A kind of preparation method of ncma quaternary precursor containing la, ce co-doping

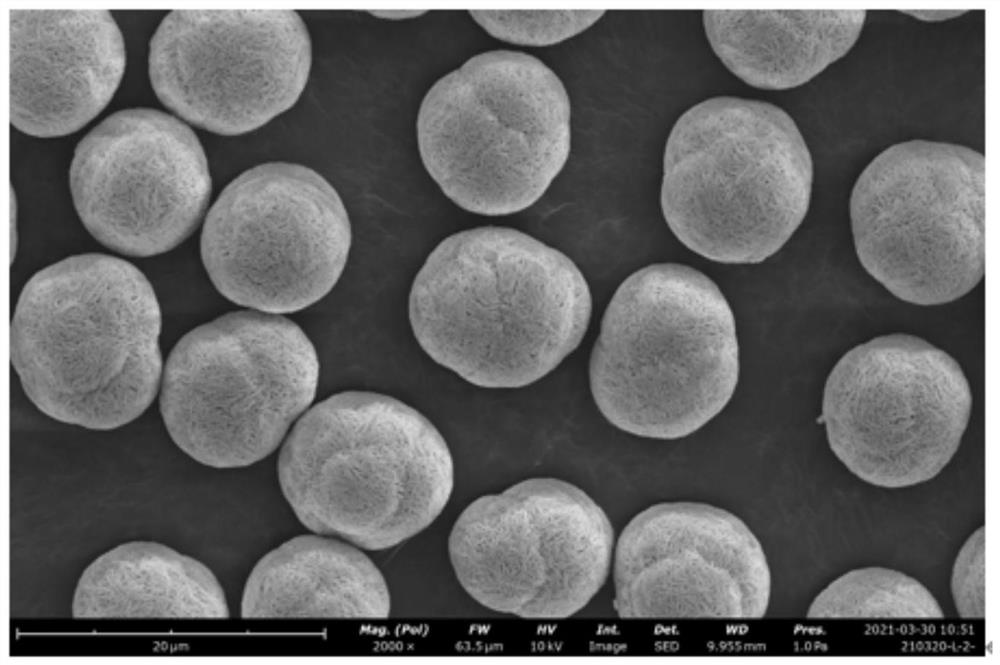

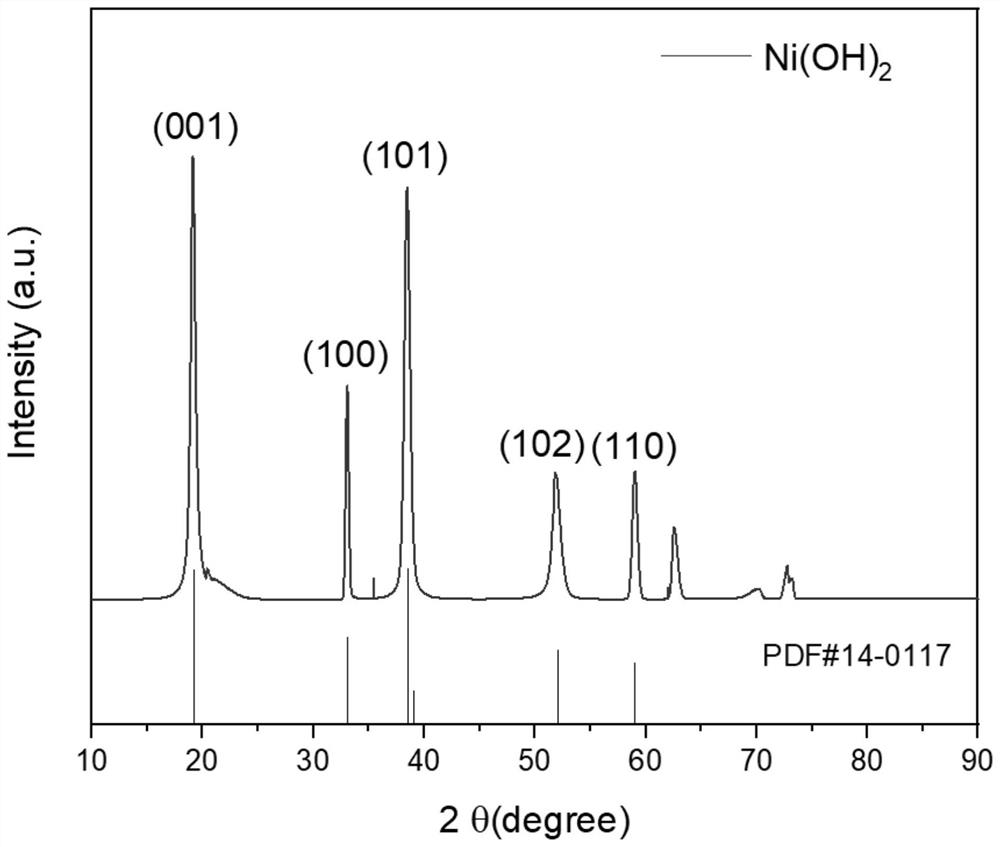

A technology of co-doping and precursors, applied in the direction of electrical components, structural parts, battery electrodes, etc., can solve the problem of hindering Li+ reversible deintercalation, affecting the stability and conductivity of ternary positive electrode materials, and the conductivity cannot be improved, etc. problem, to achieve high crystallinity, high crystallinity, and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

