Brazing diamond wire saw for cutting rare materials and manufacturing process of brazing diamond wire saw

A diamond wire saw and manufacturing process technology, which is applied to manufacturing tools, metal processing equipment, stone processing tools, etc., can solve the problems of waste, burial, and too much diamond material to be cut, so as to reduce material loss and production. cost, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the present invention will be described in further detail below in conjunction with the accompanying drawings.

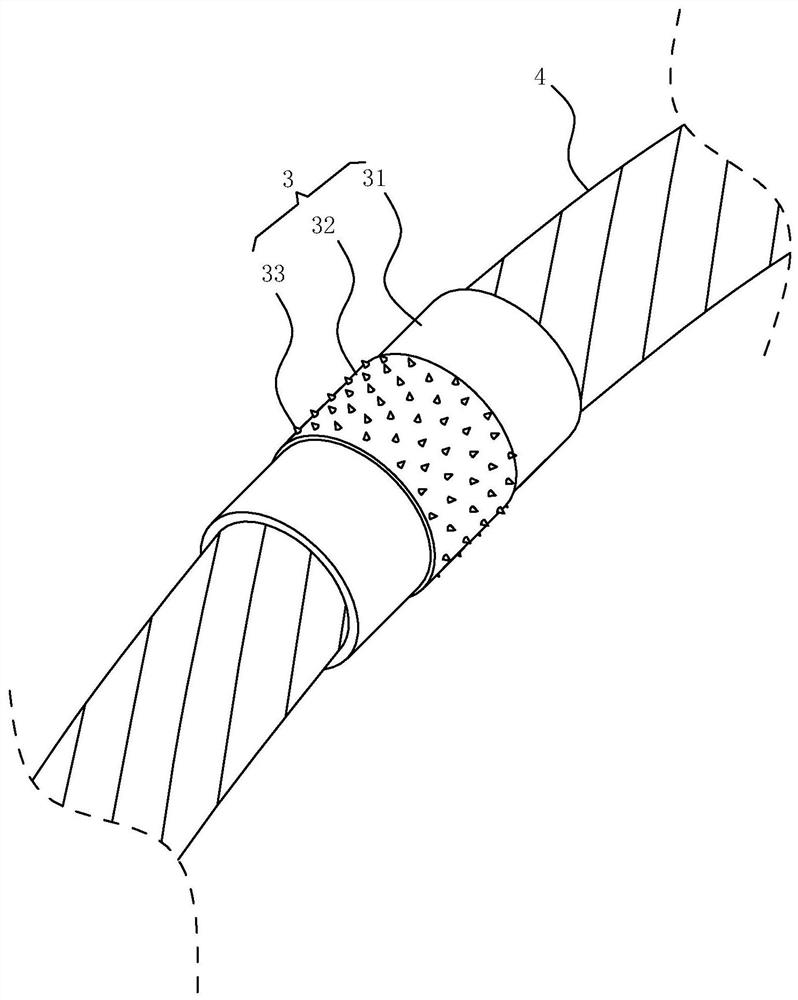

[0032] The embodiment of the invention discloses a brazed diamond wire saw for cutting precious materials. Please refer to figure 1 , the wire saw includes a steel wire rope 4 and several diamond beads 3, the diamond beads 3 are sleeved and fixed on the steel wire rope 4 at equal intervals, and the steel wire rope 4 is a multi-strand steel wire rope 4 for improving the tensile strength of the steel wire rope 4.

[0033] The diamond bead 3 includes a cylindrical base body 31 , a skin 32 covering the outer wall of the base body 31 , and a plurality of diamond particles 33 evenly fixed on the outer surface of the skin 32 . Wherein, the material skin 32 is a mixture of glue and solder, and the diamond particles 33 are fixed on the material skin 32 through a brazing process, and fixed on the outer surface of the matrix 31; the diamond p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com