Adsorbent as well as preparation method and application thereof

A technology of adsorbent and solvent, which is applied in the field of adsorbent and its preparation, can solve the problems such as the inability to prepare π-complex adsorption materials, and achieve the effects of increasing gas adsorption effect, simple and easy preparation method, and excellent specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

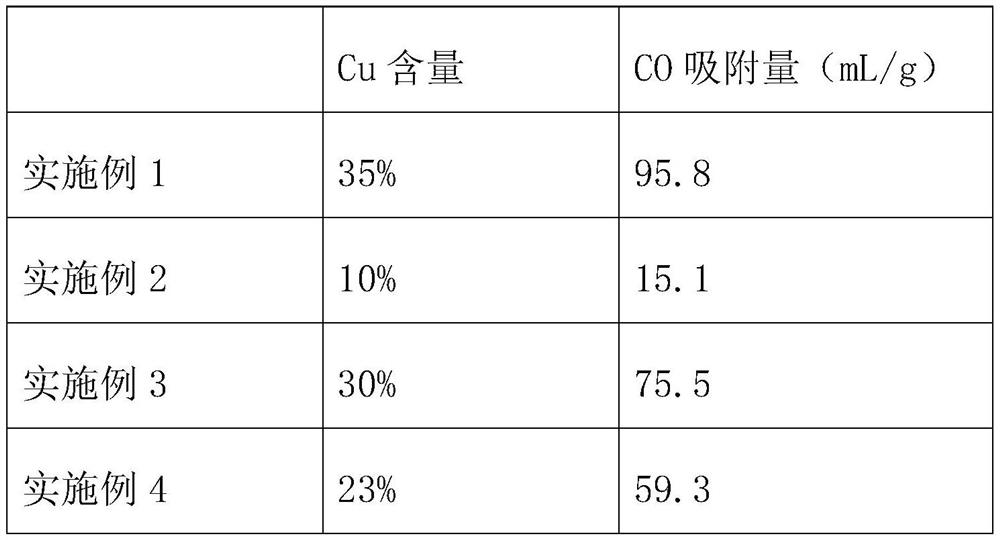

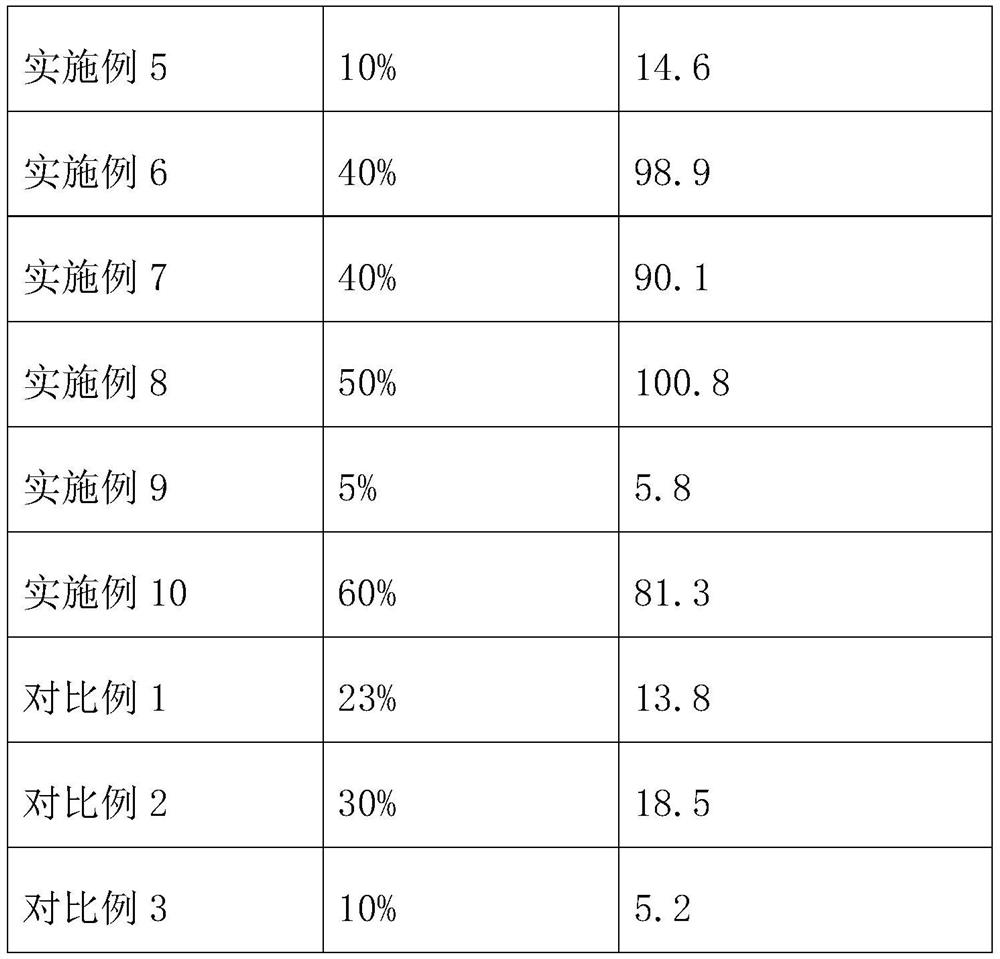

Examples

Embodiment 1

[0027] A kind of adsorbent, wherein the content of Cu is about 35%, the specific preparation process is as follows:

[0028] (1) At 25°C, 22.1g copper acetylacetonate was dissolved in 80.0g chloroform to obtain a chloroform solution of copper acetylacetonate;

[0029] (2) Using the impregnation method, 10 g of the ZIF-8 carrier was impregnated in the above-mentioned chloroform solution of copper acetylacetonate, and dried at 80° C. to obtain a sample.

[0030] (3) The sample was reduced in a nitrogen atmosphere at 300°C for 3 hours to obtain Cu-loaded + the adsorbent.

Embodiment 2

[0032] A kind of adsorbent, wherein the content of Cu is about 10%, the specific preparation process is as follows:

[0033] (1) under normal temperature, 4.5g copper acetylacetonate is dissolved in 80.0g chloroform, obtain the chloroform solution of copper acetylacetonate;

[0034] (2) Using the impregnation method, 10 g of the ZIF-8 carrier was impregnated in the above-mentioned chloroform solution of copper acetylacetonate, and dried at 80° C. to obtain a sample.

[0035] (3) The sample was reduced in a nitrogen atmosphere at 300°C for 3 hours to obtain Cu-loaded + the adsorbent.

Embodiment 3

[0037] A kind of adsorbent, wherein the content of Cu is about 30%, the specific preparation process is as follows:

[0038] (1) At 25°C, 17.6g copper acetylacetonate was dissolved in 80.0g chloroform to obtain a chloroform solution of copper acetylacetonate;

[0039] (2) Using the impregnation method, 10 g of the ZIF-8 carrier was impregnated in the above-mentioned chloroform solution of copper acetylacetonate, and dried at 80° C. to obtain a sample.

[0040] (3) The sample was reduced under a nitrogen atmosphere at 200°C for 4 hours to obtain Cu-loaded + the adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com