Patents

Literature

34results about How to "Evenly distributed and orderly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

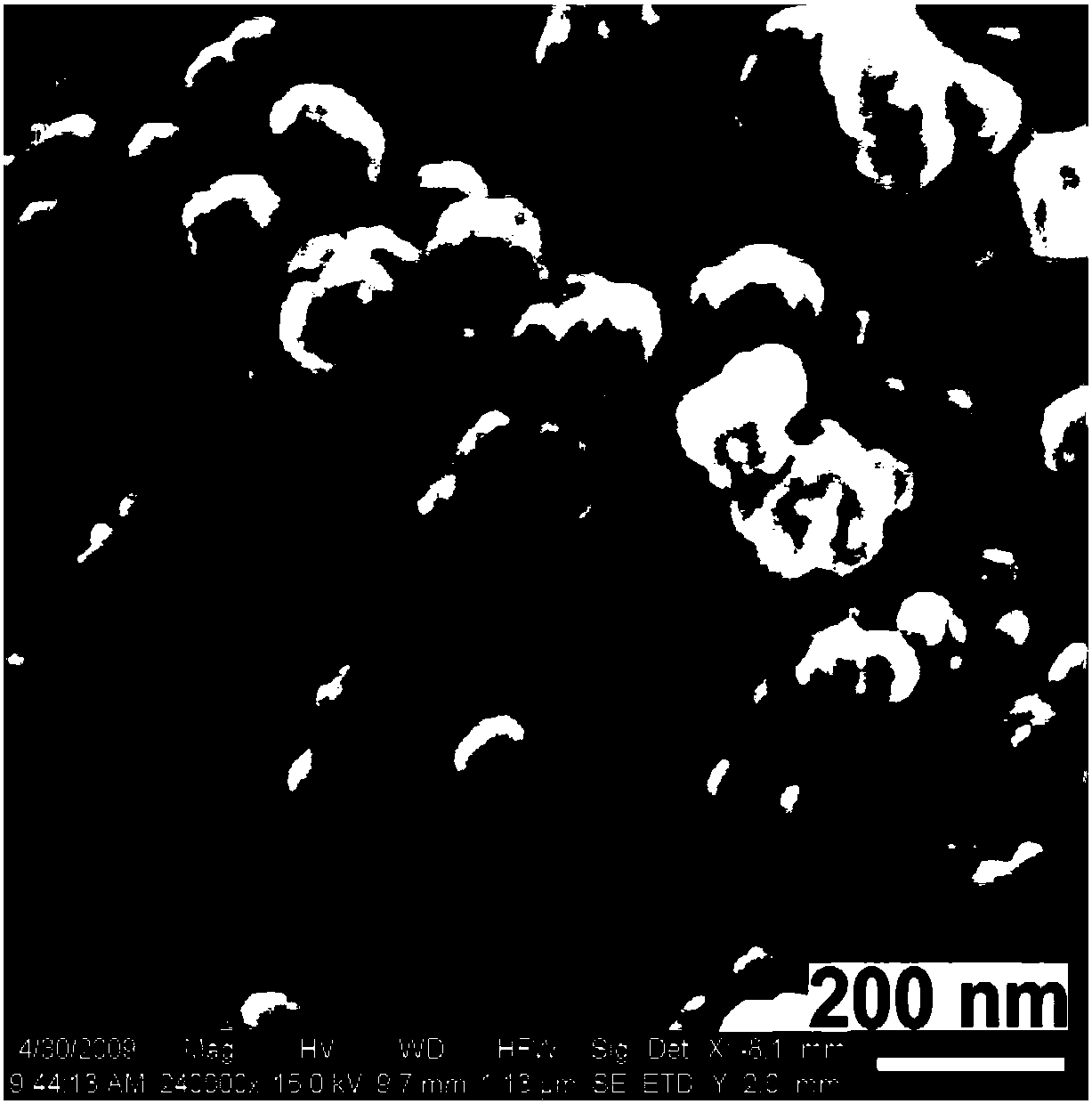

Method for improving performance of sintered Nd-Fe-B permanent magnetic material

ActiveCN101615459AEvenly distributed and orderlySolve bad problems such as α-Fe segregationInorganic material magnetismHigh energyPositive pressure

The invention relates to a method for improving performance of sintered Nd-Fe-B permanent magnetic property by a rapid-hardening flake grain boundary diffusion heavy rare earth compound in rare earth material technical field, which comprises the following steps: 1) rapid-hardening technology is adopted to prepare an Nd-Fe-B alloy rapid-hardening flake; 2) a high-energy ball mill is used to prepare the heavy rare earth compound into powder particles with diameter being smaller than 1mu m; 3) the rapid-hardening flake is put into heavy rare earth compound turbid liquid to carry out ultrasonic coating; 4) the coated rapid-hardening flake is put into a sintered furnace filled with Ar2 to carry out positive pressure thermal diffusion; 5) ball milling, powder processing, orientation shaping, isostatic pressing and vacuum sintering are adopted to prepare the strip-casting flake after the heat treatment into a magnet. The chemical formula of the Nd-Fe-B permanent magnetic material is NdxFe(100-x-y-z-xl)ByCozCuxl, and the mass percent is as follows: x is 30-31.5, y is 0.95-1, z is 1-1.2, and xl is 0-0.06. The magnet prepared by the invention improves the intrinsic coercivity on the basis of keeping the current magnetic energy product.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

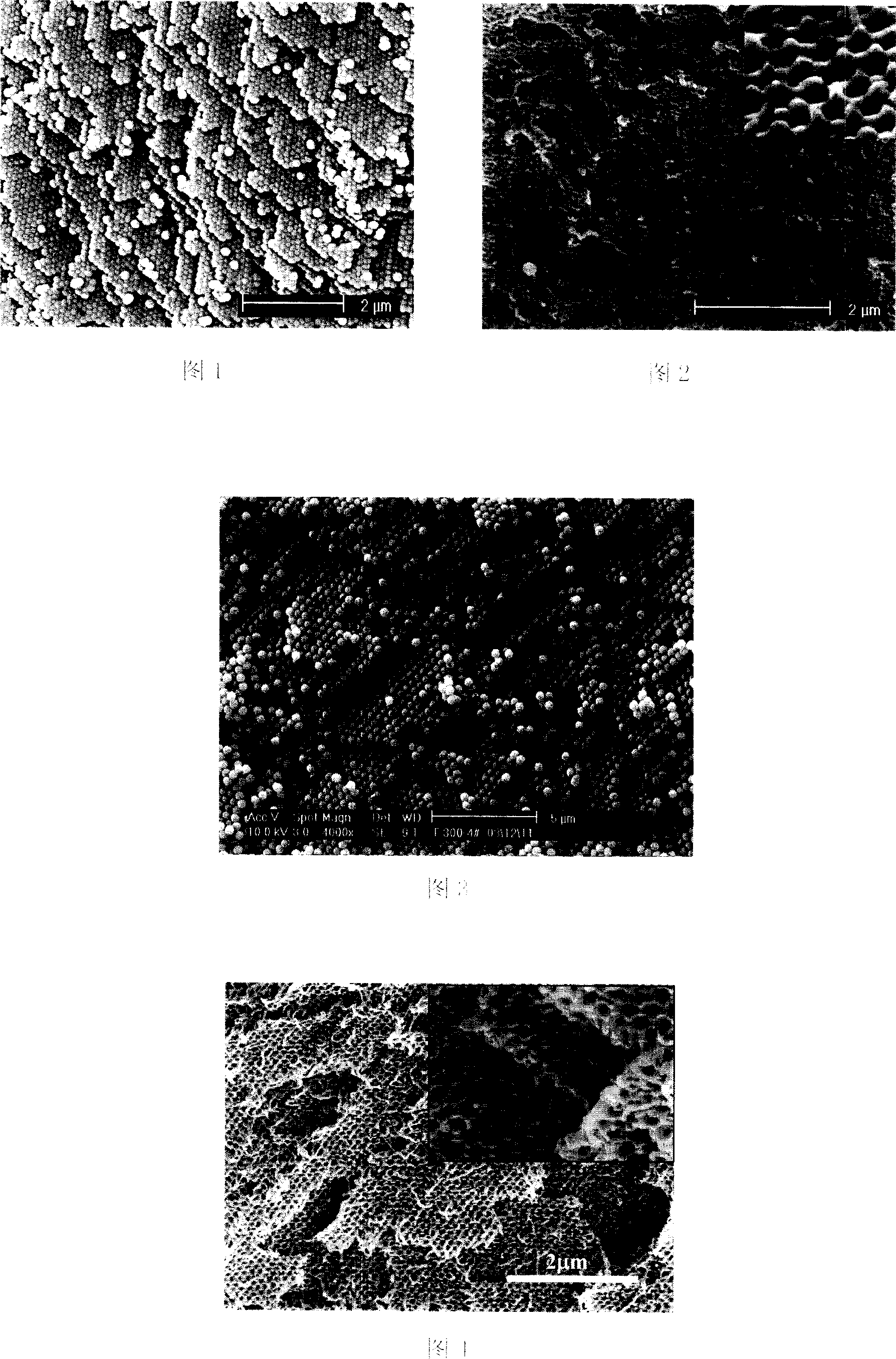

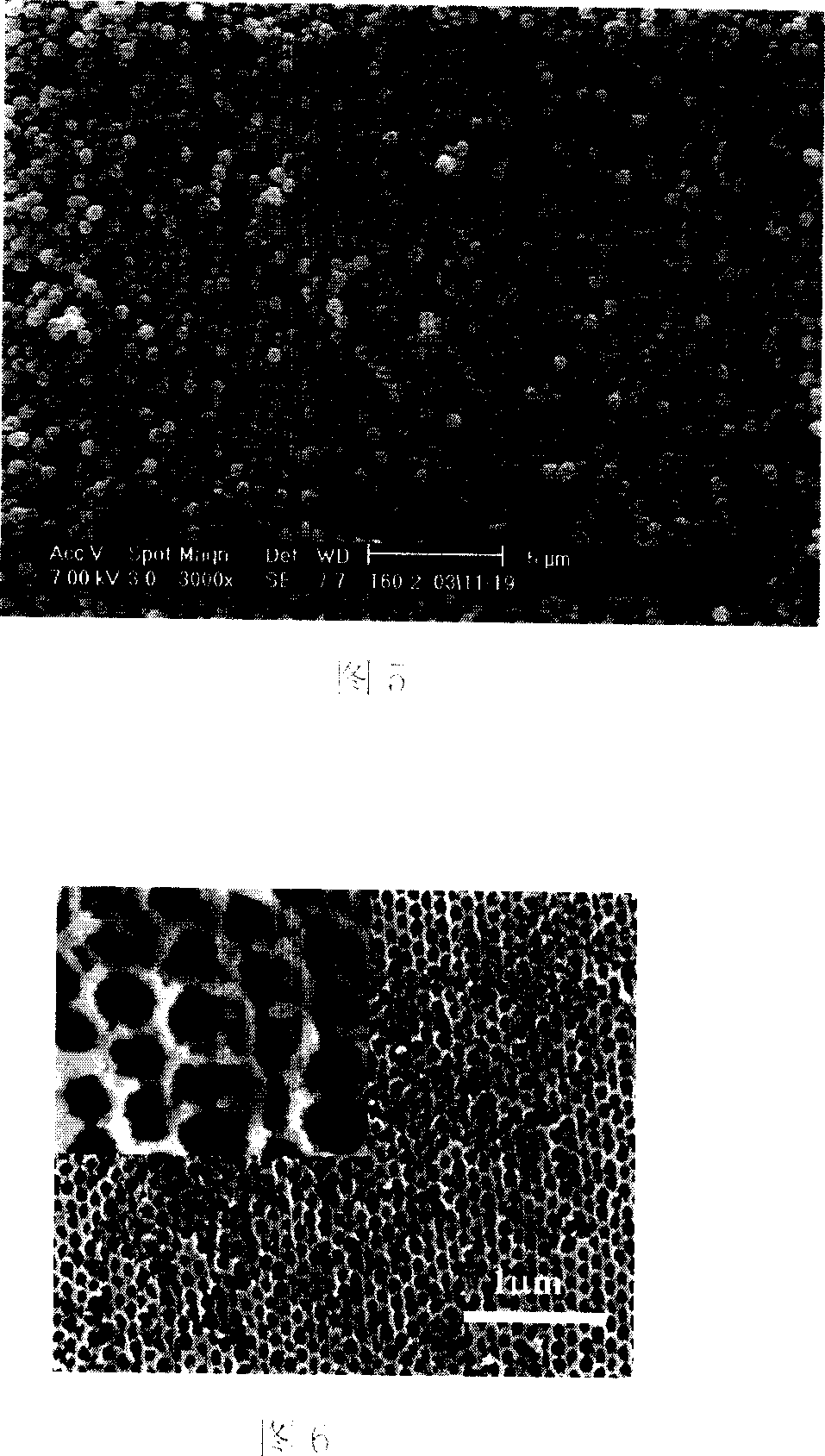

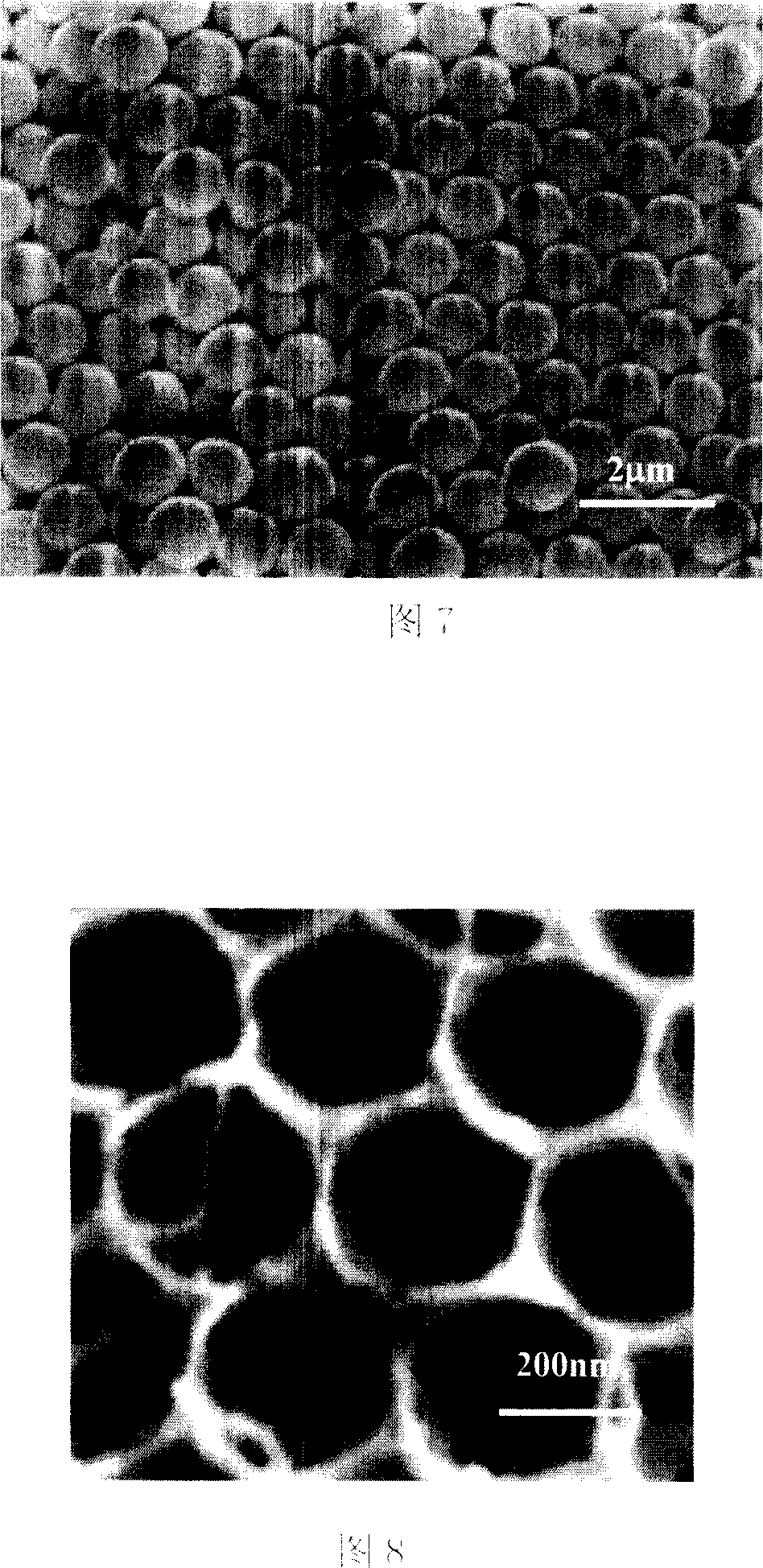

Three-dimensional ordered monodisperse macroporous material, and its preparing method and functionizing method

InactiveCN1935857AHigh melting pointFast crystallization ratePolyvinyl alcoholCoordination polymerization

The invention relates to three-dimensional order mono-disperse macropore material and its preparation method and functionalizing method. The three-dimensional order mono-disperse macropore material has 91%-98% syndiotactic polyvinyl alcohol arene, 80 nm-1000 nm average aperture. Its preparation method includes the following steps: using colloid crystal mold board method to make three-dimensional order mono-disperse macropore polyvinyl alcohol without water and oxygen by coordination polymerization; using copolymerization or chloromethylation to functionalize. It has the advantages of high melting point, quick crystallization rate, strong chemical resistance, good size stability, processing surface chemical modification, and wide application prospect in sensor, photon chip, photon band gap material preparation etc.

Owner:HEBEI UNIV OF TECH

Method for preparing fluoro-chlorine exchange catalyst with high specific surface area

ActiveCN108889321ALarge specific surface areaHigh internal pore volumeCatalyst activation/preparationSaline waterMetal-organic framework

The invention discloses a method for preparing a fluoro-chlorine exchange catalyst with high specific surface area. The method comprises the following steps: carbonizing a metal-organic framework material MIL-101 (Cr) serving as a raw material and metal brine serving as an assistant, and performing fluoridation treatment, thereby obtaining the fluoro-chlorine exchange catalyst with high specific surface area. The method disclosed by the invention has the advantages that the metal-organic framework material MIL-101 (Cr) with high specific surface area, high internal pore volume and uniform andordered Cr element distribution serves as the raw material of the fluoro-chlorine exchange catalyst, so that the prepared fluoro-chlorine exchange catalyst also has the characteristics of high specific surface area, high internal pore volume and uniform and ordered Cr element distribution; the assistants are added by an adsorption method, so that the distribution of the assistants is uniform, andthe effective utilization rate of the assistants is improved; and the product has the characteristics of high specific surface area, rich internal pores, high catalytic activity, uniform assistant distribution and the like, and is applicable to the fluoro-chlorine exchange reaction.

