A microwave-assisted method for preparing aniline-pyrrole copolymers

A pyrrole copolymer and microwave-assisted technology, which is applied in the field of microwave-assisted preparation of aniline-pyrrole copolymers, can solve the problems of long time for the reaction system to reach thermal equilibrium, difficulty in determining electrode potential matching, and difficulty in controlling the composition of the copolymer, and promote uniformity. The effect of orderly growth, small steric hindrance, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

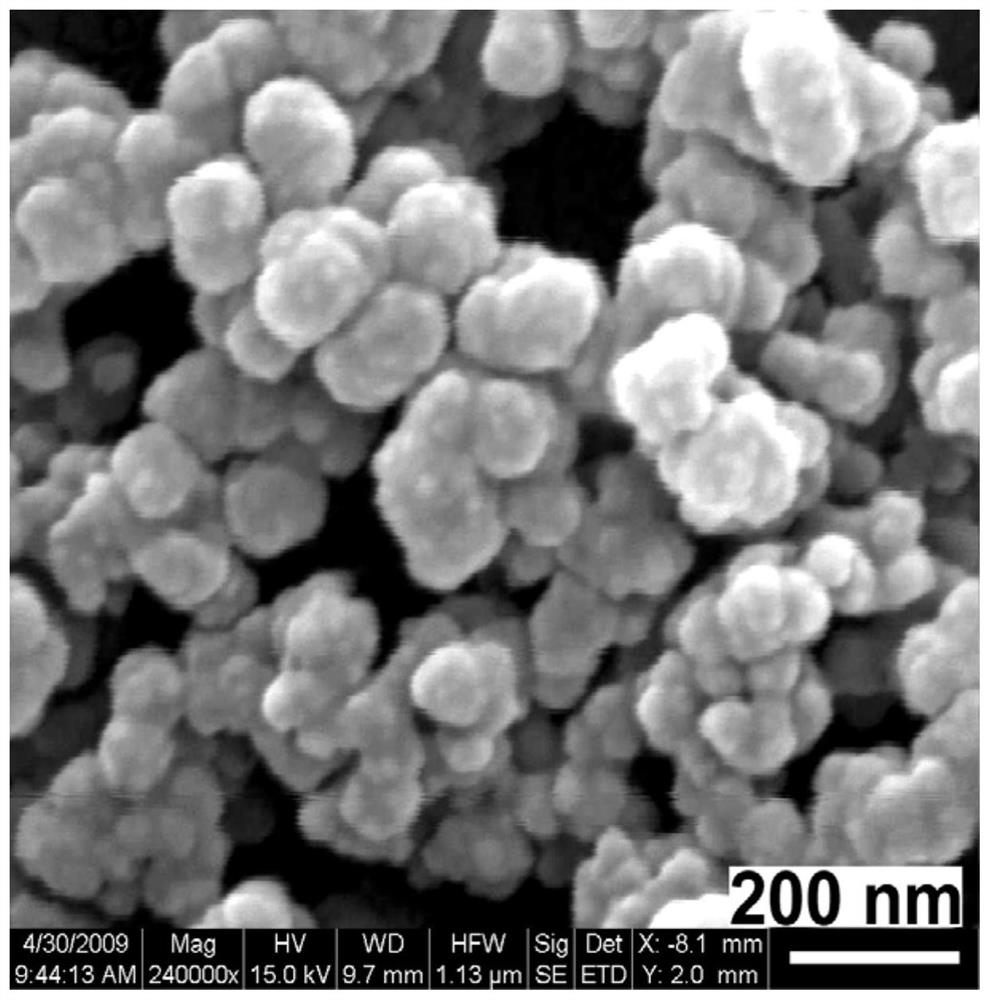

[0035] The preparation method of the present embodiment comprises the following steps:

[0036] Step 1. Add 0.01mol pyrrole, 0.01mol aniline and 0.02mol hydrochloric acid into 200mL deionized water, and then ultrasonically disperse for 30min to obtain mixed solution A;

[0037] Step 2: Add 0.02mol hydrogen peroxide and 0.2mmol silver nitrate into 200mL deionized water, and then ultrasonically disperse for 30min to obtain mixed solution B;

[0038]Step 3. Add the mixed solution B obtained in step 2 dropwise to the mixed solution A obtained in step 1 and stir evenly, then react under microwave-assisted conditions to obtain a slurry containing precipitation; the power of the microwave Be 100W, the time of described reaction is 120min;

[0039] Step 4, centrifuge the slurry obtained in step 3 and collect the precipitate, then wash the precipitate with ethanol and distilled water respectively, then centrifuge and collect the precipitate until the centrifuged supernatant is colorle...