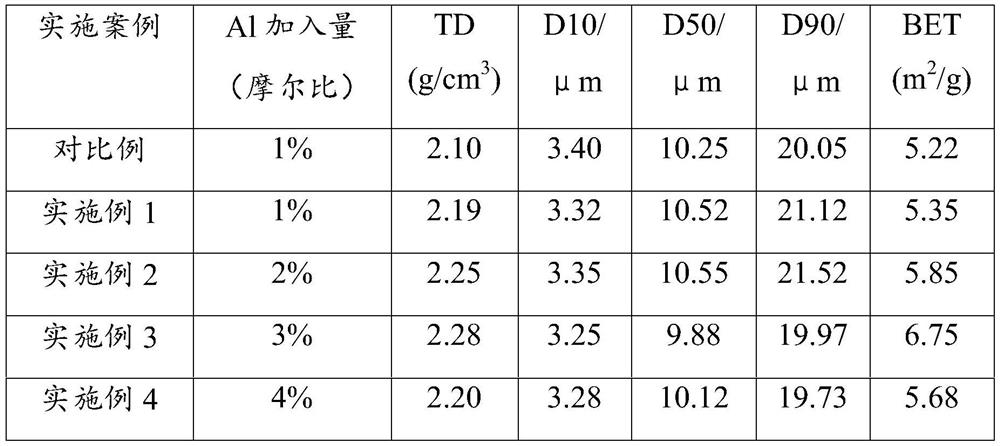

Examples

Embodiment 1

[0027] 1) Prepare a mixed solution A with a total metal ion concentration of 1.5 mol / L and a nickel-cobalt-manganese molar ratio of 90:5:4;

[0028] 2) adding lanthanum nitrate to the solution configured in step 1), the dosing amount is 0.5% of the total mass of nickel-cobalt-manganese-aluminum elements; simultaneously adding cerium nitrate, the dosing amount is 0.5% of the total mass of nickel-cobalt-manganese-aluminum elements, Stir evenly for 20 minutes to obtain solution B;

[0029] 3) Dissolve sodium metaaluminate into pure water to form a sodium metaaluminate solution with a concentration of 0.5mol / L, then add the sodium metaaluminate solution to a 5mol / L sodium hydroxide solution at a rate of 5L / h, Obtain solution C;

[0030] 4) Add the mixed solution B in step 2) and the ammonia solution of 4mol / L and the sodium hydroxide solution of 5mol / L into the reaction kettle through the metering pump according to the flow ratio of 1:0.9:0.9;

[0031] 5) When the particle size ...

Embodiment 2

[0035] 1) Prepare a mixed solution A with a total metal ion concentration of 1.5mol / L and a nickel-cobalt-manganese molar ratio of 90:5:3;

[0036] 2) adding lanthanum nitrate to the solution configured in step 1), the dosing amount is 0.5% of the total mass of nickel-cobalt-manganese-aluminum elements; simultaneously adding cerium nitrate, the dosing amount is 0.5% of the total mass of nickel-cobalt-manganese-aluminum elements, Stir evenly for 20 minutes to obtain solution B;

[0037] 3) Dissolve sodium metaaluminate into pure water to form a sodium metaaluminate solution with a concentration of 0.5mol / L, then add the sodium metaaluminate solution to a 5mol / L sodium hydroxide solution at a rate of 5L / h, Obtain solution C;

[0038] 4) Add the mixed solution B in step 2) and the ammonia solution of 4mol / L and the sodium hydroxide solution of 5mol / L into the reaction kettle through the metering pump according to the flow ratio of 1:0.9:0.9;

[0039] 5) When the particle size D...

Embodiment 3

[0043] 1) Prepare a mixed solution A with a total metal ion concentration of 1.5 mol / L and a nickel-cobalt-manganese molar ratio of 90:5:2;

[0044] 2) adding lanthanum nitrate to the solution configured in step 1), the dosing amount is 0.5% of the total mass of nickel-cobalt-manganese-aluminum elements; simultaneously adding cerium nitrate, the dosing amount is 0.5% of the total mass of nickel-cobalt-manganese-aluminum elements, Stir evenly for 20 minutes to obtain solution B;

[0045] 3) Dissolve sodium metaaluminate into pure water to form a sodium metaaluminate solution with a concentration of 0.5mol / L, then add the sodium metaaluminate solution to a 5mol / L sodium hydroxide solution at a rate of 5L / h, Obtain solution C;

[0046] 4) The mixed solution B in step 2) and the ammonia solution of 4mol / L and the sodium hydroxide solution of 5mol / L are added in the reactor by a metering pump according to the flow ratio of 1:0.9:0.9, to maintain the volume in the reactor. PH at 11....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com