Owner:天津航大翼安科技发展有限公司

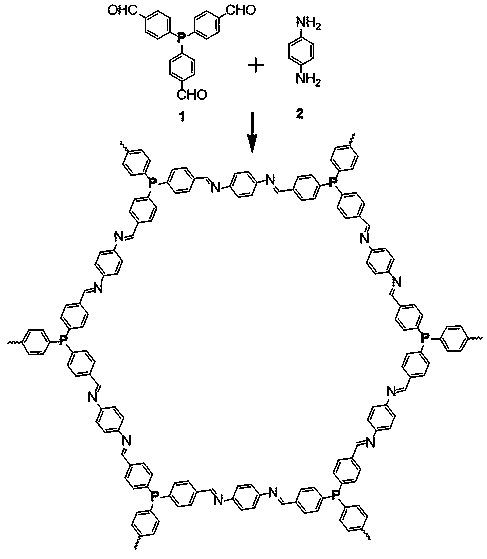

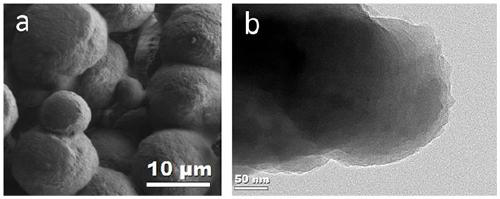

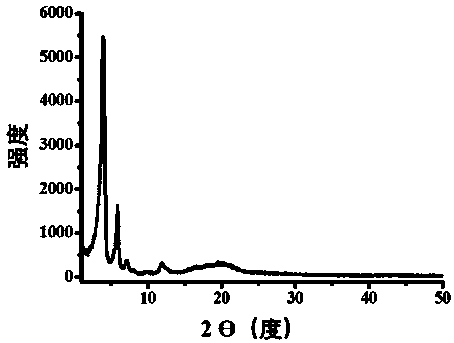

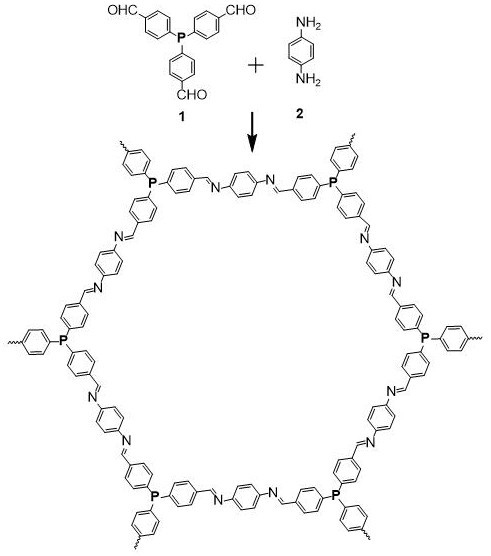

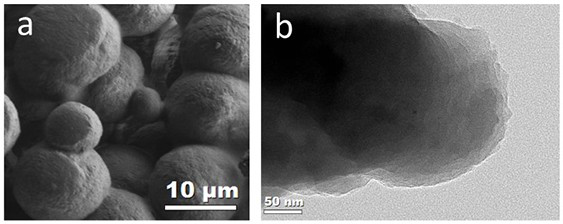

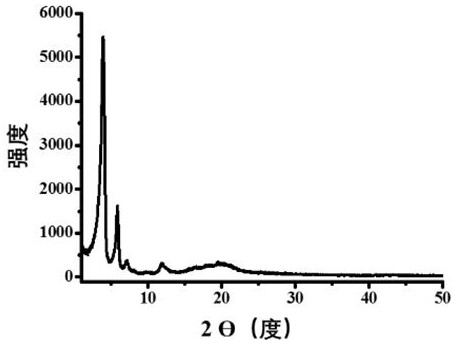

Covalent organic framework with triphenylphosphine as framework as well as preparation method and application of covalent organic framework

ActiveCN109762180AHigh crystallinityImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsN dimethylformamideFiltration

The invention discloses a covalent organic framework with triphenylphosphine as a framework as well as a preparation method and application of the covalent organic framework and relates to the field of covalent organic framework materials. The compound is formed by polycondensation of a triphenylphosphine-containing trialdehyde monomer and diamine monomer. The preparation method comprises the following steps: adding monomer triphenylphosphine trialdehyde and diamine into a solvent; carrying out ultrasonic dispersion and adding an acetic acid solution for continuous ultrasonic operation to forma suspension turbid liquid; carrying out liquid nitrogen refrigeration-vacuumizing-degassing treatment, sealing and standing on the suspension to obtain a crude product; carrying out suction filtration washing on the crude product by using N,N-dimethylformamide, and then carrying out Soxhlet extraction and vacuum drying by using tetrahydrofuran and chloroform in sequence to obtain the covalent organic framework with the triphenylphosphine as the framework. The covalent organic framework related in the invention introduces a triphenylphosphine structural unit with high coordination capabilityinto a material framework for the first time, and has a broad application prospect in the fields of gas adsorption and separation, photoelectricity, in particular to catalysis.

Owner:YUNNAN UNIV

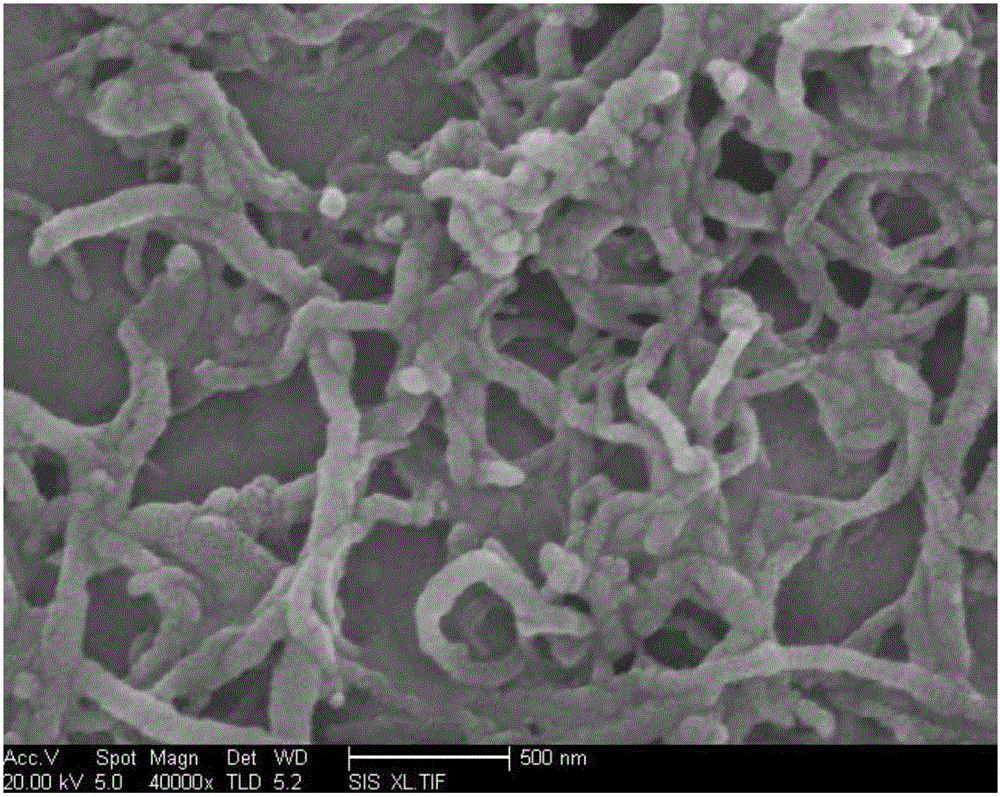

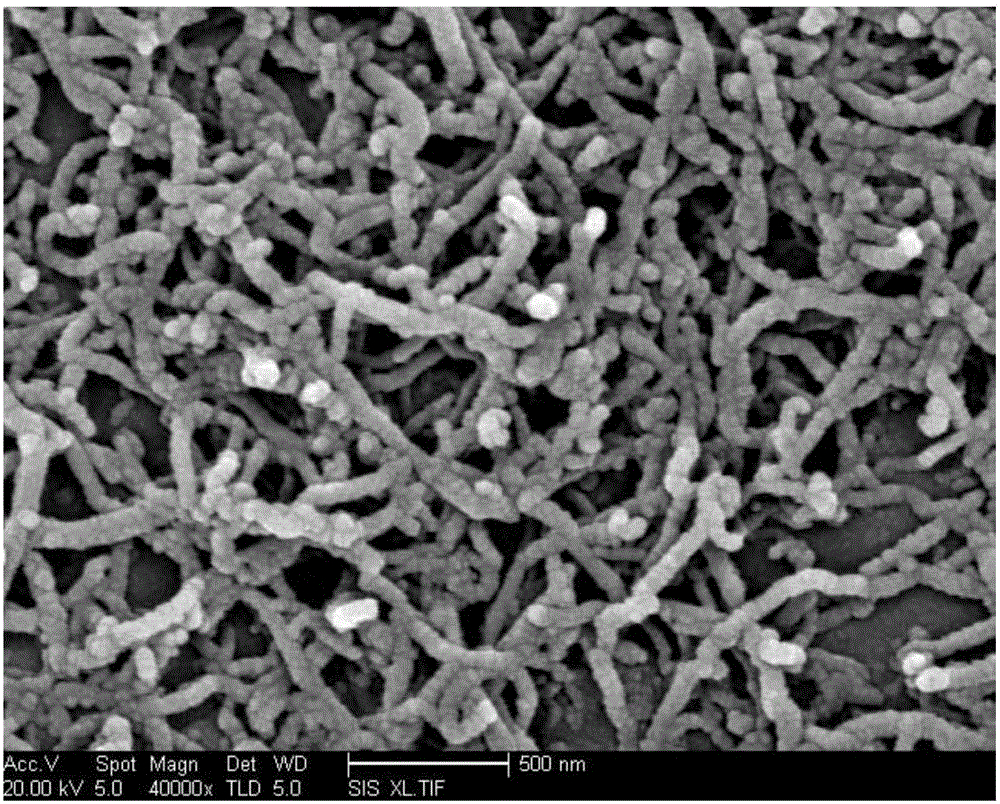

Preparation method of functionalized carbon nanotube powder

InactiveCN105733317AStrong interface bindingSignificant performance enhancementPigment physical treatmentPigment treatment with non-polymer organic compoundsTube furnaceCarbon nanotube

The invention discloses a preparation method of functionalized carbon nanotube powder, relating to a preparation method of carbon nanotube powder. The purpose of the method is to solve the problems that the existing method for preparing functionalized carbon nanotubes has a high risk of reaction and is difficult to control, the grafting rate of surface functional groups is difficult to control, and the combination of the product and the composite material is weak. Method: 1. Heat the carbon nanotubes in a tube furnace and cool down to obtain purified carbon nanotubes; 2. Prepare FeSO 4 Solution, adjust the pH; 3. Place the purified carbon nanotubes in FeSO 4 solution, forming a suspension, oil bath, H 2 o 2 Adding to the suspension, standing still after the reaction, to obtain the product; 4. Washing, replacing with an organic solvent, centrifuging to obtain a muddy product, and freeze-drying to obtain the functionalized carbon nanotube powder. The reaction of the method is controllable, and the prepared powder can be dispersed in some organic solvents to form a uniform and stable system, and has a certain orientation ability under a specific field strength. The invention is used for preparing functionalized carbon nanotubes.

Owner:HEILONGJIANG HEIKE TECH CO LTD

Composite titanium dioxide mesoporous thin membrane electrode material and preparation method thereof

ActiveCN111564325AGood electrical conductivityGood light absorption performanceHybrid capacitor electrodesHybrid/EDL manufacturePolyvinylidene fluoridePyrrole

The invention discloses a composite titanium dioxide mesoporous thin membrane electrode material and a preparation method thereof. The preparation method comprises the steps: adding a titanium sourcecompound and an antimony source compound into a hydrochloric acid solution, stirring and mixing, carrying out a hydrothermal reaction to obtain a precursor solution, and carrying out spray drying andhigh-temperature calcination on the solution to obtain a mesoporous hollow spherical antimony-doped titanium dioxide composite material; putting the obtained material into a hydrochloric acid solution, carrying out ultrasonic dispersion, adding a pyrrole monomer under a stirring condition, uniformly stirring, dropwise adding an oxidant, standing after the reaction is finished, filtering, and drying to obtain a polypyrrole@antimony / titanium dioxide composite material; and uniformly mixing the prepared polypyrrole@antimony / titanium dioxide composite material with polyvinylidene fluoride, adding1-methyl-2-pyrrolidone to blend slurry, uniformly coating a conductive substrate with the slurry, drying, and calcining to obtain the thin membrane electrode material. According to the composite thinmembrane material prepared by the invention, the photoelectric property of the titanium dioxide electrode material is remarkably improved, the structure is compact, and the performance is stable.

Owner:FOSHAN UNIVERSITY

Method for improving performance of sintered Nd-Fe-B permanent magnetic material

ActiveCN101615459BEvenly distributed and orderlySolve bad problems such as α-Fe segregationInorganic material magnetismHigh energyPositive pressure

The present invention relates to a method for improving performance of sintered Nd-Fe-B permanent magnetic property by a rapid-hardening flake grain boundary diffusion heavy rare earth compound in rare earth material technical field, which comprises the following steps: 1) rapid-hardening technology is adopted to prepare an Nd-Fe-B alloy rapid-hardening flake; 2) a high-energy ball mill is used to prepare the heavy rare earth compound into powder particles with diameter being smaller than 1mu m; 3) the rapid-hardening flake is put into heavy rare earth compound turbid liquid to carry out ultrasonic coating; 4) the coated rapid-hardening flake is put into a sintered furnace filled with Ar2 to carry out positive pressure thermal diffusion; 5) ball milling, powder processing, orientation shaping, isostatic pressing and vacuum sintering are adopted to prepare the strip-casting flake after the heat treatment into a magnet. The chemical formula of the Nd-Fe-B permanent magnetic material is NdxFe(100-x-y-z-xl)ByCozCuxl, and the mass percent is as follows: x is 30-31.5, y is 0.95-1, z is 1-1.2, and xl is 0-0.06. The magnet prepared by the invention improves the intrinsic coercivity on the basis of keeping the current magnetic energy product.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

