Forming system of sparkler tube washing machine

A technology for washing canisters and fireworks, which is applied to the types of weapons, pyrotechnics, and offensive equipment. It can solve the problems of limited production efficiency, a large number of manual interventions, and a low degree of automation. It achieves uniform and orderly distribution of paper canisters, and a high degree of equipment integration. The effect of facilitating standardized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

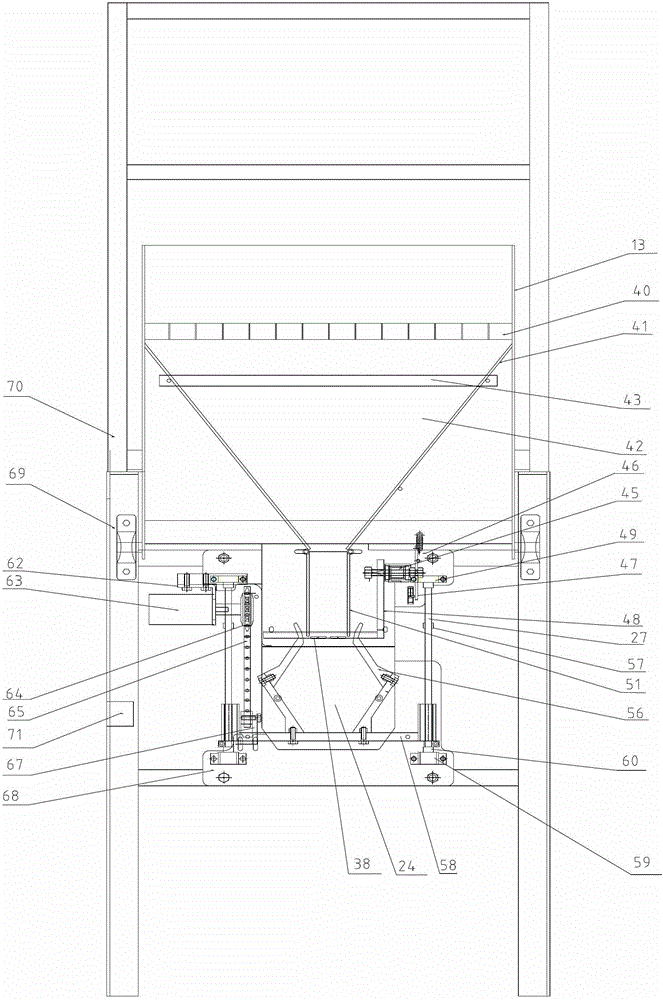

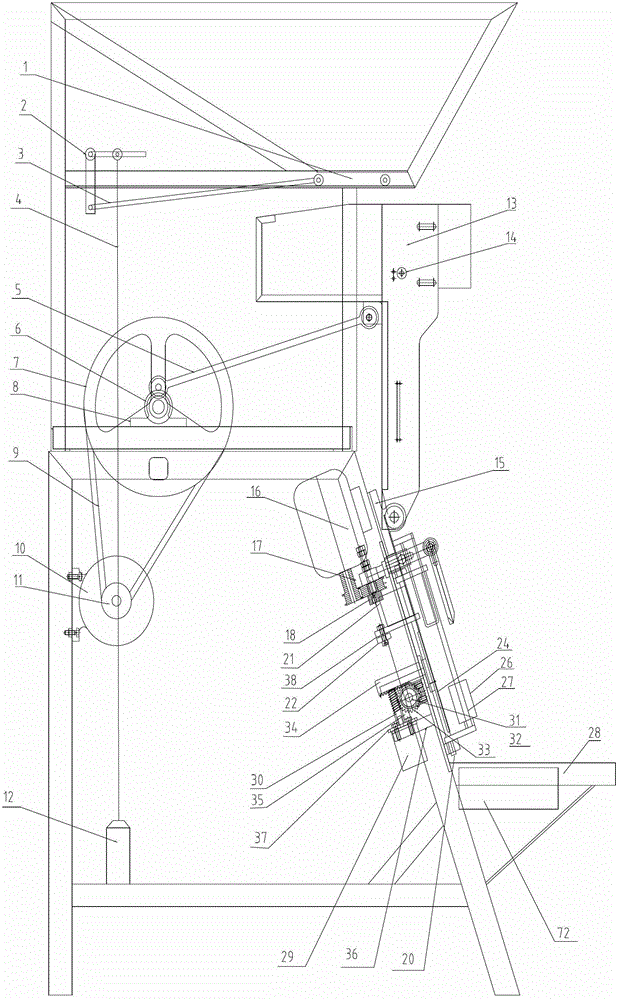

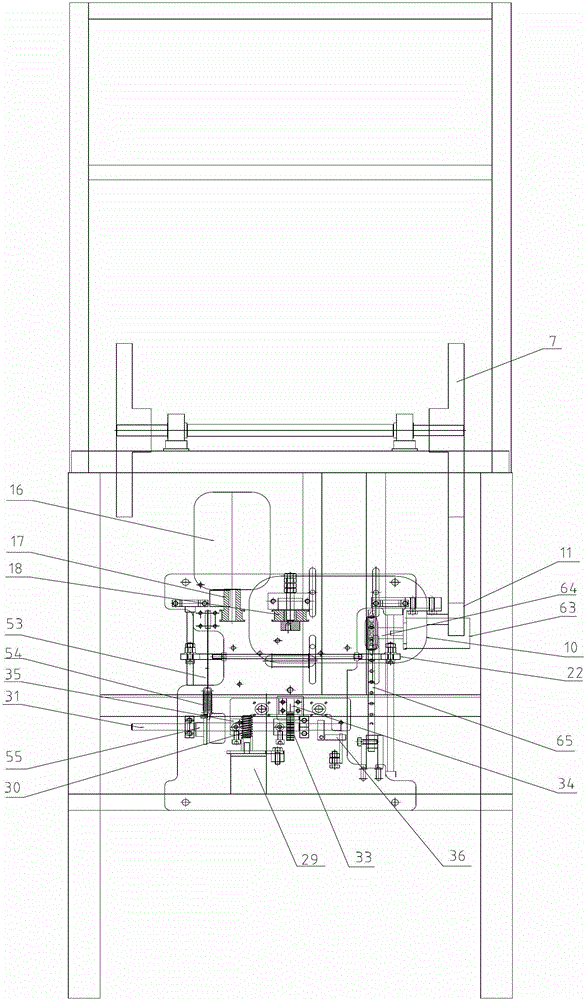

[0023] Referring to accompanying drawing, reflect a kind of specific preferred structure of the present invention, described drum washing machine forming system comprises two swing rotating shafts 20 that are installed on the frame 70, a linear guide 27 is set on each swing rotating shaft 20, and the linear guide rail The support seats 60 at both ends of 27 are affixed to the swing shaft 20, the mold frame 58 is installed on the linear guide rail 27 through the linear bearing 26, and the roots of the two side frames 56 of the mold are installed on the bottom edge of the mold frame 58. The mold frame 58 is hinged on the chain 65 of the sprocket chain mechanism through the connector 67—a part of the connector 67 is fixed to the chain 65, and the other part is fixed to the mold frame 58, forming a hinged relationship between the two parts, so that the mold frame 58 The up and down motion and the left and right swing motion do not interfere with each other. The sprocket chain mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com