A kind of preparation method of titanium alloy large homogeneous ingot

A titanium alloy, large-scale technology, applied in the field of preparation of large-scale homogeneous ingots of titanium alloys, can solve problems such as ingot composition segregation, and achieve the effect of improving the internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method specifically includes the following steps:

[0028] Step 1. Preliminarily sieving the titanium sponge according to the particle size, and sieving into large-particle sponge titanium and small-particle sponge titanium; sponge titanium is selected as grade 0 sponge titanium, large-particle sponge titanium is larger than 12.7mm, and small-particle sponge The particle size of titanium is 12.7 mm or less.

[0029] Step 2. Weigh the large-particle sponge titanium and small-particle sponge titanium with the intermediate materials, and pour the obtained N parts of mixed raw materials into N blocks respectively, and meet the requirements of the two adjacent blocks. The mixed raw materials respectively include large-particle sponge titanium and small-particle sponge titanium;

[0030] According to the proportion of the titanium alloy and the number of divisions of the auxiliary bracket, weigh the materials and mix the materials respectively, and pour them into th...

Embodiment 1

[0035] Example 1 TA2 pure titanium Φ620-2880Kg ingot smelting method: the raw materials are grade 0 sponge titanium, industrial pure Fe nail, and titanium dioxide. The alloy ratio is based on the composition Ti-0.25Fe-0.20O (wt%). The titanium sponge is sieved in advance, and is simply divided into two kinds of particles with a 12.7mm boundary.

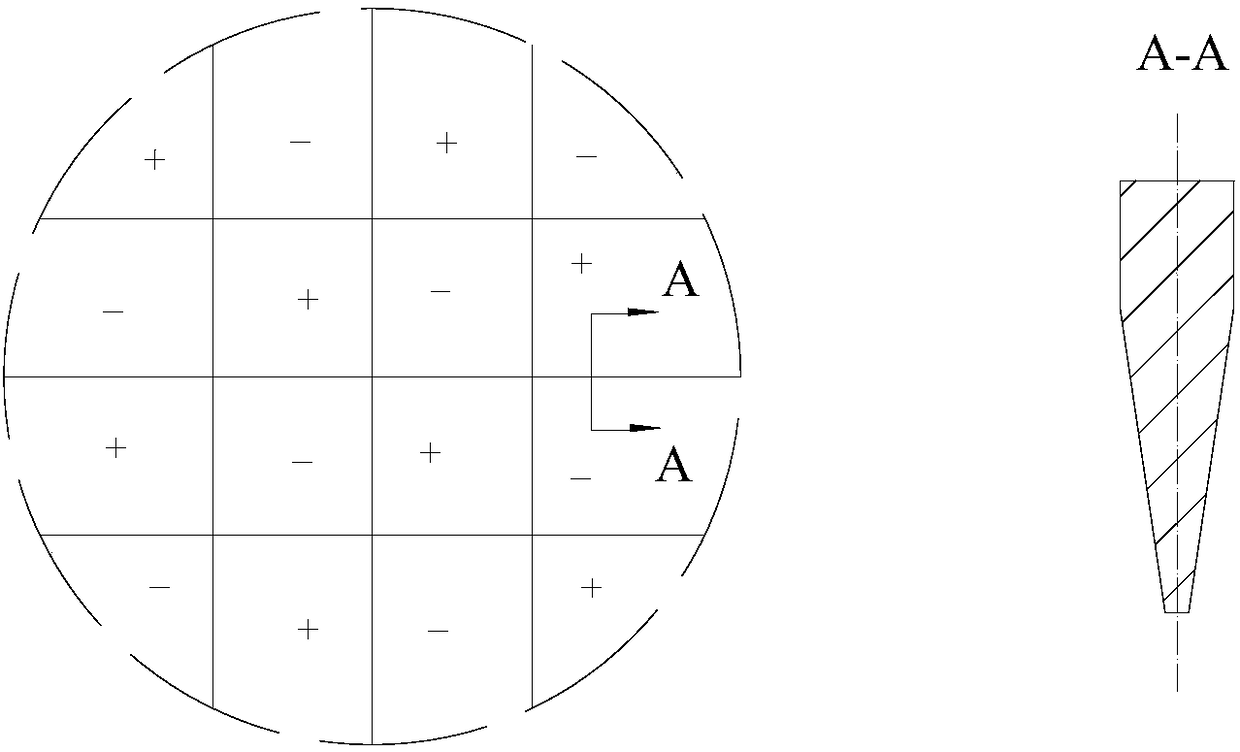

[0036] A grid-shaped auxiliary bracket is pre-placed in the Φ460 mold cavity, and the cavity is divided into sixteen parts. Respectively mix and weigh 16 times according to the weight of 10Kg, and pour them into 16 grids. Particularly place the mixture of large and small particles between phases. After loosening and taking out the bracket, it is pressed into a TA2 pure titanium electrode block of Φ460-160Kg at one time. The thickness of the pressed large single electrode block is about 300mm.

[0037] A total of 18 electrode blocks were prepared, and two consumable electrodes were assembled by welding. Followed by vacuum consumable me...

Embodiment 2

[0038] Example 2 TC4 (Ti-6Al-4V) titanium alloy Φ620-3000Kg ingot smelting method: raw materials are selected from grade 0 sponge titanium, AlV55 master alloy, industrial pure aluminum beans, and the alloy ratio is Ti-6.2%Al-4.2%V( wt%). The titanium sponge is sieved in advance, and is simply divided into two kinds of particles with a 12.7mm boundary.

[0039] A grid-shaped auxiliary bracket is pre-placed in the Φ380 mold cavity to divide the cavity into sixteen points. According to the weight of 6.25Kg, the ingredients are weighed 16 times and poured into 16 grids. Particularly place the mixture of large and small particles between phases. After loosening and taking out the bracket, it is pressed into a TC4 titanium alloy electrode block of Φ380-100Kg at one time. The thickness of the pressed large single electrode block is about 300mm.

[0040] A total of 30 electrode blocks were prepared, and 4 consumable electrodes were assembled by welding. After 3 times of vacuum consuma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com