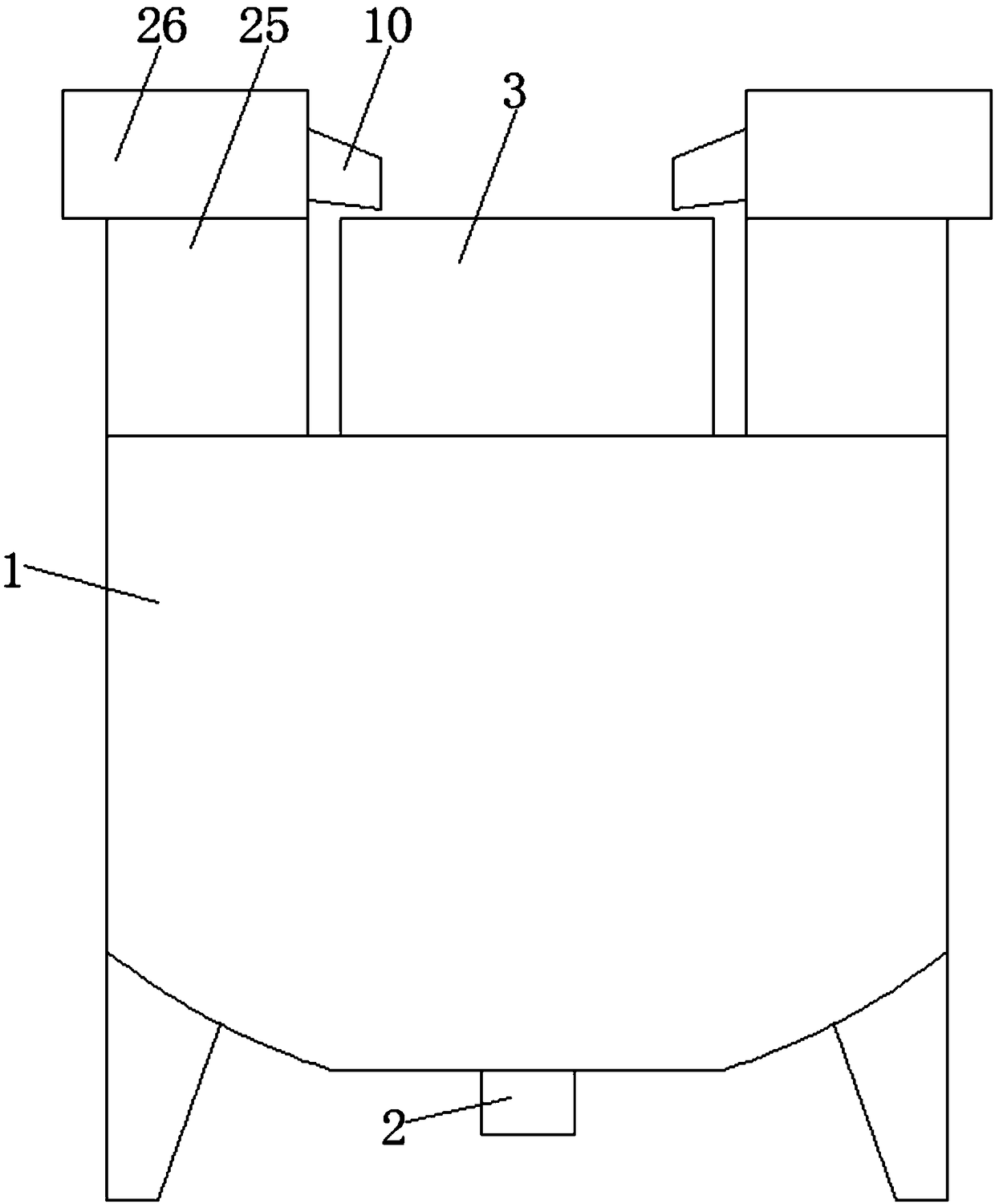

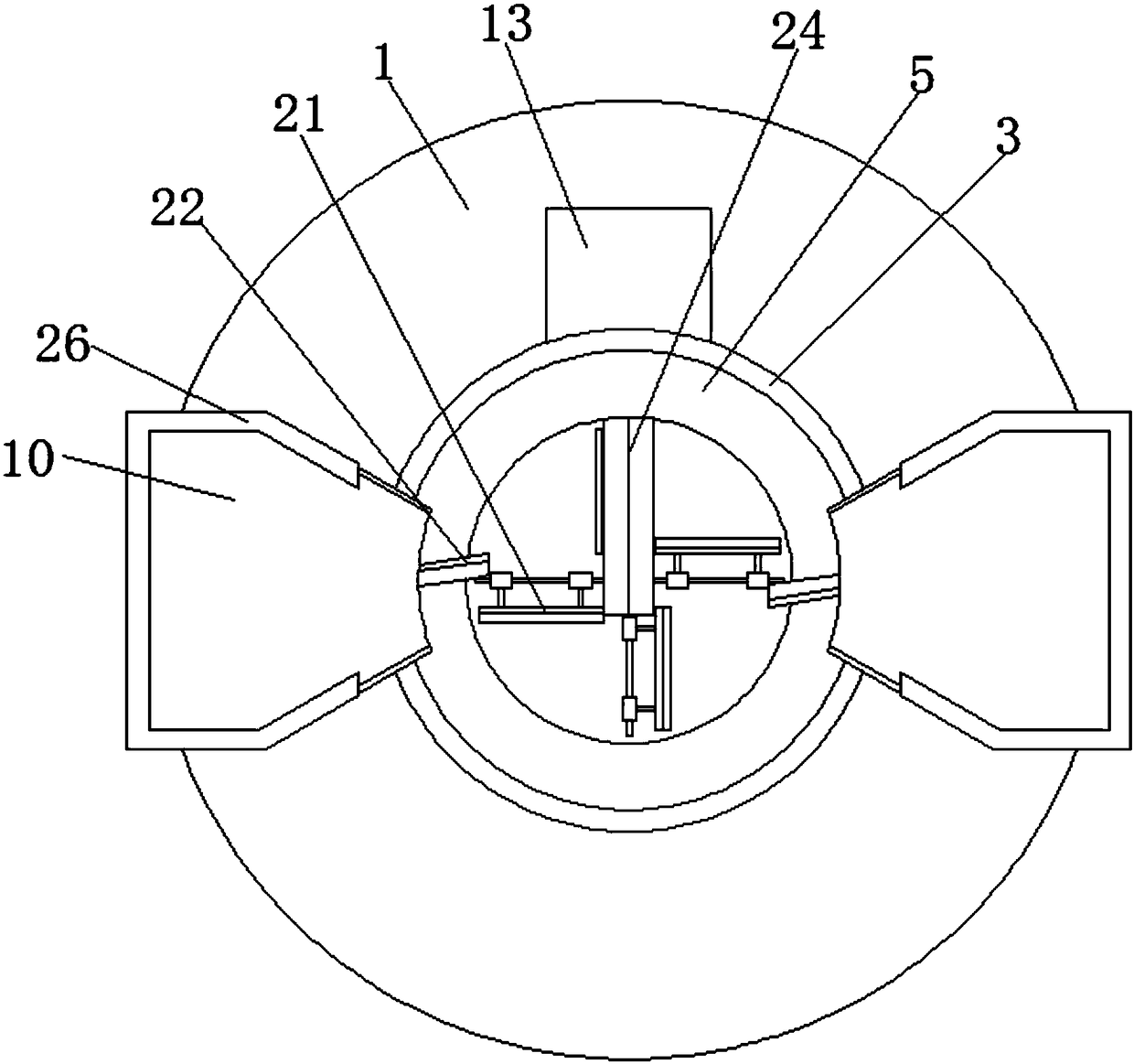

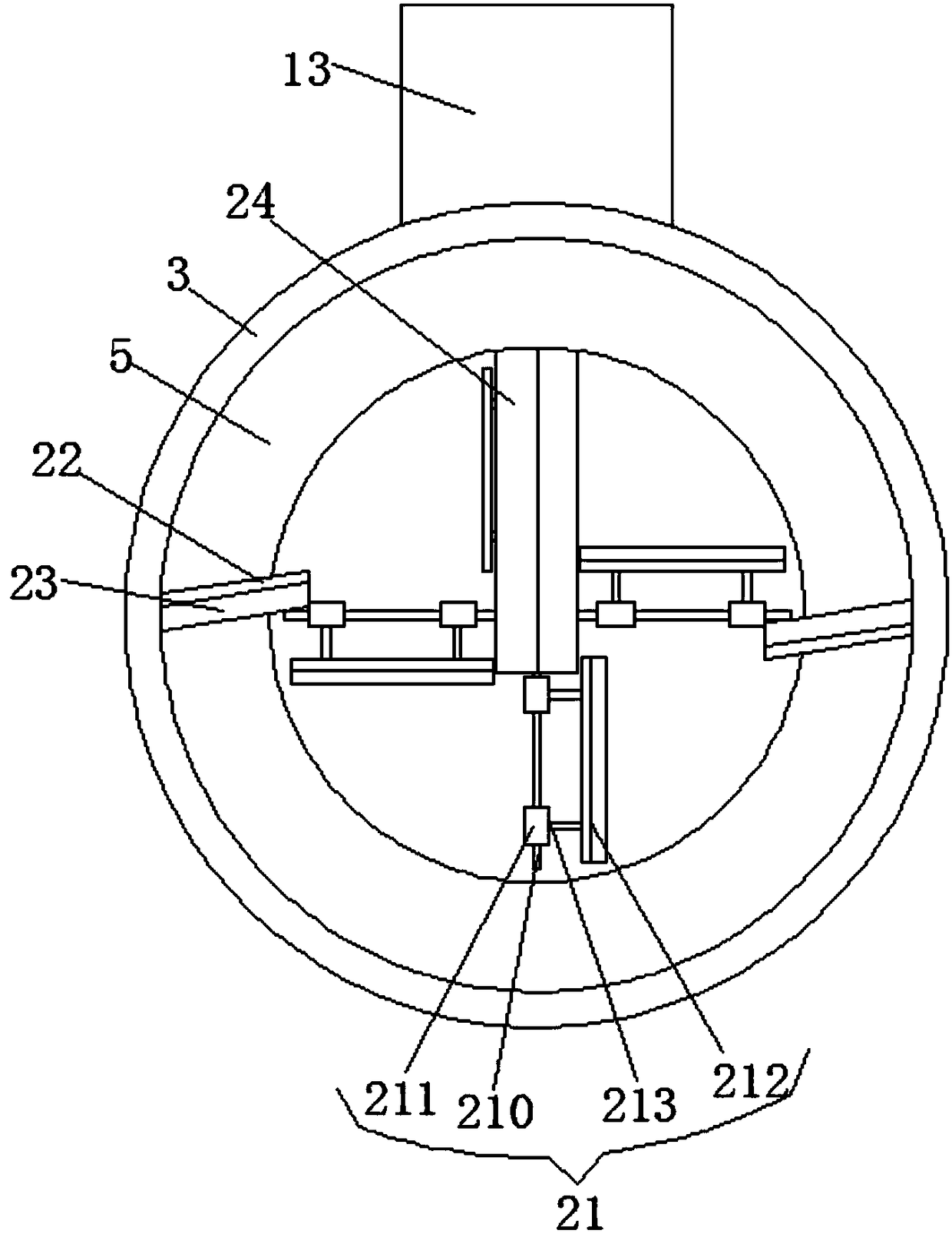

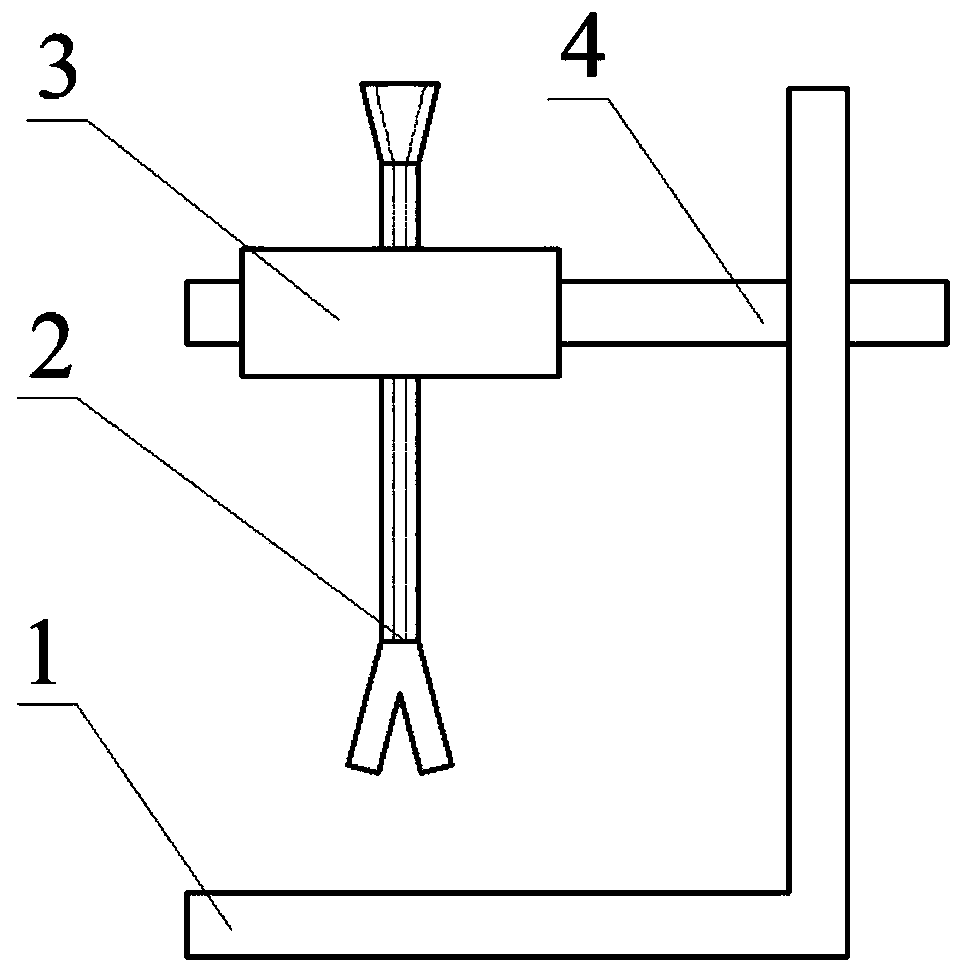

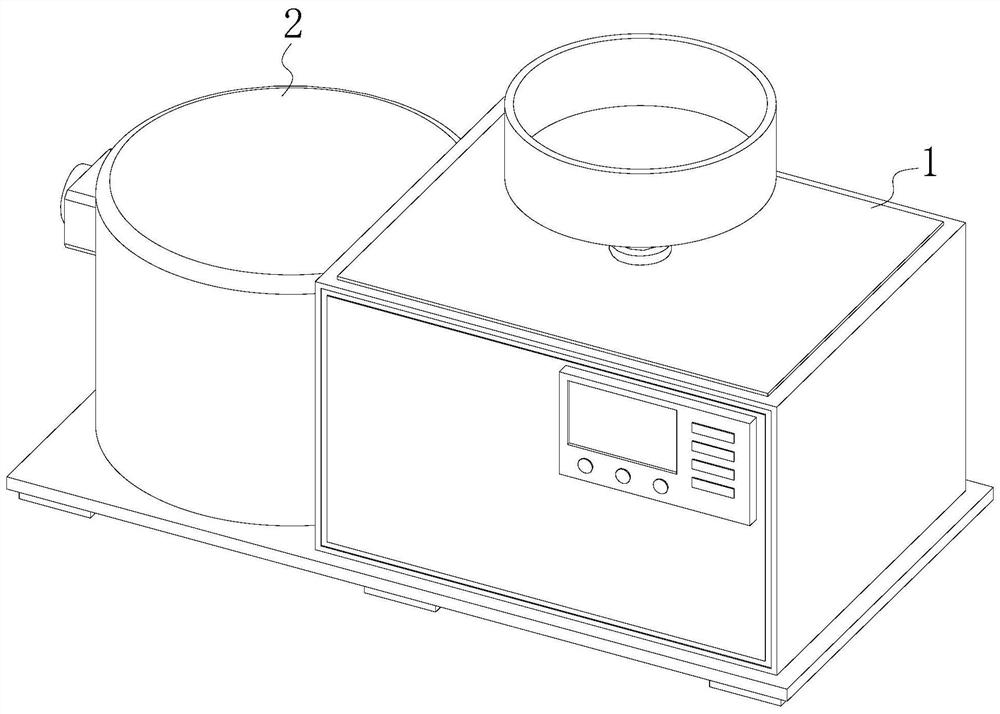

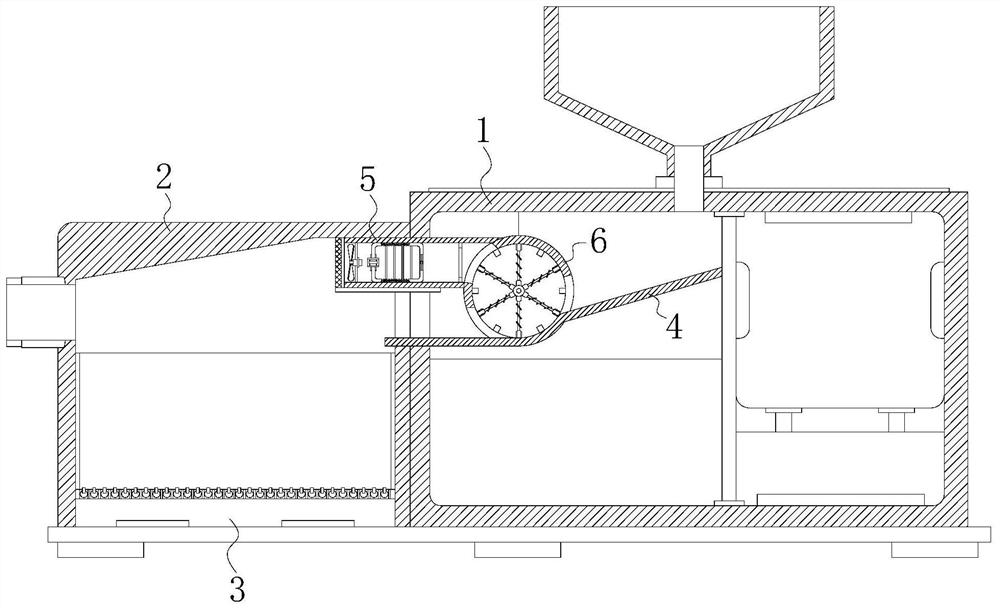

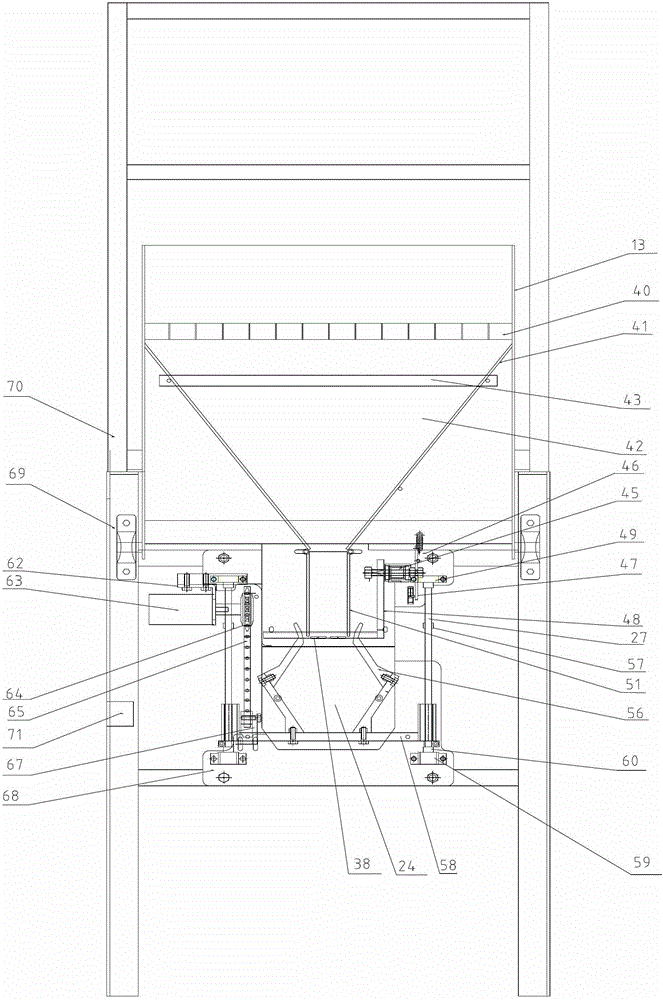

Blanking mechanism based on livestock nutrition feed mixing and stirring tank

ActiveCN108568248AReduce voidsReduce in quantityFeeding-stuffRotary stirring mixersLivestockEngineering

The invention discloses a blanking mechanism based on a livestock nutrition feed mixing and stirring tank, and relates to the field of livestock nutrition feed mixing and stirring. The blanking mechanism comprises a mixing tank, a discharging hole is arranged in the middle of the bottom of the mixing tank in a communicating manner, a blanking stopper is installed at a feeding hole in the mixing tank, the top of the cavity of the blanking stopper is arranged in a trapezoidal shape, and a driving groove, which is communicated with the trapezoid part of the cavity, is arranged in the blanking stopper. The blanking mechanism can be used for uniform blanking in order in livestock feed mixing, enables two feeds to be mixed more uniformly when the two feeds uniformly fall on the blanking stopperand are rotated by a dispersion mixing net and dispersed by meshes of the net, and can scatter feeds better, so as to mix feeds in the mixing tank better, improve the mixing efficiency and avoid excessive waste.

Owner:江西联和农牧科技集团有限公司

Casting anti-friction and abrasion-resistant high aluminum zinc-based composite material and preparation method thereof

The invention relates to a casting anti-friction and abrasion-resistant high aluminum zinc-based composite material and a preparation method thereof. The technical scheme is that the composite material takes zinc and aluminum as the base, and takes copper and magnesium as main alloy elements; trace alloy elements of strontium, titanium, boron, rare earth lanthanum and the like, and micron siliconcarbide and micron graphite non-metallic ceramic reinforcement particles are added, smelting is carried out, and thus substrate molten liquid is obtained; and the substrate molten solution is subjected to the deep processing technology of powder spraying, stirring and ultrasonic combined treatment so that the silicon carbide particles with abrasion-resistant performance and the graphite particleswith anti-friction performance can be well immersed in the substrate molten liquid and be uniformly dispersed and distributed in the composite material accordingly, and thus the fine-grained casting anti-friction and abrasion-resistant high aluminum zinc-based composite material obtained. The casting anti-friction and abrasion-resistant high aluminum zinc-based composite material has the characteristics of simple technology and low preparation cost. The reinforcement particles of the prepared product are uniformly distributed, and the composite material are excellent in plasticity, toughness and abrasion resistance, and stable in quality.