Embodiment 2

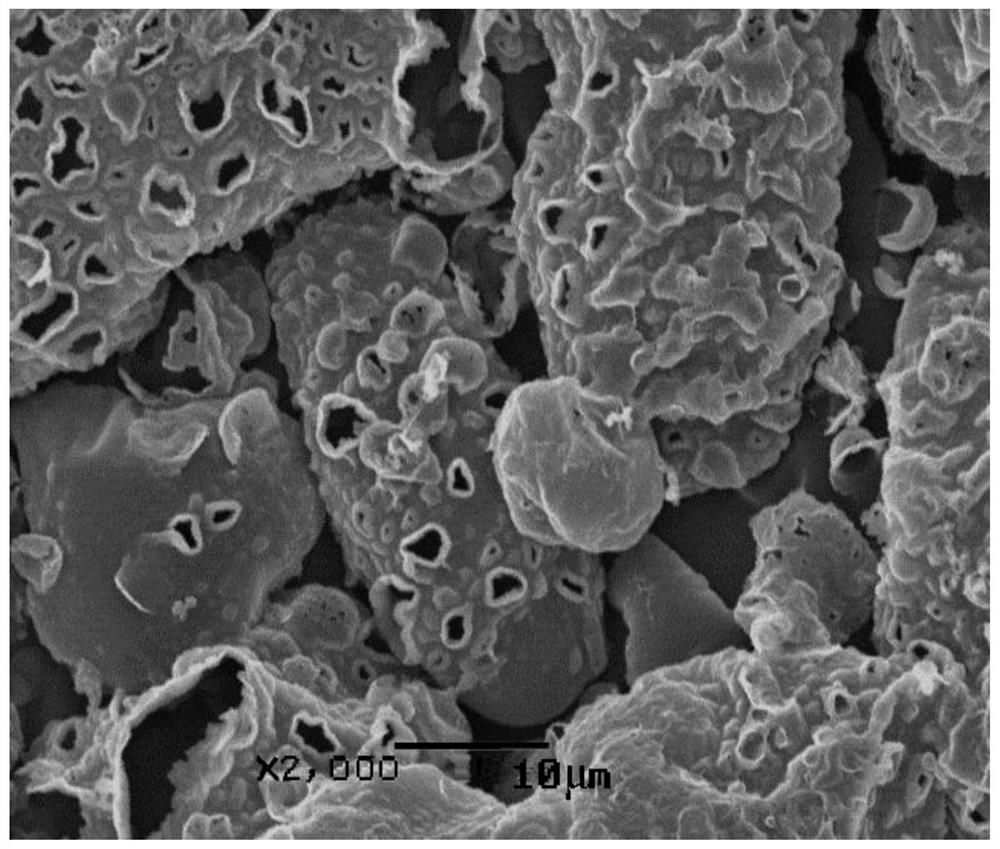

[0042] The preparation method of the present embodiment comprises the following steps:

[0043] Step 1. Add 0.02mol of pyrrole, 0.02mol of aniline and 0.2mol of hydrochloric acid into 200mL of deionized water, and then ultrasonically disperse for 30min to obtain mixed solution A;

[0044] Step 2: Add 0.04mol ammonium persulfate, 0.01mol Tween-80, and 0.4mmol ferrous chloride into 200mL deionized water, and then ultrasonically disperse for 30min to obtain mixed solution B;

[0045] Step 3. Add the mixed solution B obtained in step 2 dropwise to the mixed solution A obtained in step 1 and stir evenly, then react under microwave-assisted conditions to obtain a slurry containing precipitation; the power of the microwave Be 100W, the time of described reaction is 120min;

[0046] Step 4, centrifuge the slurry obtained in step 3 and collect the precipitate, then wash the precipitate with ethanol and distilled water respectively, then centrifuge and collect the precipitate until the...

Embodiment 3

[0049] The difference between this embodiment and embodiment 2 is that: the acid described in step 1 is sulfuric acid; the oxidant described in step 2 is potassium persulfate, and the power of the microwave described in step 3 is 300W.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com