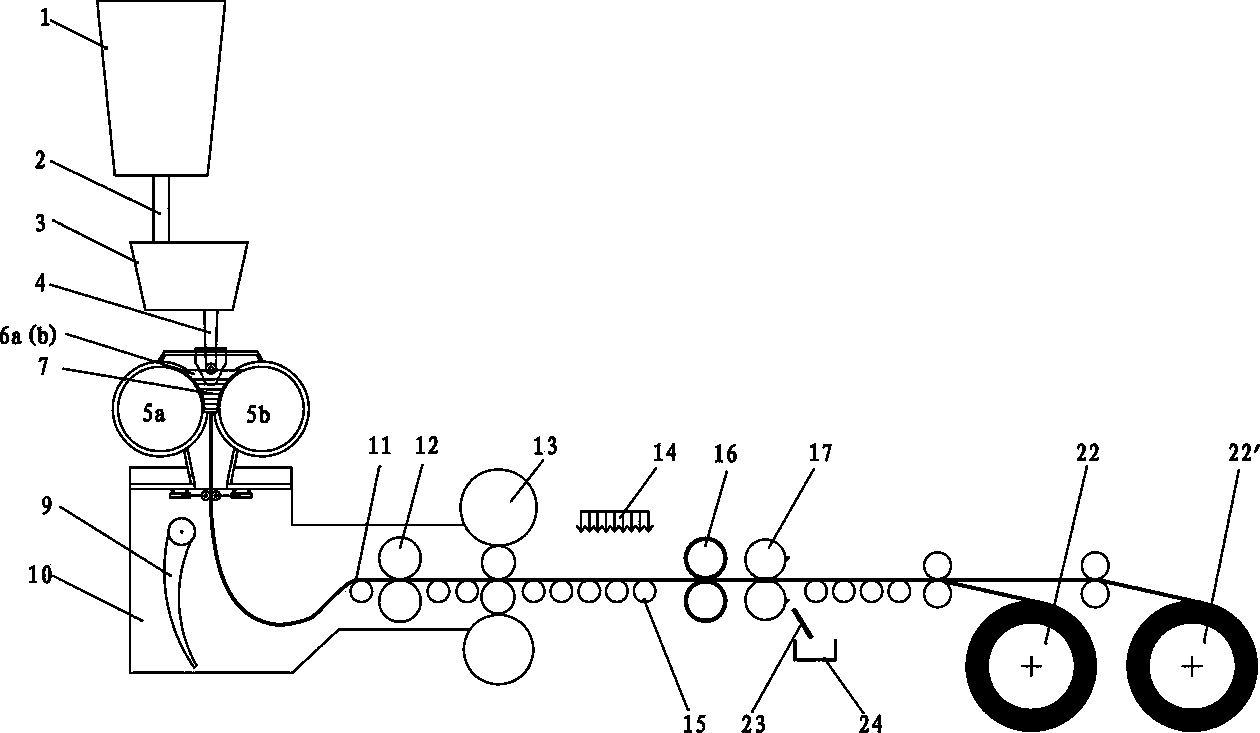

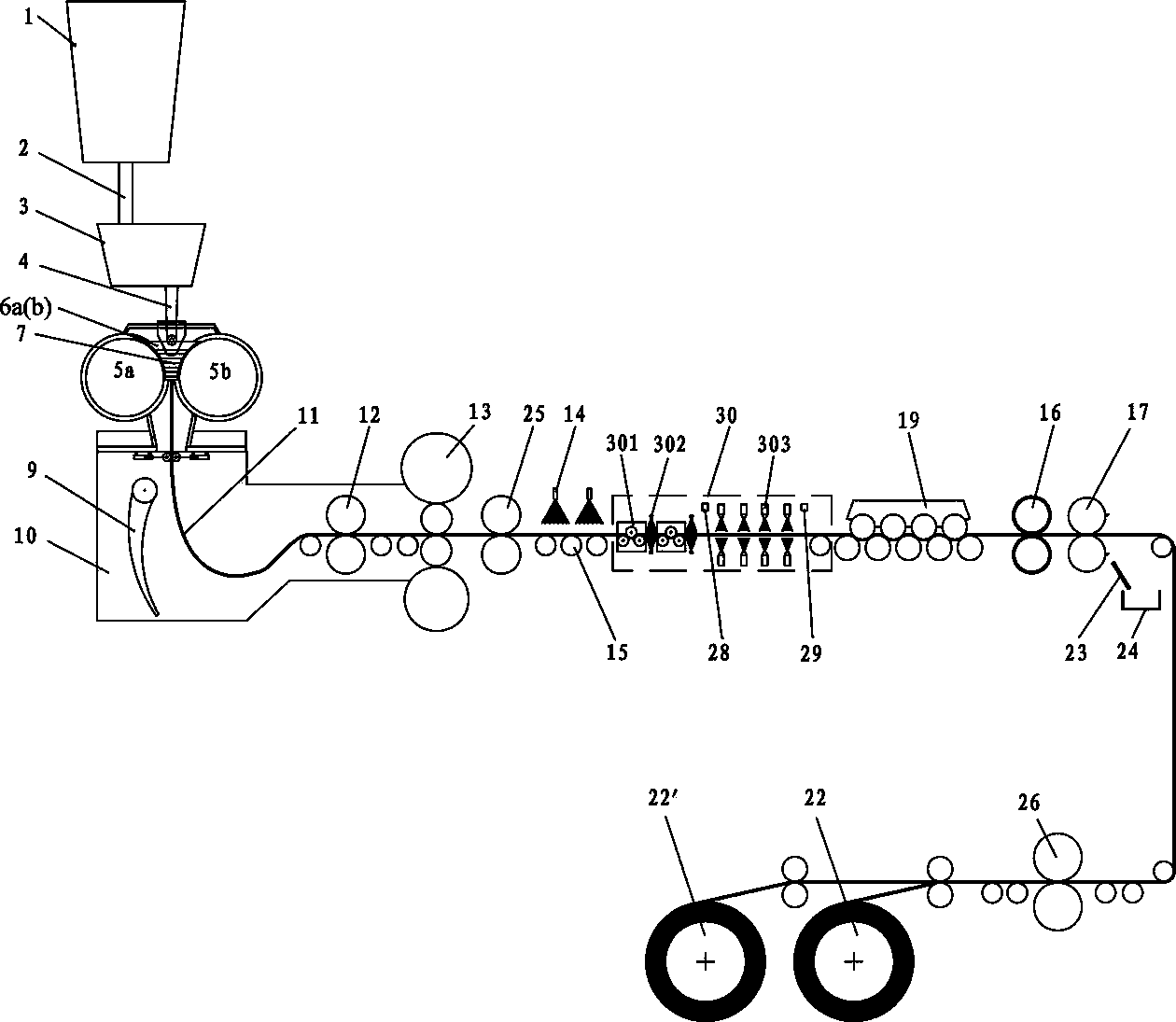

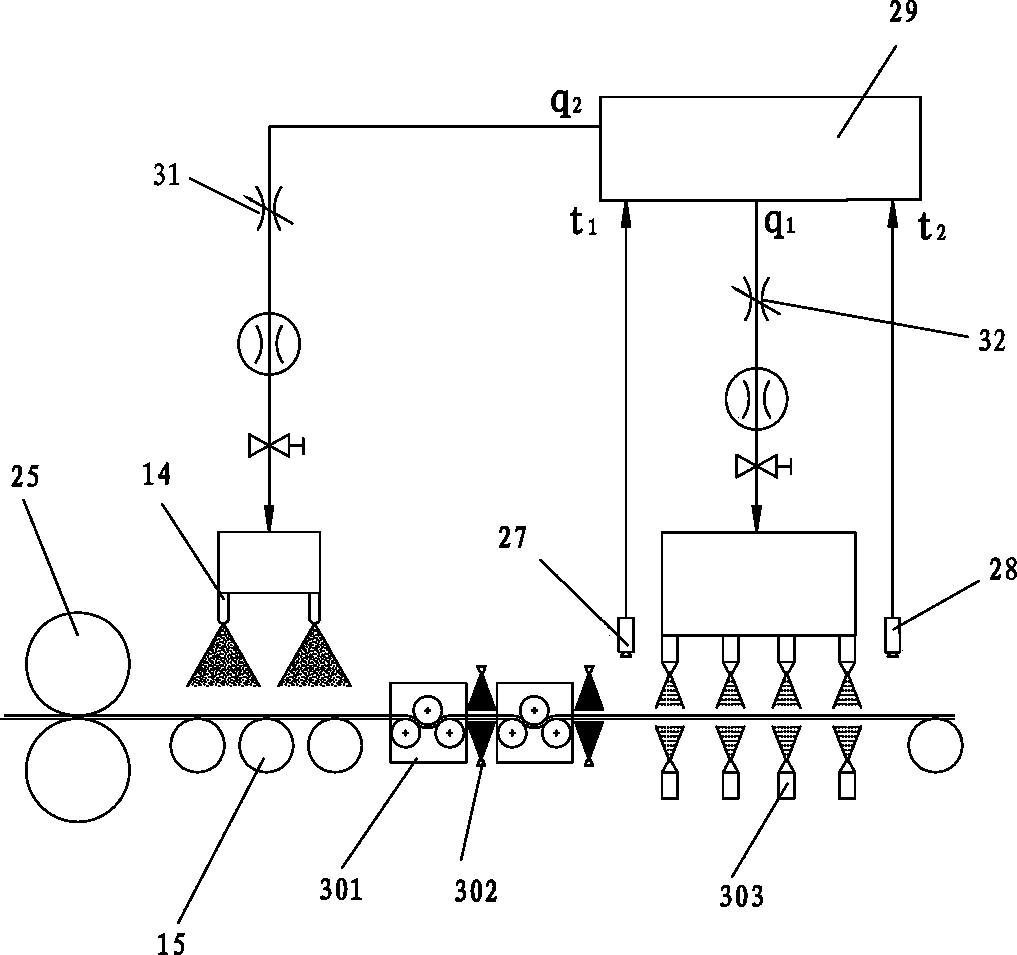

Method used

Image

Examples

Embodiment

[0065] The thickness of the high-strength atmospheric corrosion-resistant steel cast strip is 1.5mm. The chemical composition of the atmospheric corrosion-resistant steel is: C 0.04%, Si 0.5%, Mn 0.68%, P 0.03%, S≤0.006%, Cu 0.5%, Nb 0.020 %, Ti 0.025%, Al 0.04%, Cr 0.65%, Ni 0.25%, Re 0.15%; the balance is Fe and unavoidable impurities. Calculated: corrosion resistance index I = 7.4684≥7; welding cold crack sensitivity coefficient Pcm = 0.1523≤0.18%.

[0066]The cast strip is hot-rolled on-line into strip steel with a thickness of 1.2mm. The temperature at the exit of the rolling is 1000°C, and then undergoes atomization cooling, anti-oxidation enhanced cooling and dephosphorization processes for segmental cooling, dephosphorization, and straightening. For coiling, the cooling rate of atomization cooling is 50°C / s; the cooling rate of anti-oxidation enhanced cooling and dephosphorization process is 110°C / s, the mixing high pressure of gas and dry ice is 5MPa, and the mixing r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com