Owner:WUHAN UNIV OF SCI & TECH

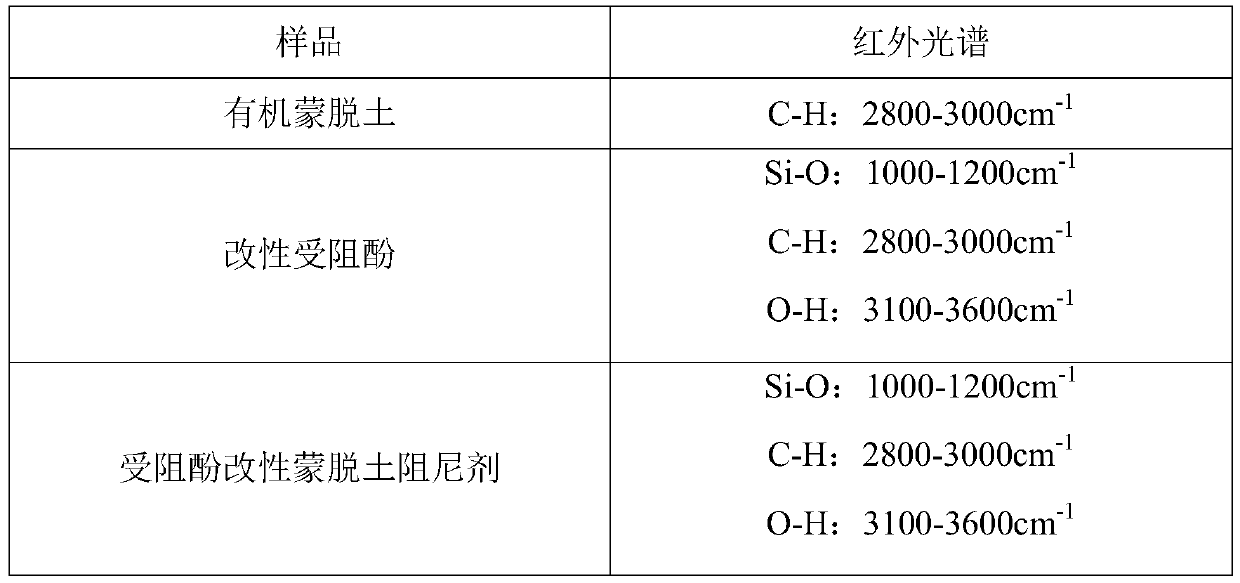

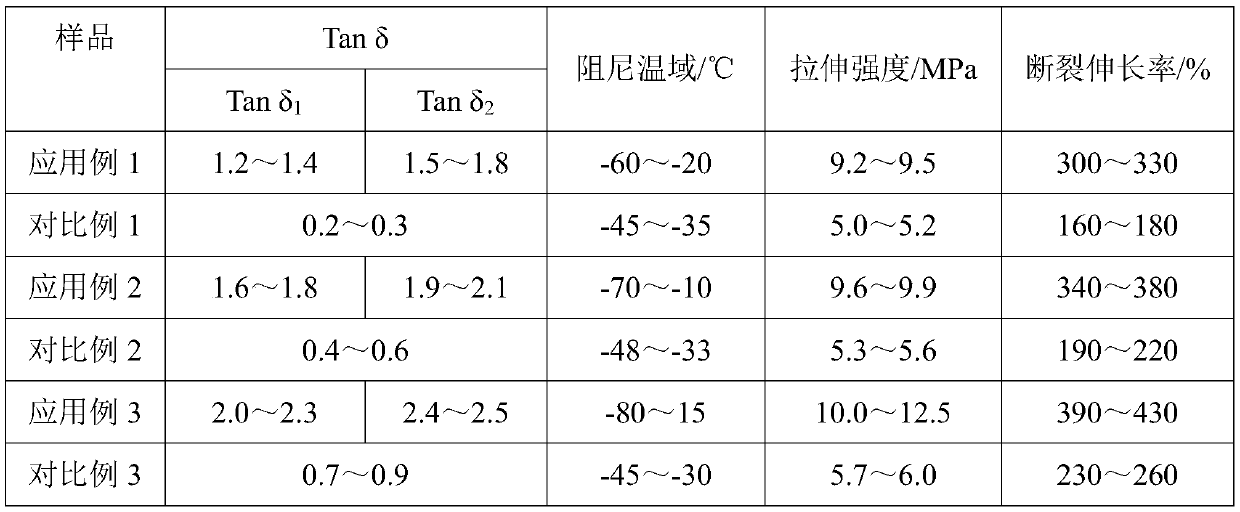

Hindered-phenol-modified montmorillonite damping agent and production method and application thereof

The invention discloses a hindered-phenol-modified montmorillonite damping agent and a production method and application thereof. The hindered-phenol-modified montmorillonite damping agent is obtainedby modifying organic montmorillonite with modified hindered phenol, the modified hindered phenol is obtained by modifying hindered phenol with a silane coupling agent, and the organic montmorilloniteis obtained by modifying inorganic montmorillonite with an alkyl quaternary ammonium salt. By adding 10-30 parts by mass of the hindered-phenol-modified montmorillonite damping agent into 100 parts by mass of a chlorobutyl damping rubber matrix, a chlorobutyl damping rubber compound material can be produced. Experiments show that the hindered-phenol-modified montmorillonite damping agent can be evenly dispersed in the chlorobutyl rubber matrix so that the damping performance, the mechanical performance and a damping temperature range of the obtained chlorobutyl damping rubber compound material can be significantly improved.

Owner:SHANGHAI UNIV OF ENG SCI

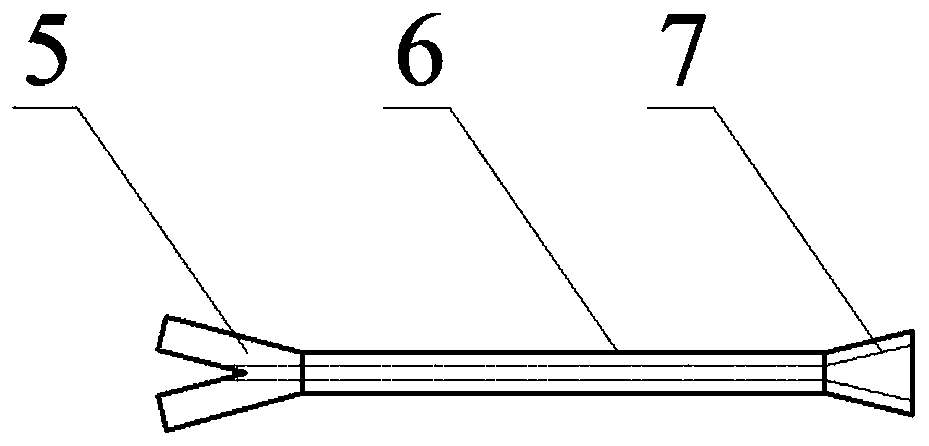

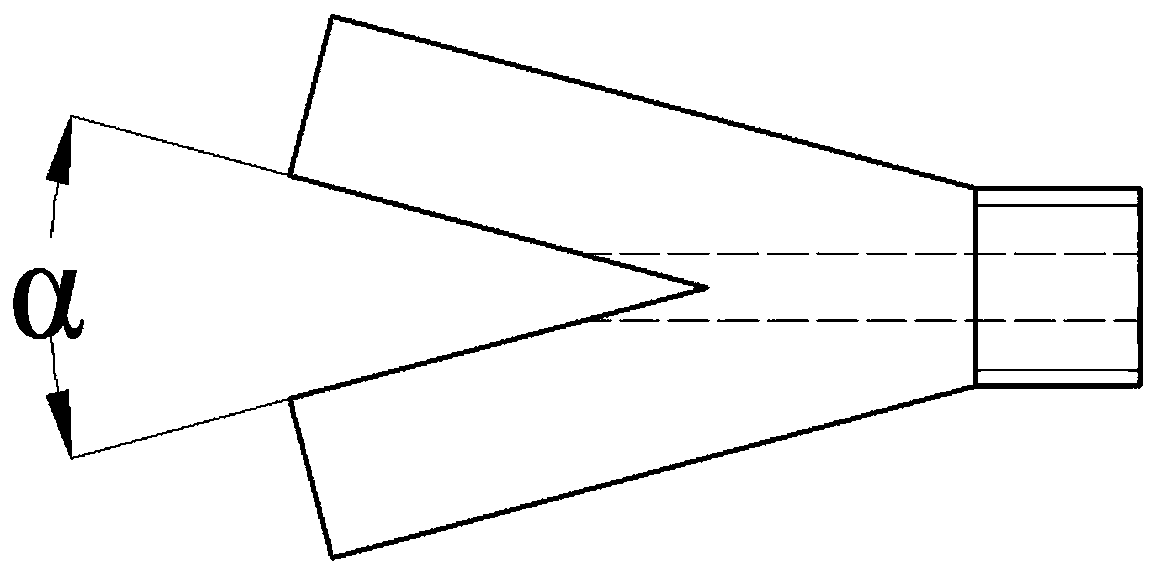

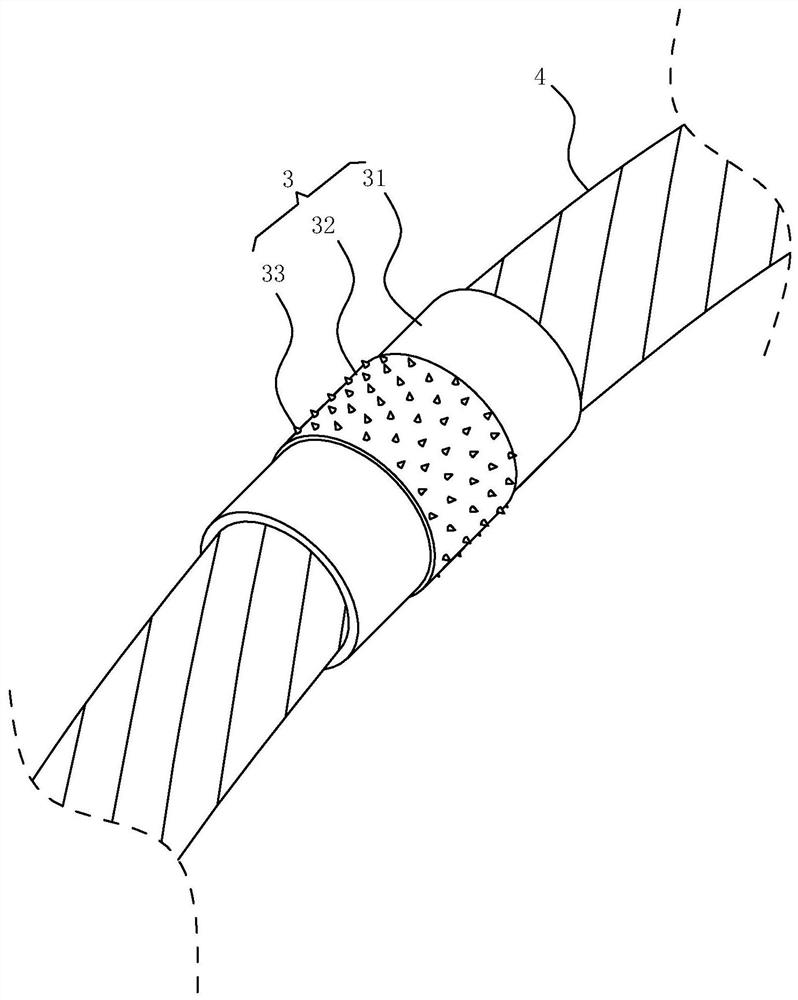

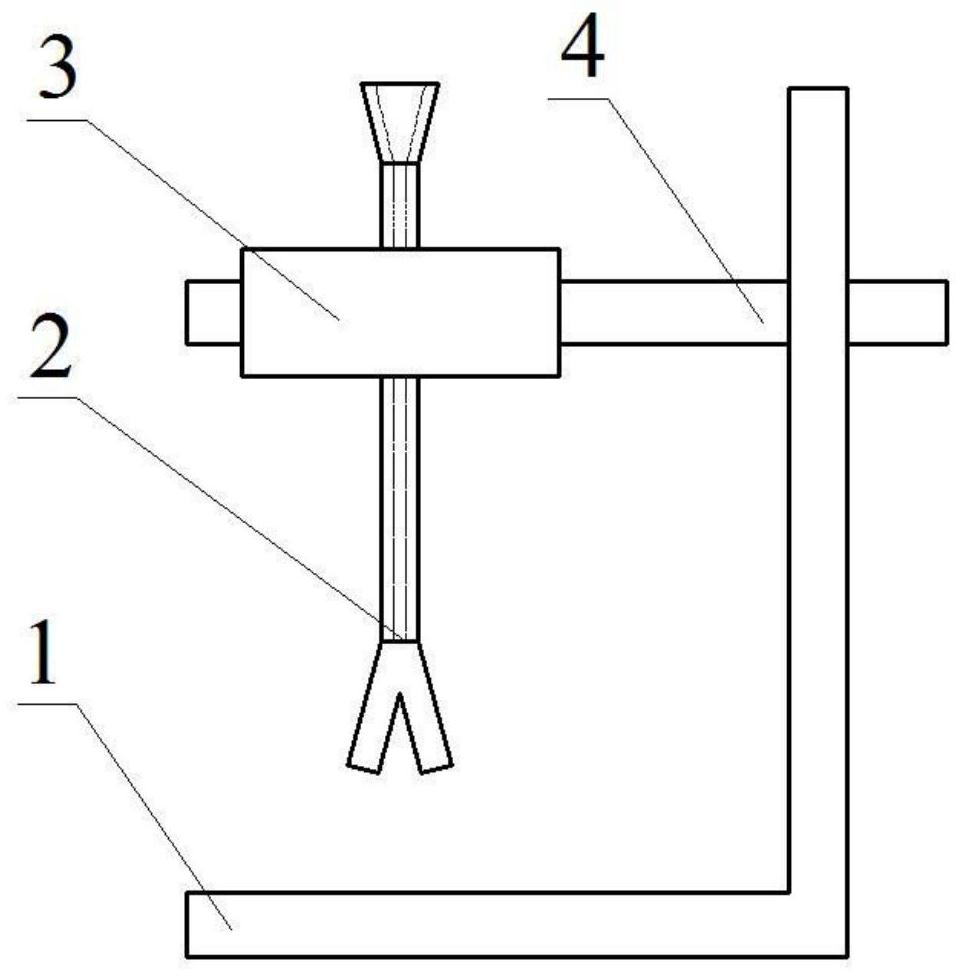

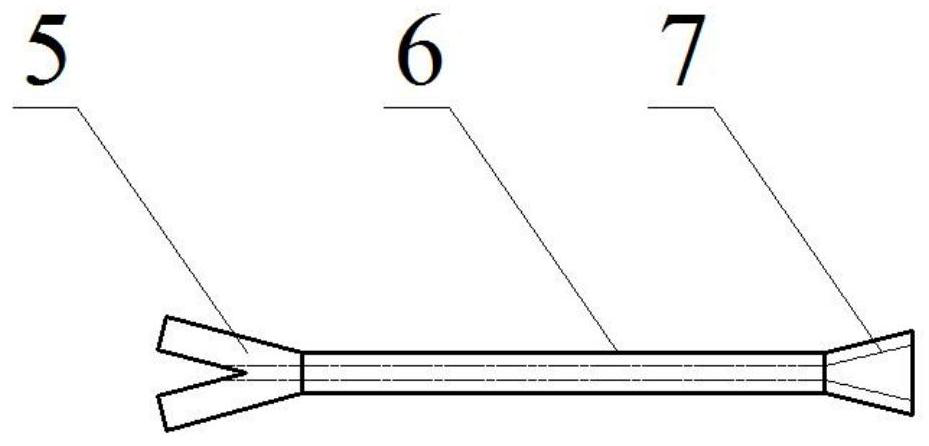

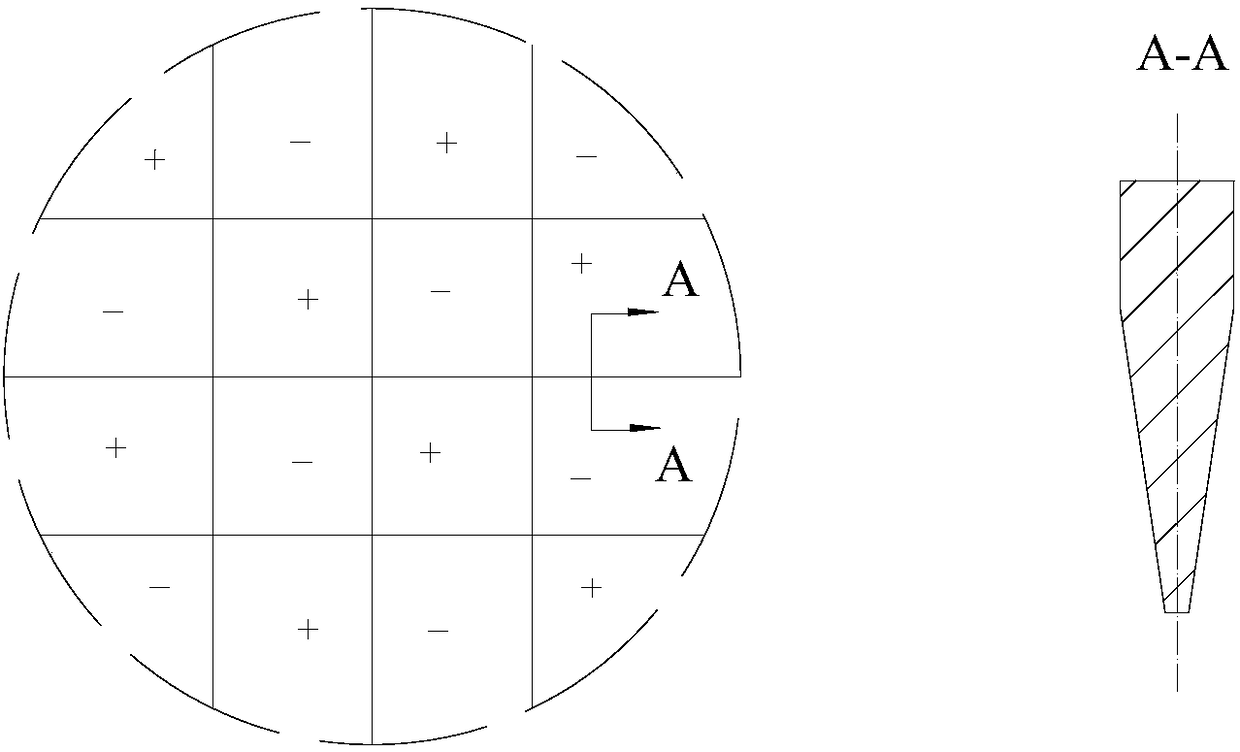

Brazing diamond wire saw for cutting rare materials and manufacturing process of brazing diamond wire saw

ActiveCN113829514ASmall particlesReduce the cross-sectional areaMetal sawing tool makingStone-like material working toolsDiamond wire sawAdhesive

The invention relates to a brazing diamond wire saw for cutting rare materials and a manufacturing process of the brazing diamond wire saw, the wire saw comprises a steel wire rope and a plurality of diamond beads fixed on the steel wire rope in a sleeving manner, and each diamond bead comprises a cylindrical base body, a material skin covering the outer wall of the base body and a plurality of diamond particles uniformly and fixedly arranged on the outer surface of the base body. The manufacturing process of the wire saw comprises the steps that an adhesive with brazing filler metal is manufactured, and the diamond particles uniformly adhere to the adhesive to form the material skin; the material skin is cut and adheres to the outer surface of the base body to form a bead green body, and the green body is brazed to form the diamond beads; and the diamond beads are arranged on a rope body in a sleeving mode and fixed through the TPU injection molding technology, and therefore the diamond wire saw is formed. The brazing diamond wire saw for cutting the rare materials and the manufacturing process of the brazing diamond wire saw have the effects of reducing the diameter of the cross section of the wire saw and improving the cutting efficiency.

Owner:石家庄雷力工具有限公司

A kind of composite titanium dioxide mesoporous film electrode material and preparation method thereof

InactiveCN111564325BEvenly distributed and orderlyHigh activityHybrid capacitor electrodesHybrid/EDL manufacturePolypyrroleSlurry

The invention discloses a composite titanium dioxide mesoporous thin-film electrode material and a preparation method thereof. The preparation method comprises: adding a titanium source and an antimony source compound to a hydrochloric acid solution, stirring and mixing to obtain a precursor solution after hydrothermal reaction, and spraying the solution Drying and calcining at high temperature to obtain mesoporous hollow spherical antimony-doped titanium dioxide composite material; placing in hydrochloric acid solution, ultrasonically dispersing, adding pyrrole monomer under stirring condition, stirring uniformly, adding oxidant dropwise, standing after completion of the reaction, filtering, drying to obtain polypyrrole@antimony / titanium dioxide composite material; uniformly mix the prepared polypyrrole@antimony / titanium dioxide composite material with polyvinylidene fluoride, add 1-methyl-2-pyridinone to prepare a slurry, It is uniformly coated on the conductive substrate, and calcined after drying to obtain the thin film electrode material. The composite thin film material prepared by the invention significantly improves the photoelectric performance of the titanium dioxide electrode material, and has a compact structure and stable performance.

Owner:FOSHAN UNIVERSITY

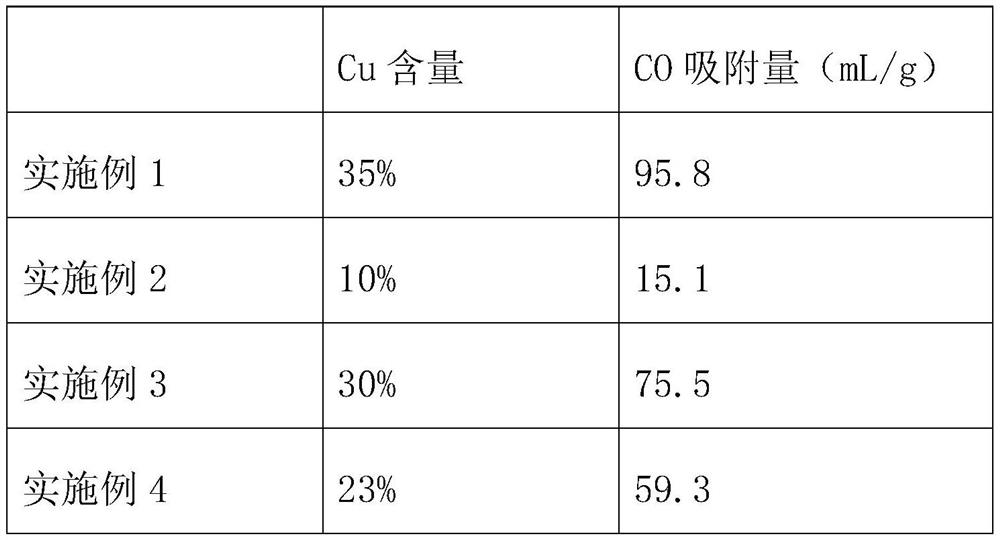

Adsorbent as well as preparation method and application thereof

PendingCN113351171ALarge specific surface areaImprove adsorption capacityHydrogen separation by selective and reversible uptakeOther chemical processesAlcoholSorbent

The invention discloses an adsorbent and a preparation method and application thereof. The preparation method of the adsorbent comprises the following steps: preparation of metal salt solution, specifically, metal salt is dissolved in a solvent to obtain the metal salt solution, the metal salt is copper salt, and the solvent is ethyl alcohol or chloroform; loading: dipping the ZIF-8 carrier in a metal salt solution, and drying to obtain a dried product; and reduction: reducing the dried product into an adsorbent containing monovalent metal ions in an inert atmosphere at the temperature of less than or equal to 400 DEG C. The adsorbent containing the monovalent metal ions can be effectively prepared by adopting an organic solvent impregnation method, the preparation method does not cause framework collapse of MOFs, and the preparation method is simple, easy to implement and suitable for large-scale production; and the prepared adsorbent has more efficient CO gas adsorption capacity.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

A kind of preparation method of high specific surface area fluorine-chlorine exchange catalyst

ActiveCN108889321BLarge specific surface areaHigh internal pore volumeCatalyst activation/preparationPtru catalystPhysical chemistry

Owner:天津航大翼安科技发展有限公司

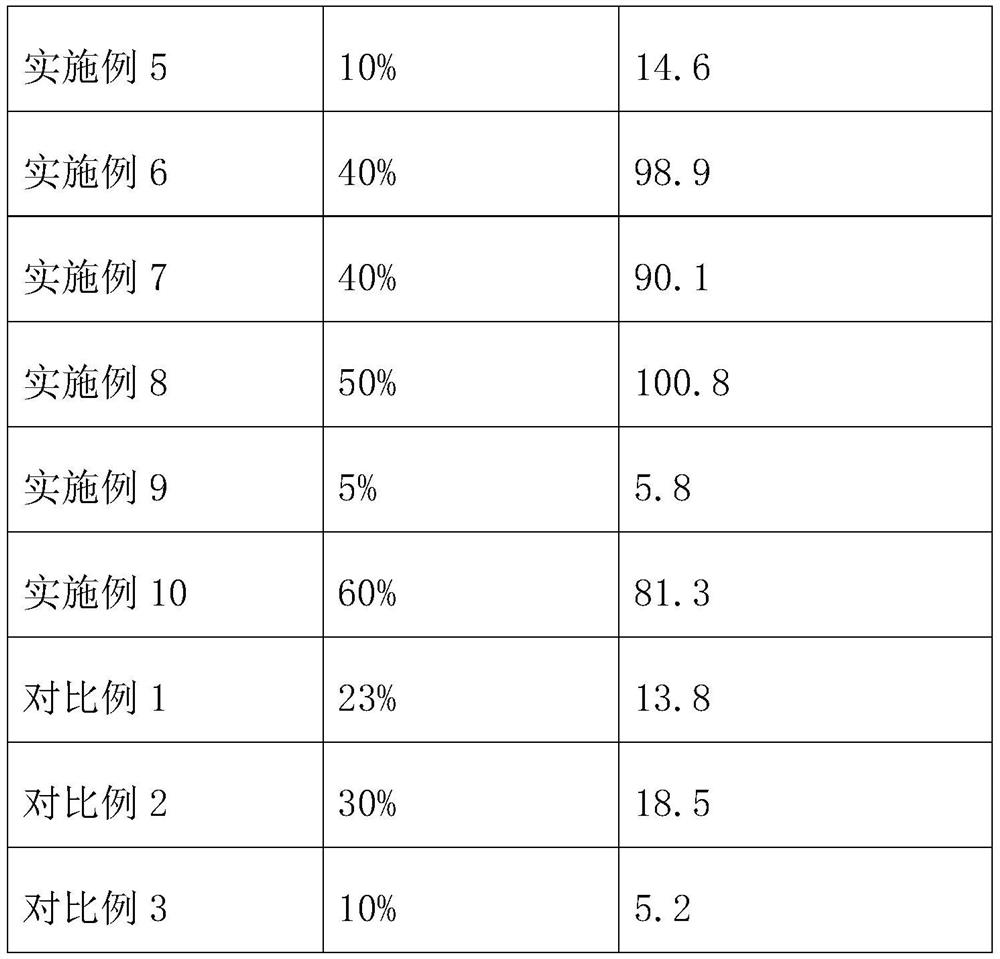

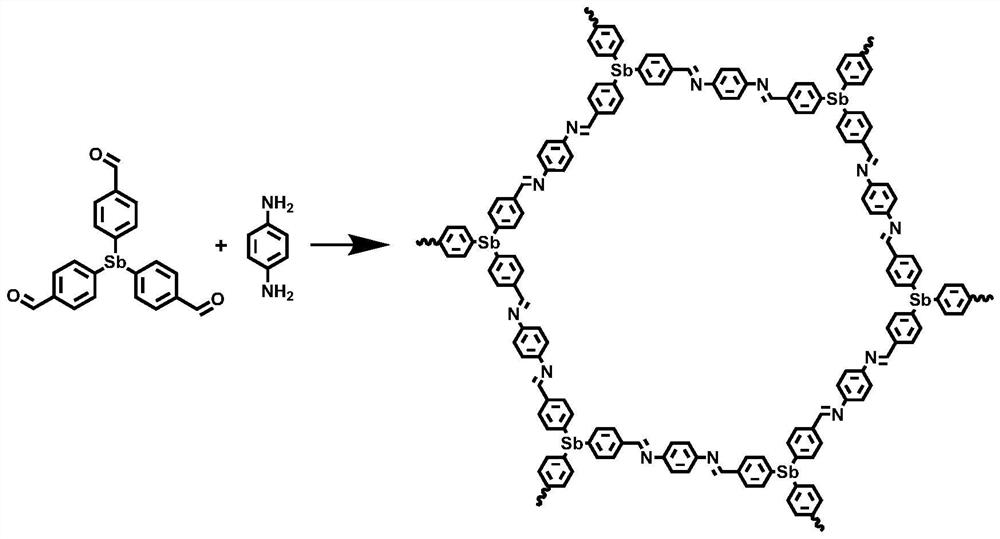

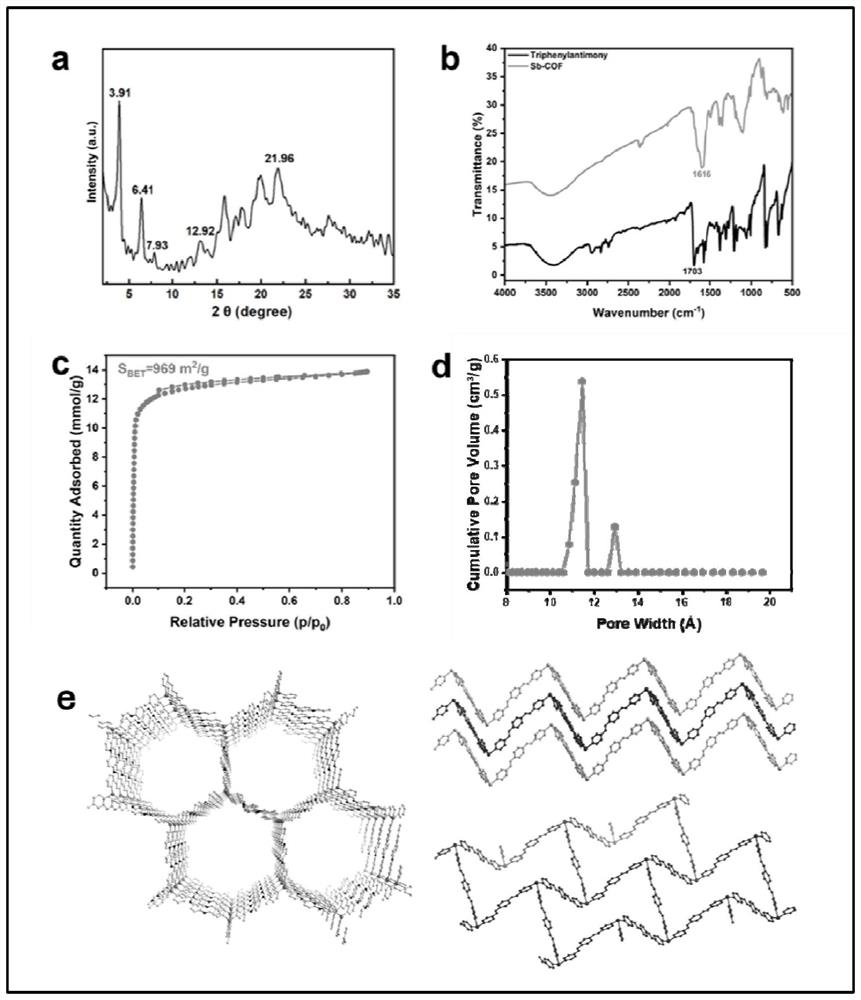

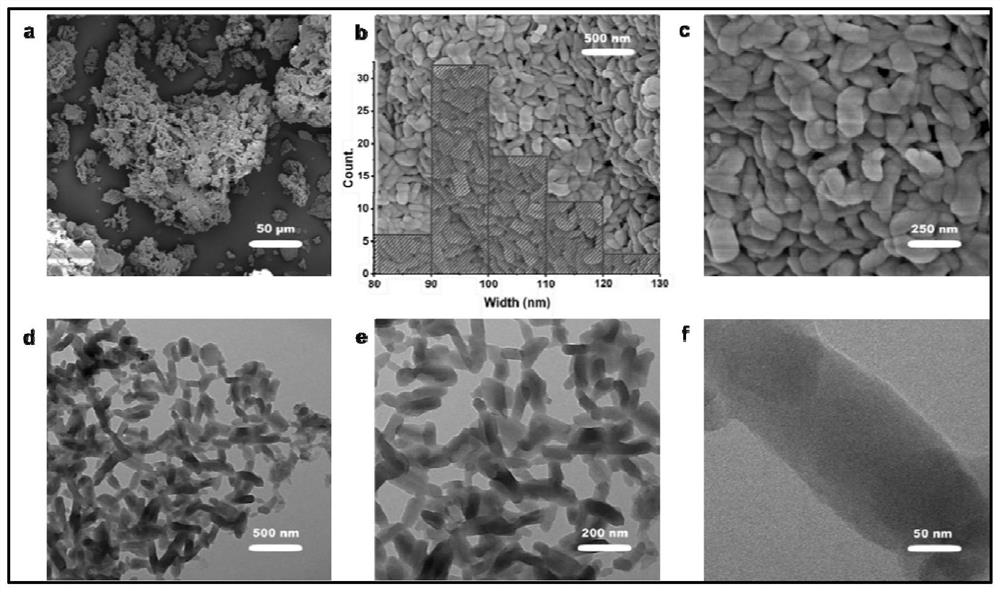

Covalent organic framework with triphenyl antimony as skeleton and preparation method and application thereof

ActiveCN114479110AHigh crystallinityImprove stabilityHybrid capacitor electrodesPolymer scienceOrganic solvent

The invention discloses a covalent organic framework taking triphenyl antimony as a framework as well as a preparation method and application thereof, and relates to the field of covalent organic frameworks (COFs) materials. The material is prepared by condensing a trialdehyde compound containing triphenyl antimony and an aromatic diamine monomer, and the preparation method comprises the following steps: 1) respectively adding tri (4-formylphenyl) antimony and aromatic diamine into an organic solvent, carrying out ultrasonic dispersion, and adding an acetic acid solution to obtain a turbid liquid; (2) carrying out liquid nitrogen freezing, vacuumizing and degassing treatment on the obtained turbid liquid, sealing, and heating for 72 hours to obtain a crude product; and 3) carrying out suction filtration and washing on the obtained crude product by using N, N-dimethylformamide (DMF), then carrying out Soxhlet extraction by using tetrahydrofuran (THF), and carrying out vacuum drying to obtain the covalent organic framework taking triphenyl antimony as the skeleton. The covalent organic framework material disclosed by the invention takes a triphenyl antimony structural unit with oxidation-reduction activity as a framework for the first time, and an electrode taking the triphenyl antimony structural unit as an active material shows excellent supercapacitor performance.

Owner:YUNNAN UNIV

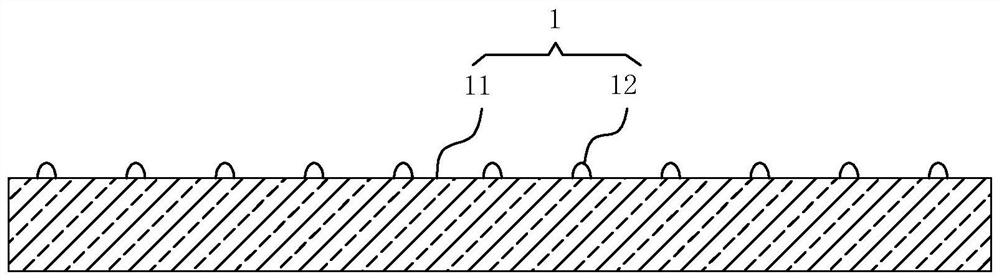

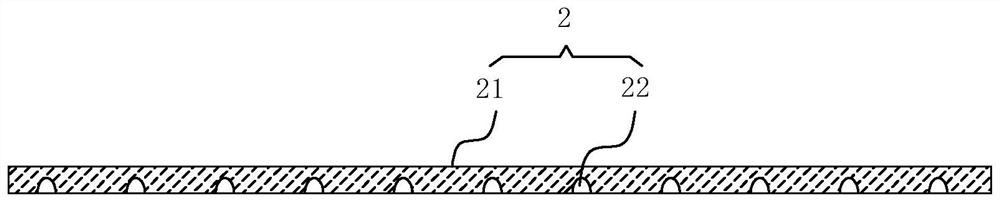

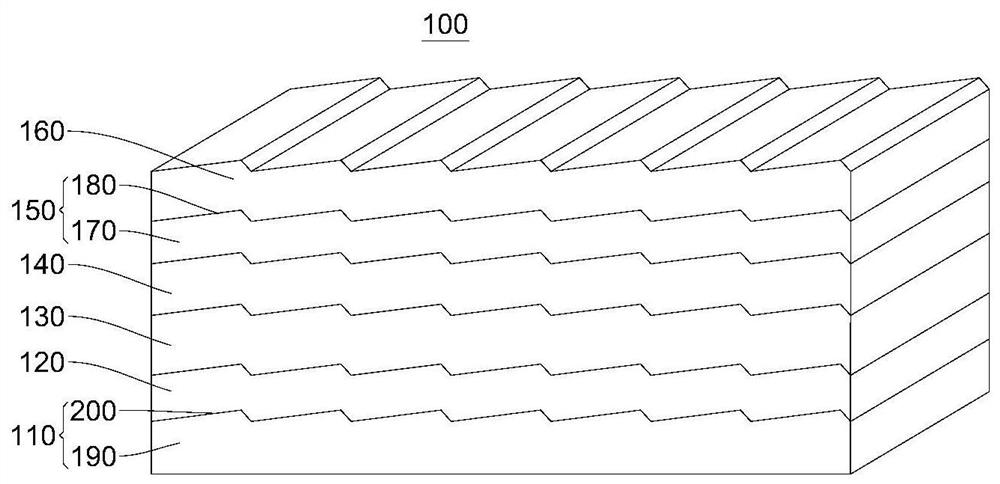

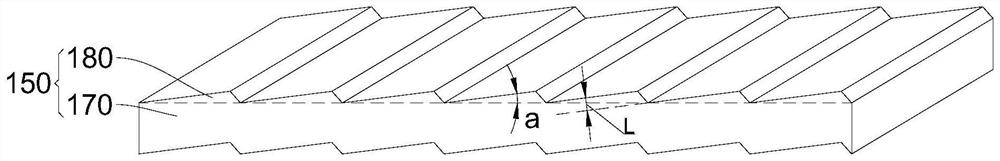

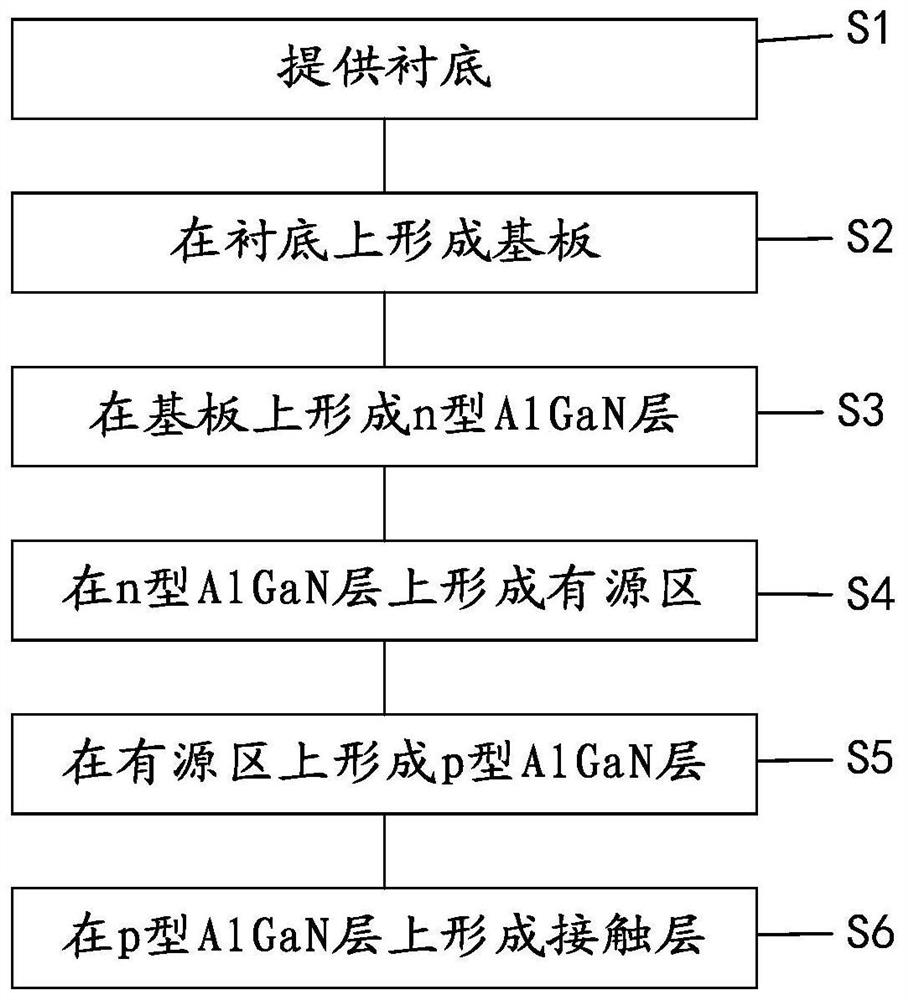

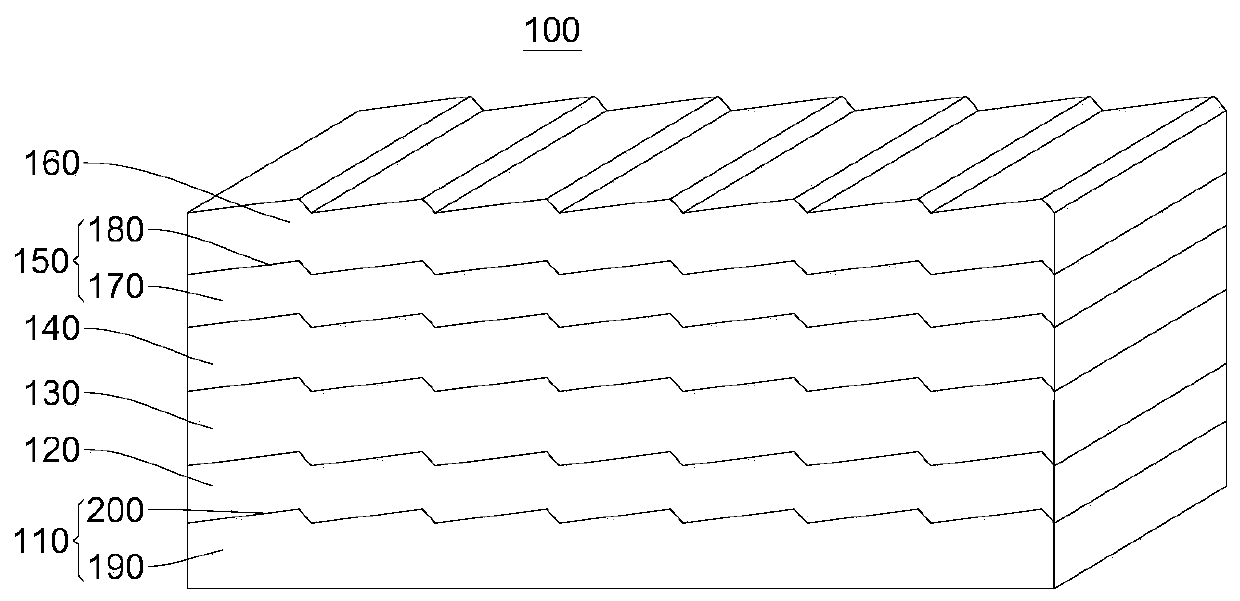

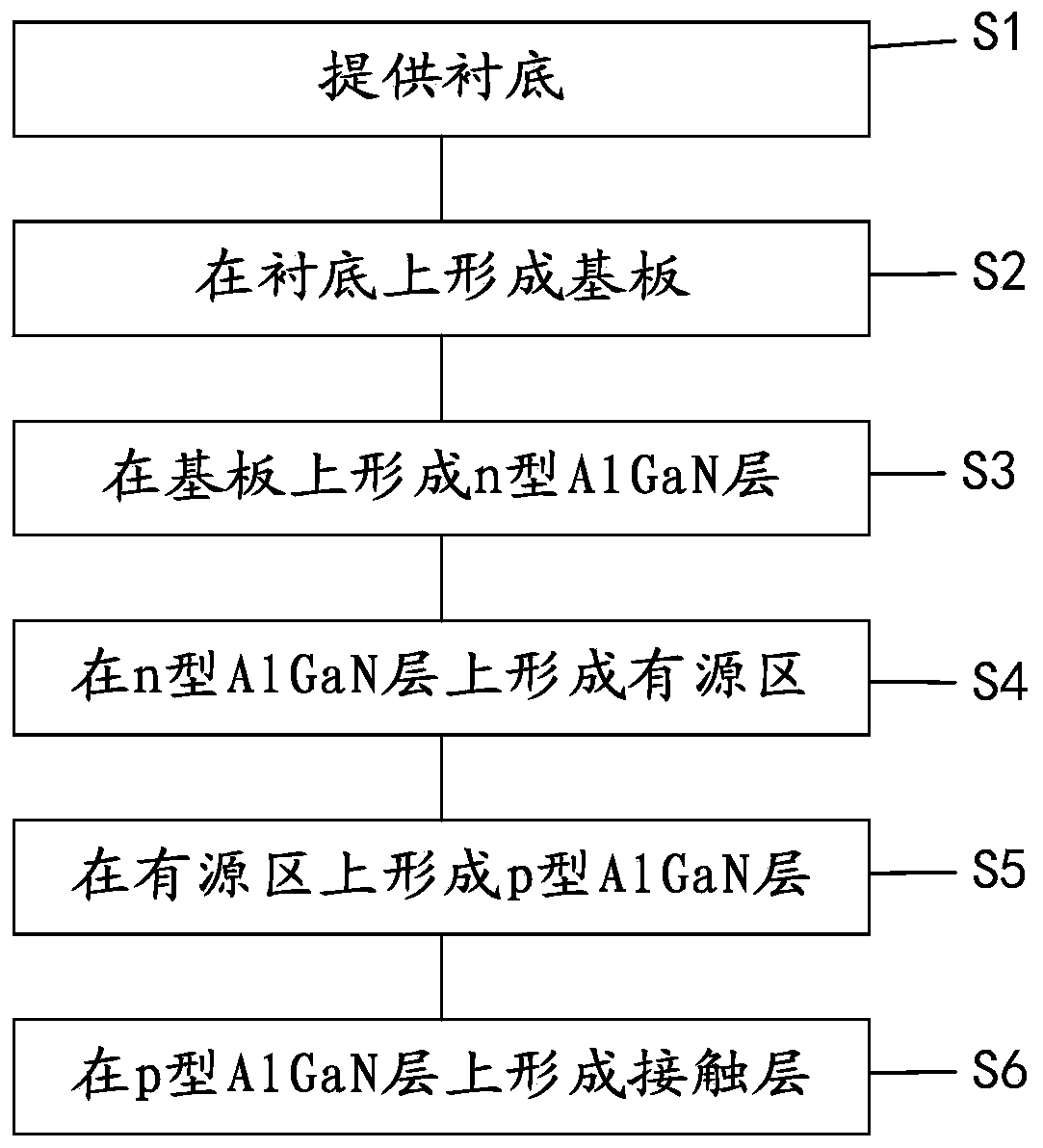

A kind of ultraviolet photoelectric device and preparation method thereof

ActiveCN111063750BReduced band gapImprove transportation efficiencyFinal product manufacturePhotovoltaic energy generationUv absorbanceEngineering

The invention provides an ultraviolet photoelectric device and a preparation method thereof, which relate to the technical field of semiconductors. The ultraviolet photoelectric device includes a substrate, a substrate grown sequentially on the substrate, an n-type AlGaN layer, an active region, and a p-type AlGaN layer; the p-type AlGaN layer includes a first body and is located on the first For the first step on the top surface of the body, the drop distance L between two adjacent first steps is greater than the thickness of the monoatomic layer. The ultraviolet photoelectric device and its preparation method can stack a plurality of single atoms in the direction of the difference between two adjacent first steps, and form a step bunching effect on the p-type AlGaN layer, thereby increasing the number of holes Transport efficiency and weaken the ultraviolet absorption, improve the photoelectric conversion efficiency of the device.

Owner:GUANGDONG INST OF SEMICON IND TECH

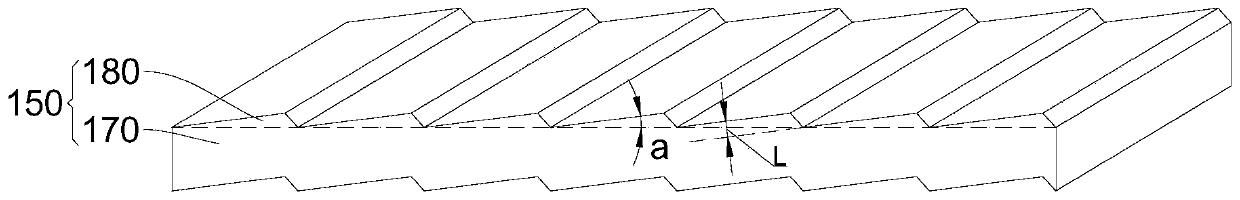

Ultraviolet photoelectric device and preparation method thereof

ActiveCN111063750AReduced band gapImprove transportation efficiencyFinal product manufacturePhotovoltaic energy generationUv absorbanceUltraviolet absorption

The invention provides an ultraviolet photoelectric device and a preparation method thereof, and relates to the technical field of semiconductors. The ultraviolet photoelectric device comprises a substrate, a base plate, an n-type AlGaN layer, an active region and a p-type AlGaN layer, wherein the base plate, the n-type AlGaN layer, the active region and the p-type AlGaN layer sequentially grow onthe substrate. The p-type AlGaN layer comprises a first body and first steps located on the top face of the first body, and the fall distance L between every two adjacent first steps is larger than the thickness of a monatomic layer. According to the ultraviolet photoelectric device and the preparation method thereof, a plurality of single atoms can be piled up in the fall direction of two adjacent first steps, and a step coalescence effect is formed on the p-type AlGaN layer; the hole transport efficiency is improved; the ultraviolet absorption is weakened; and the photoelectric conversion efficiency of the device is improved.

Owner:GUANGDONG INST OF SEMICON IND TECH

A casting anti-friction and wear-resistant high-aluminum zinc-based composite material and its preparation method

ActiveCN109778014BSolve the problem of uniform dispersionImprove the predicamentLanthanumGraphite particle

The invention relates to a casting anti-friction and abrasion-resistant high aluminum zinc-based composite material and a preparation method thereof. The technical scheme is that the composite material takes zinc and aluminum as the base, and takes copper and magnesium as main alloy elements; trace alloy elements of strontium, titanium, boron, rare earth lanthanum and the like, and micron siliconcarbide and micron graphite non-metallic ceramic reinforcement particles are added, smelting is carried out, and thus substrate molten liquid is obtained; and the substrate molten solution is subjected to the deep processing technology of powder spraying, stirring and ultrasonic combined treatment so that the silicon carbide particles with abrasion-resistant performance and the graphite particleswith anti-friction performance can be well immersed in the substrate molten liquid and be uniformly dispersed and distributed in the composite material accordingly, and thus the fine-grained casting anti-friction and abrasion-resistant high aluminum zinc-based composite material obtained. The casting anti-friction and abrasion-resistant high aluminum zinc-based composite material has the characteristics of simple technology and low preparation cost. The reinforcement particles of the prepared product are uniformly distributed, and the composite material are excellent in plasticity, toughness and abrasion resistance, and stable in quality.

Owner:WUHAN UNIV OF SCI & TECH

Non-combustible cigarette fuming base strip and preparation method thereof

ActiveCN109222221AFlat sectionEvenly distributed and orderlyTobacco preparationCigarette manufactureEngineeringConveyor belt

The invention relates to the technical field of cigarette making, and provides a preparation method of a non-combustible cigarette fuming base strip. The method comprises: at least one strip-shaped raw material is adsorbed on a conveyor belt under negative pressure to be conveyed; Screening and removing at least one strip-shaped raw material during the conveying process; Fragrance at least one ofthe strip-shaped raw materials during transport; Laying at least one strip-shaped raw material in an orderly manner; At least one of the orderly laid strips of raw material is rolled into a base strip. In the preparation process, the method can reduce the crushing of the strip-shaped raw material, ensure the smoothness of the end face of the base strip, and reduce the phenomenon of short end or virtual end of the cigarette rod. The invention also provides a non-combustible cigarette fuming base strip prepared by the method, wherein the cigarette shreds are uniformly and orderly distributed, and the cigarette shreds have no empty head or imaginary head phenomenon.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

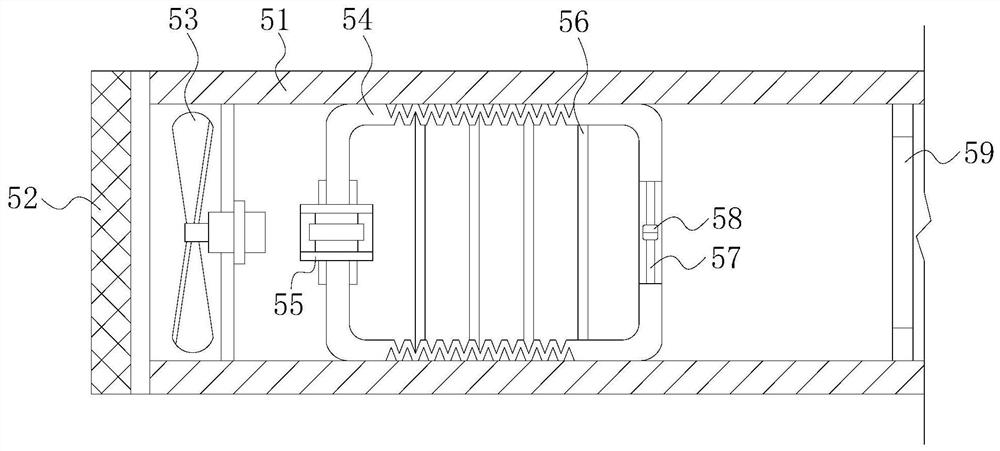

A biomass energy-saving and environment-friendly combustion furnace

ActiveCN110345469BEffective air dryingReduce moistureDrying gas arrangementsSolid fuel combustionEnvironmental engineeringCotton cloth

The invention discloses a biomass energy-saving and environment-friendly combustion furnace, which relates to the technical field of combustion furnaces. The biomass energy-saving and environment-friendly combustion furnace includes a body. A furnace body is fixedly installed on the left side of the body, and a grate is arranged in the furnace body. The cavity is connected, and a material guide plate is arranged under the hopper, and the right side of the material guide plate is fixedly connected with the inner wall of the machine body, and the left side of the material guide plate penetrates between the machine body and the furnace body and extends to the furnace body. An air guiding mechanism is arranged between the top and the inner top of the body. The biomass energy-saving and environment-friendly combustion furnace collects part of the steam generated during the working process of the furnace body through the air guide mechanism and absorbs moisture through the cotton cloth, so that the air guide mechanism can effectively prevent the exhaust gas from passing through the material guide plate when blowing the air flow into the processing mechanism. The fuel entering the furnace body is air-dried, which greatly reduces the moisture contained in the fuel.

Owner:台州市黄岩智正信息科技有限公司

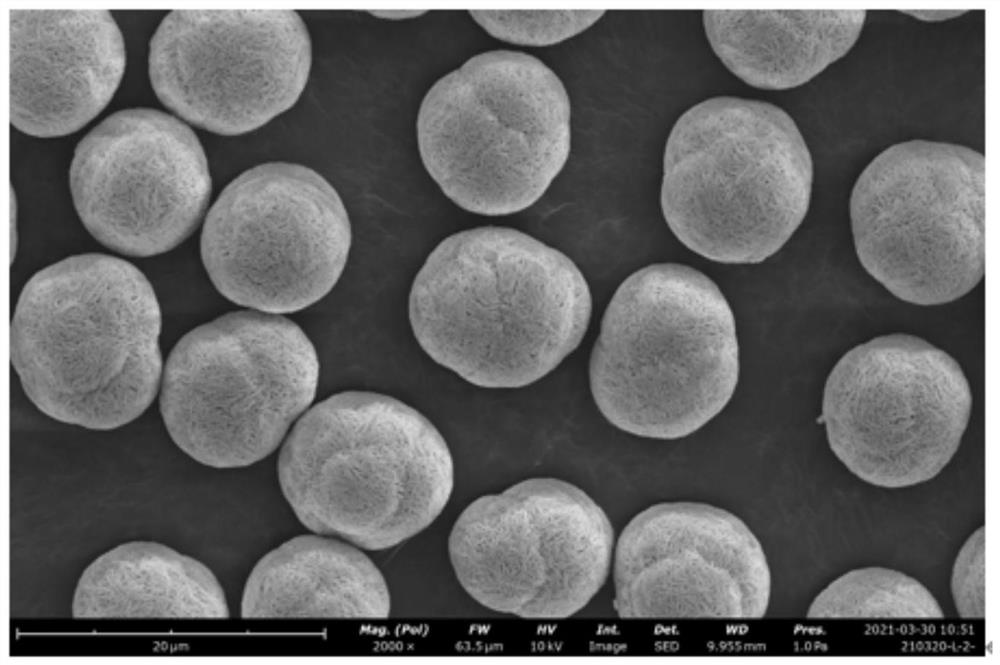

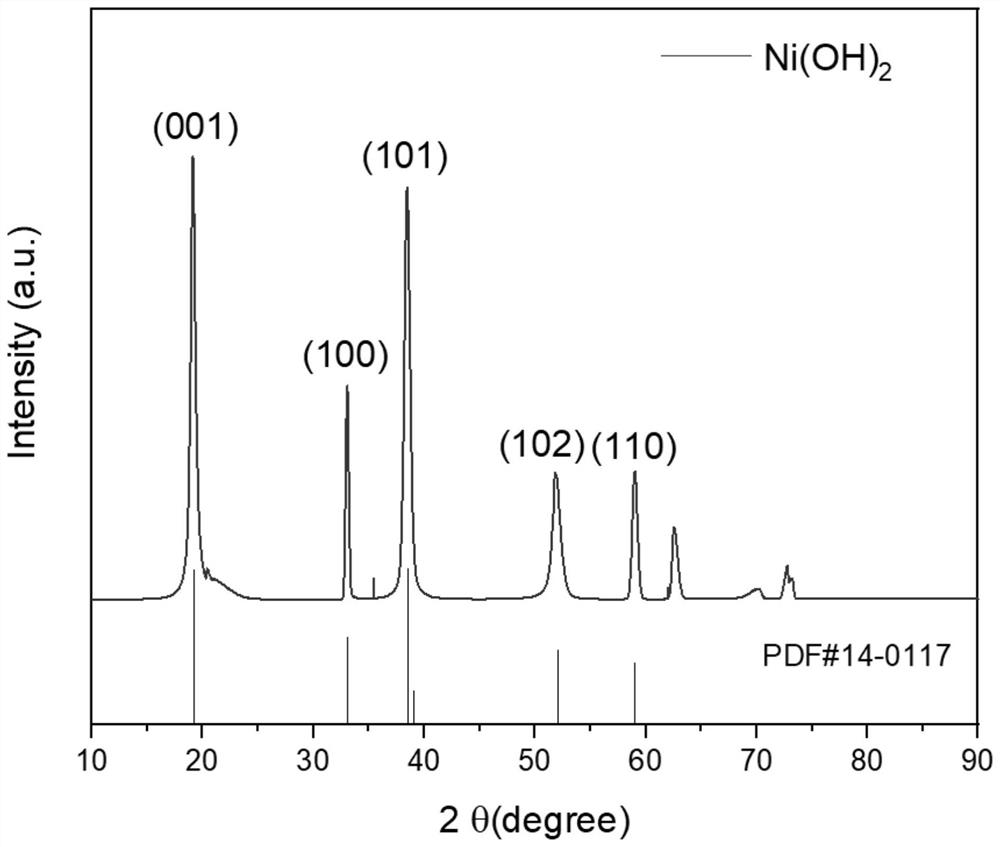

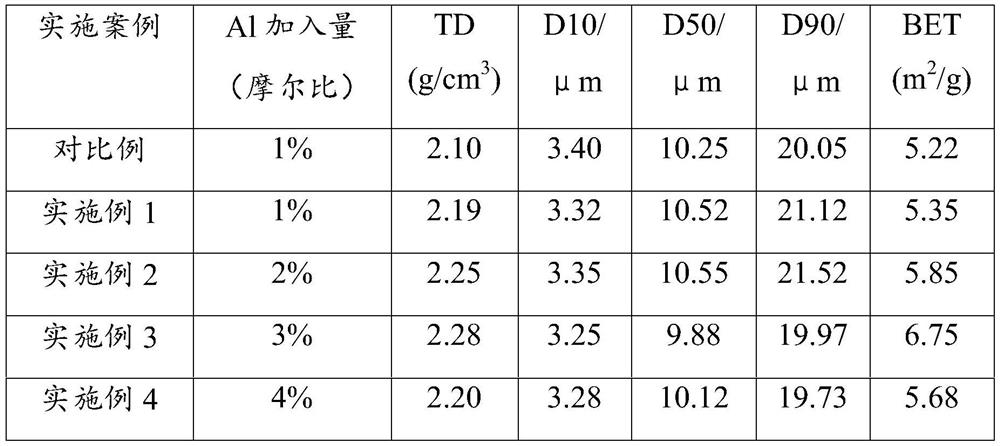

A kind of preparation method of ncma quaternary precursor containing la, ce co-doping

ActiveCN113363438BImprove conductivityRaise the average valenceCell electrodesLi-accumulatorsNickel saltSodium aluminate

The invention discloses a method for preparing a NCMA quaternary precursor containing La and Ce co-doped, comprising: 1) configuring soluble nickel salt, cobalt salt, and manganese salt so that the total metal ion concentration is 1.5mol / L-2.0mol / L solution A; 2) Add lanthanum salt and cerium salt solution to mixed solution A and mix evenly to obtain solution B; 3) Add sodium metaaluminate solution to sodium hydroxide solution at a preset rate to obtain solution C; 4) Add solution B, sodium hydroxide solution, and ammonia solution to the reaction kettle for co-precipitation reaction; 5) When the crystal particle size D50 grows to 6um, pass solution C into the reaction kettle to continue the reaction; 6) The particle size of the product to be overflowed After the D50 grows to 10±1um, the reaction is stopped, and the overflow slurry is aged, washed, dried, and iron-removed to obtain a nickel-cobalt-manganese-aluminum precursor; the present invention prepares high sphericity, NCMA precursor with high crystallinity and high vibration.

Owner:XIAMEN UNIV

Covalent organic framework with triphenylphosphine as skeleton, preparation method and application thereof

ActiveCN109762180BHigh crystallinityImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceEthylic acid

The invention discloses a covalent organic framework with triphenylphosphine as a framework as well as a preparation method and application of the covalent organic framework and relates to the field of covalent organic framework materials. The compound is formed by polycondensation of a triphenylphosphine-containing trialdehyde monomer and diamine monomer. The preparation method comprises the following steps: adding monomer triphenylphosphine trialdehyde and diamine into a solvent; carrying out ultrasonic dispersion and adding an acetic acid solution for continuous ultrasonic operation to forma suspension turbid liquid; carrying out liquid nitrogen refrigeration-vacuumizing-degassing treatment, sealing and standing on the suspension to obtain a crude product; carrying out suction filtration washing on the crude product by using N,N-dimethylformamide, and then carrying out Soxhlet extraction and vacuum drying by using tetrahydrofuran and chloroform in sequence to obtain the covalent organic framework with the triphenylphosphine as the framework. The covalent organic framework related in the invention introduces a triphenylphosphine structural unit with high coordination capabilityinto a material framework for the first time, and has a broad application prospect in the fields of gas adsorption and separation, photoelectricity, in particular to catalysis.

Owner:YUNNAN UNIV

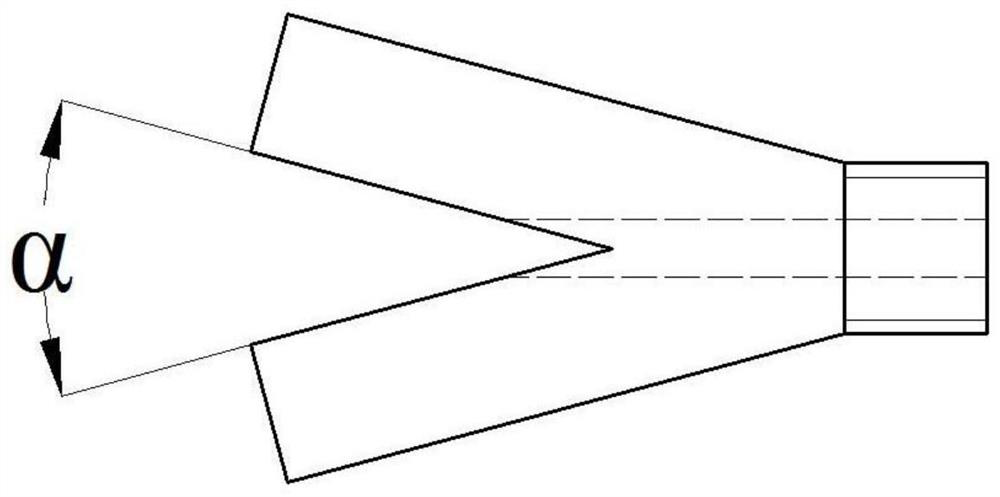

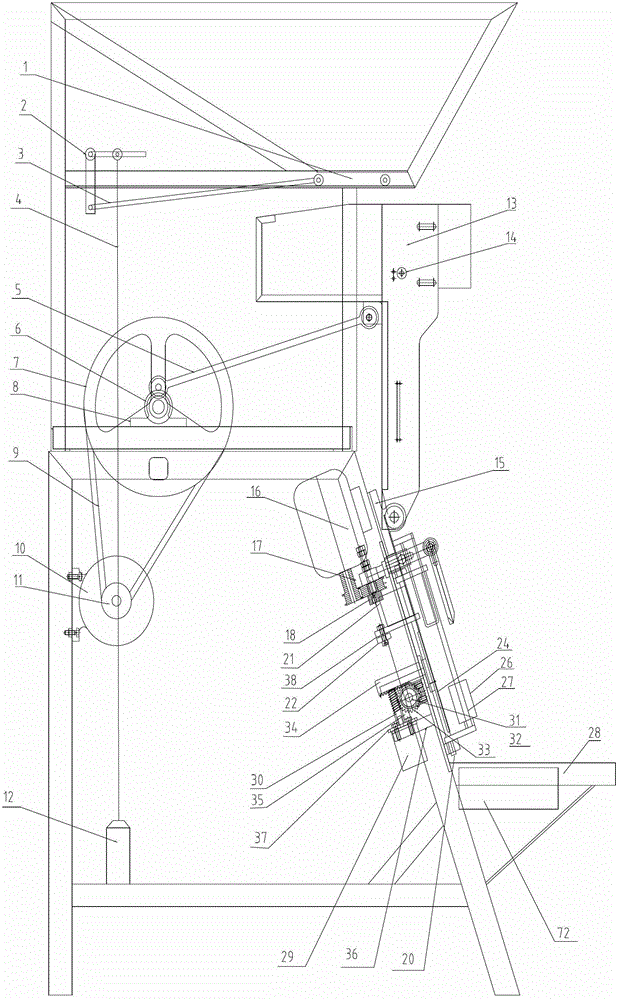

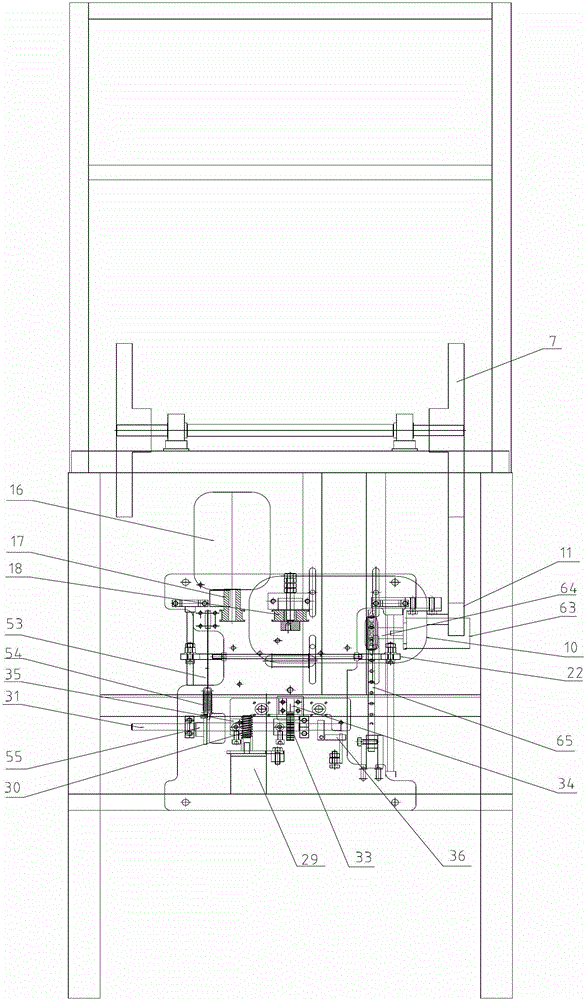

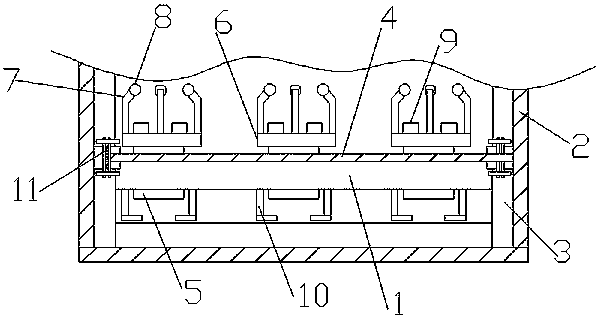

Forming system of sparkler tube washing machine

InactiveCN103033096BEvenly distributed and orderlyNo human intervention requiredFireworksPush offBiochemical engineering

The invention discloses a forming system of a sparkler tube washing machine. The forming system comprises a mold upstream-downstream receiving mechanism, a mold left-right swinging mechanism and a mold baseplate push-off and reset mechanism, which are compatible with one another to run. The forming system has the benefits that the forming work is fully-automatically completed, the human intervention is not needed in the whole process, paper tubes are uniformly and sequentially distributed, the forming quality is high, the degree of equipment integration is high, the mechanisms are reduced, the standardized production is convenient, and the debugging and the maintenance are convenient.

Owner:黄永秋

A non-burning cigarette smoking base strip and its preparation method

ActiveCN109222221BFlat sectionEvenly distributed and orderlyTobacco preparationCigarette manufactureConveyor beltBiology

The present invention relates to the technical field of cigarette making, and provides a method for preparing a non-burning cigarette smoking basic strip, which includes: absorbing at least one strip-shaped raw material on a conveyor belt through negative pressure and transporting it; Sieving and removing impurities from strip-shaped raw materials; flavoring at least one strip-shaped raw material during the transmission process; laying at least one strip-shaped raw material in an orderly manner; rolling at least one strip-shaped raw material after orderly laying Basic article. During the preparation process, the method can reduce the fragmentation of the strip-shaped raw materials, ensure the flat end surface of the basic strip, and reduce the phenomenon of short or empty ends in the tobacco strip. The present invention also provides a basic non-combustible cigarette rod prepared by the above method, in which shredded tobacco is evenly and orderly distributed, and the tobacco rod has no empty ends or empty ends.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

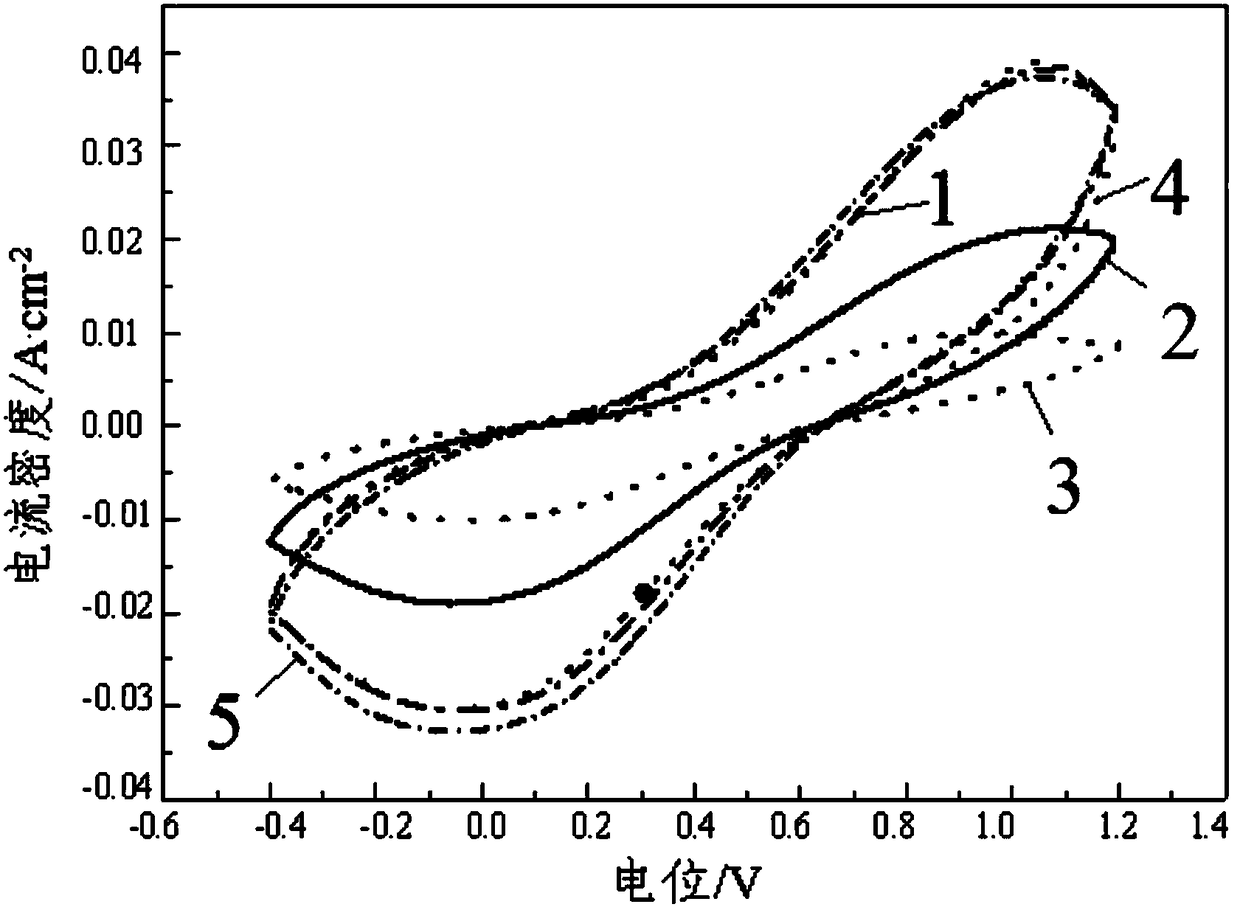

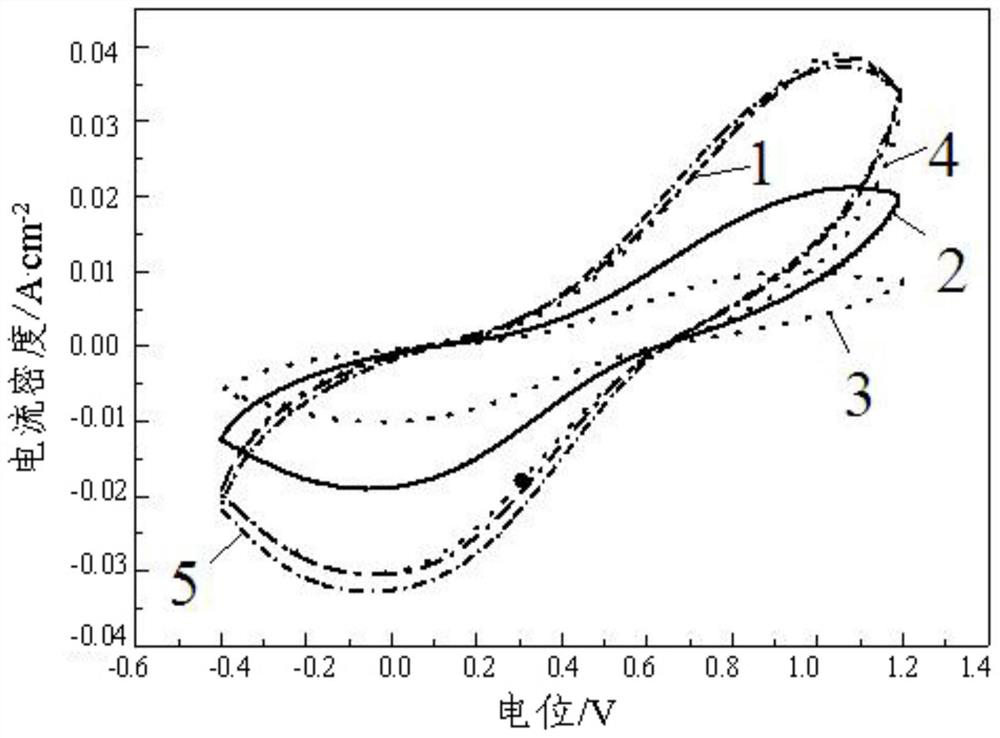

Method for preparing aniline-pyrrole copolymer under assistance of microwaves

ActiveCN108424515AEffectively control the composition of the structureEffective control of microstructureSlurryPseudocapacitance

The invention discloses a method for preparing an aniline-pyrrole copolymer under assistance of microwaves. The method comprises steps as follows: 1, pyrrole, aniline and acid are added to deionized water for ultrasonic dispersion, and a mixed solution A is obtained; 2, an oxidizing agent, a surfactant and a catalyst are added to the deionized water for ultrasonic dispersion, and a mixed solutionB is obtained; 3, the mixed solution B is dropwise added to the mixed solution A for a microwave-assisted reaction, and slurry containing precipitates is obtained; 4, the slurry is centrifuged, the precipitates are collected, washing, centrifugation and vacuum drying are performed sequentially, and the aniline-pyrrole copolymer is obtained. The aniline-pyrrole copolymer is prepared under assistance of the microwaves, uniform and ordered growth of aniline and pyrrole molecules is promoted through radiation heating of aniline, pyrrole molecules and water by use of microwaves, the obtained aniline-pyrrole copolymer has a relatively loose 3D ordered structure and fewer defects, so that the pseudocapacitance of the aniline-pyrrole copolymer as an electrode material is improved, the cycle life of the aniline-pyrrole copolymer is prolonged, and the electric conductivity is improved.

Owner:XIAN UNIV OF SCI & TECH

Cable distributing and clamping device for high-voltage cable branch box

InactiveCN108347031AStable deliveryRealize position adjustmentCable junctionsEngineeringHigh pressure

The present invention provides a cable distributing and clamping device for a high-voltage cable branch box. The device comprises a distribution support disk. Each end of the distribution support diskis slidably fixed on a support column of the box body and is rotatingly provided with a clamping block. The distribution support disk is provided with multiple rows of sliding bars, and each row of the sliding bars is slidingly provided with a plurality of wire-passing hole pieces in order. Each of the wire-passing hole pieces is sleeved with a support ring. Springs extend upwards from the support rings, and the top of each of the springs is slidingly provided with a ball. The device has the advantages of reasonable design, uniform and orderly cable distribution, the improvement of stability,convenient operation and the prolongation of the service life.

Owner:JIANGSU JIANXIONG ELECTRIC CO LTD

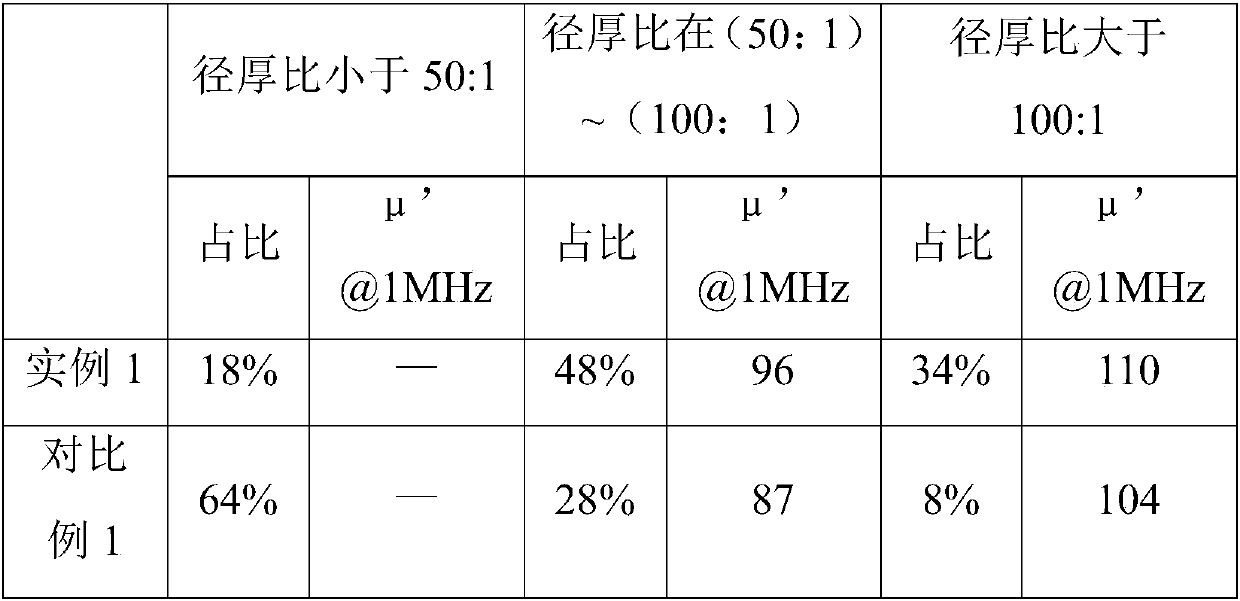

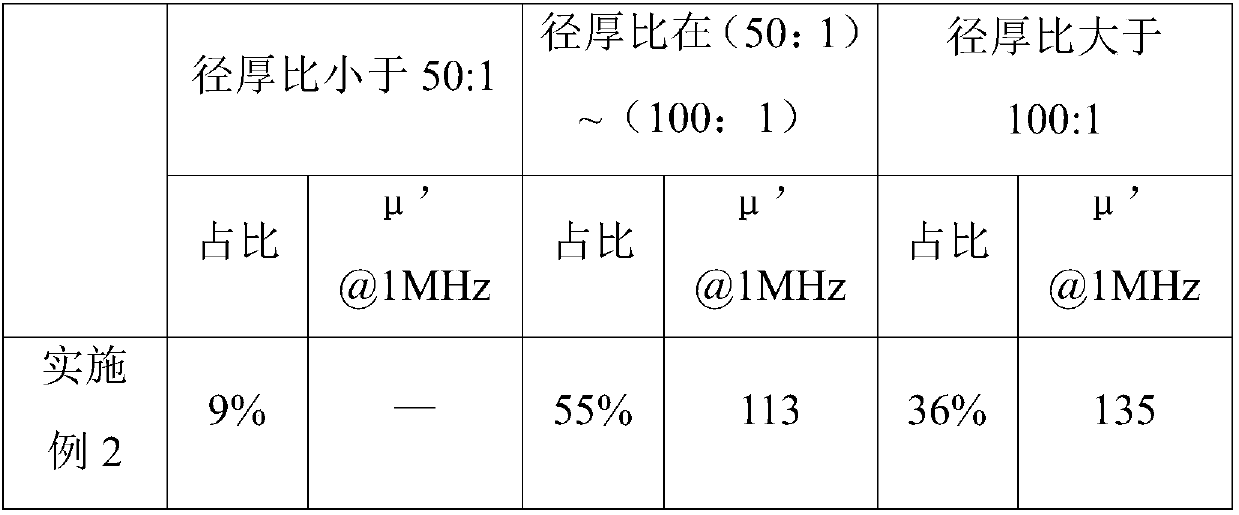

A kind of preparation method of high magnetic permeability flaky soft magnetic alloy powder

ActiveCN105834440BMicro stress reliefImprove plastic deformation abilityTransportation and packagingMetal-working apparatusManufacturing technologyReduction treatment

The invention discloses a preparation method of high magnetic permeability flaky soft magnetic alloy powder, which is characterized in that it comprises the following steps: (1), raw material selection: select soft magnetic alloy magnetic powder that can be used for absorbent, and the shape is not limited , select solvent; (2), primary ball milling; (3), primary reduction treatment; (4), secondary ball milling; (5), classification: by air classification technology, the magnetic powder in step (4) is carried out particle size classification, respectively Screen out the magnetic powder whose diameter-to-thickness ratio is less than 50:1, between (50:1) and (100:1), and greater than 100:1; (6), secondary reduction annealing treatment; (7), dispersion treatment. The invention has the characteristics of simple manufacturing process, low manufacturing cost, high yield, large diameter-thickness ratio, high magnetic permeability and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

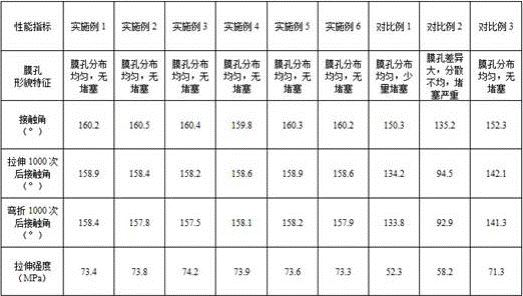

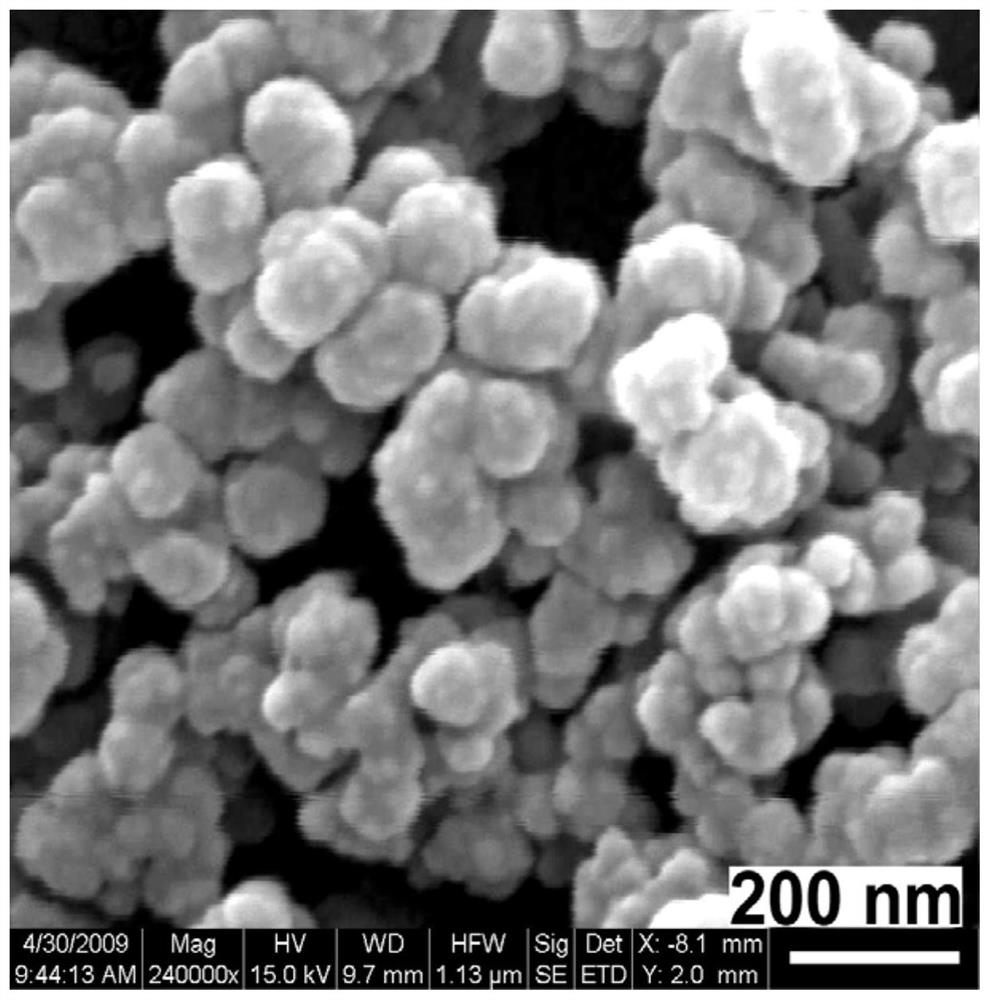

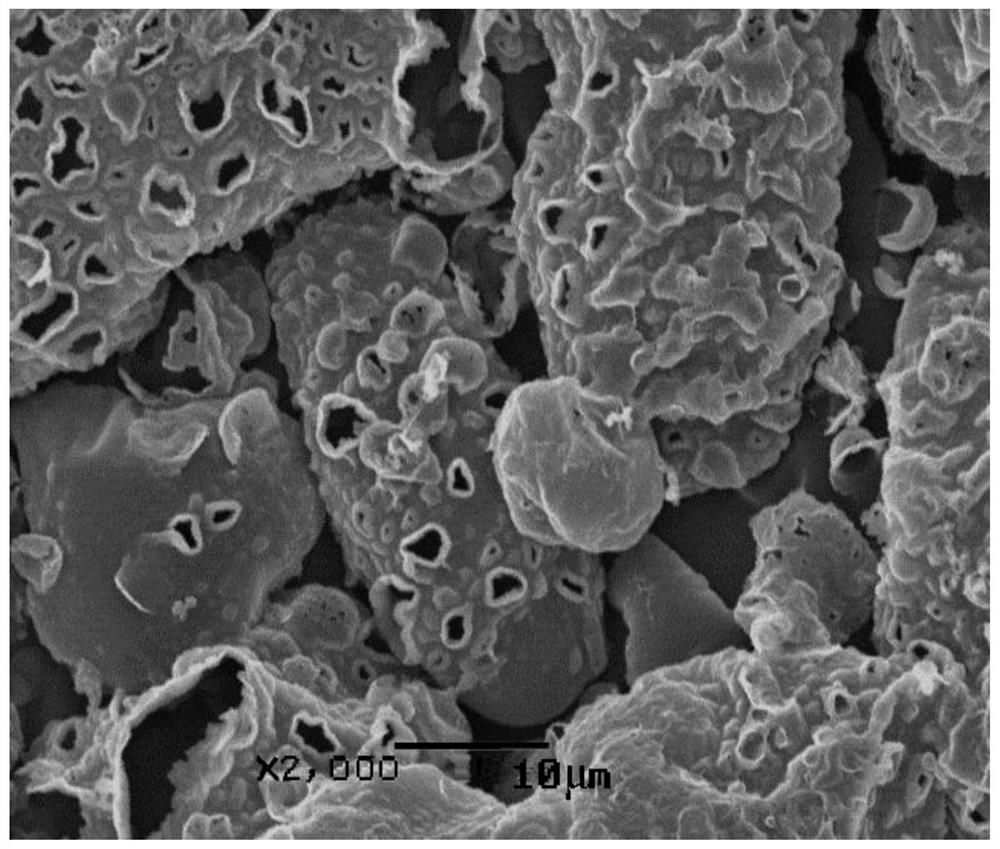

A method for preparing polycarbonate/graphene superhydrophobic porous membrane by 3D printing

ActiveCN109126484BIncrease elasticityHigh mechanical strengthMembranesSemi-permeable membranes3d printRough surface

The invention belongs to the technical field of superhydrophobic materials and provides a method for preparing a polycarbonate / graphene superhydrophobic porous membrane by 3D printing. The method comprises the following steps: preparing fluorinated graphene aerogel, performing grinding and crushing, adding powder, an antioxidant and a lubricant to molten polycarbonate, uniformly mixing the mixture, and performing 3D printing according to set parameters to obtain a porous membrane with a submicron rough surface; further modifying the surface of the membrane with vinyl to prepare the polycarbonate / graphene superhydrophobic porous membrane. Compared with the traditional method, the porous membrane adopts a 3D printing rapid forming technology which has simple and easy-to-control process, andthe membrane has uniform and orderly membrane pores, good mechanical stability, high deformation capability and excellent superhydrophobic performance, thereby having broad application prospect.

Owner:黄素环

A microwave-assisted method for preparing aniline-pyrrole copolymers

The invention discloses a method for preparing an aniline-pyrrole copolymer under assistance of microwaves. The method comprises steps as follows: 1, pyrrole, aniline and acid are added to deionized water for ultrasonic dispersion, and a mixed solution A is obtained; 2, an oxidizing agent, a surfactant and a catalyst are added to the deionized water for ultrasonic dispersion, and a mixed solutionB is obtained; 3, the mixed solution B is dropwise added to the mixed solution A for a microwave-assisted reaction, and slurry containing precipitates is obtained; 4, the slurry is centrifuged, the precipitates are collected, washing, centrifugation and vacuum drying are performed sequentially, and the aniline-pyrrole copolymer is obtained. The aniline-pyrrole copolymer is prepared under assistance of the microwaves, uniform and ordered growth of aniline and pyrrole molecules is promoted through radiation heating of aniline, pyrrole molecules and water by use of microwaves, the obtained aniline-pyrrole copolymer has a relatively loose 3D ordered structure and fewer defects, so that the pseudocapacitance of the aniline-pyrrole copolymer as an electrode material is improved, the cycle life of the aniline-pyrrole copolymer is prolonged, and the electric conductivity is improved.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com